Mobile smash-type grid sewage removing machine

A decontamination machine and pulverizing technology, which is applied in the directions of fixed filter element filters, filtration and separation, chemical instruments and methods, etc., can solve the problems of inconvenient maintenance, increased manpower, difficult maintenance, etc., and achieves easy installation and maintenance. The effect of crushing range and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with embodiment (accompanying drawing):

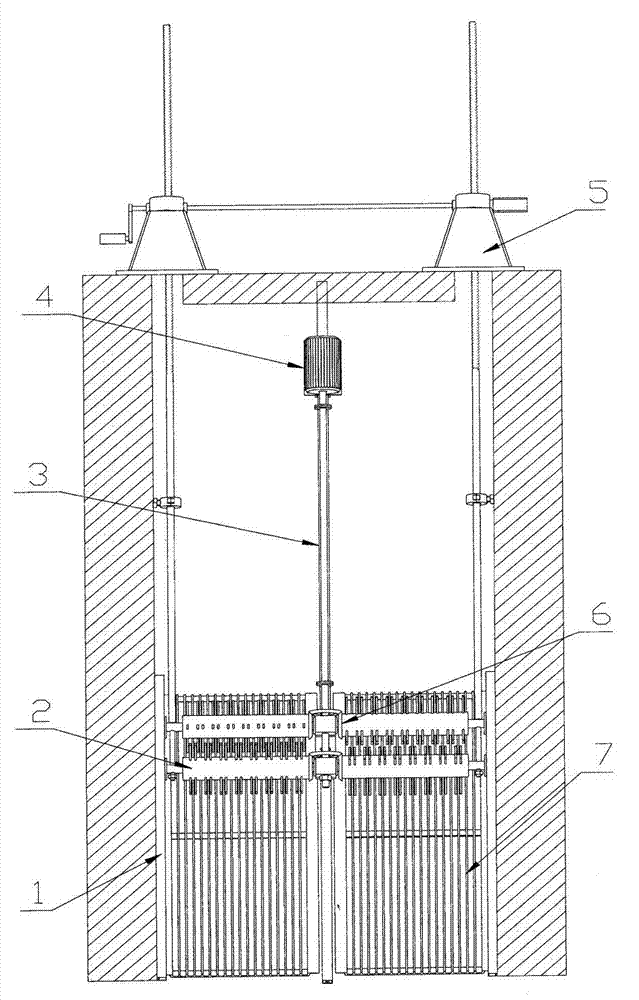

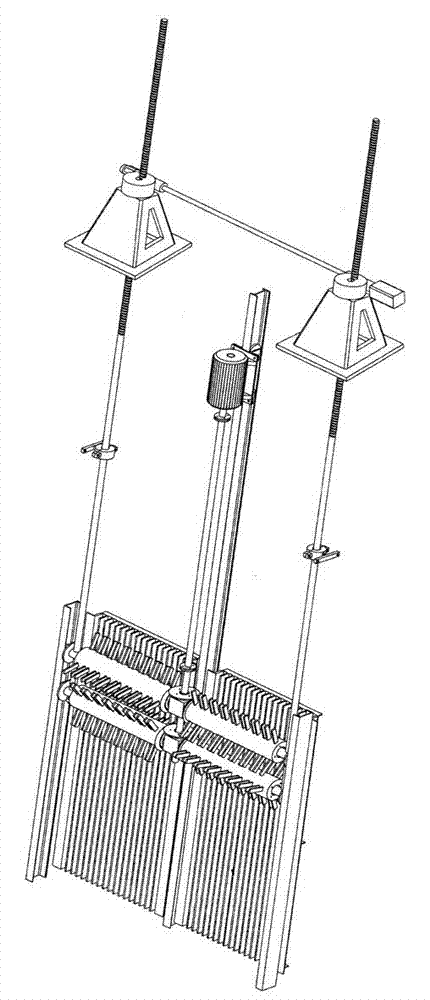

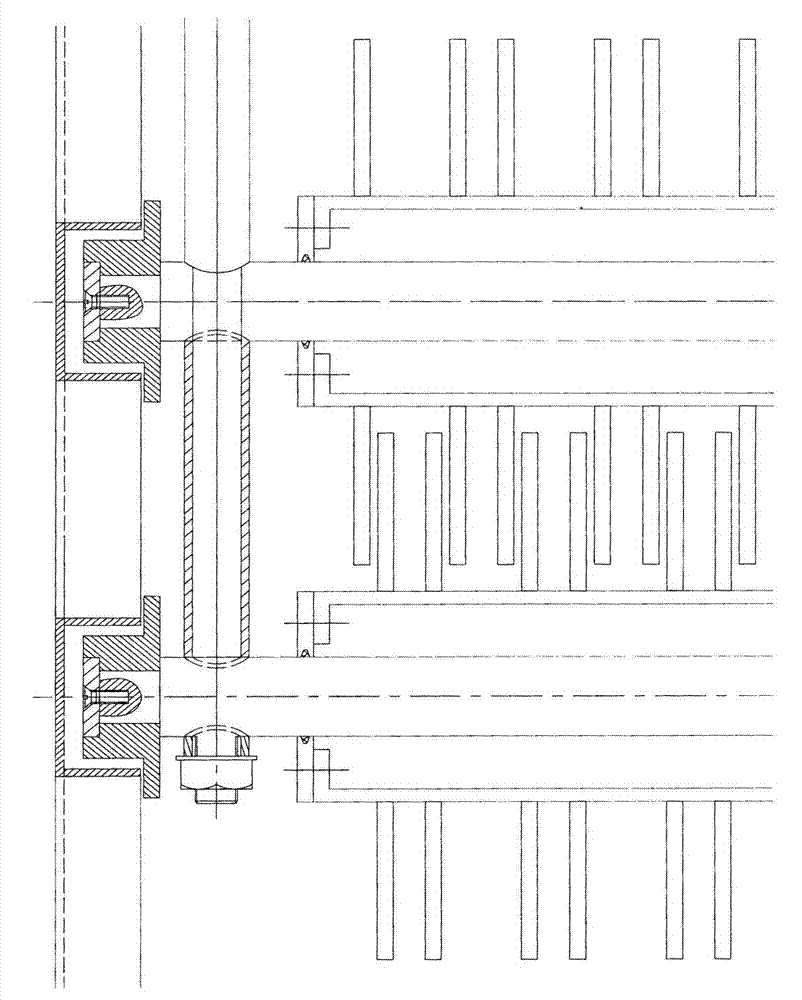

[0015] like figure 1 , figure 2 As shown, the mobile crushing grid decontamination machine of the present invention includes a water-passing grid 7 fixedly installed in the grid room, and a hoist 5 installed above the two side walls of the grid room, and the water-passing grid 7 is composed of left and right grids symmetrically arranged on both sides of the middle guide rail 3; on the side of the water-facing surface of the water-passing grid (located on the water surface and above the water surface), slideways driven by the hoist 5 along both sides are installed. 1. A drum-type crushing device for crushing sundries that moves up and down; the drum-type crushing device is an upper and lower transmission device driven by a power source, and is installed on the upper and lower sides in a horizontal and symmetrical manner. Two sets of upper and lower crushing d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com