Cylinder body combined constant-liquid-level gas-liquid separator

A gas-liquid separator and combined technology, which is used in the production of fluids, wellbore/well components, and earth-moving drilling, etc., can solve the problems of hysteresis, small oil well holes, and high pressure, and reduce the impact height and strength. Number of air bubbles, weakening effect of axial shock

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

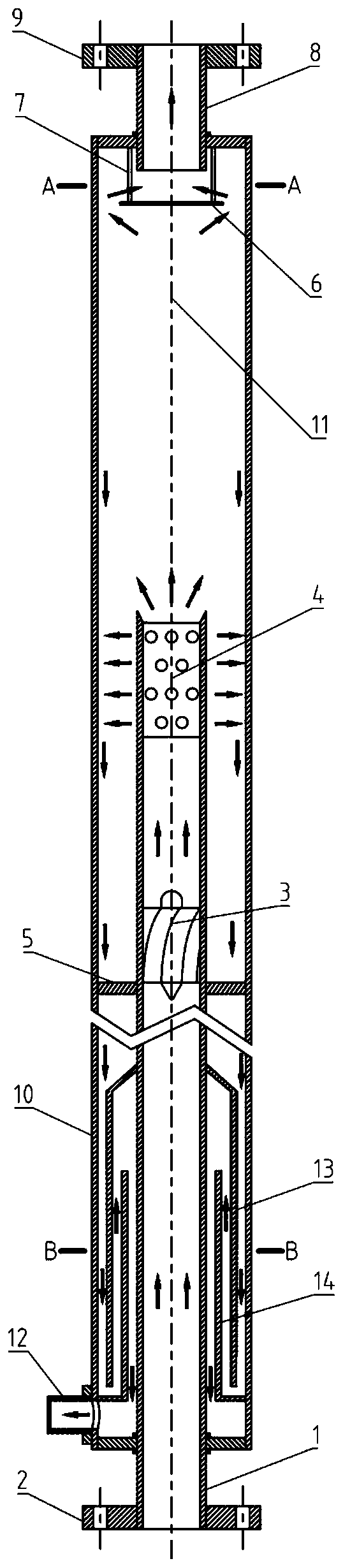

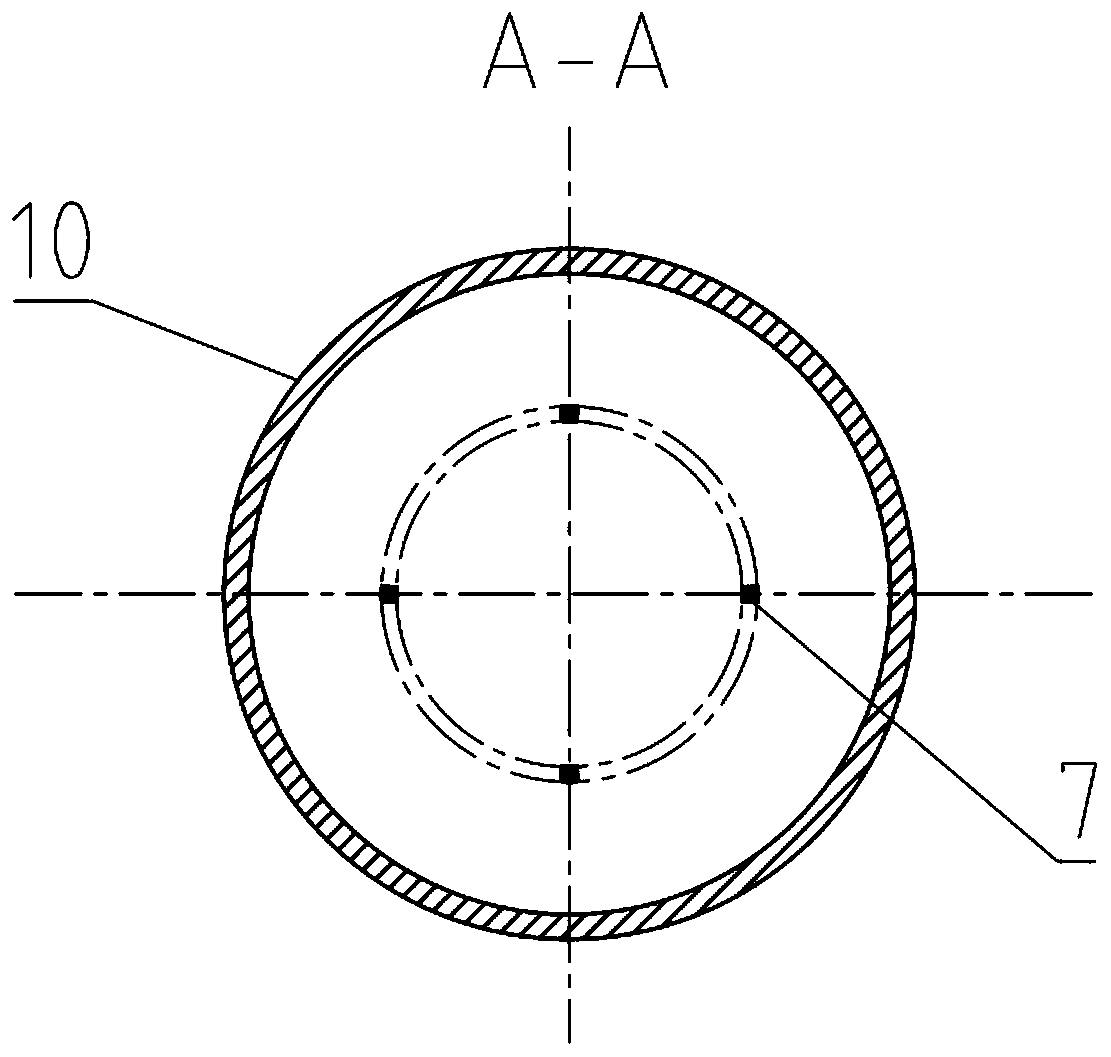

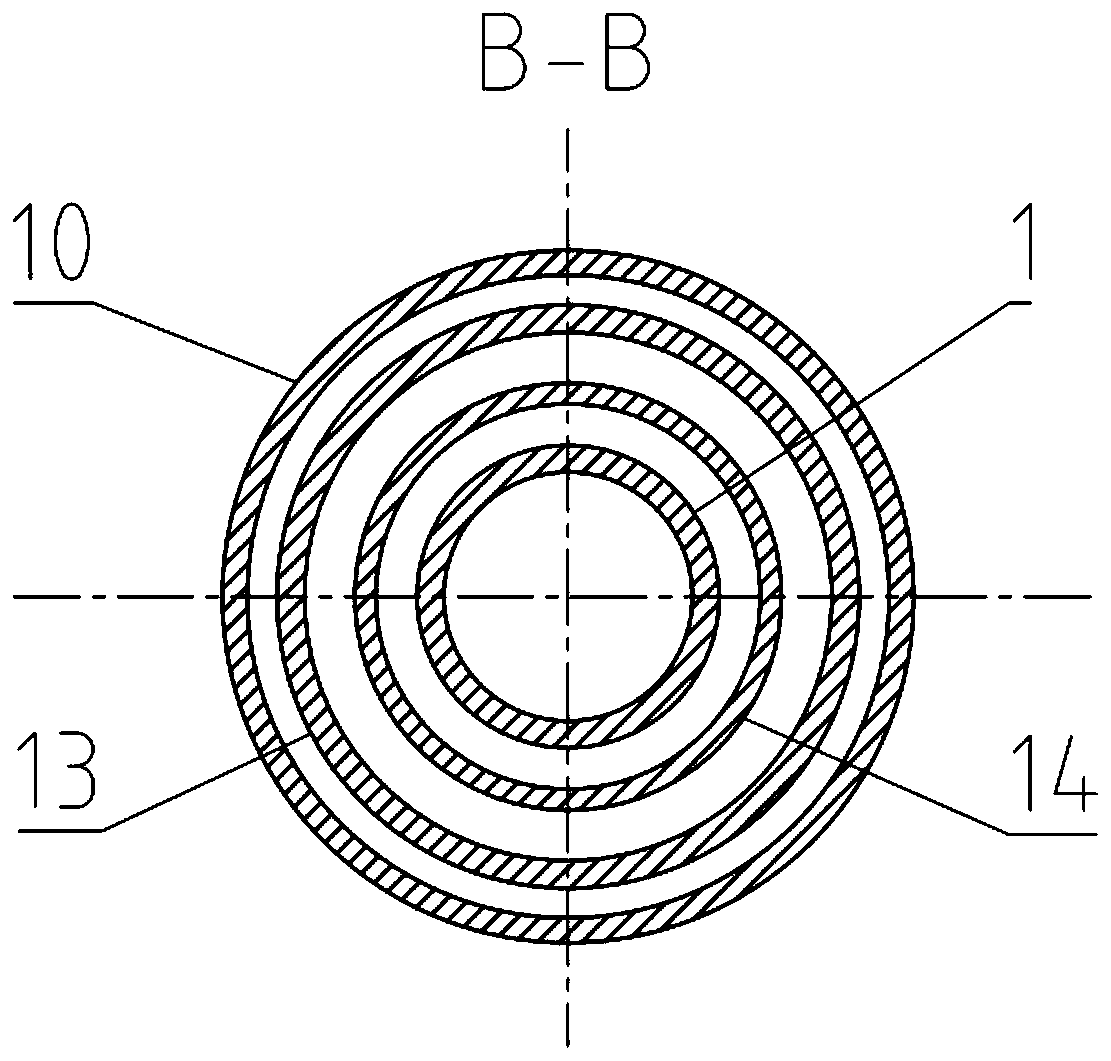

[0036] Embodiment 1: Combining Figure 1-3, a cylinder combined constant liquid level gas-liquid separator provided by the present invention, the main structure of the separator is composed of mutually nested cylinder structures, including a core cylinder 1, an outer cylinder 10, a drainage cylinder 13, and a liquid control cylinder 14 , and the upper end of the outer cylinder 10 is provided with a gas phase outlet 8, and the lower end is provided with a liquid phase outlet 12; a water barrier 6 is arranged below the gas phase outlet 8, and is fixed on the top of the outer cylinder 10 by a connecting rod 7; The upper part of 1 is provided with a drain section 4, and there are multiple rows of drain holes in the drain section 4; an impeller 3 is placed below the drain section 4 in the core tube 1; A drainage tube 13 and a hydraulic control tube 14 are arranged, the top of the drainage tube 13 is fixed on the outer wall of the core tube 1 , and the bottom of the hydraulic contro...

Embodiment approach 2

[0041] Embodiment 2: Combining Figure 4 , a cylinder combined gas-liquid separator provided by the present invention, comprising: a core cylinder 1, an inlet flange 2, a secondary impeller 23, a liquid discharge section 4, an anti-vibration strip 5, a water retaining plate 6, a connecting rod 7. Separator gas phase outlet 8, outlet flange 9, outer cylinder 10, water shielding ring 21, separator liquid phase outlet 12, drainage tube 13, liquid control tube 14, tertiary separation orifice plate 15, secondary separation Orifice plate 16, primary separation orifice plate 17, outlet cylinder 18, primary impeller 19. On the basis of Embodiment 1, an outlet cylinder 18 is added, and the impeller is changed into a primary impeller 19 and a secondary impeller 23. The primary impeller 19 is installed in the core cylinder 1, and the secondary impeller 23 is installed at the outlet of the core cylinder. The air outlet cylinder 18 is Permeable structure, the outlet tube 18 is located abo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com