Patents

Literature

35results about How to "High rate of mechanization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

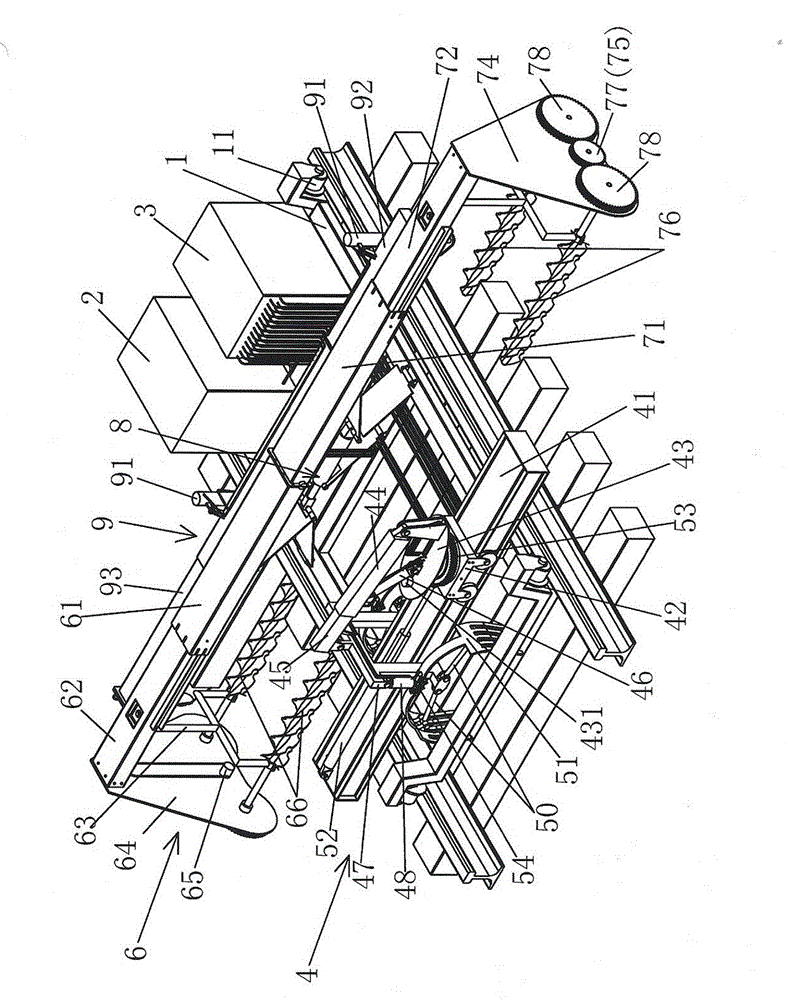

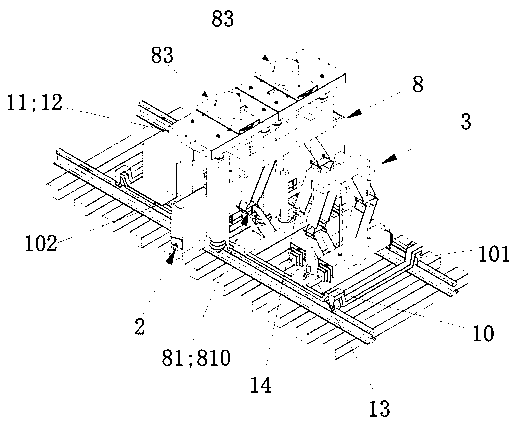

Full-mechanical rapid sleeper replacement machine

InactiveCN104195902AQuick alignmentAutomatic separation and dischargeBallastwayRailway track constructionPush and pullEngineering

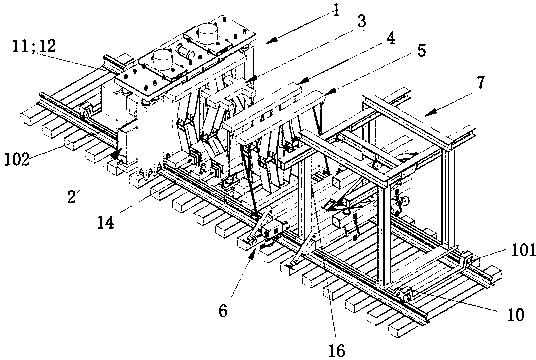

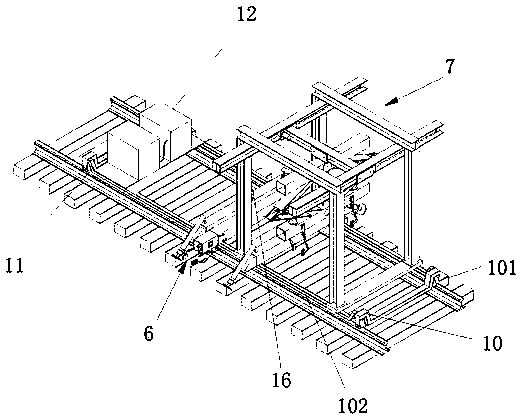

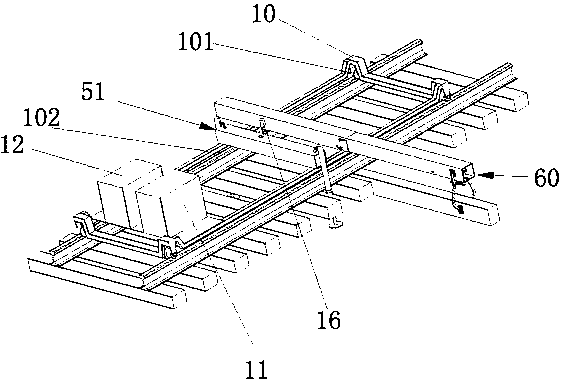

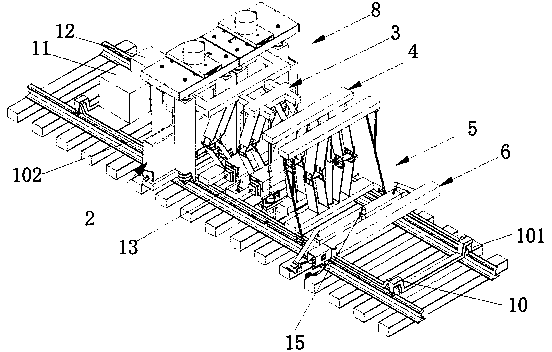

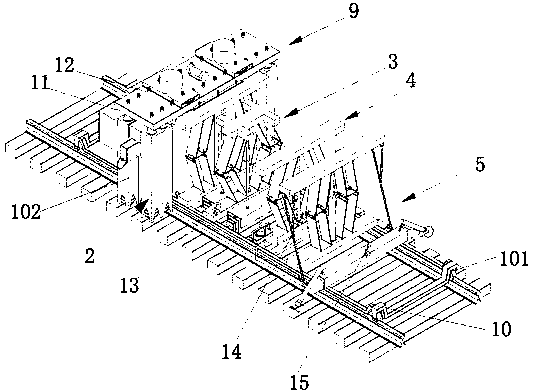

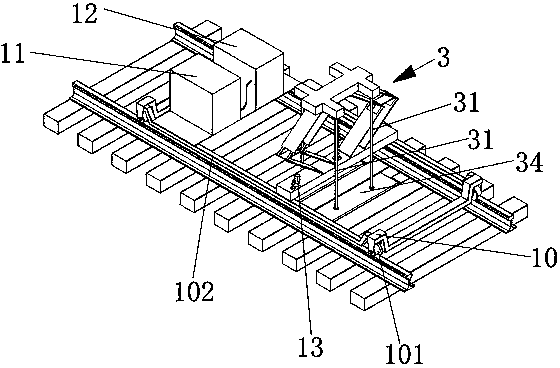

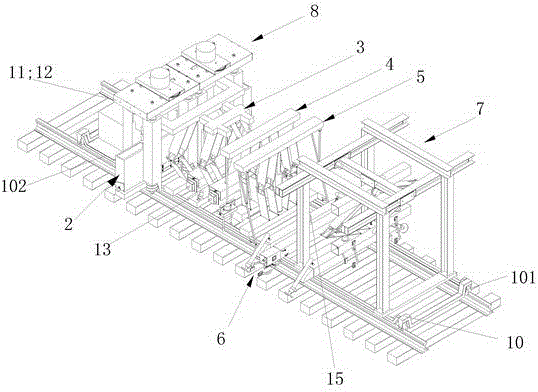

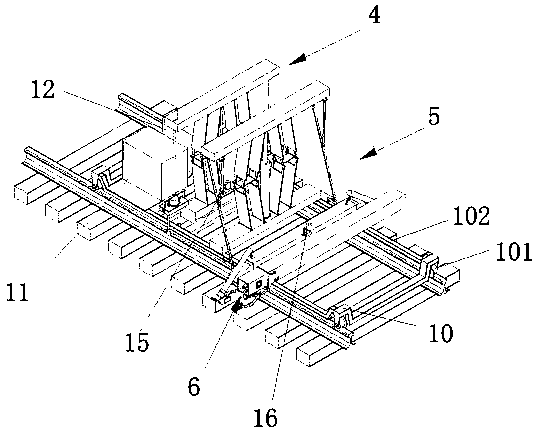

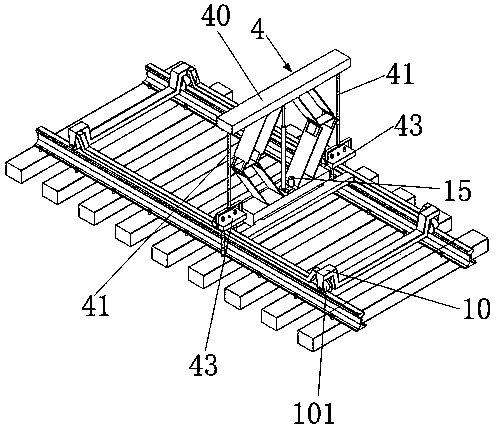

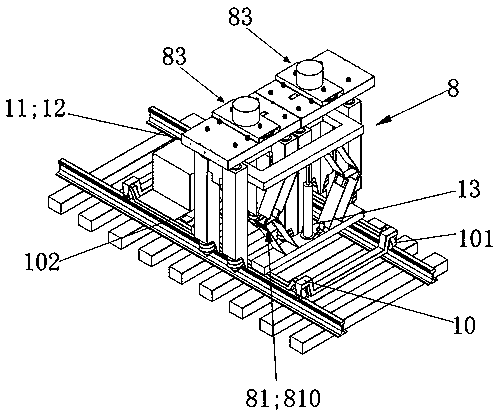

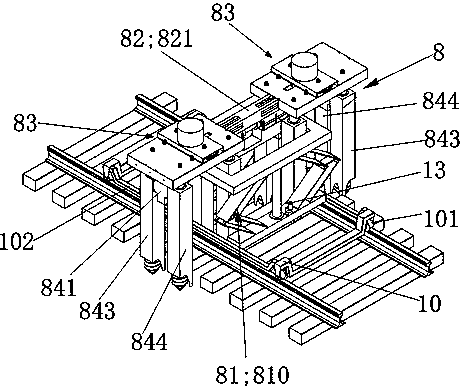

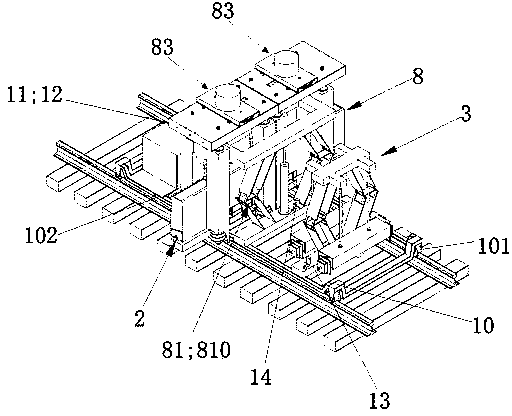

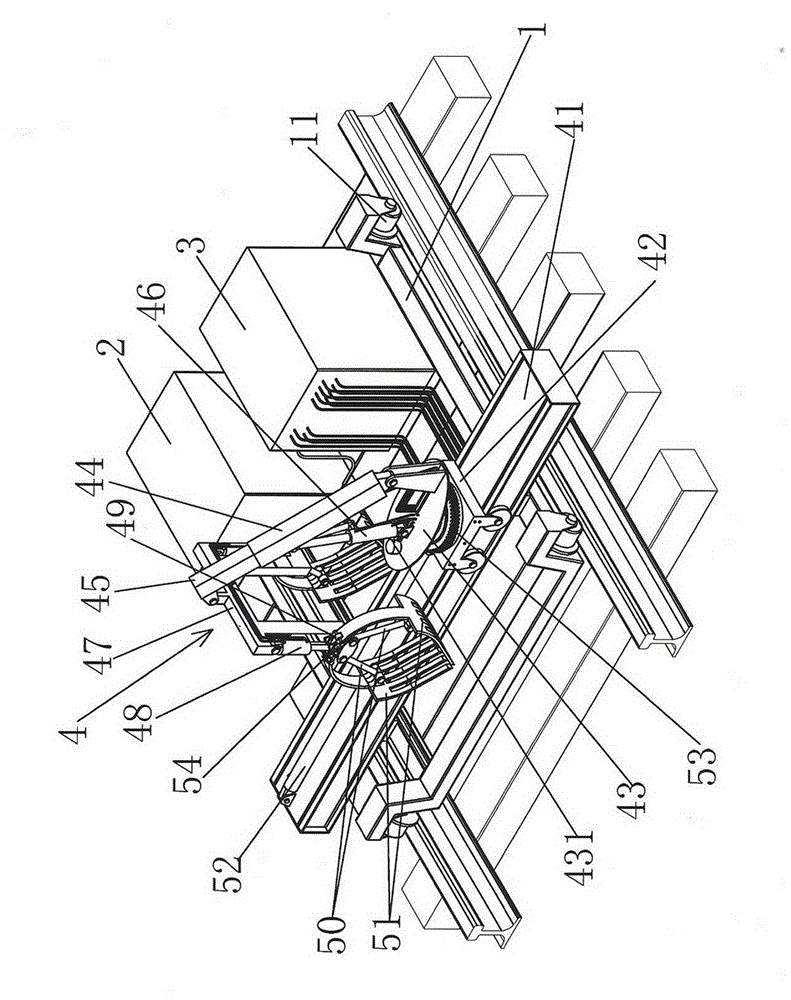

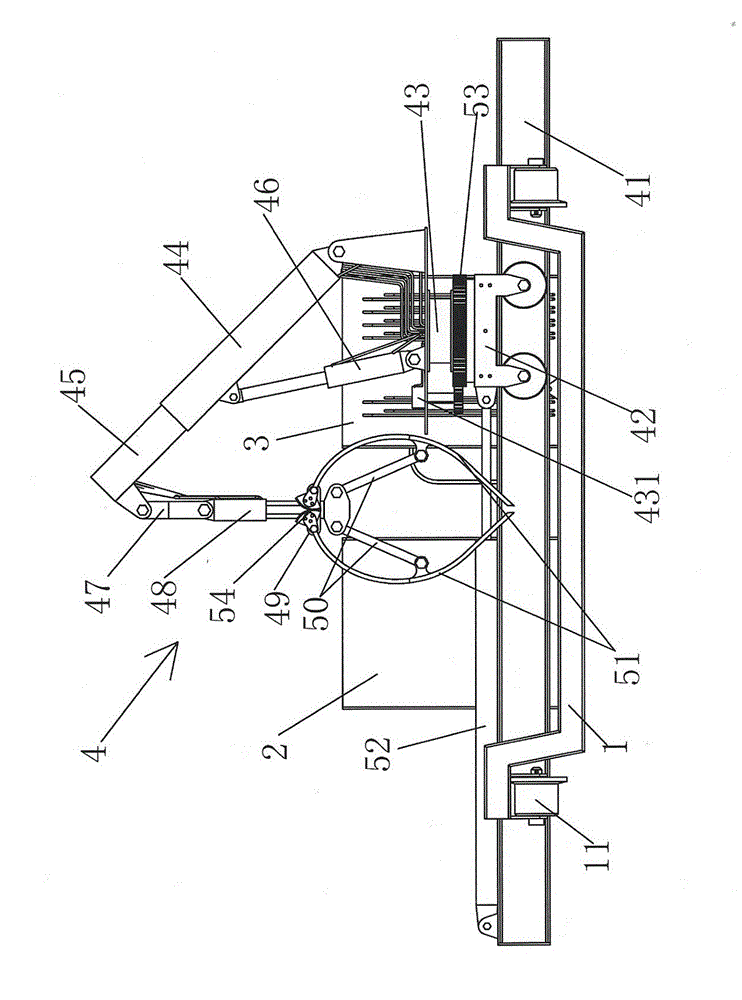

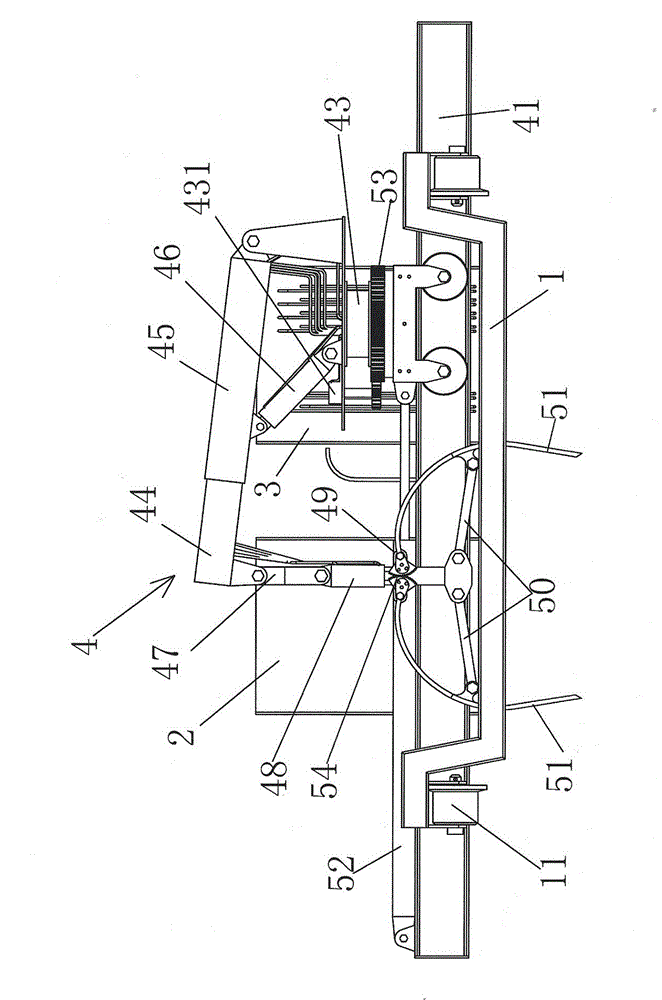

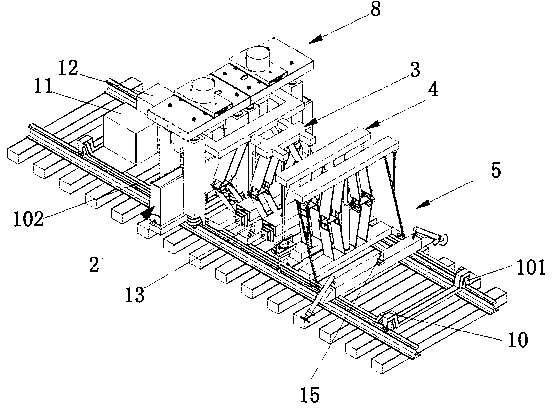

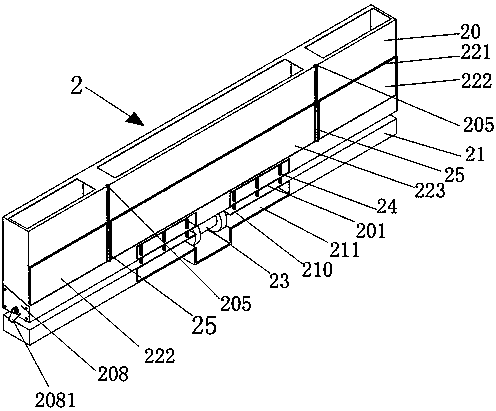

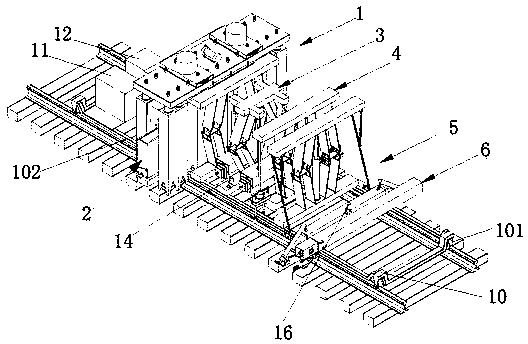

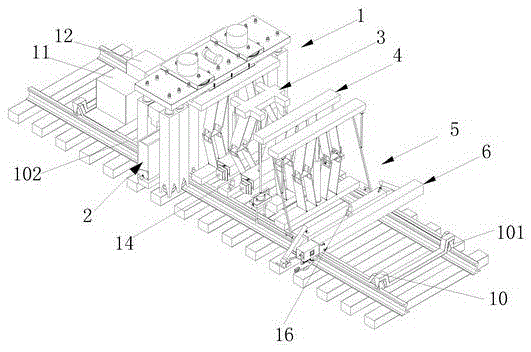

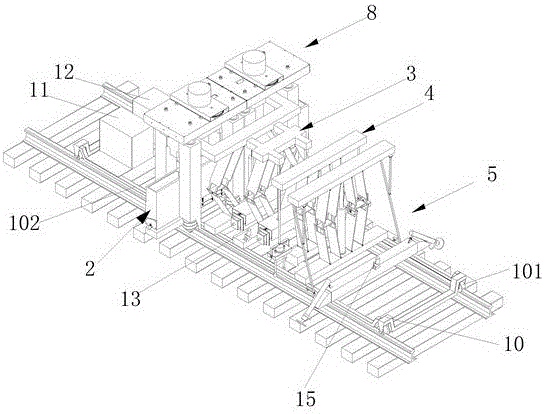

The invention discloses a full-mechanical rapid sleeper replacement machine which comprises a vibration rotary excavating and ballast removing device, a ballast collecting and discharging device, a vibration ballast pushing device, a four-nut synchronous assembly and disassembly device, a sleeper lifting and rotating device, a sleeper pushing and pulling device, a sleeper hoisting device, a rail car, a power generator, a hydraulic system box, a first camera assembly, a second camera assembly, a third camera assembly, a fourth camera assembly, a fifth camera assembly, a sixth camera assembly and a monitor. A plurality of casters and two longitudinal beams are arranged on the rail car, the vibration rotary excavating and ballast removing device, the ballast collecting and discharging device, the vibration ballast pushing device, the four-nut synchronous assembly and disassembly device, the sleeper lifting and rotating device, the sleeper pushing and pulling device, the sleeper hoisting device, the power generator and the hydraulic system box are arranged on the two longitudinal beams of the rail car, and the monitor is arranged in a cab of a tow tractor. The full-mechanical rapid sleeper replacement machine is suitable for rapid sleeper replacement on straight-line and curved rail rod segments, operating time in repairing skylight through limited line can be made full and reasonable use of, and full-mechanical sleeper replacement can be achieved.

Owner:KUNMING UNIV

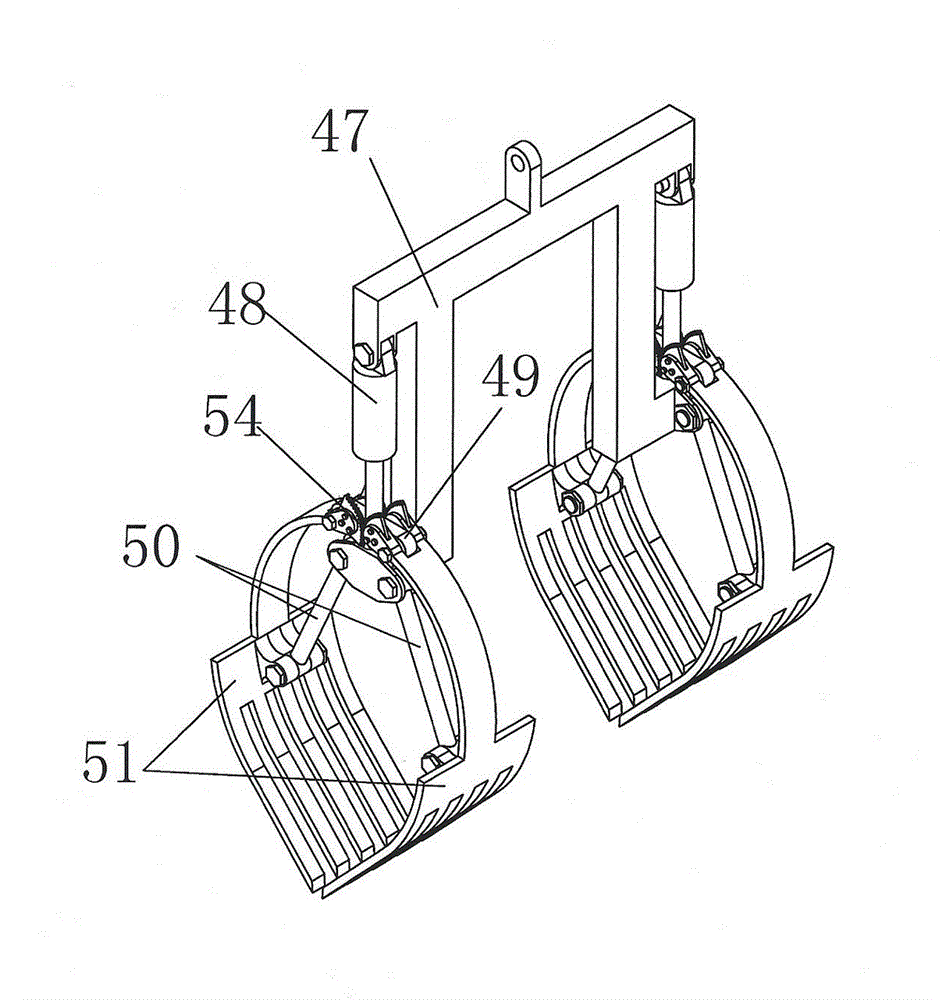

Grab stone cleaning machine between sleepers

The invention discloses an inter-sleep grab bucket stone remover, which consists of a track vehicle, a generator, an operation control box and a grab bucket stone removal device, wherein the generator, the operation control box and the grab bucket stone removal device are arranged on the track vehicle and can be pushed to move on a track by man power; the grab bucket stone removal device consistsof a cross beam, a trolley, a rotary table, a hoisting basic arm, a hoisting telescopic arm, a hoisting arm variable-amplitude oil cylinder, a portal-type steel frame, a grab bucket opening and closing oil cylinder, a force application plate, a brace rod, two grab buckets, an oil cylinder for driving the trolley to move, a rotary steady bearing and a fan-shaped wheel group; the grab bucket stone removal device can move, rotate and rise and fall on the trolley; and opening and closing of the two grab buckets can release and hold stones. The inter-sleep grab bucket stone remover can quickly remove stones between two sides of the sleep, is convenient for operation, reliable in performance and high in mechanical working efficiency and has a simple structure; moreover, the inter-sleep grab bucket stone remover is so light that two workers can move the remover from the track conveniently; and the finite line repair 'skylight' working time can be used fully and rationally.

Owner:KUNMING UNIV

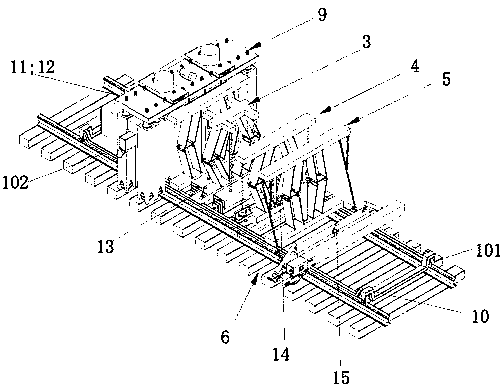

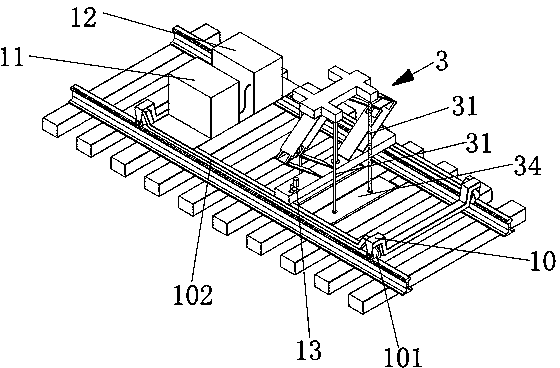

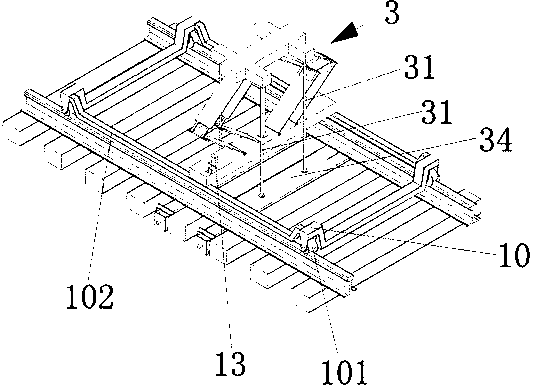

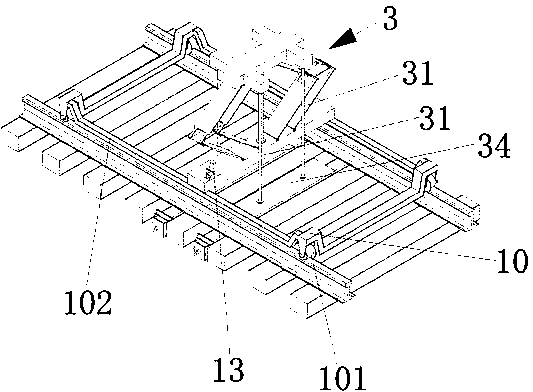

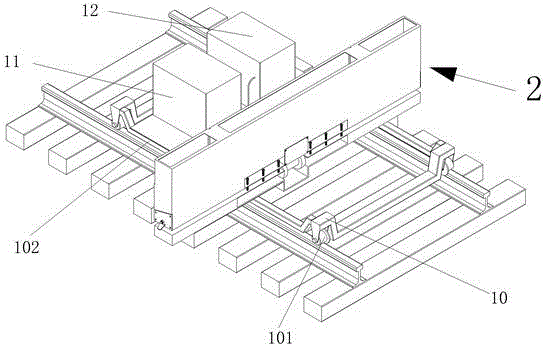

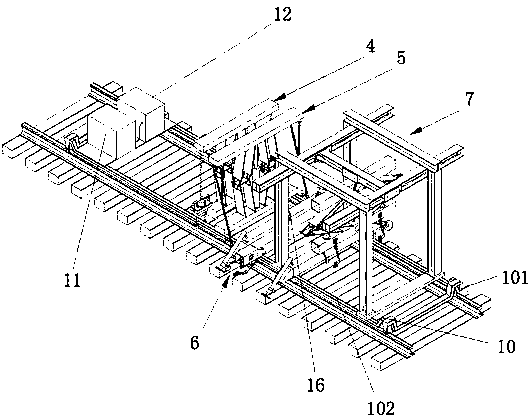

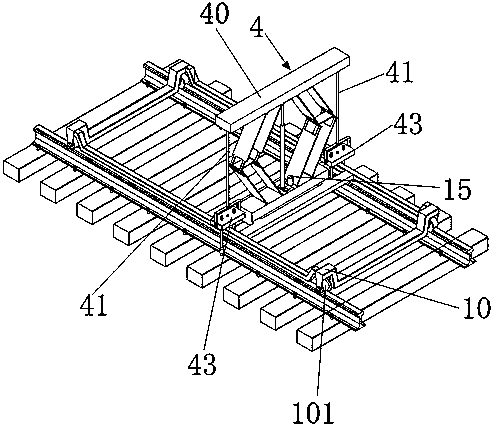

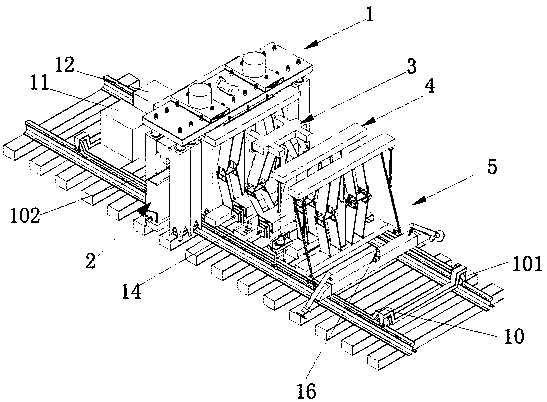

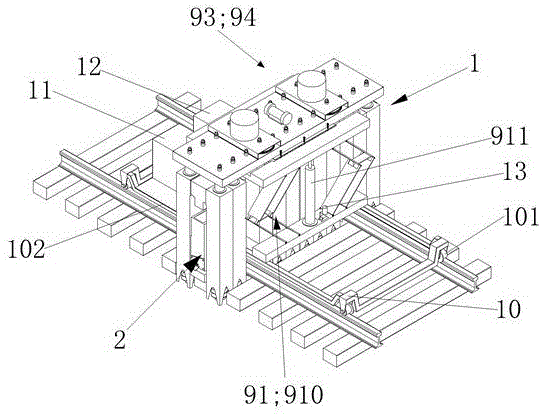

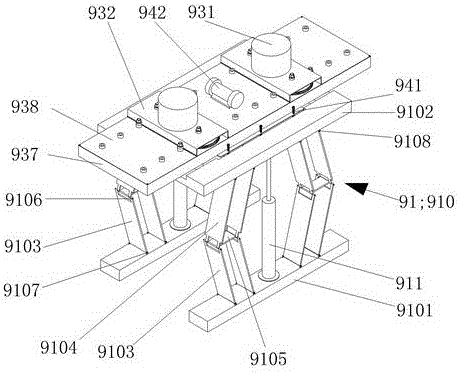

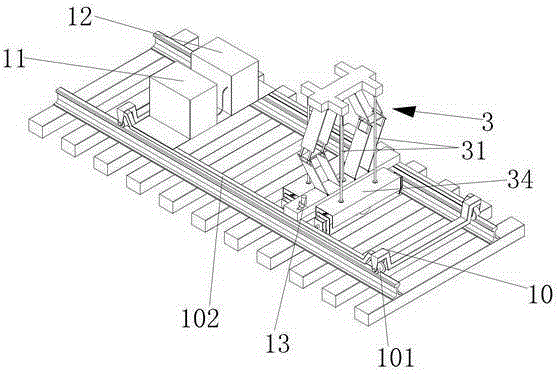

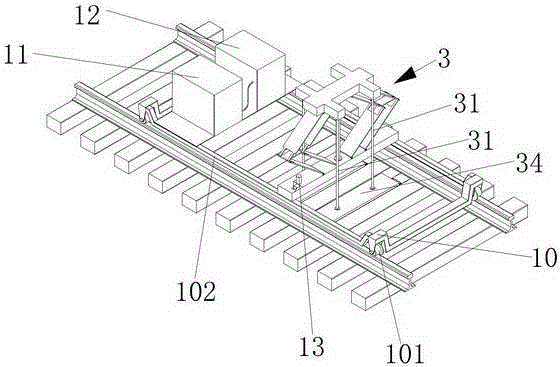

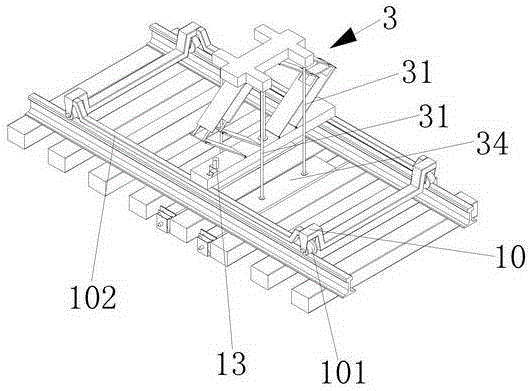

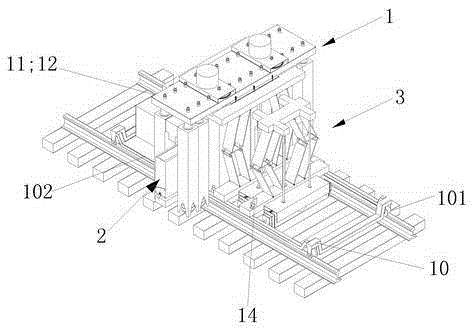

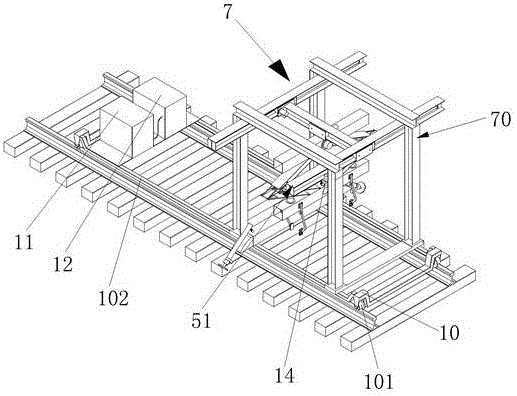

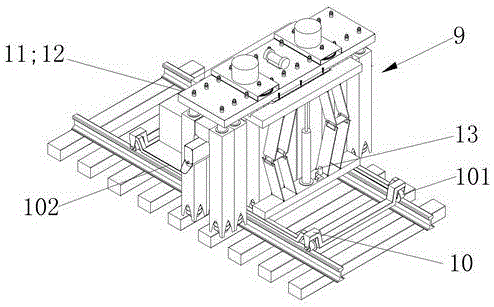

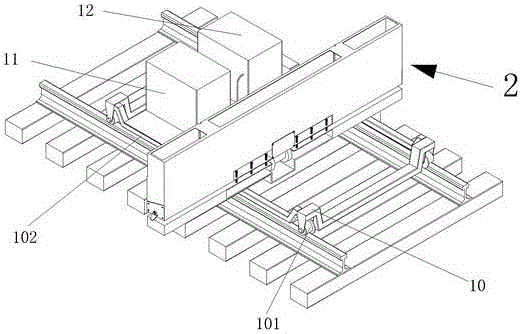

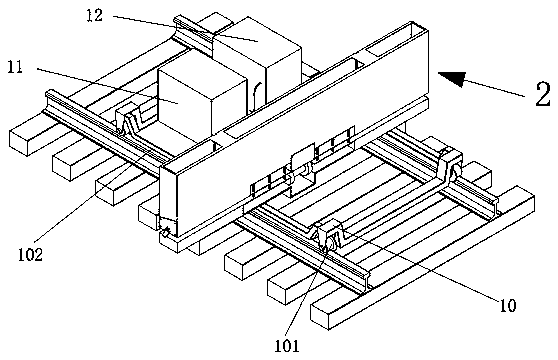

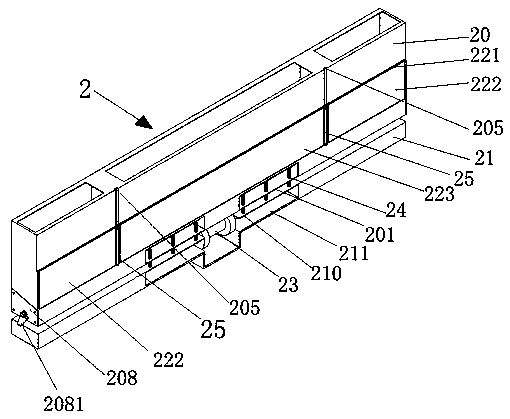

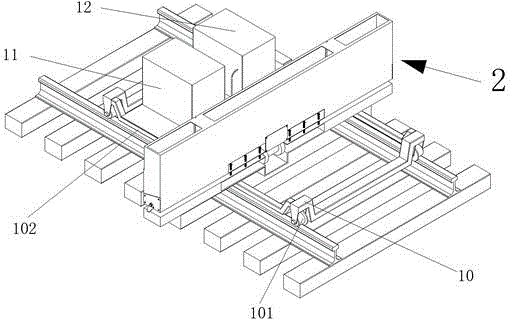

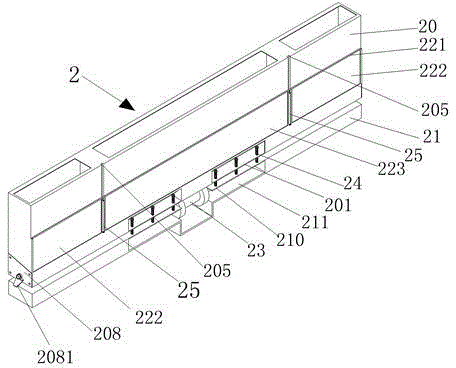

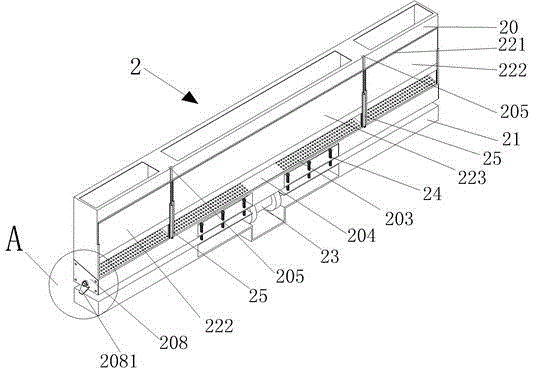

Sleeper replacing device

InactiveCN104164808AQuick alignmentSimple structureRailway track constructionAutomatic controlPush pull

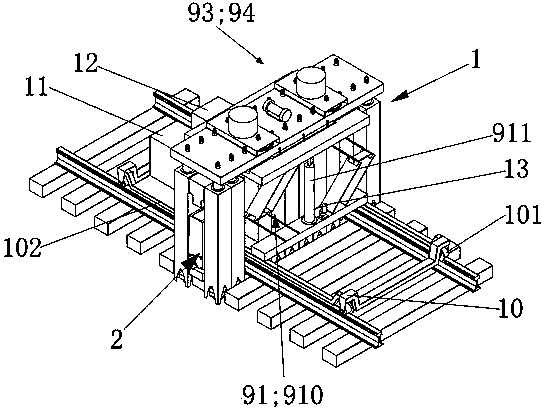

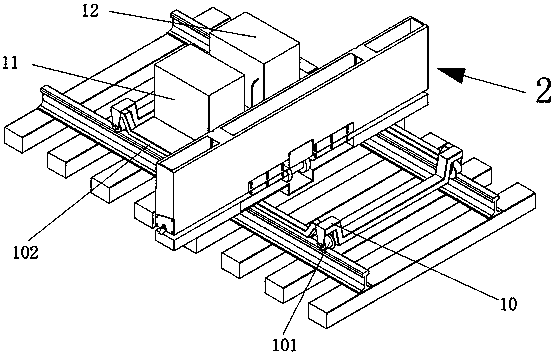

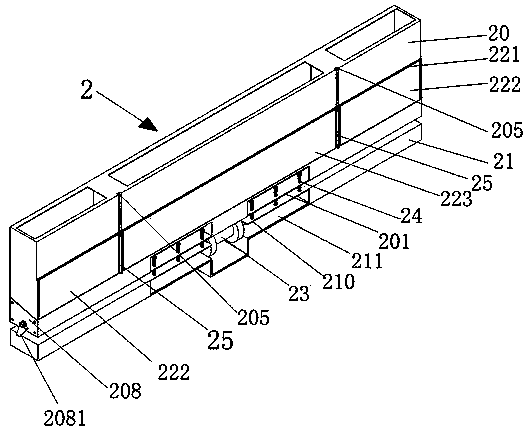

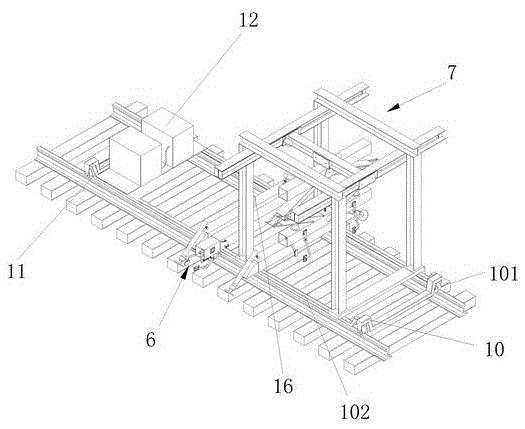

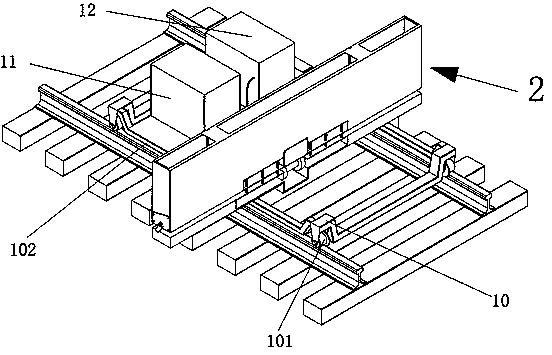

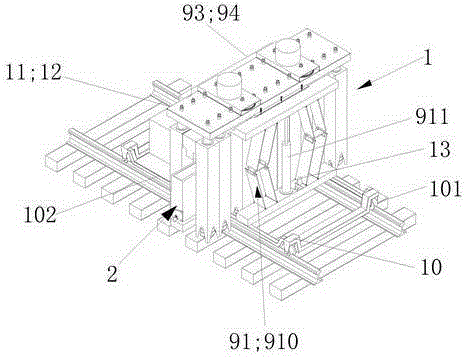

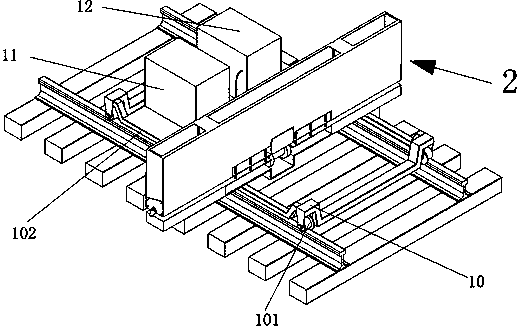

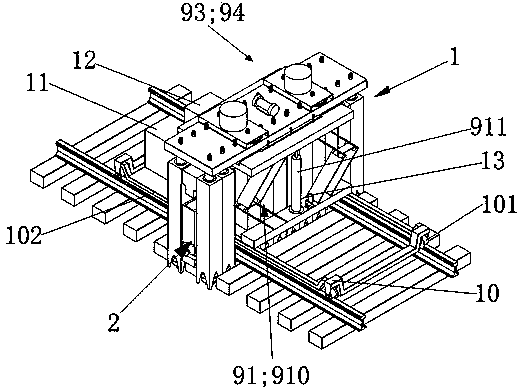

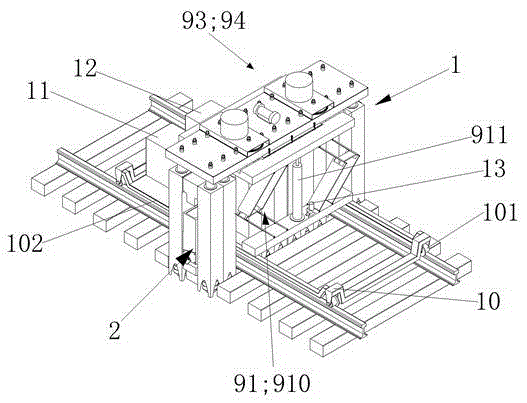

The invention discloses a sleeper replacing device which is composed of a rail-lifting and sleeper-push-pull device, a sleeper lifting and transporting device, a rail car, a generator, a hydraulic system box, a first camera shooting assembly, a second camera shooting assembly and a monitor. The rail car is provided with four castors and two longitudinal beams. The rail-lifting and sleeper-push-pull device, the sleeper lifting and transporting device, the generator and the hydraulic system box are arranged on the two longitudinal beams of the rail car. The rail car is dragged through an engineering van, the monitor is arranged in a cab of the dragging van, and the generator supplies power to an oil pump and a motor. By means of the sleeper replacing device, a working device can be rapidly aligned with the working position; a sleeper push-pull control mechanism is simple in structure and reliable in work; the sleeper replacing device can adapt to sleeper lifting, transporting and placing work of linear and curve rail sections; automatic program control is easy to achieve, and the sleeper replacing device is convenient to operate; the sleeper replacing device is simple in structure, reliable in performance and high in mechanization operation rate, and limited rail maintenance time can be sufficiently and reasonably used for completing the sleeper replacing work.

Owner:KUNMING UNIV

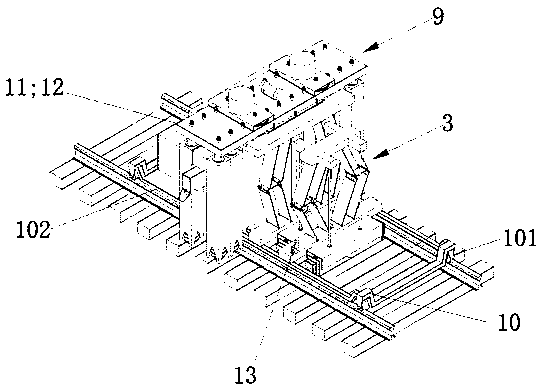

Sleeper replacement device

InactiveCN104179096AQuick alignmentAdapt to changing pillowsBallastwayRailway track constructionPush and pullAutomatic control

The invention discloses a sleeper replacement device. The sleeper replacement device is composed of a vibration stone pushing device, a four nut synchronization assembly and disassembly device, a rail lifting sleeper rotation device, a sleeper pushing and pulling device, a vibration rotary excavating stone discharging device, a rail car, an electric generator, a hydraulic system case, a first camera component, a second camera component, a third camera component, a forth camera component and a monitor, wherein a plurality of trundles and two longitudinal beams are installed on the rail car, the vibration stone pushing device, the four nut synchronization assembly and disassembly device, the rail lifting sleeper rotation device, the sleeper pushing and pulling device, the vibration rotary excavating stone discharging device, the electric generator and the hydraulic system case are arrange on the two longitudinal beams of the rail car, and the monitor is arranged in a cab of a tractor truck. The sleeper replacement device can rapidly align a working device to a position to be processed, can adapt to sleeper replacement work of straight and curve rail segments, easily achieves program automatic control, is convenient to operate, simple in structure, reliable in performance, and high in mechanization operating rate, and can fully and reasonably use limited line repair skylight operation time to complete the sleeper replacement work.

Owner:KUNMING UNIV

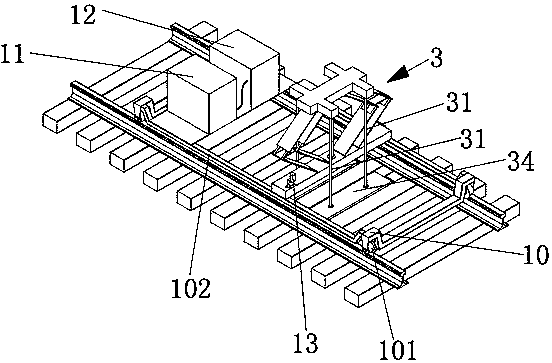

Mechanization sleeper replacement device

InactiveCN104179095AQuick alignmentAutomatic separation and dischargeBallastwayRailway track constructionPush and pullAutomatic control

The invention discloses a mechanization sleeper replacement device. The mechanization sleeper replacement device is composed of a ballast collection and discharging device, a vibration stone pushing device, a four nut synchronization assembly and disassembly device, a rail lifting sleeper rotation device, a sleeper pushing and pulling device, a transverse moving vibration rotary excavating stone discharging device, a rail car, an electric generator, a hydraulic system case, a first camera component, a second camera component, a third camera component, a forth camera component and a monitor, wherein a plurality of trundles and two longitudinal beams are installed on the rail car, the ballast collection and discharging device, the vibration stone pushing device, the four nut synchronization assembly and disassembly device, the rail lifting sleeper rotation device, the sleeper pushing and pulling device, the transverse moving vibration rotary excavating stone discharging device, the electric generator and the hydraulic system case are arrange on the two longitudinal beams of the rail car, and the monitor is arranged in a cab of a tractor truck. The mechanization sleeper replacement device can rapidly align a working device to a position to be processed, can adapt to sleeper replacement work at straight and curve rail segments, easily achieves program automatic control, is convenient to operate, and can fully and reasonably use limited line repair skylight operation time to complete the sleeper replacement work.

Owner:KUNMING UNIV

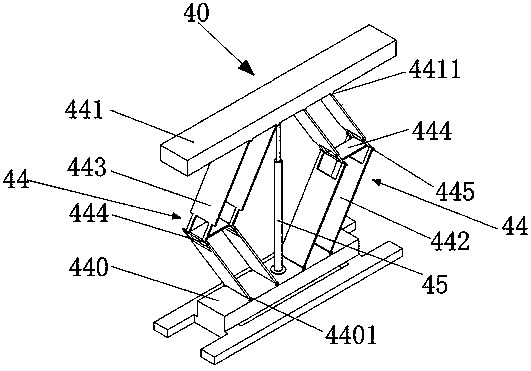

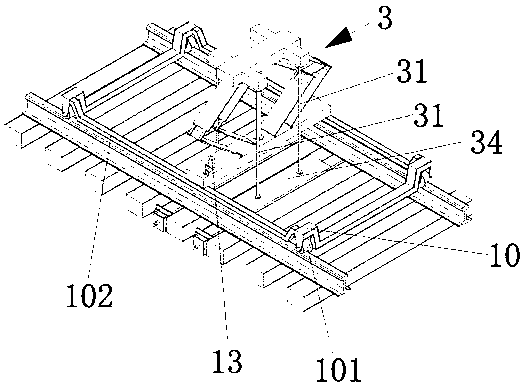

Quick mechanical sleeper rotating machine

InactiveCN104195899AQuick alignmentEasy dischargeBallastwayRailway track constructionEngineeringBallast

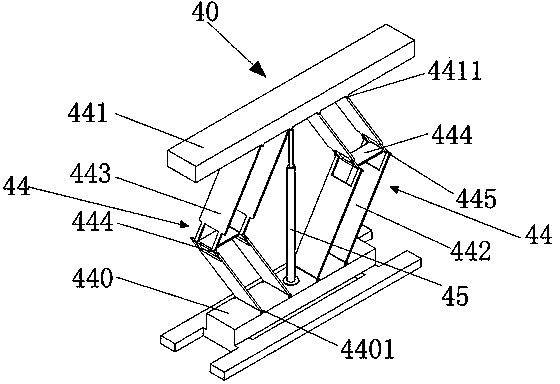

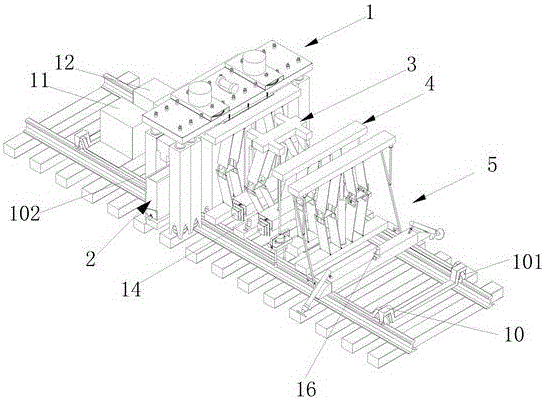

The invention discloses a quick mechanical sleeper rotating machine. The quick mechanical sleeper rotating machine is composed of a vibration stone pushing device, a four nut synchronous mounting and dismounting device, a rail lifting and sleeper rotating device, a vibration rotary excavating type stone removing device, a rail car, a power generator, a hydraulic system box, a first camera shooting component, a second camera shooting component, a third camera shooting component, a fourth camera shooting component and a monitor, wherein the rail car is provided with multiple trundles and two longitudinal beams, the vibration stone pushing device, the four nut synchronous mounting and dismounting device, the rail lifting and sleeper rotating device, the vibration rotary excavating type stone removing device, the power generator and the hydraulic system box are arranged on the two longitudinal beams of the rail car, the rail car is pulled by an engineering van, and the monitor is arranged in a tractor cab. According to the quick mechanical sleeper rotating machine, a working device can be aligned with a working position quickly; stone ballast between sleepers can be removed quickly, so that quick sleeper replacement is guaranteed; requirements for stone removal, nut dismounting and mounting and sleeper rotation on linear and curve rail sections can be met; limited train passing gaps for track maintenance can be fully and reasonably utilized to achieve sleeper rotation.

Owner:KUNMING UNIV

Rapid sleeper replacing machine

InactiveCN104153261AQuick alignmentAutomatic separation and dischargeRailway track constructionPush and pullAutomatic control

The invention discloses a rapid sleeper replacing machine which is composed of a ballast collecting and removing device, a vibration stone pushing device, a four-nut synchronous mounting and dismounting device, a rail lifting and sleeper rotating device, a sleeper push-and-pull device, a sleeper lifting device, a transversely moving vibration rotary excavating and stone removing device, a railcar, a generator, a hydraulic system box, a first photographing assembly, a second photographing assembly, a third photographing assembly, a fourth photographing assembly, a fifth photographing assembly, a sixth photographing assembly and a monitor. The railcar is provided with a plurality of trundles and two longitudinal beams, the ballast collecting and removing device, the vibration stone pushing device, the four-nut synchronous mounting and dismounting device, the rail lifting and sleeper rotating device, the sleeper push-and-pull device, the sleeper lifting device, the transversely moving vibration rotary excavating and stone removing device, the generator and the hydraulic system box are arranged on the two longitudinal beams of the railcar, and the monitor is arranged in a cab of a tractor. The rapid sleeper replacing machine enables a working device to be aligned to a working position rapidly and can be adapted to the work of rapid sleeper replacement of linear and curve rail sections, automatic program control is achieved easily, and operation is convenient.

Owner:KUNMING UNIV

Rail lifting and quick sleeper-replacing machine

InactiveCN104195898AQuick alignmentImprove work efficiencyRailway track constructionPush and pullAutomatic control

The invention discloses a rail lifting and quick sleeper-replacing machine which consists of a four-nut synchronous mounting and dismounting device, a rail lifting and sleeper turning device, a rail sleeper pushing and pulling device, a rail hoisting device, a rail car, a generator, a hydraulic system tank, a first camera shooting assembly, a second camera shooting assembly, a third camera shooting assembly, a fourth camera shooting assembly and a monitor. The rail car is provided with multiple trundles and two longitudinal beams, the four-nut synchronous mounting and dismounting device, the rail lifting and sleeper turning device, the rail sleeper pushing and pulling device, the rail hoisting device, the generator and the hydraulic system tank are arranged on the two longitudinal beams of the rail car, the rail car is dragged by an engineering truck, and the monitor is arranged in a motor tractor cab. The rail lifting and quick sleeper-replacing machine can enable a working device to be quickly aligned to a working position. Four nuts are synchronously dismounted, the time is saved, and the working efficiency is high. The rail lifting and quick sleeper-replacing machine can adapt to rail sleeper hoisting and arrangement work at straight-line and curved-line rail road sections. Automatic program control is easy to achieve, and operation is convenient. The mechanical operability is high, the limited line repair 'skylight' operation time can be fully and reasonably utilized, and sleeper-replacing work can be completed.

Owner:KUNMING UNIV

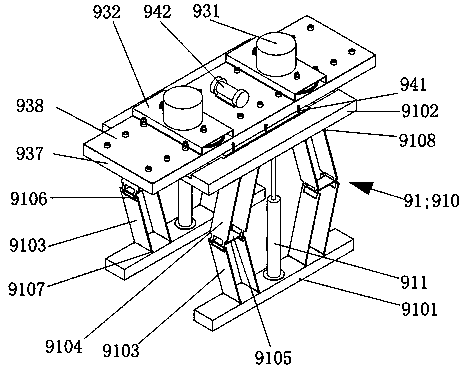

Rail lifting sleeper changing machine

InactiveCN104164807AEasy to realize automatic controlEasy to operateRailway track constructionPush and pullAutomatic control

The invention discloses a rail lifting sleeper changing machine. The rail lifting sleeper changing machine is composed of a four-nut synchronous mounting and dismounting device, a rail lifting sleeper turning device, a sleeper pushing and pulling device, a railway car, a generator, a hydraulic system box, a first camera assembly, a second camera assembly and a monitor, wherein the railway car is provided with multiple trundles and two longitudinal beams, wherein the four-nut synchronous mounting and dismounting device, the rail lifting sleeper turning device, the sleeper pushing and pulling device railway car, the generator and the hydraulic system box are arranged on the two longitudinal beams of the railway car, the railway car is dragged by an engineering car, the monitor is arranged in a cab of a traction car, and the generator provides power for an oil pump and a motor. According to the rail lifting sleeper changing machine, a work component can be rapidly aligned with a work object, four nuts are synchronously dismounted, time is saved, and work efficiency is high. Automatic control over programs can be realized easily, and operation is convenient. The rail lifting sleeper changing machine is simple in structure, reliable in performance, high in mechanical operation efficiency and capable of making full use of the limited circuit repairing 'skylight' operation time to finish the sleeper changing work.

Owner:KUNMING UNIV

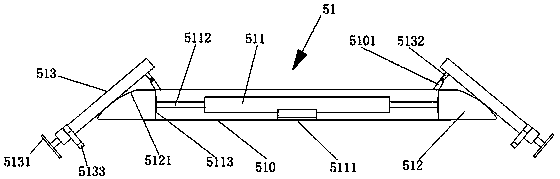

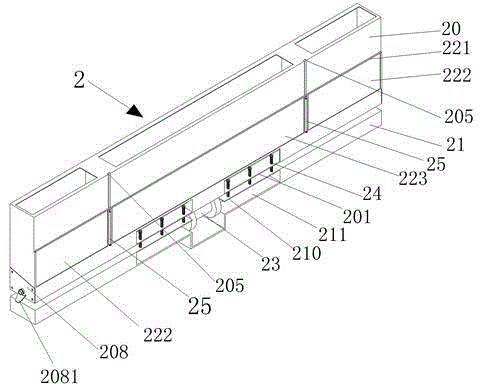

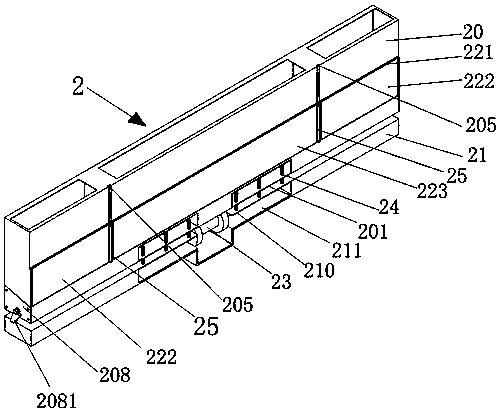

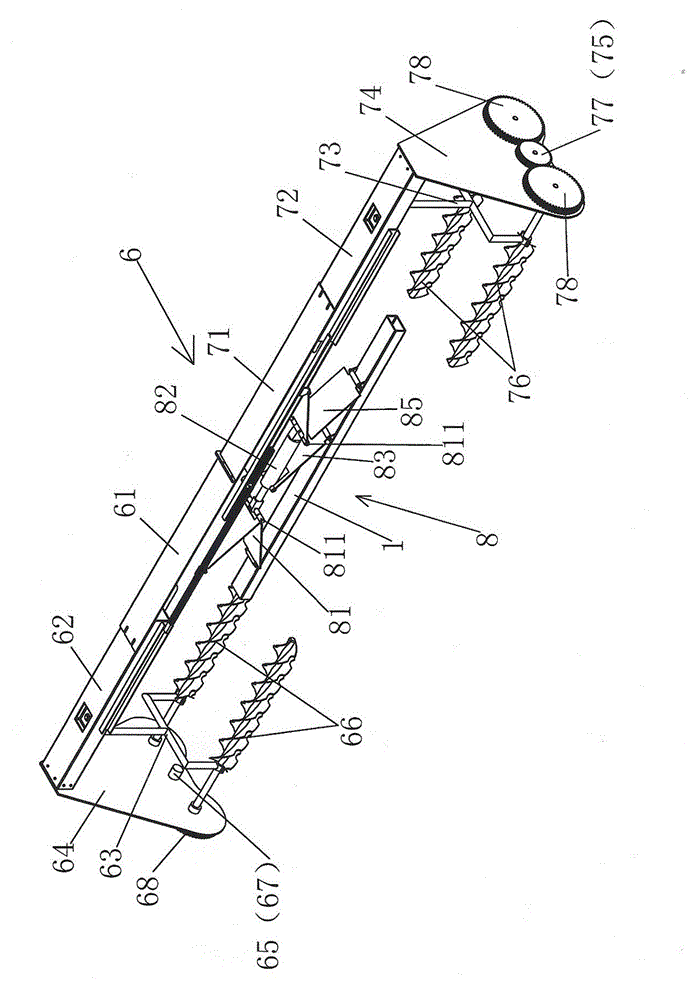

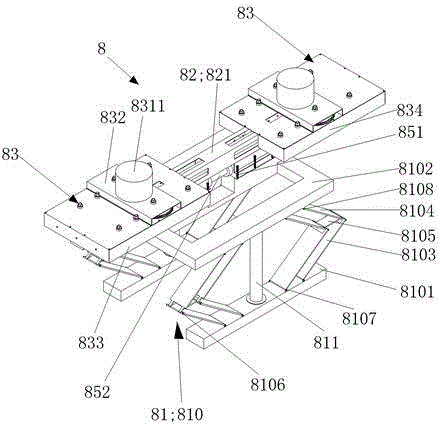

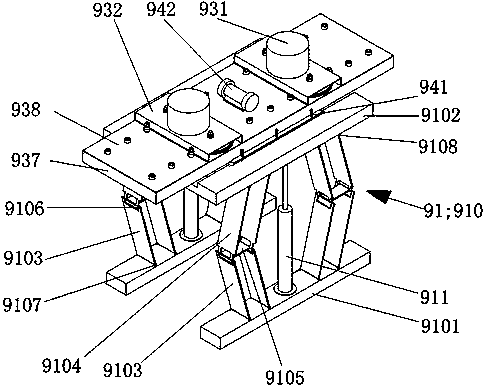

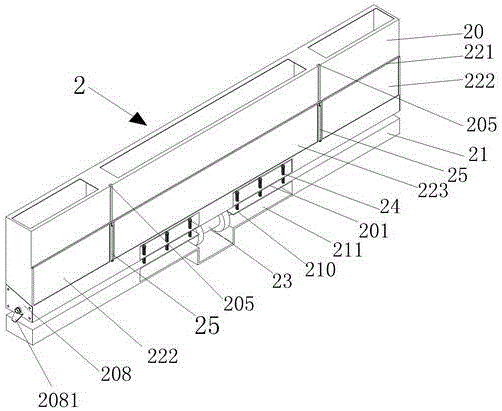

Traverse moving vibration rotary excavating stone discharging device

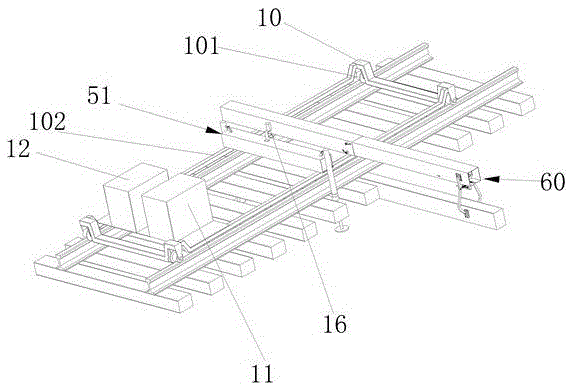

The invention discloses a traverse moving vibration rotary excavating stone discharging device used among sleepers. The traverse moving vibration rotary excavating stone discharging device is composed of traverse moving vibration rotary excavating stone discharging equipment, a rail car, an electric generator, a hydraulic system case, a camera component and a monitor, wherein four trundles and two longitudinal beams are installed on the rail car, the traverse moving vibration rotary excavating stone discharging equipment, the rail car, the electric generator and the hydraulic system case are arranged on the two longitudinal beams of the rail car, the rail car is dragged by an engineering truck, the monitor is arranged in a cab of a tractor truck, the electric generator provides power to an oil pump, and an oil tank, the oil pump and various hydraulic control valves are arranged in the hydraulic system case. The traverse moving vibration rotary excavating stone discharging device can rapidly align two rows of rotary excavating stirring cages to a space between sleepers on two sides of another sleeper to be replaced, can rapidly discharge ballast among the sleepers, provides guarantees to rapid sleeper replacement work, can adapt to stone discharging work at straight and curve rail segments, easily achieves program automatic control, is convenient to operate, simple in structure, reliable in performance, and high in mechanization operating rate, and can fully and reasonably use limited line repair skylight operation time to complete the stone discharging work.

Owner:KUNMING UNIV

A sleeper replacement device

InactiveCN104164808BQuick alignmentSimple structureRailway track constructionAutomatic controlPush pull

Owner:KUNMING UNIV

Mechanical sleeper rotating machine

InactiveCN104195901AQuick alignmentAutomatic separation and dischargeBallastwayRailway track constructionElectric machineEngineering

The invention discloses a mechanical sleeper rotating machine. The mechanical sleeper rotating machine is composed of a vibration rotary excavating type stone removing device, a stone ballast collecting and discharging device, a vibration stone pushing device, a four nut synchronous mounting and dismounting device, a rail lifting and sleeper rotating device, a rail car, a power generator, a hydraulic system box, a first camera shooting component, a second camera shooting component, a third camera shooting component, a fourth camera shooting component and a monitor, wherein the rail car is provided with multiple trundles and two longitudinal beams, the vibration rotary excavating type stone removing device, the stone ballast collecting and discharging device, the vibration stone pushing device, the four nut synchronous mounting and dismounting device, the rail lifting and sleeper rotating device, the power generator and the hydraulic system box are arranged on the two longitudinal beams of the rail car, the rail car is pulled by an engineering van, the monitor is arranged in a tractor cab, and the power generator provides power for an oil pump and a motor. According to the mechanical sleeper rotating machine, stone ballast between sleepers can be quickly discharged into a stone collecting box, and sand in the stone ballast can be separated from the stone ballast and discharged automatically; four nuts are dismounted synchronously, and quick sleeper rotation is achieved; the structure is simple, performance is high, mechanical working efficiency is high, and limited train passing gaps for track maintenance can be fully and reasonably utilized to achieve sleeper rotation.

Owner:KUNMING UNIV

Mechanization rapid ballast discharging and filling machine used among sleepers

The invention discloses a mechanization rapid ballast discharging and filling machine used among sleepers. The mechanization rapid ballast discharging and filling machine used among the sleepers is composed of a ballast collection and discharging device, a vibration stone pushing device, a traverse moving vibration rotary excavating stone discharging device, a rail car, an electric generator, a hydraulic system case, a first camera component, a second camera component and a monitor, wherein four trundles and two longitudinal beams are installed in the rail car, the ballast collection and discharging device, the vibration stone pushing device, the traverse moving vibration rotary excavating stone discharging device, the electric generator and the hydraulic system case are arranged on the two longitudinal beams of the rail car, the rail car is dragged by an engineering truck, the monitor is arranged in a cab of a tractor truck, and the electric generator provides power to an oil pump and a motor. The mechanization rapid ballast discharging and filling machine used among the sleepers can rapidly align a working device to a position to be processed, can rapidly discharge ballast among the sleepers into a stone collection box, can automatically separate sandy soil from the ballast and discharge the sandy soil, can rapidly backfill two sides of a sleeper which replaces a previous sleeper with the ballast in the stone collection box, can adapt to stone discharging work of straight and curve rail segments, and can fully and reasonably use limited line repair skylight operation time to complete ballast cleaning work.

Owner:KUNMING UNIV

A mechanized pillow turning machine

InactiveCN104195901BQuick alignmentAutomatic separation and dischargeBallastwayRailway track constructionRational useMachining vibrations

The invention discloses a mechanized sleeper turning machine, which is composed of a vibrating rotary excavation stone discharge device, a ballast collecting and discharging device, a vibrating stone pushing device, a four-nut synchronous assembly and disassembly device, a rail lifting and turning sleeper device, a rail car, a generator, The hydraulic system box, the first camera assembly, the second camera assembly, the third camera assembly, the fourth camera assembly and a monitor are composed. The rail car is equipped with multiple casters and two longitudinal beams. The collecting and arranging device, the vibrating stone pushing device, the four-nut synchronous assembly and disassembly device, the rail lifting and turning sleeper device, the generator and the hydraulic system box are arranged on the two longitudinal beams of the rail car, and the rail car is pulled by an engineering vehicle, and the monitor is set on the In the cab of the tractor, the generator provides power for the oil pump and the motor; the invention can quickly discharge the ballast between the sleepers into the stone collection box, and automatically separate and discharge the sand in the ballast; the four nuts are dismantled synchronously, and the sleeper is quickly rotated; The structure is simple, the performance is reliable, and the mechanized operation rate is high, which can make full and reasonable use of the limited working time for repairing the "skylight" of the line to complete the work of turning the pillow.

Owner:KUNMING UNIV

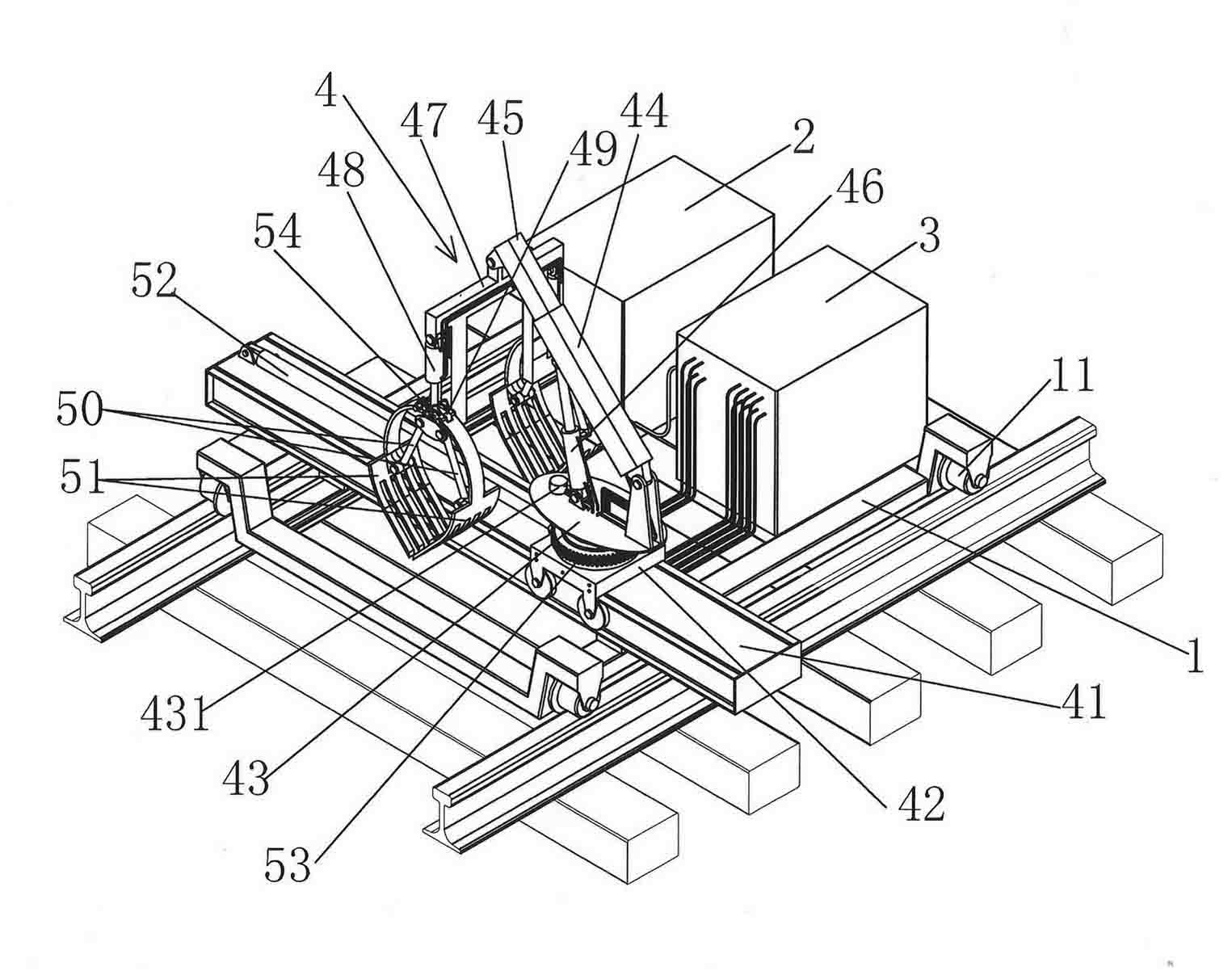

Sleeper rapid replacing machine

The invention discloses a sleeper rapid replacing machine. The machine comprises a motor trolley, a generator, an operation control box, a grab stone removing device, a rotary drilling mechanism and a rail-raising and sleeper-replacing mechanism. Four feet of the motor trolley are provided with casters. With the help of manpower, the motor trolley can advance on a rail. The generator, the controloperation box and the grab stone removing device are arranged on the motor trolley. The rotary drilling mechanism and the rail-raising and sleeper-replacing mechanism are transversely arranged on themotor trolley. The grab stone removing device and the rotary drilling mechanism can be used for rapidly removing roadbed stone ballast between every two sleepers. The rail-raising and sleeper-replacing mechanism can be used for rapidly replacing the sleeper, and then, the grab stone removing device is used for filling the stone ballast between every two sleepers. Manual ballast-flattening and rail-replacing operation is completed. The machine disclosed by the invention not only has the advantages of convenient operation, reliable performance and high mechanical operation rate but also has theadvantages of simple structure and light weight, thus, the whole machine can be lifted off the rail by four persons; and skylight repairing operation can be carried out by utilizing a limited line sufficiently and rationally so that the replacement of the sleeper is completed.

Owner:KUNMING UNIV

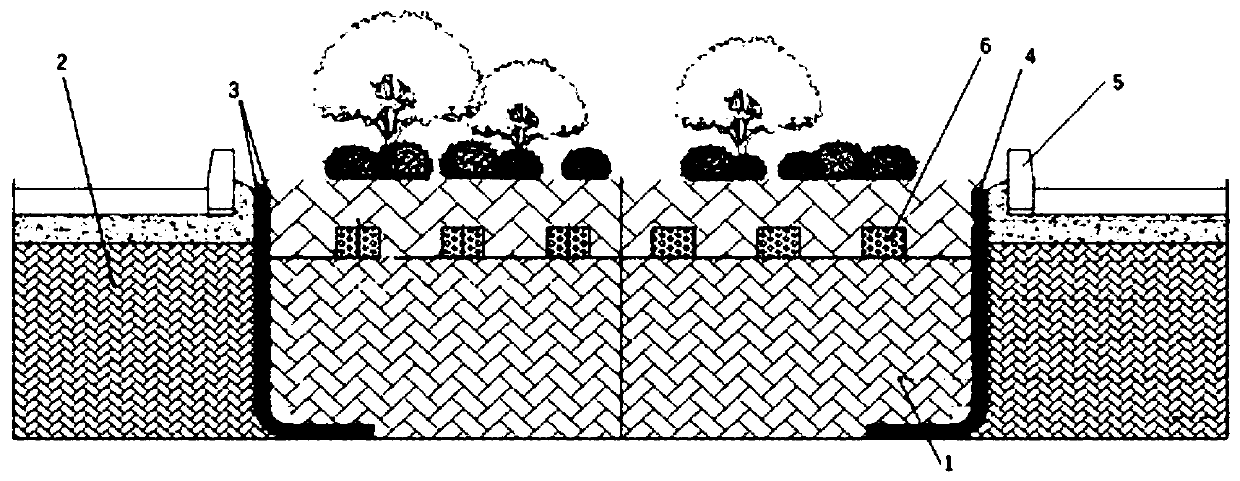

Improved water retention method for gobi desertification soil through afforesting planting soil

InactiveCN111567332AReduce entryReduce subsidenceOther chemical processesClimate change adaptationWater useSoil science

The invention provides an improved water retention method for gobi desertification soil through afforesting planting soil. Compared with a traditional park afforesting planting soil backfilling method, the method comprises the steps of laying a layer of waterproof blankets between municipal afforesting planting soil and an edge in contact with a municipal road, then performing backfilling on the afforesting planting soil; and after backfilling of the afforesting planting soil is completed, performing leveling and compacting, before afforesting planting, performing mechanical furrowing at an afforesting planting region, laying organic matter mixed fertilizers in furrows, then performing backfilling and leveling on furrow tops, and finally performing afforesting planting. According to the method disclosed by the invention, seepage isolation measures of the bentonite waterproof blankets and the like are increased at the edge of the municipal road, the situation that conservation and irrigation water enters a roadbed can be reduced, the situation that the roadbed settles and sinks due to being in contact with water can be reduced, and the quantity of the conservation and irrigation water is reduced; through furrowing and burying the organic matter mixed fertilizers, soil layers having different structures are formed, and hardening of the soil is reduced; and besides, polyacrylamideand bentonite have strong adsorbing capacity, so that the capacity of desertification soil for evaporation resistance and water retention can be increased.

Owner:SHANGHAI ERSHIYE CONSTR CO LTD +1

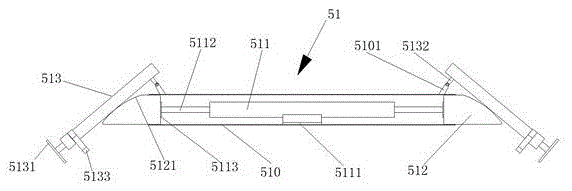

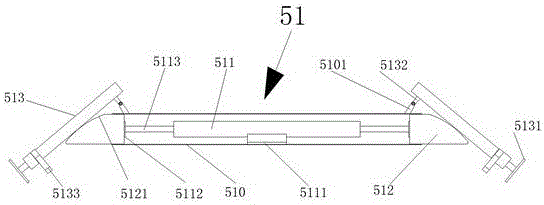

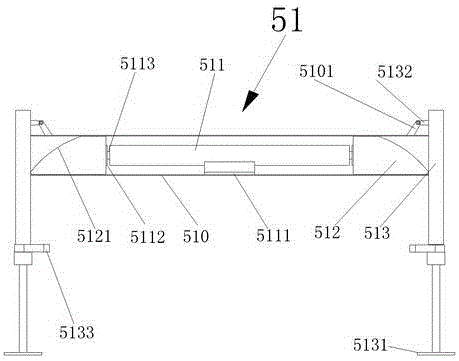

Vibrating stone pushing device under rails

The invention discloses an under-rail vibrating ballast pushing device. The under-rail vibrating ballast pushing device is composed of vibrating ballast pushing devices, a railway car, a generator, a hydraulic system manifold, a camera assembly and a monitor. The railway car is provided with four trundles and two longitudinal beams; the vibrating ballast pushing devices, the generator and the hydraulic system manifold are arranged on the two longitudinal beams of the railway car; the railway car is pulled through an engineering car; the monitor is arranged inside the cab of the traction car; the generator powers an oil pump and a vibrating motor; the camera assembly is composed of a camera and a camera support, wherein the camera support is provided with an isosceles trapezoid reference plane coplanar with the axis of the camera, and a bottom plate; the inside of the hydraulic system case is provided with an oil tank, the oil pump and various hydraulic control pressure valves. The under-rail vibrating ballast pushing device can rapidly align the two vibrating ballast pushing assemblies to the space between the two side sleeper bodies of a sleeper to be replaced to push ballast under steel rails between the sleeper bodies rapidly, is applicable to ballast pushing of linear and curved rail sections, and can easily achieve programmed automatic control and operating convenience.

Owner:KUNMING UNIV

Vibration rotary excavating type quick stone removing machine used between sleepers

The invention discloses a vibration rotary excavating type quick stone removing machine used between sleepers. The machine is composed of a vibration stone pushing device, a vibration rotary excavating type stone removing device, a rail car, a power generator, a hydraulic system box, a first camera shooting component, a second camera shooting component and a monitor, wherein the rail car is provided with four trundles and two longitudinal beams, the vibration stone pushing device, the vibration rotary excavating type stone removing device, the power generator and the hydraulic system box are arranged on the two longitudinal beams of the rail car, the rail car is pulled by an engineering van, the monitor is arranged in a tractor cab, and the power generator provides power for an oil pump and a motor. According to the machine, a working device can be aligned with a work position quickly; stone ballast between the sleepers can be removed quickly, so that quick sleep replacement is guaranteed; requirements for stone removal on linear and curve rail sections can be met; automatic program control can be achieved easily, and operation is convenient; the structure is simple, performance is reliable, mechanical working efficiency is high, and limited train passing gaps for track maintenance can be fully and reasonably utilized to achieve stone removal.

Owner:KUNMING UNIV

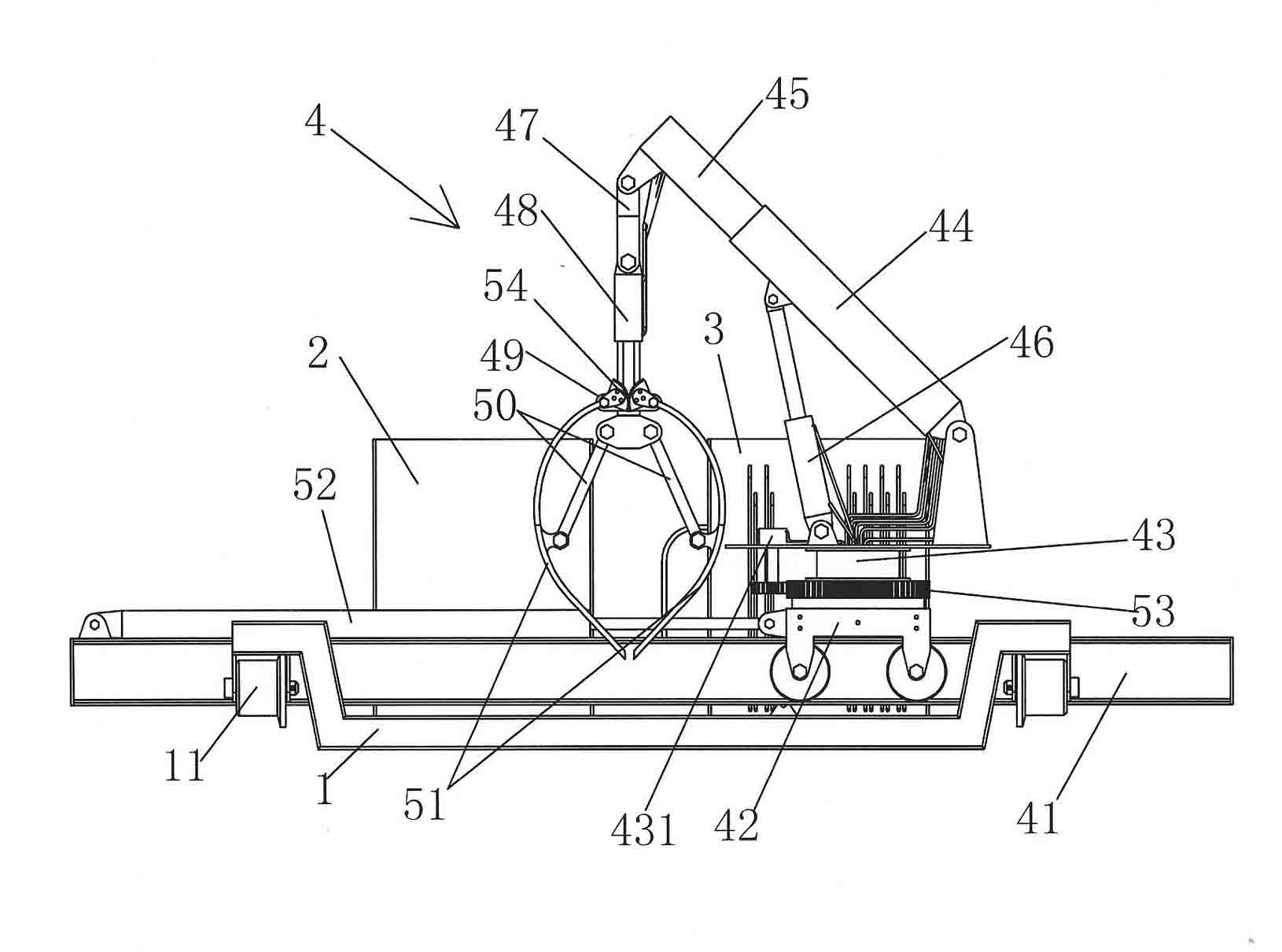

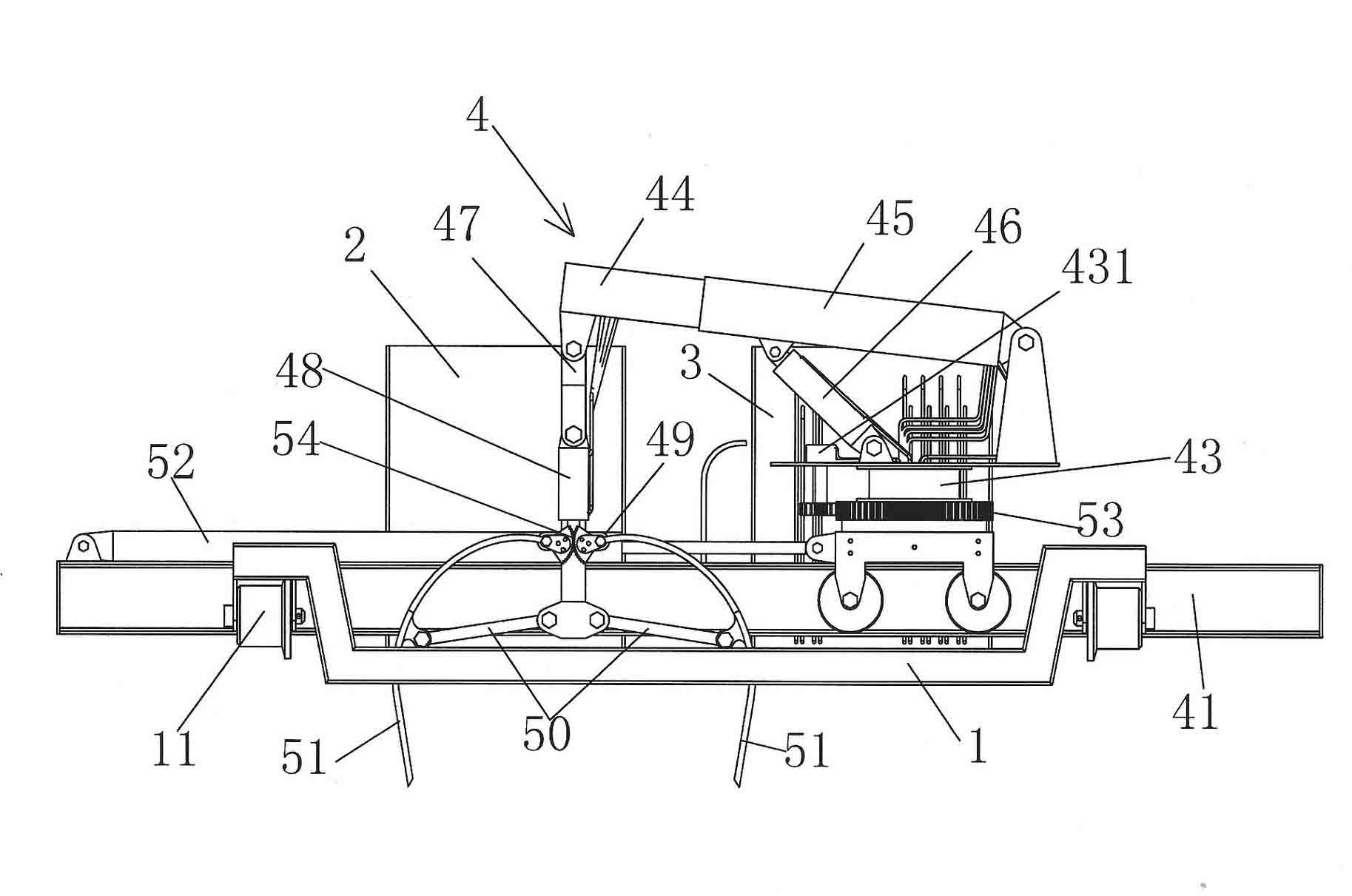

Inter-sleep grab bucket stone remover

The invention discloses an inter-sleep grab bucket stone remover, which consists of a track vehicle, a generator, an operation control box and a grab bucket stone removal device, wherein the generator, the operation control box and the grab bucket stone removal device are arranged on the track vehicle and can be pushed to move on a track by man power; the grab bucket stone removal device consistsof a cross beam, a trolley, a rotary table, a hoisting basic arm, a hoisting telescopic arm, a hoisting arm variable-amplitude oil cylinder, a portal-type steel frame, a grab bucket opening and closing oil cylinder, a force application plate, a brace rod, two grab buckets, an oil cylinder for driving the trolley to move, a rotary steady bearing and a fan-shaped wheel group; the grab bucket stone removal device can move, rotate and rise and fall on the trolley; and opening and closing of the two grab buckets can release and hold stones. The inter-sleep grab bucket stone remover can quickly remove stones between two sides of the sleep, is convenient for operation, reliable in performance and high in mechanical working efficiency and has a simple structure; moreover, the inter-sleep grab bucket stone remover is so light that two workers can move the remover from the track conveniently; and the finite line repair 'skylight' working time can be used fully and rationally.

Owner:KUNMING UNIV

A vibrating rotary excavation and ballast filling machine between sleepers

The invention discloses a vibration rotary excavating ballast discharging and filling machine used among sleepers. The vibration rotary excavating ballast discharging and filling machine used among the sleepers is composed of a vibration rotary excavating stone discharging device, a ballast collection and discharging device, a rail car, an electric generator, a hydraulic system case, a camera component and a monitor, wherein four trundles and two longitudinal beams are installed on the rail car, the vibration rotary excavating stone discharging device, the ballast collection and discharging device, the electric generator and the hydraulic system case are arranged on the two longitudinal beams of the rail car, the rail car is dragged by an engineering truck, the monitor is arranged in a cab of a tractor truck, and the electric generator provides power to an oil pump and a motor. The vibration rotary excavating ballast discharging and filling machine used among the sleepers can rapidly align a working device to a position to be processed, can rapidly discharge ballast among the sleepers into a stone collection box, can automatically separate sandy soil from the ballast and discharge the sandy soil, can rapidly backfill two sides of a sleeper which replaces a previous sleeper with the ballast in the stone collection box, can adapt to stone discharging work at straight and curve rail segments, easily achieves program automatic control, is convenient to operate, simple in structure, reliable in performance and high in mechanization operation rate, and can fully and reasonably use limited line repair skylight operation time to complete macadam cleaning work.

Owner:KUNMING UNIV

A rock-discharging device for laterally moving vibratory rotary excavation

The invention discloses a traverse moving vibration rotary excavating stone discharging device used among sleepers. The traverse moving vibration rotary excavating stone discharging device is composed of traverse moving vibration rotary excavating stone discharging equipment, a rail car, an electric generator, a hydraulic system case, a camera component and a monitor, wherein four trundles and two longitudinal beams are installed on the rail car, the traverse moving vibration rotary excavating stone discharging equipment, the rail car, the electric generator and the hydraulic system case are arranged on the two longitudinal beams of the rail car, the rail car is dragged by an engineering truck, the monitor is arranged in a cab of a tractor truck, the electric generator provides power to an oil pump, and an oil tank, the oil pump and various hydraulic control valves are arranged in the hydraulic system case. The traverse moving vibration rotary excavating stone discharging device can rapidly align two rows of rotary excavating stirring cages to a space between sleepers on two sides of another sleeper to be replaced, can rapidly discharge ballast among the sleepers, provides guarantees to rapid sleeper replacement work, can adapt to stone discharging work at straight and curve rail segments, easily achieves program automatic control, is convenient to operate, simple in structure, reliable in performance, and high in mechanization operating rate, and can fully and reasonably use limited line repair skylight operation time to complete the stone discharging work.

Owner:KUNMING UNIV

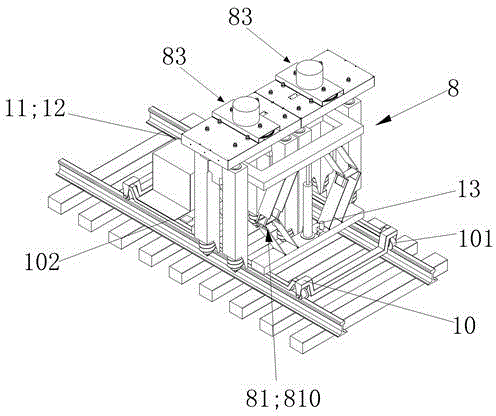

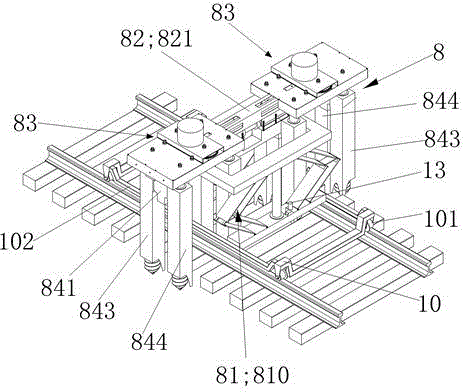

Fully-mechanized quick sleeper-changing machine

InactiveCN104179094AQuick alignmentAutomatic separation and dischargeRailway track constructionAutomatic controlBallast

The invention discloses a fully-mechanized quick sleeper-changing machine. The fully-mechanized quick sleeper-changing machine consists of a stone ballast collecting and discharging device, a vibration stone pushing device, a four-nut synchronous assembling and disassembling device, a sleeper lifting and changing device, a transverse moving vibration rotary excavating stone removing device, a track car, a generator, a hydraulic system box, a first camera shooting assembly, a second camera shooting assembly, a third camera shooting assembly, a fourth camera shooting assembly and a monitor. A plurality of trundles and two longitudinal beams are mounted on the track car, the stone ballast collecting and discharging device, the vibration stone pushing device, the four-nut synchronous assembling and disassembling device, the sleeper lifting and changing device, the transverse moving vibration rotary excavating stone removing device, the generator and the hydraulic system box are arranged on the longitudinal beams of the track car, and the monitor is arranged in a cab of a motor tractor; the machine can be used for quickly aligning the working position of the working device; the machine can be suitable for stone removing work, nut disassembling work and sleeper changing work of straight line and curve track road segments; the machine is easy for realizing automatic control for program, and is convenient to operate; limited circuit repair skylight work time can be fully and reasonably utilized, so that the sleeper-changing work is completed.

Owner:KUNMING UNIV

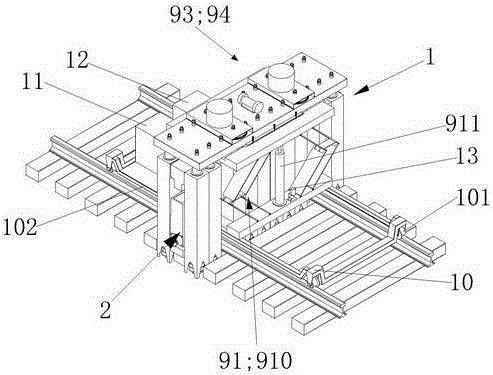

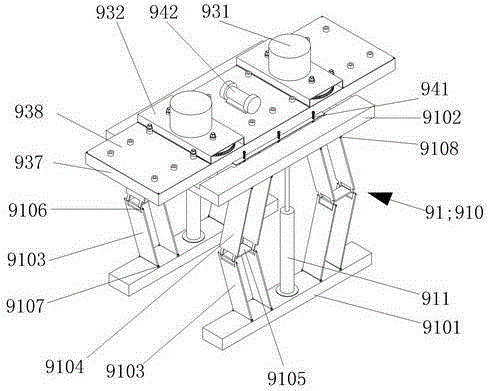

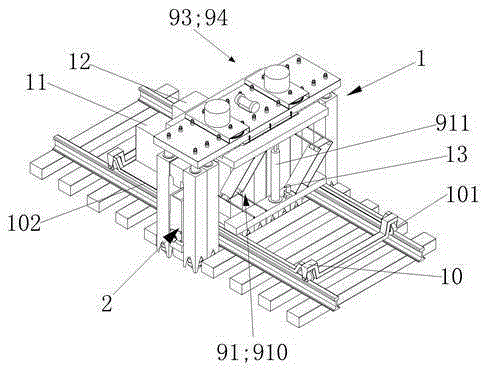

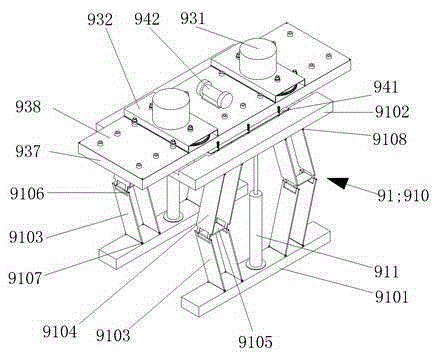

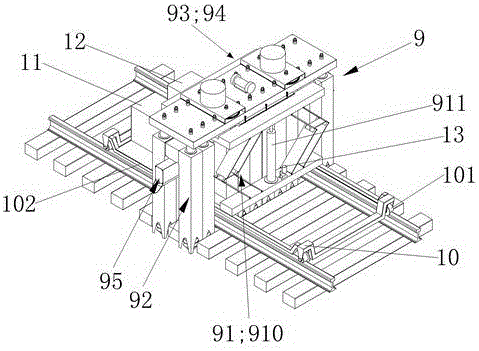

Quick sleeper-changing machine

InactiveCN104179093AQuick alignmentAutomatic separation and dischargeRailway track constructionPush and pullBallast

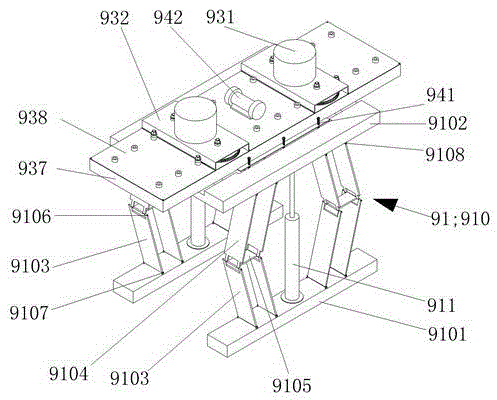

The invention discloses a quick sleeper-changing machine. The quick sleeper-changing machine consists of a vibration rotary excavating stone discharging device, a stone ballast collecting and discharging device, a vibration stone pushing device, a four-nut synchronous assembling and disassembling device, a rail lifting sleeper-rotating device, a sleeper pushing and pulling device, a rail car, a generator, a hydraulic system box, a first video component, a second video component, a third video component, a fourth video component and a monitor; a plurality of trundles and two longitudinal beams are mounted on the rail car, the vibration rotary excavating stone discharging device, the stone ballast collecting and discharging device, the vibration stone pushing device, the four-nut synchronous assembling and disassembling device, the rail lifting sleeper-rotating device, the sleeper pushing and pulling device, the generator and the hydraulic system box are arranged on the two longitudinal beams of the rail car, and the monitor is arranged in a motor tractor cab. According to the quick sleeper-changing machine, stone ballast among the sleepers is quickly discharged in a stone collection box and is automatically separated to discharge sand in the stone ballast; the quick sleeper-changing machine can be suitable for straight-line and curve rail road sleeper-changing work; limited circuit repair skylight work time can be fully and reasonably utilized, so that the sleeper-changing work is completed.

Owner:KUNMING UNIV

A Mechanized Ballast Discharging Machine Between Sleepers

The invention discloses a mechanization ballast discharging and filling machine used among sleepers. The mechanization ballast discharging and filling machine used among the sleepers is composed of a vibration rotary excavating stone discharging device, a ballast collection and discharging device, a vibration stone pushing device, a rail car, an electric generator, a hydraulic system case, a first camera component, a second camera component and a monitor, wherein four trundles and two longitudinal beams are installed on the rail car, the vibration rotary excavating stone discharging device, the ballast collection and discharging device, the vibration stone pushing device, the electric generator and the hydraulic system case are arranged on the two longitudinal beams of the rail car, the rail car is dragged by an engineering truck, the monitor is arranged in a cab of a tractor truck, and the electric generator provides power to an oil pump and a motor. The mechanization ballast discharging and filling machine used among the sleepers can rapidly align a working device to a position to be processed, can rapidly discharge ballast among the sleepers into a stone collection box, can automatically separate sandy soil from the ballast and discharge the sandy soil, can rapidly backfill two sides of a sleeper which replaces a previous sleeper with the ballast in the stone collection box, can adapt to stone discharging work of straight and curve rail segments, easily achieves program automatic control, and is convenient to operate, simple in structure and high in mechanization operation rate.

Owner:KUNMING UNIV

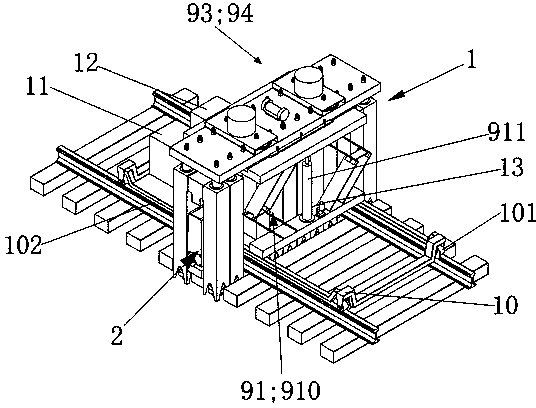

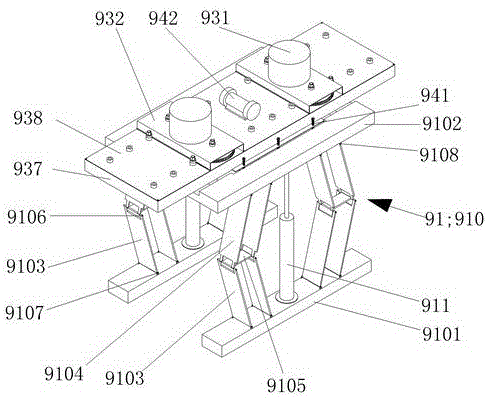

A sleeper lifting device

InactiveCN104195903BQuick alignmentEasy to realize automatic controlRailway track constructionAutomatic controlAutomatic train control

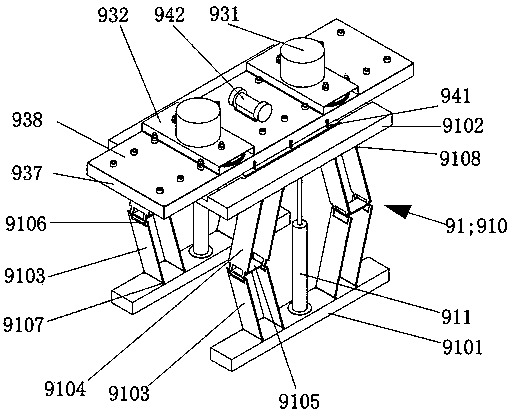

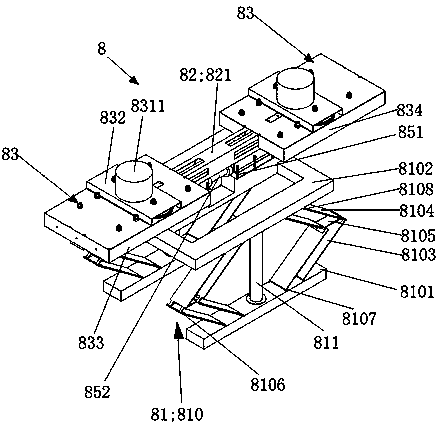

The invention discloses a sleeper hoisting device. The sleeper hoisting device is composed of a hoisting device body, a rail car, a power generator, a hydraulic system box, a first camera shooting component, a second camera shooting component and a monitor, wherein the rail car is provided with four trundles and two longitudinal beams, the hoisting device body, the power generator and the hydraulic system box are arranged on the two longitudinal beams of the rail car, the rail car is pulled by an engineering van, the monitor is arranged in a tractor cab, and the power generator provides power for an oil pump and a motor. According to the sleeper hoisting device, a working component can be aligned with a work target quickly, requirements for sleeper hoisting and arrangement on linear and curve rail sections can be met, automatic program control can be achieved easily, and operation is convenient; the structure is simple, performance is reliable, mechanical working efficiency is high, limited train passing gaps for track maintenance can be fully and reasonably utilized, and quick sleeper replacement is guaranteed.

Owner:KUNMING UNIV

A Vibrating Rotary Digging Machine Between Sleepers

The invention discloses a vibration rotary excavating type stone removing machine used between sleepers. The machine is composed of a vibration rotary excavating type stone removing device, a rail car, a power generator, a hydraulic system box, a camera shooting component and a monitor, wherein the rail car is provided with four trundles and two longitudinal beams, the vibration rotary excavating type stone removing device, the power generator and the hydraulic system box are arranged on the two longitudinal beams of the rail car, the rail car is pulled by an engineering van, the monitor is arranged in a tractor cab, the power generator provides power for an oil pump and a motor, and an oil tank, the oil pump and various hydraulic control valves are arranged in the hydraulic system box. According to the machine, two rows of rotary excavating augers can be quickly aligned with the space between sleepers on the two sides of a sleeper to be replaced; stone ballast between the sleepers can be removed quickly, so that quick sleep replacement is guaranteed; requirements for stone removal on linear and curve rail sections can be met; automatic program control can be achieved easily, and operation is convenient; the structure is simple, performance is reliable, mechanical working efficiency is high, and limited train passing gaps for track maintenance can be fully and reasonably utilized to achieve stone removal.

Owner:KUNMING UNIV

A quick pillow changing machine

InactiveCN104179093BQuick alignmentAutomatic separation and dischargeRailway track constructionPush and pullEngineering

Owner:KUNMING UNIV

A fully mechanized fast pillow turning machine

InactiveCN104179094BQuick alignmentAutomatic separation and dischargeRailway track constructionAutomatic controlEngineering

Owner:KUNMING UNIV

A mechanized rapid ballast discharge and filling machine between sleepers

InactiveCN104179088BQuick alignmentAutomatic separation and dischargeBallastwayRational useEngineering

The invention discloses a mechanized and fast ballast discharge and filling machine between sleepers, which is composed of a ballast collection and discharge device, a vibrating stone pushing device, a lateral movement vibration rotary excavation stone discharge device, a rail car, a generator, a hydraulic system box, a first Composed of a camera component, a second camera component and a monitor; the rail car is equipped with four casters and two longitudinal beams, a ballast collecting and discharging device, a vibrating rock pushing device, a lateral vibrating rotary excavating and rock discharging device, a generator and a hydraulic system The box is arranged on the two longitudinal beams of the rail car, the rail car is pulled by the engineering vehicle, the monitor is set in the cab of the tractor, and the generator provides power for the oil pump and the motor; the invention can quickly align the working device to the working position; Quickly discharge the ballast between sleepers into the stone collection box, and automatically separate and discharge the sand and soil in the stone ballast; quickly backfill the stone ballast in the stone collection box to both sides of the replaced sleeper; can adapt to straight and curved rail sections for stone discharge work; can make full and reasonable use of the limited line repair "skylight" operation time to complete the work of clearing the ballast.

Owner:KUNMING UNIV

A multifunctional ballast collecting and discharging device between sleepers

The invention discloses a multifunctional ballast collection and discharging device used among sleepers. The multifunctional ballast collection and discharging device used among the sleepers is composed of a ballast collection and discharging device, a rail car, an electric generator and a hydraulic system case, wherein four trundles and two longitudinal beams are installed on the rail car, the ballast collection and discharging device, the electric generator and the hydraulic system case are respectively arranged on the two longitudinal beams of the rail car, the rail car is dragged by an engineering truck, the electric generator provides power to an oil pump and a motor, and an oil tank, an oil pump and various hydraulic control valves are installed in the hydraulic system case. The multifunctional ballast collection and discharging device used among the sleepers is used to stack ballast among the sleepers, automatically separates sandy soil from the ballast and discharges the sandy soil, can rapidly backfill two sides of a sleeper which replaces a previous sleeper with the ballast in a stone collection box, is high in mechanization operation rate, and can fully and reasonably use limited line repair skylight operation time.

Owner:KUNMING UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com