Inter-sleep grab bucket stone remover

A technology of stone clearing machine and grab bucket, which is applied in the direction of track, road, ballast layer, etc., can solve the problems of time-consuming, laborious, low efficiency, etc., and achieve the effect of convenient operation, reliable performance, and high mechanized operation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

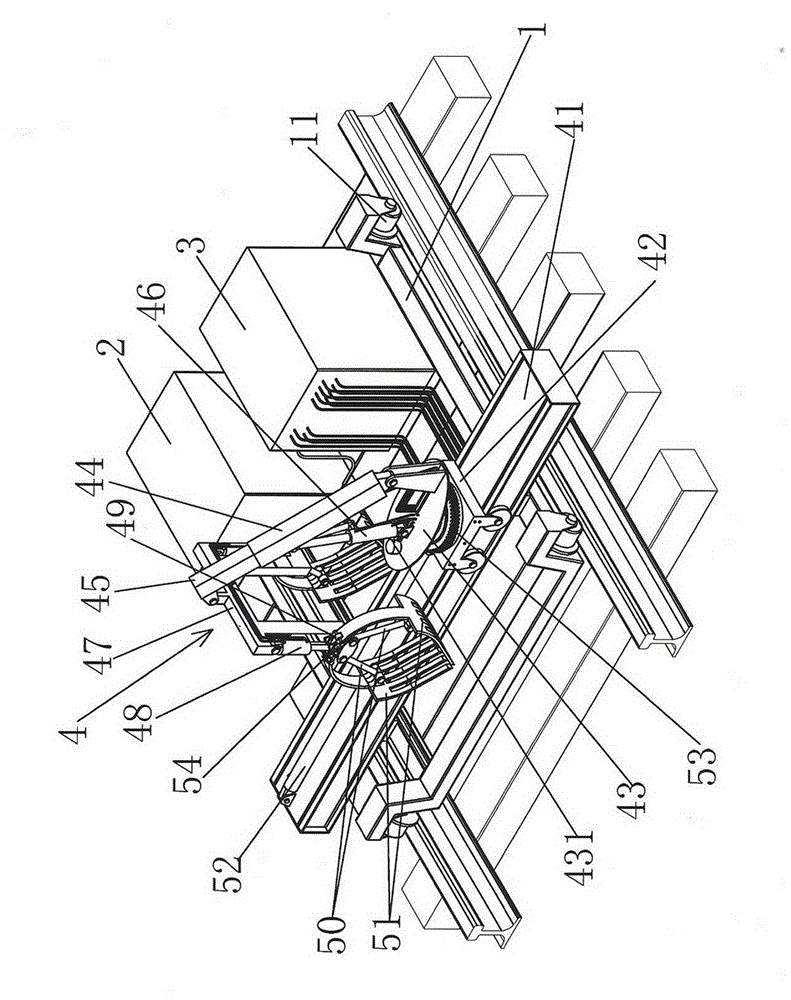

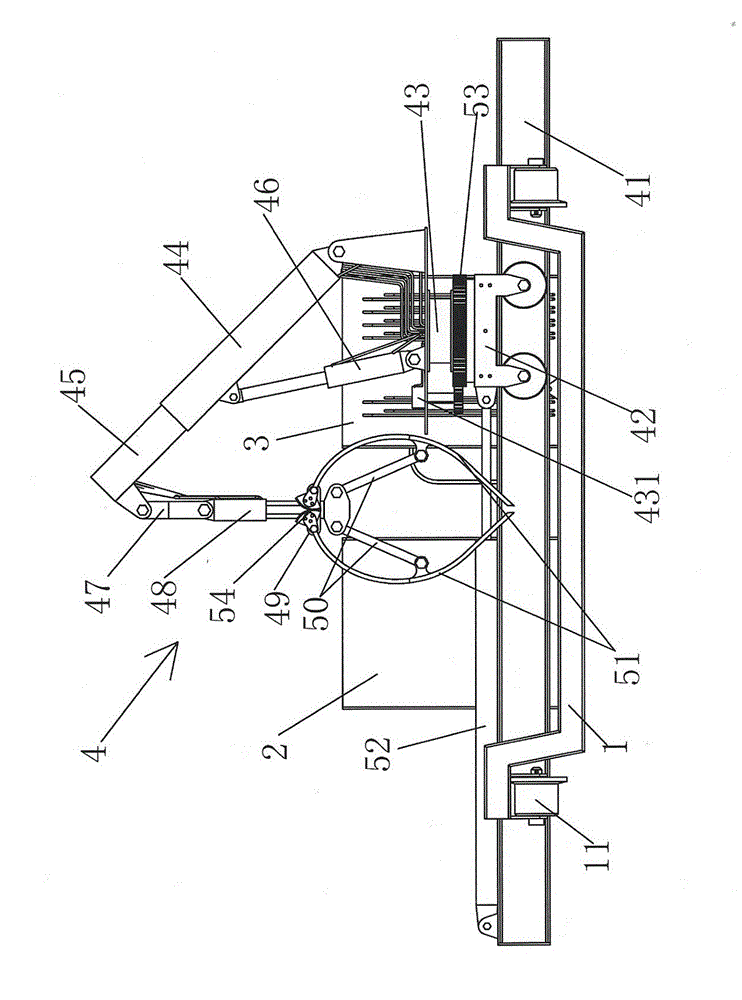

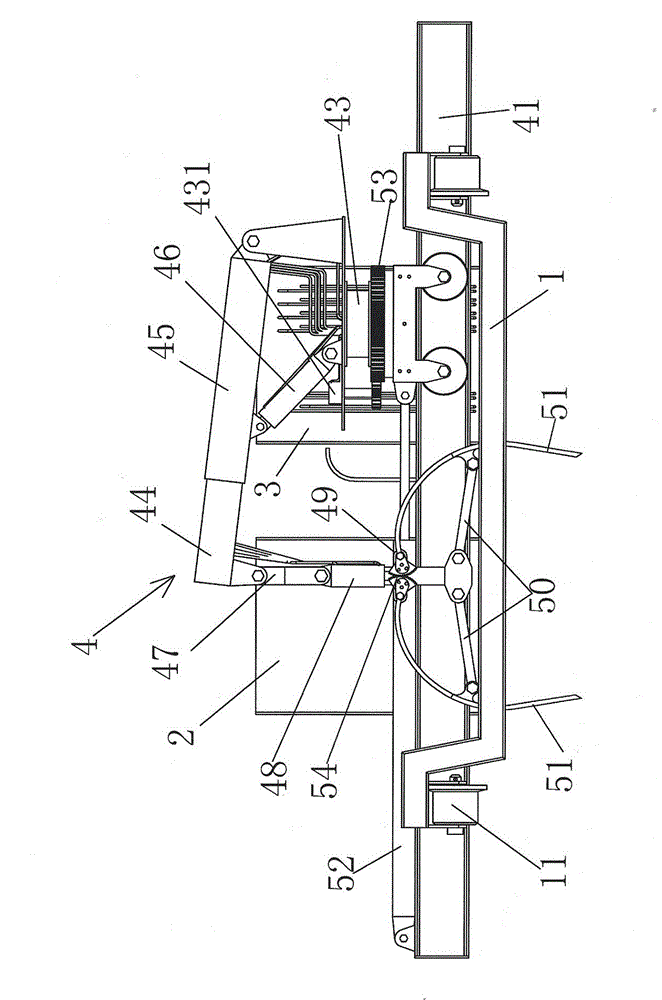

[0013] see figure 1 , figure 2 , image 3 and Figure 4 Shown, is the embodiment of the present invention, and this embodiment is made up of rail car 1, generator 2, operation control box 3 (fuel tank, oil pump and various control valves are housed), grab stone clearing device 4, rail car The four legs of 1 are equipped with casters 11, the rail car 1 can travel on the track with the help of manpower, the generator 2, the control operation box 3 and the grab stone cleaning device 4 are arranged on the rail car 1, the generator 2 provides power for the oil pump, The grab stone clearing device 4 is composed of a beam 41, a trolley 42, a rotary table 43, a lifting basic arm 44, a lifting telescopic arm 45, a lifting arm luffing cylinder 46, a portal steel frame 47, and a grab opening and closing cylinder. 48. The afterburner plate 49, the strut 50, the grab bucket 51, the oil cylinder 52 that drives the trolley to move, the slewing support bearing 53 and the sector gear set 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com