Recirculation unit for a fuel cell system

A fuel cell system and fuel cell technology, which is applied to fuel cells, fuel cell additives, circuits, etc., can solve the problems of loss, the loss of hydrogen gas is higher than the necessary loss, and achieve the effect of low-cost implementation and implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

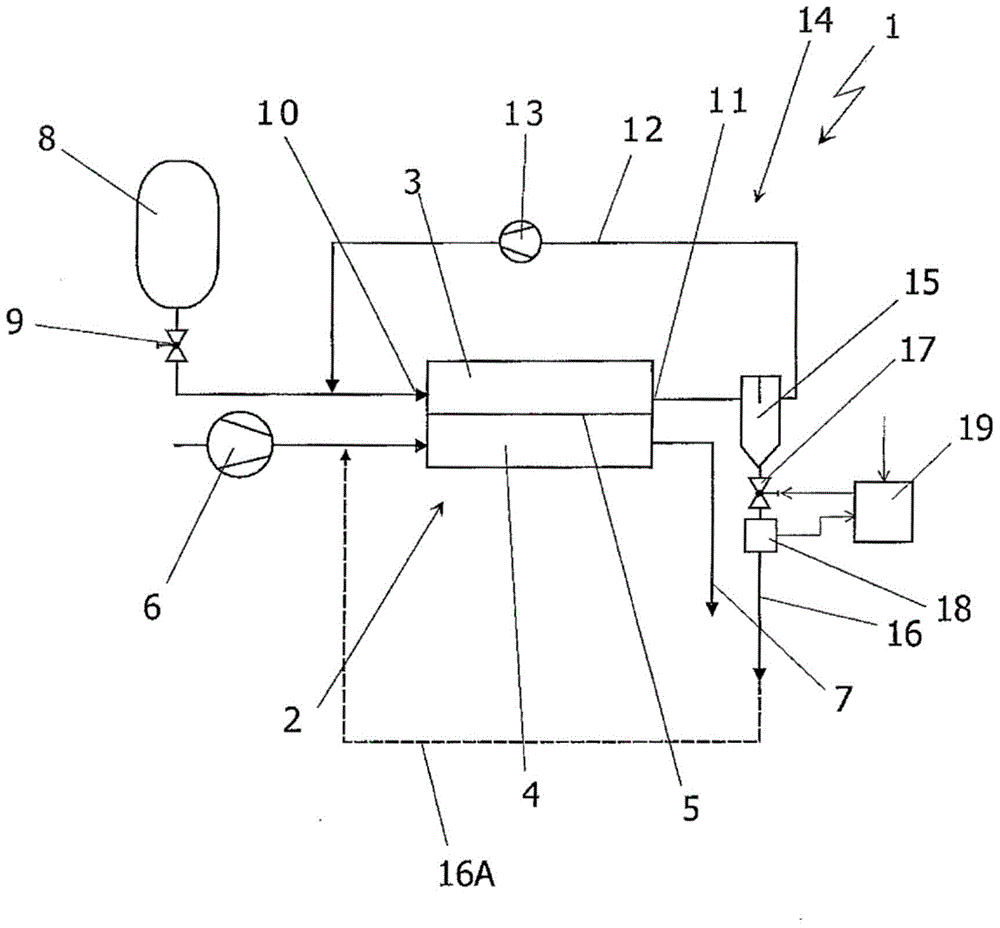

[0025]The diagrams in the figures illustrate the principle of the fuel cell system 1 . The core of the fuel cell system 1 is the fuel cell 2, which is designed as a stack of several individual fuel cells, a so-called fuel cell stack. The fuel cell 2 has an anode region 3 and a cathode region 4 which are separated by a proton-conducting membrane 5 . Thus, the fuel cell 2 is a PEM fuel cell. The filtered air is fed as an oxygen-containing medium to the cathode region 4 of the fuel cell 2 via the air feed device 6 . The used exhaust gas is discharged from the fuel cell system 1 through the exhaust gas duct 7 . The above-mentioned exhaust gases can, for example, be released into the environment, relieved of pressure (entspannt) by means of a turbine and / or supplied to combustion. But this is irrelevant for the invention.

[0026] The hydrogen in the compressed gas store 8 is fed to the anode region 3 of the fuel cell 2 via a valve and a pressure regulator 9 . The fresh hydrog...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com