Small integrated high-pressure pneumatic control valve

A high-pressure gas and small-scale technology, applied in the field of small integrated high-pressure air-controlled valves, can solve problems such as difficulty in adapting to large-vibration dynamic environments and complex structure of air-controlled stop valves, and achieve enhanced adaptability to large-vibration dynamic environments and shorten the axial direction. The effect of cantilever length and strong adaptability to mechanical environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The content of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

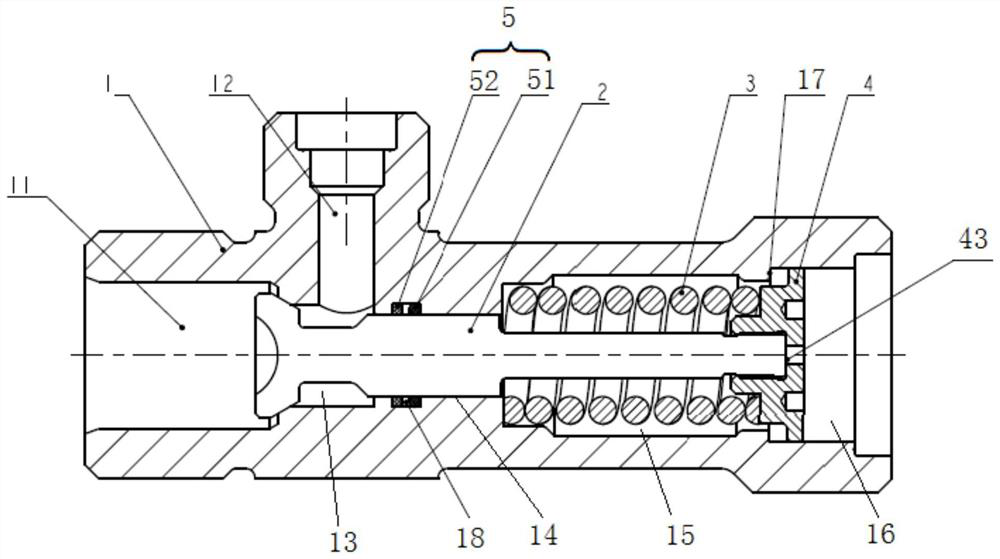

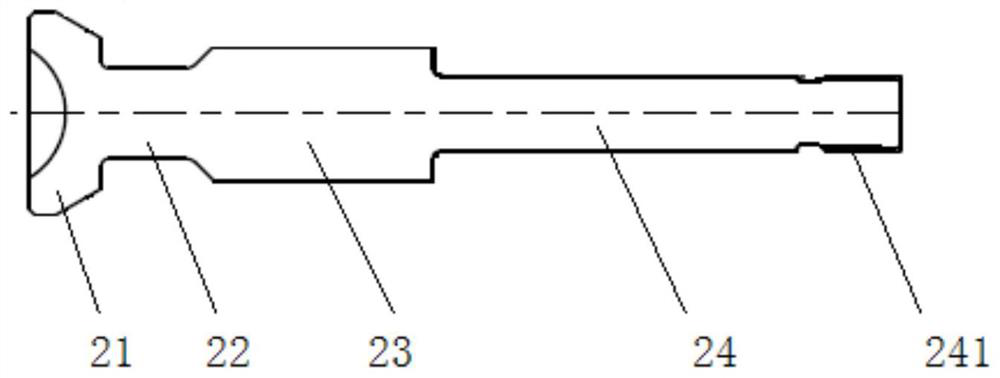

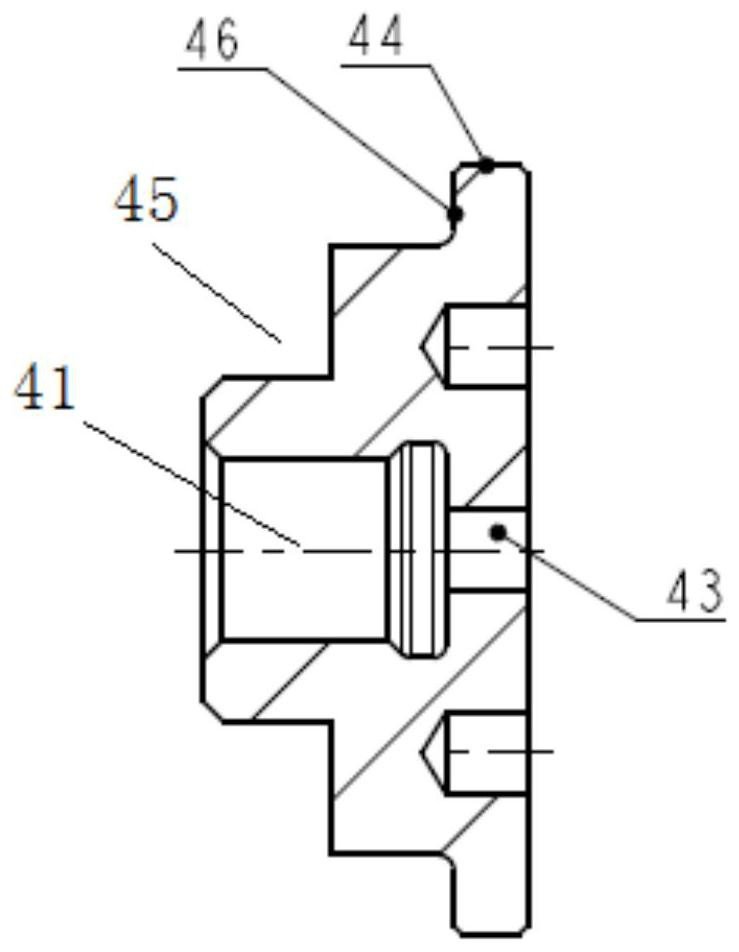

[0032] Such as figure 1 As shown, a small integrated high-pressure air control valve includes a housing 1, a valve core 2, a spring 3, a spring seat 4 and a sealing assembly 5. The present invention is a normally closed high-pressure air control stop valve. When ventilating, the valve core 2 It is opened by overcoming the resistance; after degassing, the valve core 2 returns under the force of the spring 3 and closes reliably.

[0033] The housing 1 is provided with an inlet flow channel 11, a medium channel 13, a mounting cavity 14, a spring cavity 15 and a control cavity 16 which are sequentially connected and coaxial from the left end face to the right end face; the connection between the inlet flow channel 11 and the medium channel 13 is the first A tapered surface, matched with the valve core 2, is used to block t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com