Leakage test method of polymerization kettle

A technology for polymerization kettle and leak testing, which is applied in the testing of fluid tightness, testing of machine/structural components, and detecting the appearance of fluid at the leakage point, etc., which can solve the problem of affecting equipment utilization, reducing production efficiency, and taking a long time for leakage and other issues to achieve the effects of saving costs, improving production efficiency, and reducing testing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

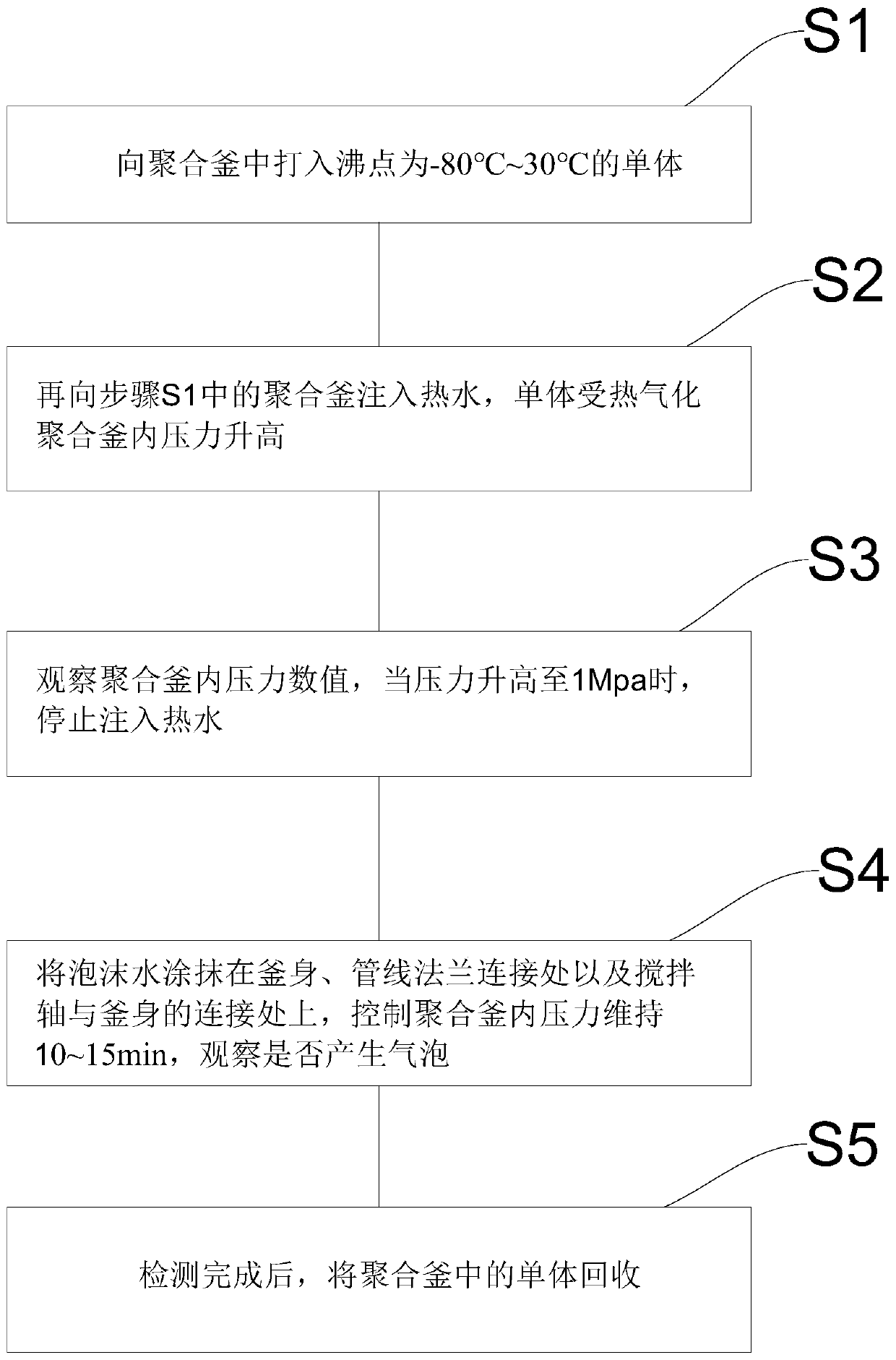

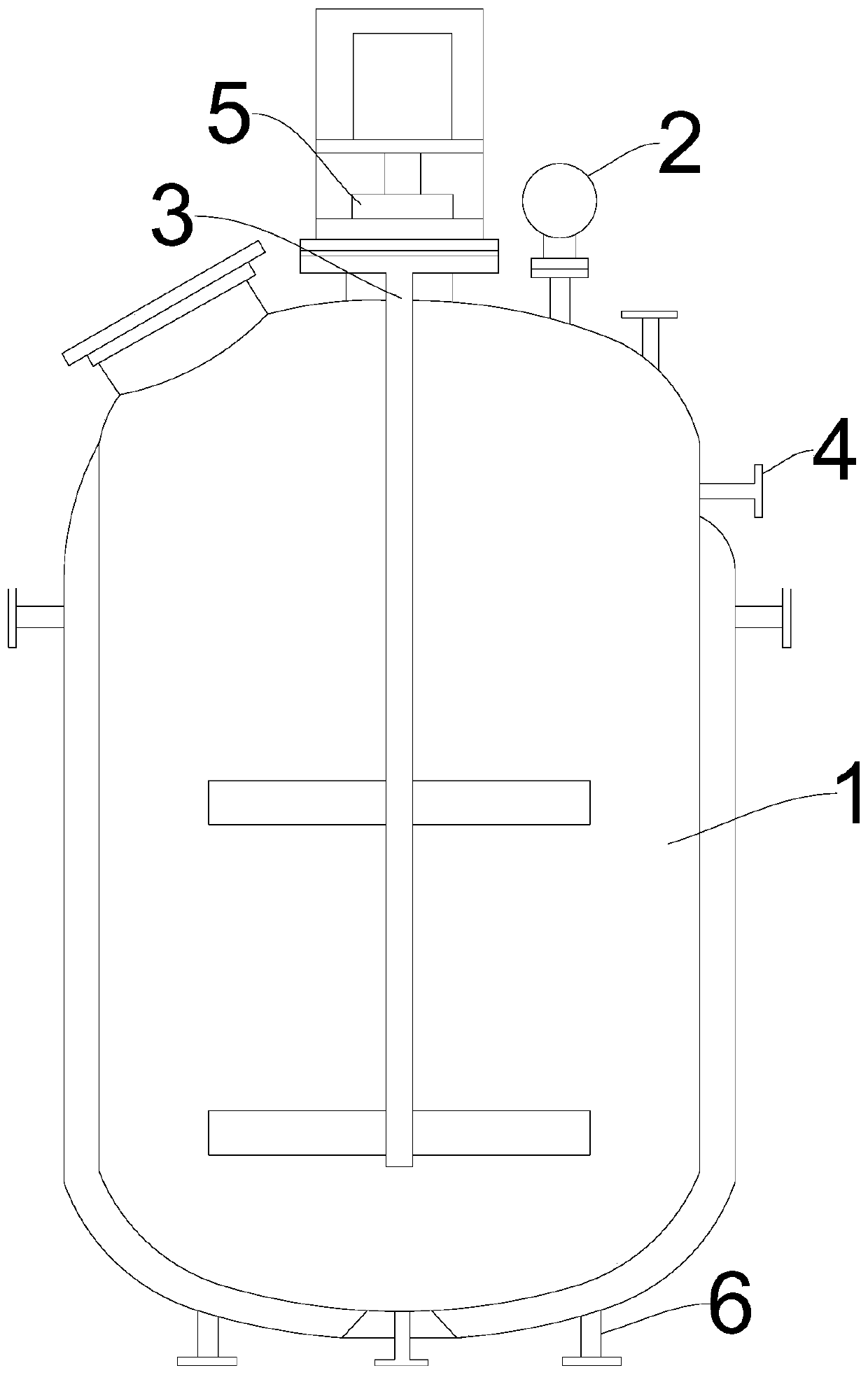

[0037] This embodiment provides a leak test method for a polymerization kettle, and the specification of this polymerization kettle is 60m 3 , for the production of polyvinyl chloride, comprising the following steps:

[0038] S1. After cleaning the inside of the polymerization kettle, first vacuumize the polymerization kettle to -0.05Mpa, and then inject 4m 3 Vinyl chloride monomer at -13°C; observe whether the pipeline flange on the outside of the polymerization kettle is sealed and connected. If there is leakage, recover the vinyl chloride monomer in the polymerization kettle and tighten the pipeline flange. Inject 2.5 tons of vinyl chloride monomers; if there is no leakage, directly continue to inject 2.5 tons of vinyl chloride monomers; the total quality of adding the monomers is 2.5 tons.

[0039] S2, in the polymerization kettle of step S1 again with 35m 3 Inject hot water at a rate of 80°C at a rate of / h. The hot water enters the polymerization kettle and transfers h...

Embodiment 2

[0045] This embodiment provides a leak test method for a polymerization kettle, and the specification of this polymerization kettle is 110m 3 , for the production of polyvinyl chloride, comprising the following steps:

[0046] S1. After cleaning the inside of the polymerization kettle, vacuumize the polymerization kettle to -0.05Mpa first, and then inject 5m 3 Vinyl chloride monomer at -13°C; observe whether the pipeline flange on the outside of the polymerization kettle is sealed and connected. If there is leakage, recover the vinyl chloride monomer in the polymerization kettle and tighten the pipeline flange. Inject 4 tons of vinyl chloride monomer; if there is no leakage, directly continue to inject 4 tons of vinyl chloride monomer;

[0047] S2, to the polymerization kettle in the step S1 again with 50m 3 Inject hot water at a rate of 85°C at a rate of / h. The hot water enters the polymerization kettle and transfers heat to the monomers. The monomers are heated and vapori...

Embodiment 3

[0053] This embodiment provides a leak test method for a polymerization kettle, and the specification of this polymerization kettle is 130m 3 , for producing polypropylene, comprising the following steps:

[0054] S1. After cleaning the inside of the polymerization kettle, vacuumize the polymerization kettle to -0.05Mpa first, and then inject 5m 3 Propylene monomer at -47°C; observe whether the pipeline flange on the outside of the polymerization kettle is sealed and connected. If leakage occurs, recover the propylene monomer in the polymerization kettle and tighten the pipeline flange. After tightening, re-insert 5 tons of propylene monomer; if there is no leakage, directly continue to inject 5 tons of propylene monomer;

[0055] S2, then to the polymerization kettle in the step S1 with 60m 3 The rate of / h injects hot water at a temperature of 75°C. The hot water enters the polymerization kettle and transfers heat to the propylene monomer, which is heated and vaporized, wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com