Reaction kettle type foaming device of thermally expandable microspheres and foaming method

A technology for expanding microspheres and a foaming device, applied in the field of microsphere foaming, can solve the problems of excessively long foaming time, difficult foaming degree of microspheres, unsuitable for preparing high temperature and ultra-high temperature, etc., so as to reduce shrinkage and foaming. sticky effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Such as figure 1 As shown, this example provides a reactor-type foaming device for thermally expandable microspheres, comprising a kettle-type foaming tank body 1, a kettle-type foaming tank cover 2 and a steam engine 6; The tank body 1 is sealed and detachably connected with the kettle-type foaming tank cover 2, and the kettle-type foaming tank cover 2 is communicated with the steam engine 6 through a pipeline; the kettle-type foaming tank body 1 is a sandwich structure, so The lid 2 of the still-type foaming tank is provided with a pressure gauge 4 and a temperature measuring device 5 for detecting the pressure and temperature in the tank body 1 of the still-type foaming tank. The temperature measuring device 5 is a thermometer and extends into the The tank body 1 of the still-type foaming tank; the pressure gauge 4 and the temperature measuring device 5 on the cover 2 of the still-type foaming tank can accurately monitor the pressure and temperature during the foamin...

Embodiment 2

[0035] This embodiment provides a foaming method for thermally expandable microspheres, using the reactor type foaming device described in Embodiment 1, comprising the following steps:

[0036] (1) Add heat-expandable microspheres to the kettle-type foaming tank body 1 through the water inlet 3, and close the valves on the water inlet 3, the outlet 7 and the exhaust port 8;

[0037] (2) Adjust the pressure of the steam generated by the steam engine 6 to 0.3-0.5 MPa, open the steam valve to feed the steam into the tank 1 of the kettle-type foaming tank, control the time of feeding the steam to 5-20s, and record the foaming at the same time Pressure and temperature detected by pressure gauge 4 and temperature measuring device 5 in the process;

[0038] (3) After the steam is fed in, fully open the valve of the exhaust port 8 to release the pressure, record the foaming situation at the same time, and quickly inject cooling water through the water inlet 3, and then collect it thro...

Embodiment 3

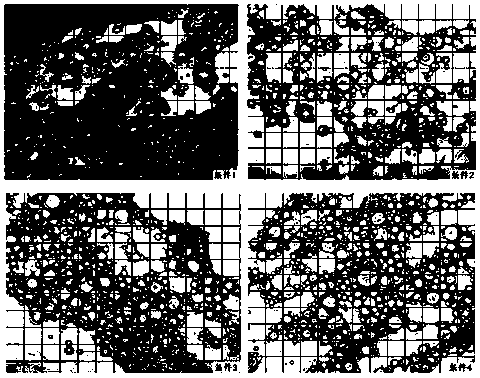

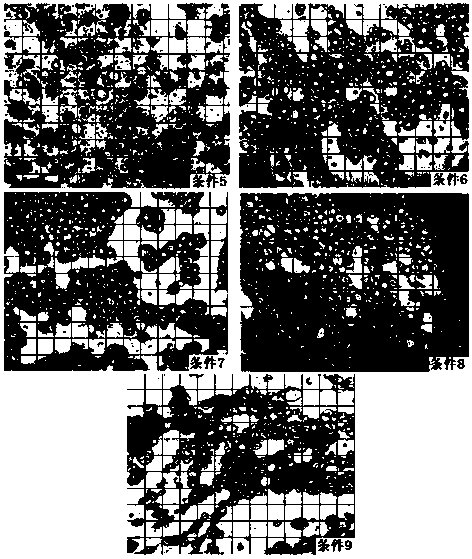

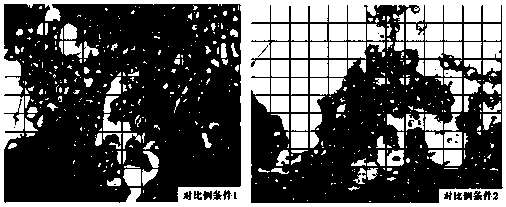

[0041]Using the foaming method in Example 2, the type 1 heat-expandable microspheres and the type 2 heat-expandable microspheres are foamed under different conditions, and the saturated steam pressure, temperature, whether to add cooling water and foaming are determined. The effect of time on the appearance, bonding and dust / gas conditions of thermally expandable microspheres, the effect on appearance is as follows Figure 2-3 As shown, the results of the influence on the bonding situation and the dust / gas situation are shown in Table 1.

[0042] Among them, type 1 and type 2 heat-expandable microspheres are provided by Cresire Technology (Shanghai) Co., Ltd., and their maximum foaming temperatures (Tmax) are 135°C and 148°C, respectively.

[0043] Table 1

[0044]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com