Energy-saving control system used for photovoltaic electric generator

An energy-saving control system and photovoltaic generator technology, applied in the field of die-casting machine equipment, can solve the problems of wasting electric energy, oil pump motor electric energy loss, etc., and achieve the effect of fast pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

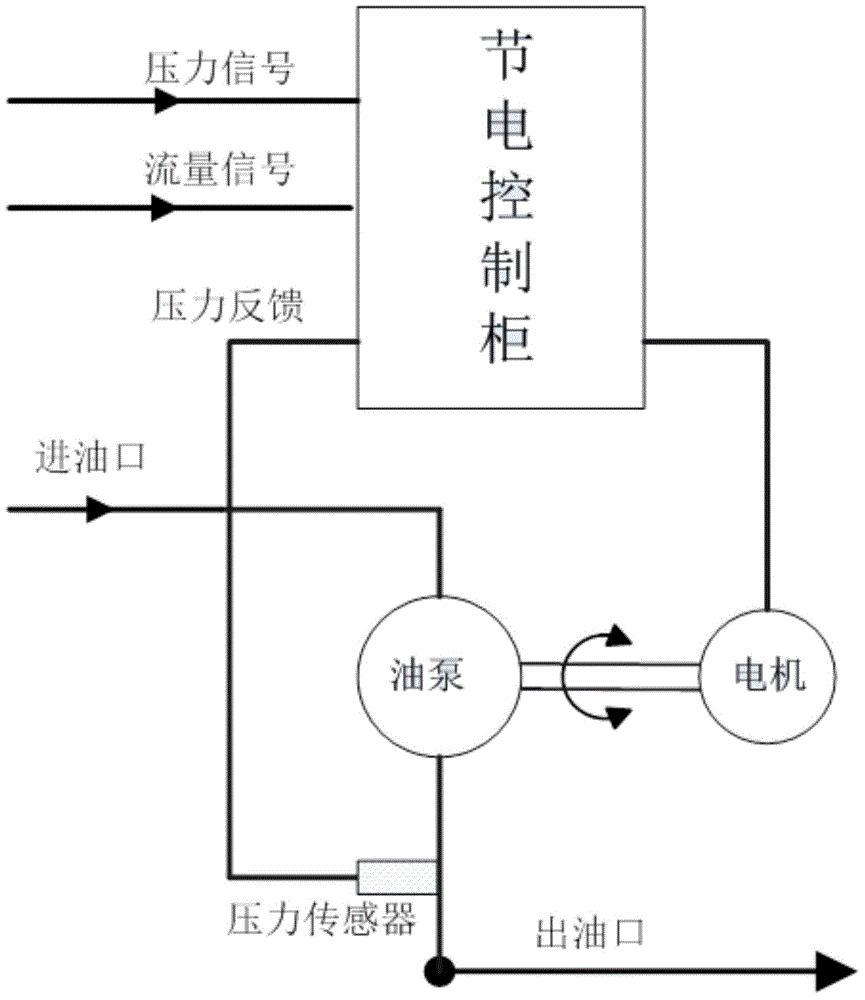

[0008] Such as figure 1 As shown, the energy-saving control system for photovoltaic generators of the present invention includes an energy-saving control cabinet capable of collecting the pressure and flow of the die-casting machine. The energy-saving control cabinet is connected to a motor, and the motor drives an oil pump. A pressure sensor, the pressure sensor is connected with the power-saving control cabinet.

[0009] The advantages of the energy-saving control system for photovoltaic generators of the present invention are as follows:

[0010] The energy-saving control system for photovoltaic generators of the present invention detects and feeds back the pressure and flow of the system at all times, changes the speed and torque of the synchronous motor through the energy-saving controller in time, makes corresponding adjustments to the pressure and flow, and finally maintains the system The pressure reaches the set pressure and flow quickly, accurately and steadily; the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com