Pneumatic pantograph lifting device for tram and pantograph lifting control method

A tram and pneumatic technology, applied in the field of rail vehicle braking system design, can solve the problems of insufficient pressure of the system air source system, reduce the reliability of the air source system, and sticking of the blowdown valve spool, so as to reduce the failure rate of the device and maintenance cost, the principle design is ingenious, and the effect of shortening the life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific preferred embodiments.

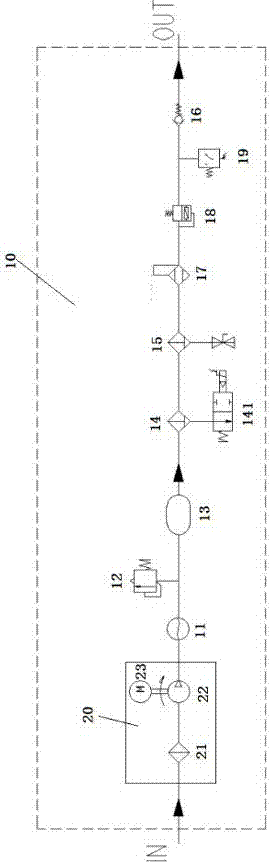

[0044] Such as figure 1 As shown, a pneumatic lifting device for a tram includes an air box 10 connected to a pantograph, and the air box is used to control the lifting of the pantograph.

[0045] The air circuit box includes energy box 20, air cooler 11, gas-water separator 14, sewage solenoid valve 141, particle filter 15, heater, check valve 16, AMT dryer 17, overflow valve 18 and pressure switch 19 .

[0046] The energy box includes an oil-free air compressor 22 , an air filter 21 and a brushless DC motor 23 .

[0047] The air filter is arranged at the inlet end of the oil-free air compressor.

[0048] The oil-free air compressor is preferably a 24V oil-free piston air compressor, single-cylinder single-stage compression, the speed is 1400r / min, and the rated pressure is 9bar.

[0049] A brushless DC motor powers the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com