Drying device for rice processing

A drying device, rice technology, applied in the direction of heating device, drying gas arrangement, grain drying, etc., to achieve the effect of facilitating recycling, improving drying efficiency, and preventing interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

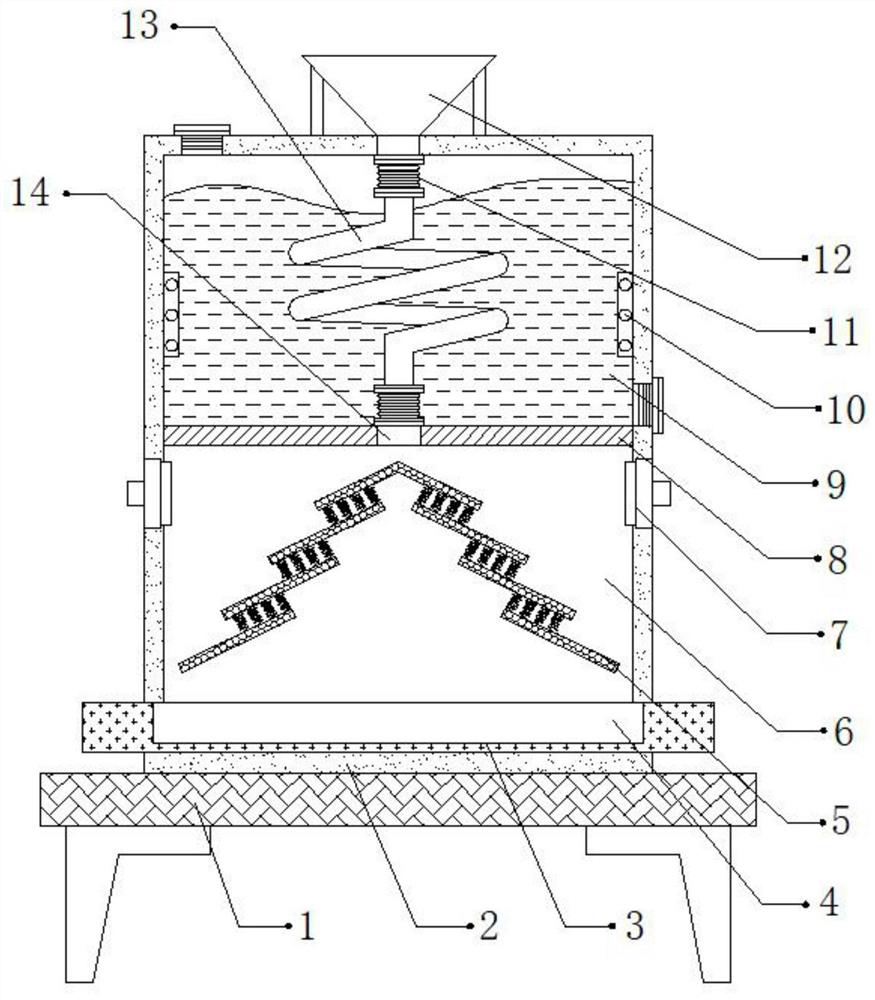

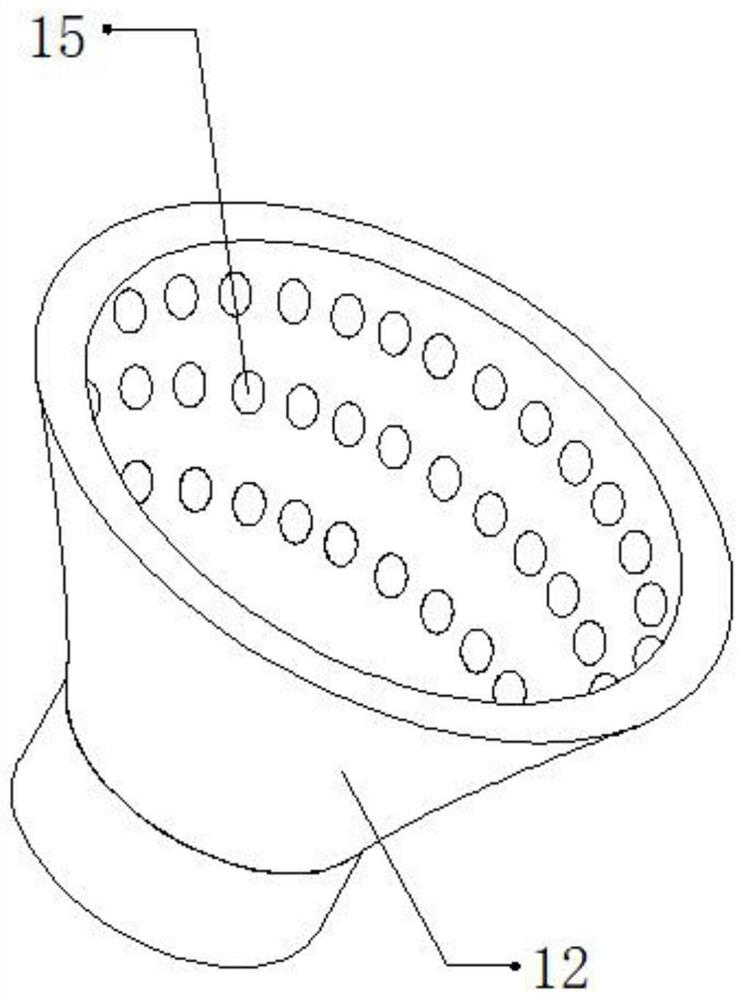

[0024] refer to Figure 1-2 , a drying device for rice processing, comprising a fixed seat 1, the top outer wall of the fixed seat 1 is connected with a box body 2 by bolts, and the box body 2 is composed of a drying chamber 6 and a heating chamber 9, and the drying chamber 6 and the heating chamber 9 There are partitions 8 connected by bolts, the top outer wall of the partition 8 is provided with a port 14, the top outer wall of the box body 2 is provided with a feed port, and the edge of the inner wall of the feed port and the edge of the inner wall of the port 14 There are bellows 11 connected by flanges, and a conduit 13 is connected between the two bellows 11 by flanges, and the shape of the conduit 13 is helical. The conduit 13 is made of heat-conducting material, and the inner walls on both sides of the heating chamber 9 are connected by bolts. There is a heater 10 , a feed hopper 12 is provided on the inner wall of the feed inlet, and a plurality of bumps 15 are provid...

Embodiment 2

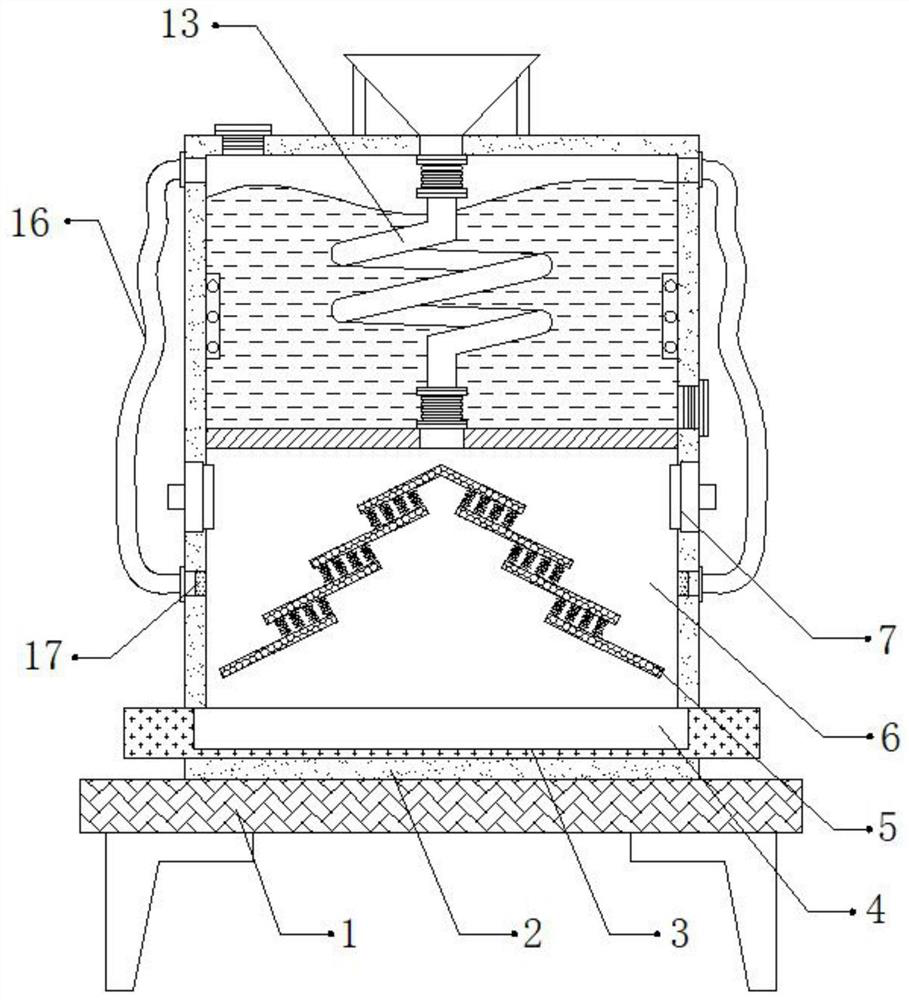

[0028] refer to image 3 , a drying device for rice processing. Compared with Embodiment 1, the inner walls on both sides of the heating chamber 9 and the inner walls on both sides of the drying chamber 6 are provided with air holes, and the upper and lower air holes are connected by flanges. There is a gas pipe 16, and the inside of the air hole is filled with a desiccant 17.

[0029] Working principle: when in use, fill the rice into the inside of the box body 2 through the feed hopper 12, and slow down the flow speed of the rice through the bump 15, and the rice will enter the inside of the conduit 13 through the bellows 11, during which time, through the water inlet to An appropriate amount of water is injected into the heating chamber 9, and the heater 10 is started to heat the water, and then the rice is pre-dried. After the rice is pre-dried, it will flow to the inside of the drying chamber 6. The rice is dispersed so as to improve the drying efficiency of the device t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com