Integrated control valve and oil tank using integrated control valve

A technology that integrates control valves and fuel tanks. It is applied in the direction of safety valves, balance valves, and valve devices. It can solve problems such as excessive emissions or fires, high fuel leakage risks, and cost increases. It achieves oil leakage prevention, compact structure, and prevent unintended effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to facilitate a better understanding of the present invention, the present invention will be further explained below in conjunction with the accompanying drawings of related embodiments. Embodiments of the invention are shown in the drawings, but the invention is not limited to the preferred embodiments described above. Rather, these embodiments are provided so that the disclosure of the invention will be thorough.

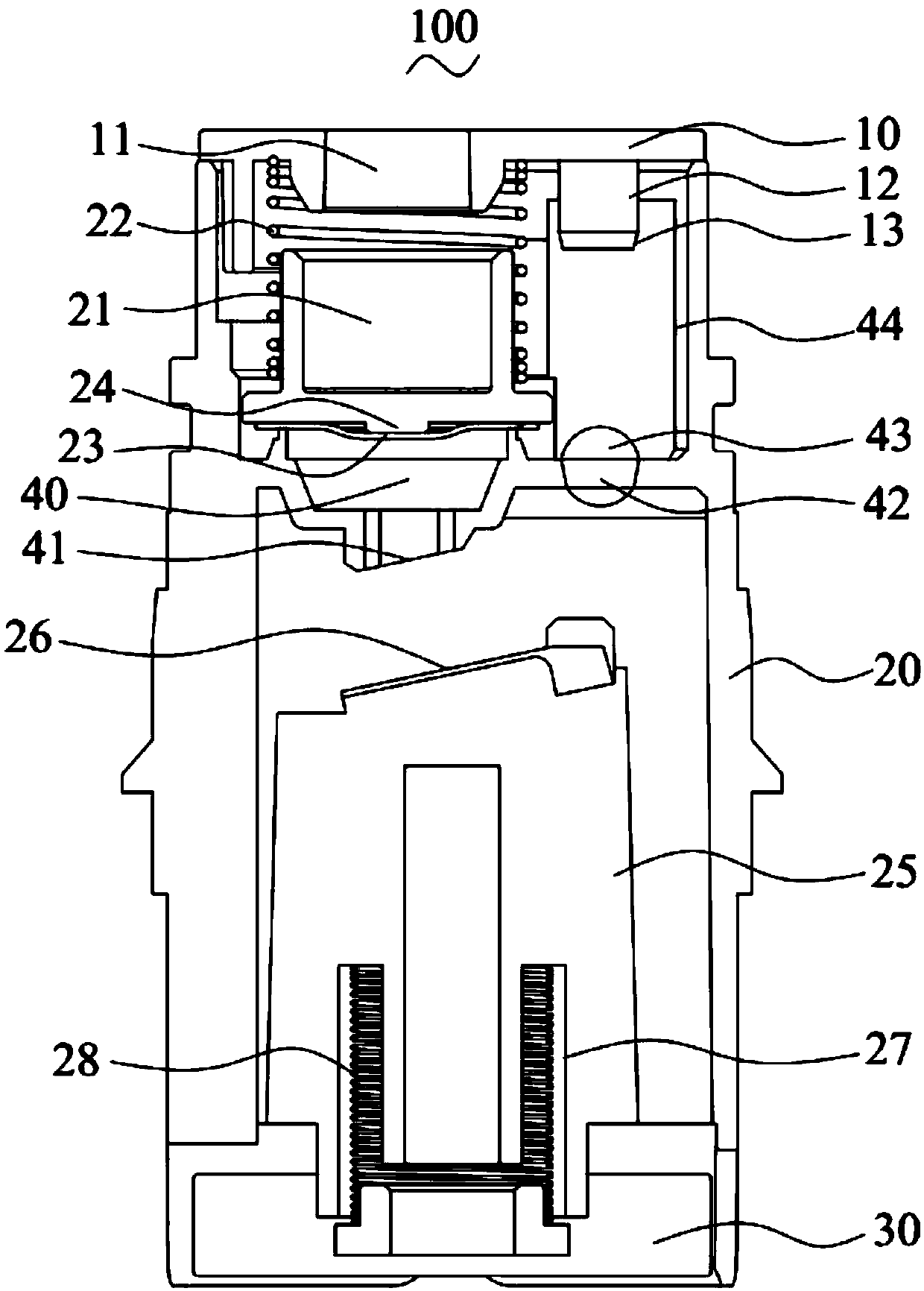

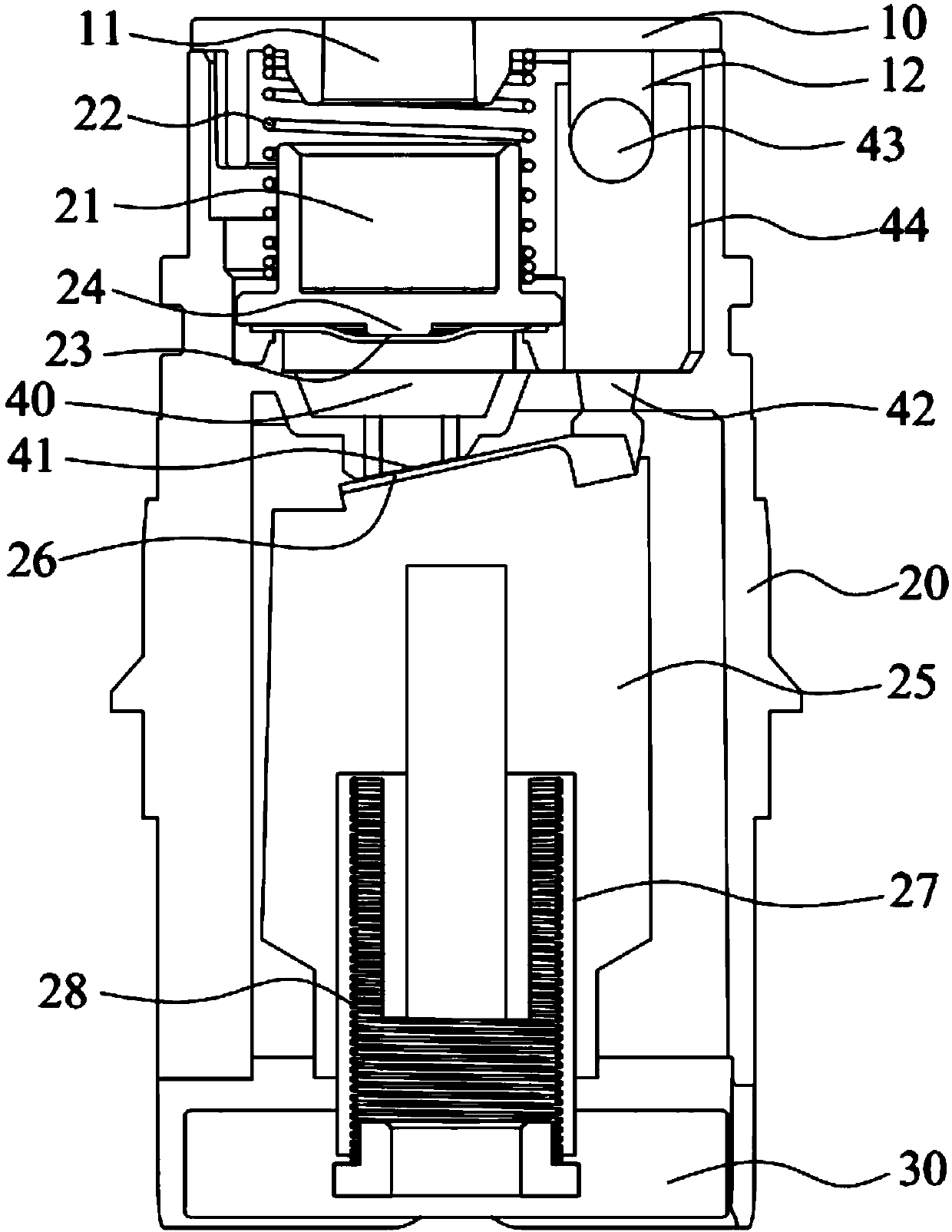

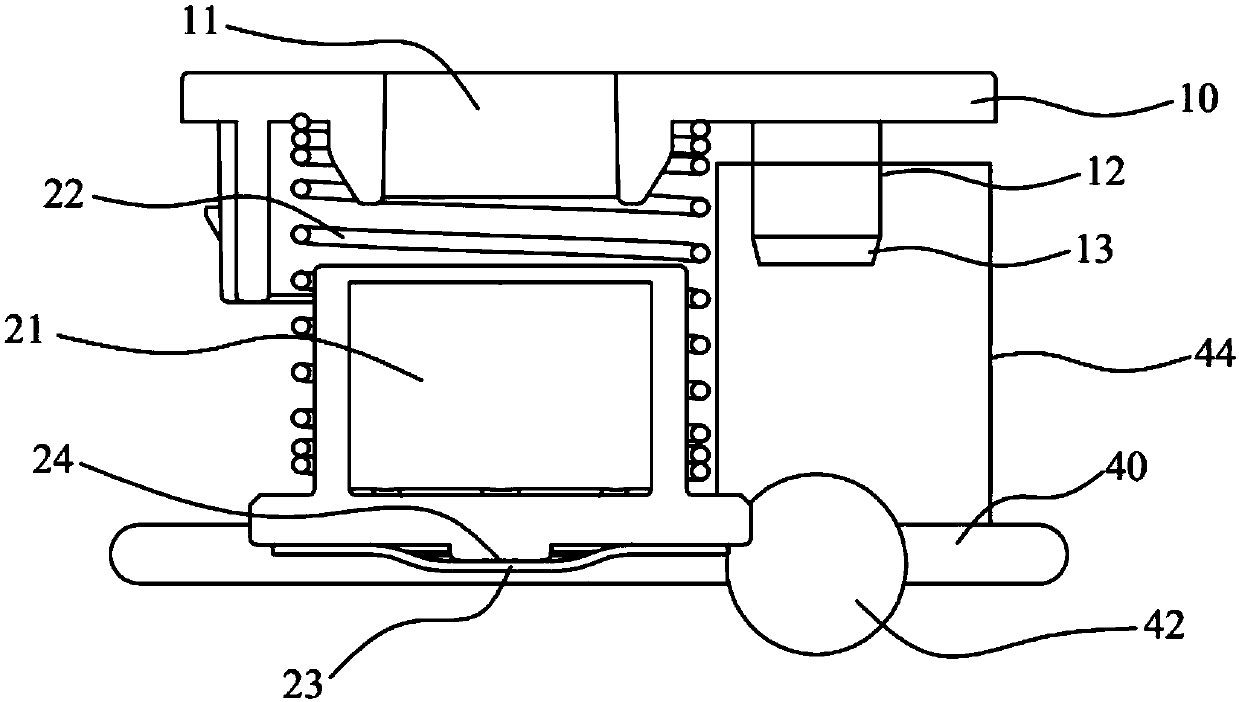

[0029] see Figure 1 to Figure 4 , the first embodiment of the present invention provides an integrated control valve 100, which is arranged on the oil outlet hole and the pressure discharge hole of the fuel tank, and includes an upper cover 10, a cover body 20 and a lower cover 30 connected in sequence, and the upper cover 10 A first vent hole 11 is provided inside, and a plurality of second vent holes are provided on the lower cover 30, and the first vent hole 11 and the second vent hole are used for two-way communication between the cover body ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com