Mechanical throttling governing valve with adjustable damping hole

A technology of throttling speed regulation and damping holes, which is applied in the direction of mechanical equipment, fluid pressure actuators, servo motor components, etc., can solve the problems of hydraulic component damage, stall, and the system cannot quickly build up pressure, etc., to achieve high control accuracy, The effect of accurate pressure control and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the purpose, content, and advantages of the present invention clearer, the specific embodiments of the present invention will be described in further detail below with reference to the accompanying drawings and embodiments.

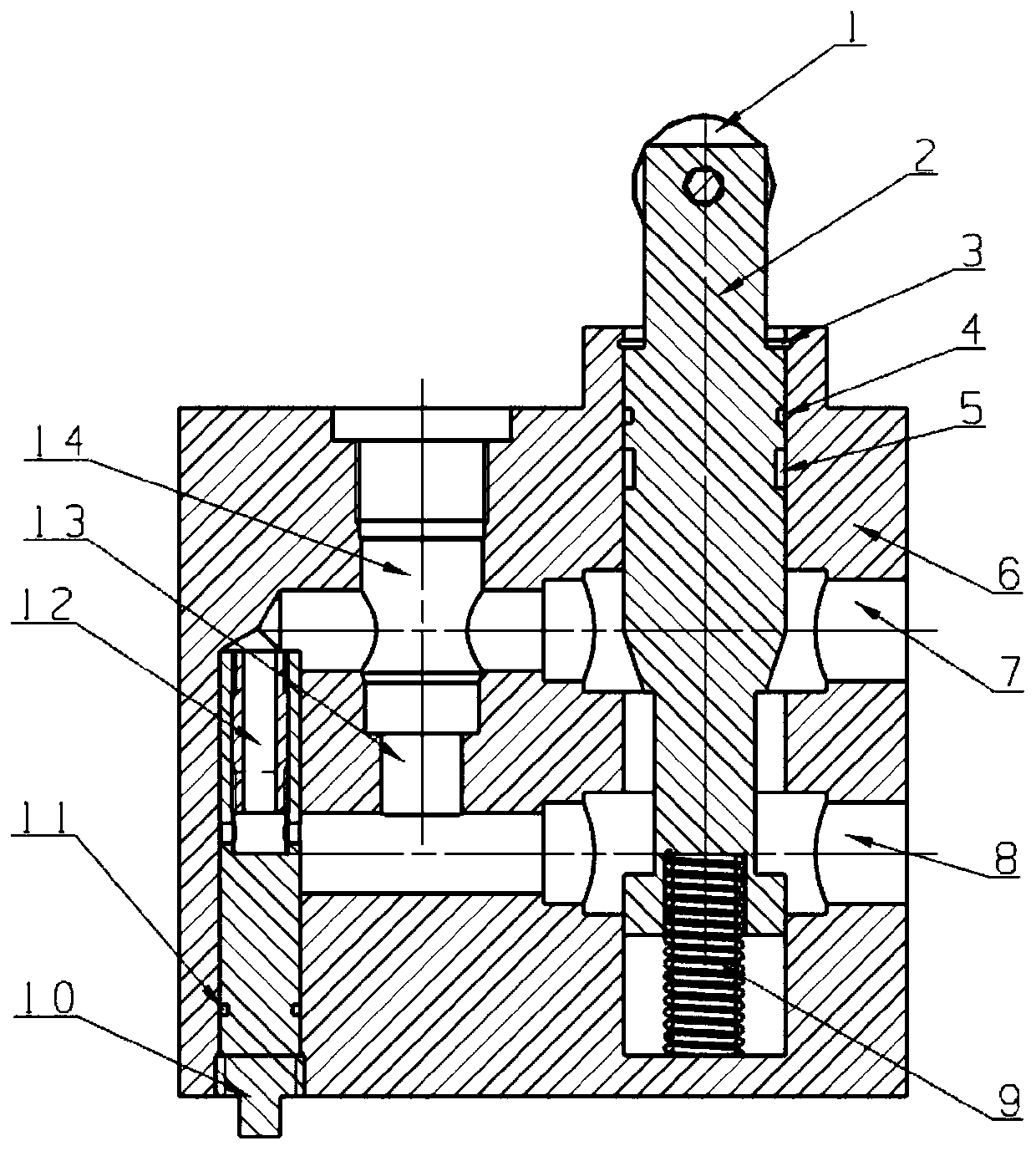

[0021] Such as figure 1 As shown, the present invention provides a mechanical throttle valve with adjustable damping holes, including: roller 1, valve core 2, elastic retaining ring 3, sealing ring 4, guide belt 5, valve body 6, return spring 9 , Nut 10, O-ring 11 and cartridge check valve; among them, the valve body 6 is provided with a plunger cavity required for the sliding of the valve core 2, and the valve body 6 is provided with a positive oil cavity 7 and an anti-oil cavity 8. The two are communicated through the flow area of the valve core 2. There are undercut grooves at the connection between the oil ports of the positive oil chamber 7 and the anti-oil chamber 8 and the plunger chamber in the valve body 6. The upper part o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com