Bearing components including diamond inner coating

A technology of diamond coating and bearing parts, which is applied in the direction of bearing components, bearings for rotating motion, rotating parts against centrifugal force, etc., to achieve the effect of increasing service life, long service life and reducing wear and tear.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

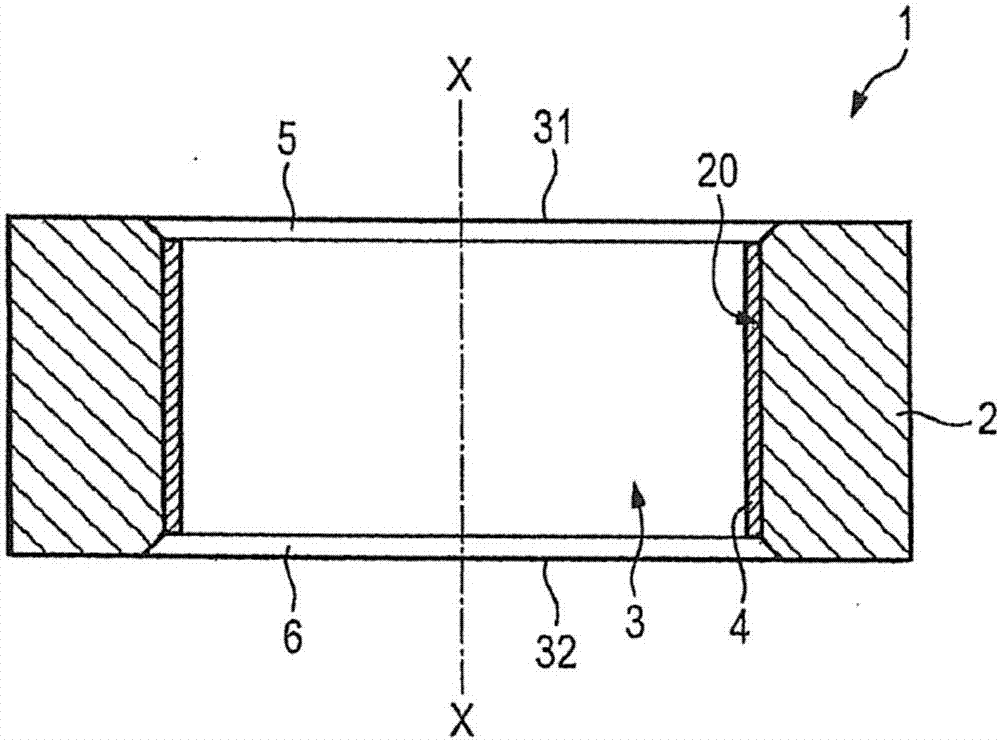

[0020] As can be seen from a cross-sectional view of a bearing component 1 according to the invention, the bearing component 1 comprises a base part 2 comprising an opening 3 . The opening 3 of the present embodiment is formed as a through opening.

[0021] The opening 3 is configured cylindrically and has a diamond coating 4 on the inner bearing surface 20 of the base body 2 . The diamond coating 4 is formed on the entire inner bearing surface 20 of the opening 3 .

[0022] The opening 3 forms an inner bearing surface and serves to accommodate, for example, a shaft mounted in the opening 3 in a manner to be rotatable in forward and reverse circumferential directions.

[0023] Furthermore, a first bevel 5 is formed on the first side 31 of the opening 3 , and a second bevel 6 is formed on the second side 32 of the opening 3 . The bearing member 1 of the present embodiment is formed as a radial sliding bearing.

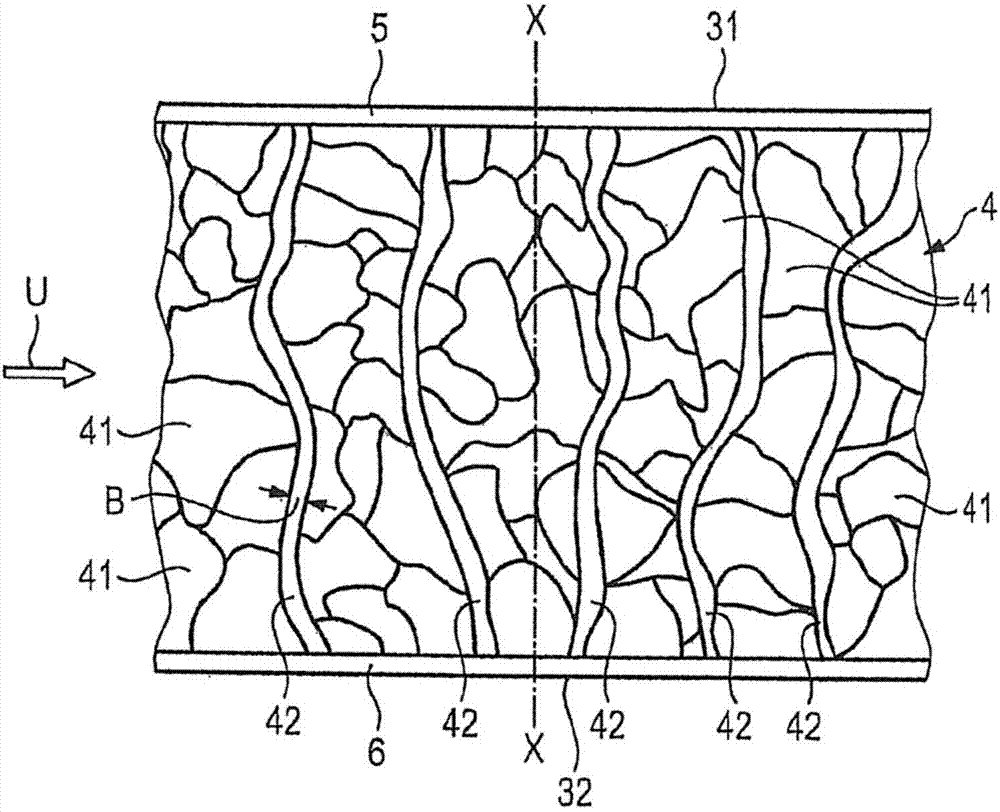

[0024] figure 2 is an enlarged detail view of the surface of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com