Vertical surface roughness measuring head and surface roughness instrument

A surface roughness and vertical technology, applied in the field of measuring equipment, can solve problems such as large system noise, and achieve the effects of high measurement accuracy, low price and fast measurement speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

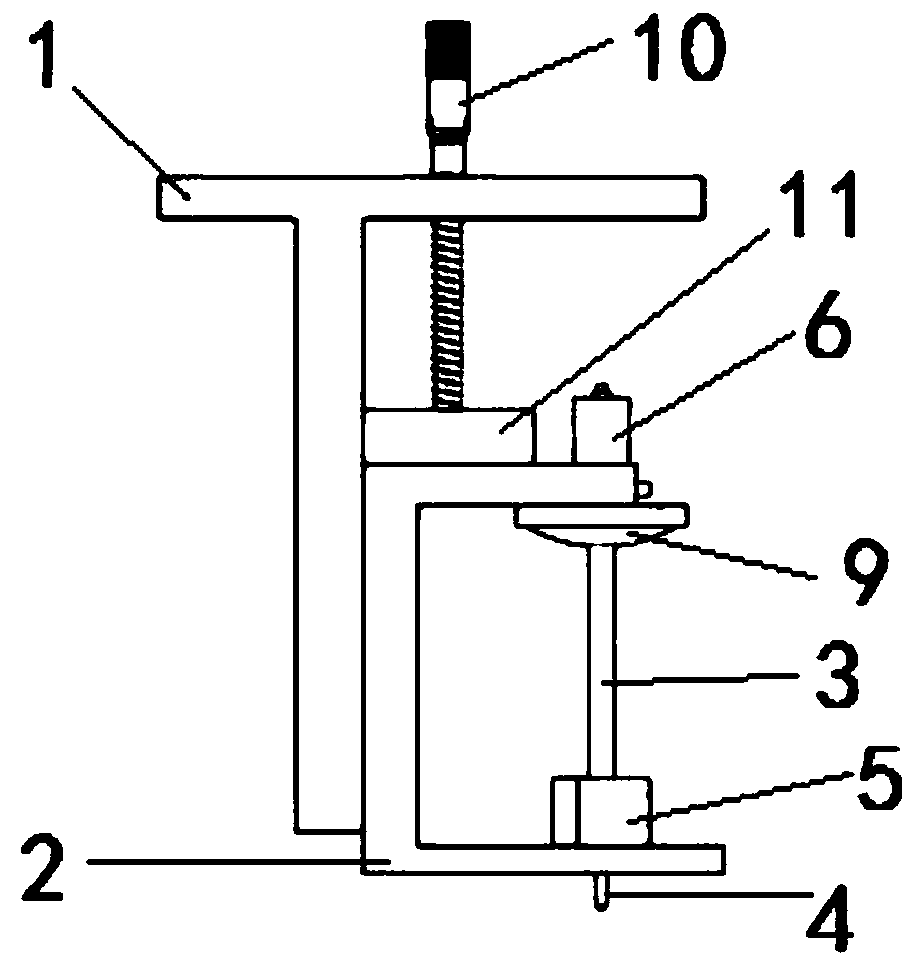

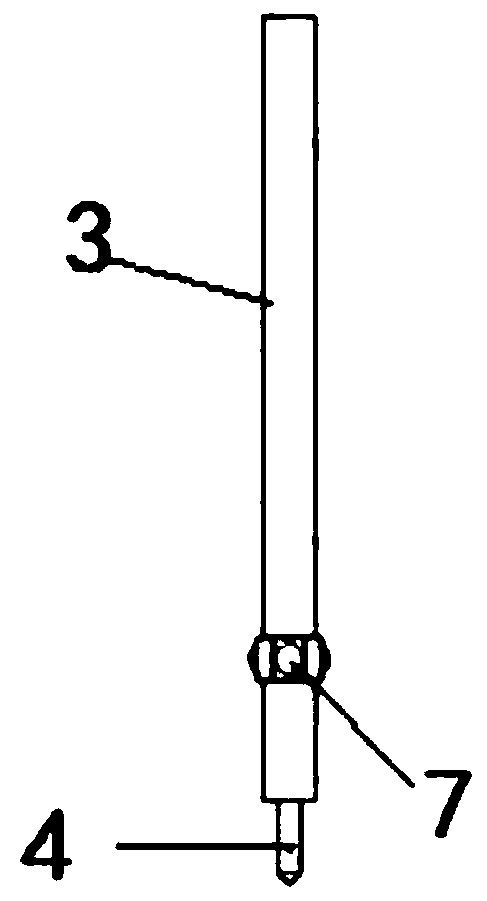

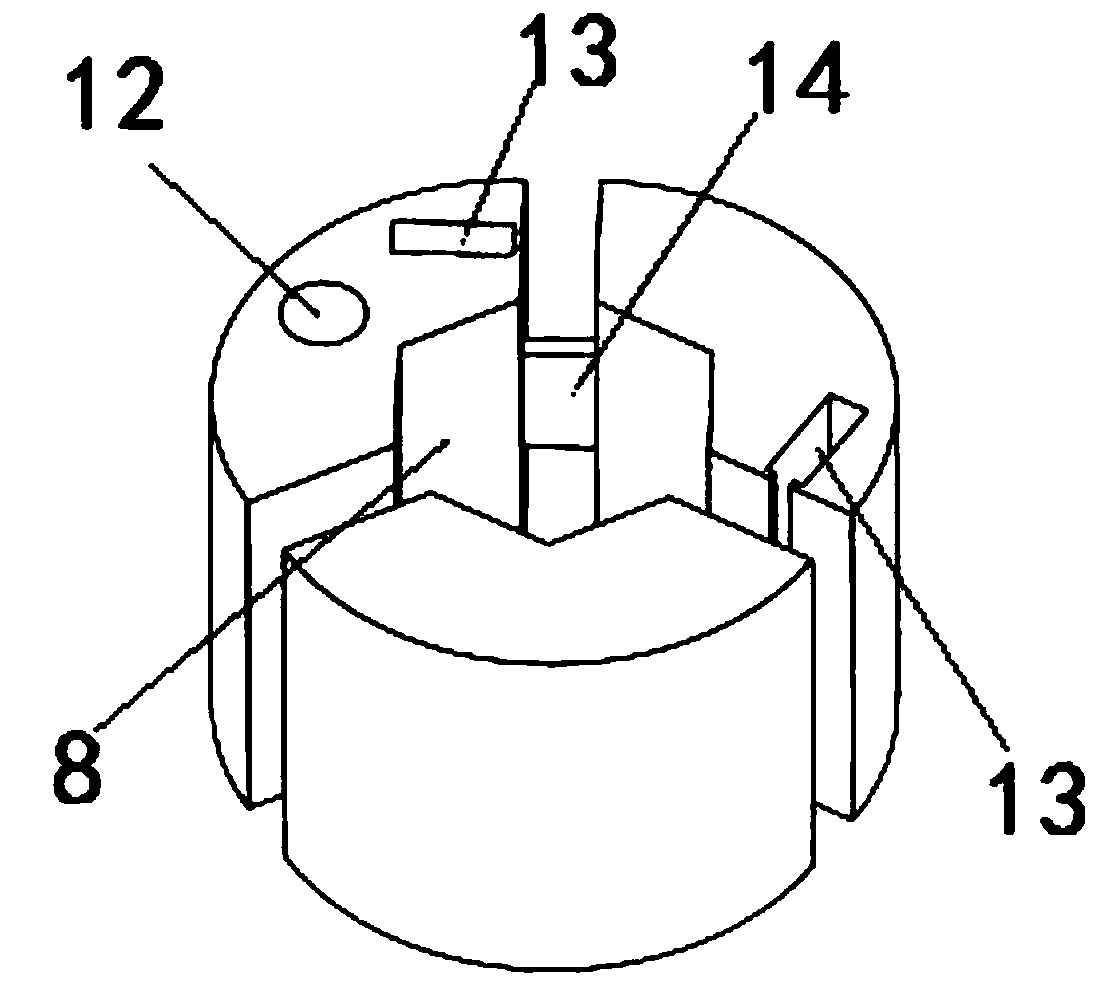

[0035] This embodiment provides a vertical surface roughness measuring head, such as Figure 1~3 As shown, in this embodiment, the vertical surface roughness measuring head includes a fixed frame 1, a mobile frame 2, a displacement measurement module, a needle bar 3, a stylus 4 and a guide device, and the mobile frame 2 is vertically slidably connected to the fixed frame 1, when measuring the surface roughness of the workpiece to be measured, the height of the moving frame 2 can be adjusted up and down according to the size of the workpiece to be measured, adjusted to the right position and the relative position of the moving frame 2 and the fixed frame 1 is fixed, and then the measurement is started, which is easy to operate , the mobile frame 2 includes a top plate, a vertical plate and a bottom plate, the two ends of the vertical plate are respectively fixedly connected with the top plate and the bottom plate, and the top of the needle bar 3 is elastically connected with the...

Embodiment 2

[0045] This embodiment provides a surface roughness meter. In this embodiment, the surface roughness meter includes a frame, a mobile device, and the vertical surface roughness measuring head of Embodiment 1. The fixed frame 1 is slidably connected with the frame, and the frame The body is fixed with a moving device, which can drive the fixed frame 1 to slide in the horizontal direction, and then drive the vertical surface roughness measuring head to move horizontally, and stop moving after moving to the set distance and return to the original position, which is easy to operate , High measurement accuracy.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com