Two-phase pressure-less container combustion water gas steam engine

A pressure vessel and steam engine technology, applied in the field of steam engines, can solve the problems of boilers that cannot be dry fired, low energy consumption, low thermal efficiency, etc., and achieves the effects of energy saving and fast temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

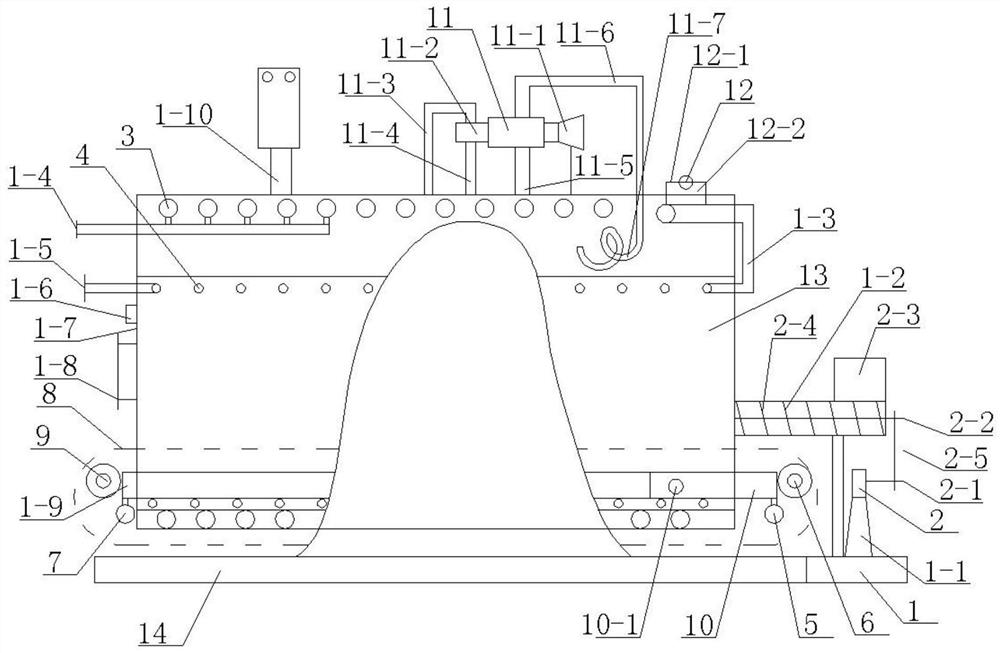

[0017] As a preferred embodiment of the present invention, a blower 2 7 is fixedly installed at the bottom of one end of the combustion bed 1-9, and the combustion bed 1-9 is connected to the coal gasification bed 10 .

[0018] As a preferred embodiment of the present invention, a driving wheel 9 and a driven wheel 6 are installed on the top of the base 1, and a chain row 8 is set on the driving wheel 9 and the driven wheel 6, and the top of the base 1 is installed Electric control box 14 is arranged.

[0019] As a preferred embodiment of the present invention, the coal gasification bed 10 is provided with a steam inlet 10-1.

[0020] As a preferred embodiment of the present invention, a screw 2-4 is installed on the sprocket screw 2-2.

[0021] This two-phase non-pressure container water gas steam engine solves the problems that the steam pressure and temperature cannot be controlled and adjusted for a long time, the boiler cannot be dry-fired, the boiler pressure cannot be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com