Method for draining oil and salting fried peanuts

A technology for draining oil and peanuts, which is applied to the field of oil-draining and salt-spraying fried peanuts, can solve the problems of unhealthy consumers, affect the taste of peanuts, and cannot drain the oil, so as to prevent the seasoning from sinking, speed up the rotation, and improve the spraying. the effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

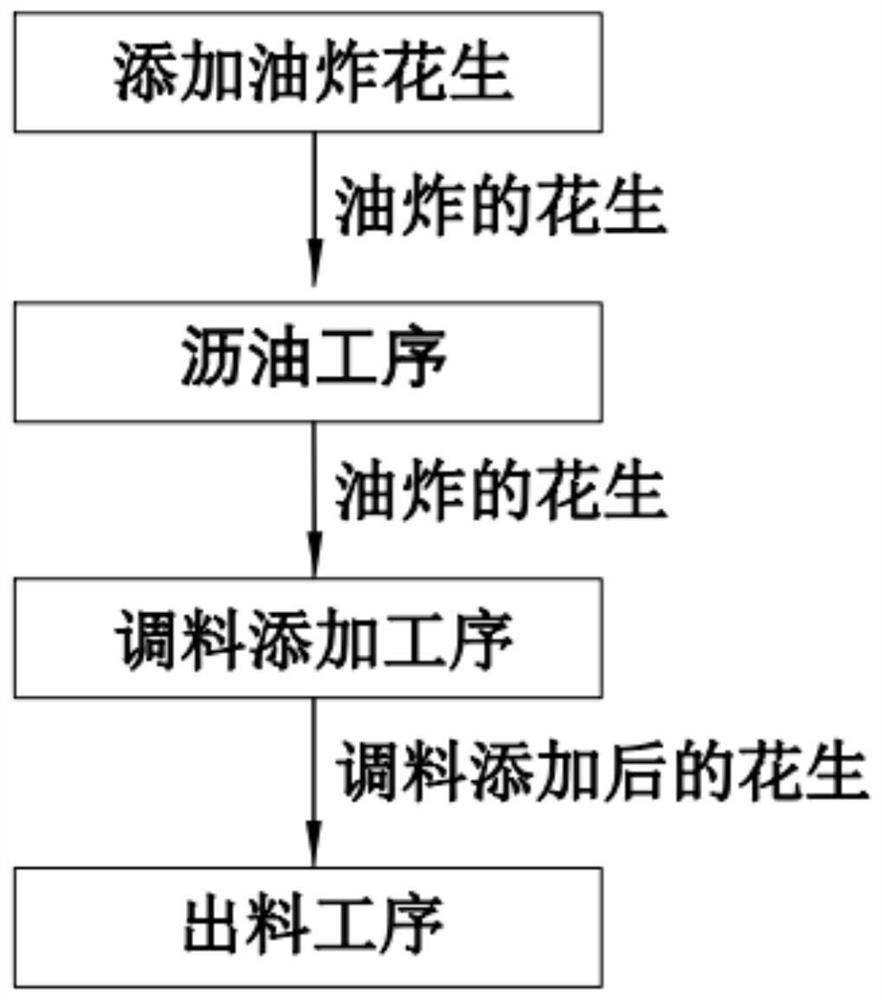

[0060] A method for frying peanuts, draining oil and sprinkling salt, comprising the following steps:

[0061] Step 1, add fried peanuts process, the fried peanuts are added to the feeding space 100 through the feeding port 23 and fall onto the fan-shaped feeding tray 3;

[0062] Step 2, the oil draining process, utilize the transmission shaft 73 in the drive unit 7 to drive the fan-shaped material tray 3 to rotate, and utilize the joint action of the annular track groove 41 and the guide link assembly 5 offered on the annular guide frame 4 to make the fan-shaped material tray 3 While rotating, it swings up and down to realize the shaking of peanuts up and down to complete oil draining;

[0063] Step 3, seasoning addition process, when fan-shaped material tray 3 rotates to seasoning spraying space 200, utilize the piston assembly 63 that is arranged in the seasoning box 62 in the seasoning spraying unit 6 and cooperate stirring unit 64 to realize the spraying of intermittent s...

Embodiment 2

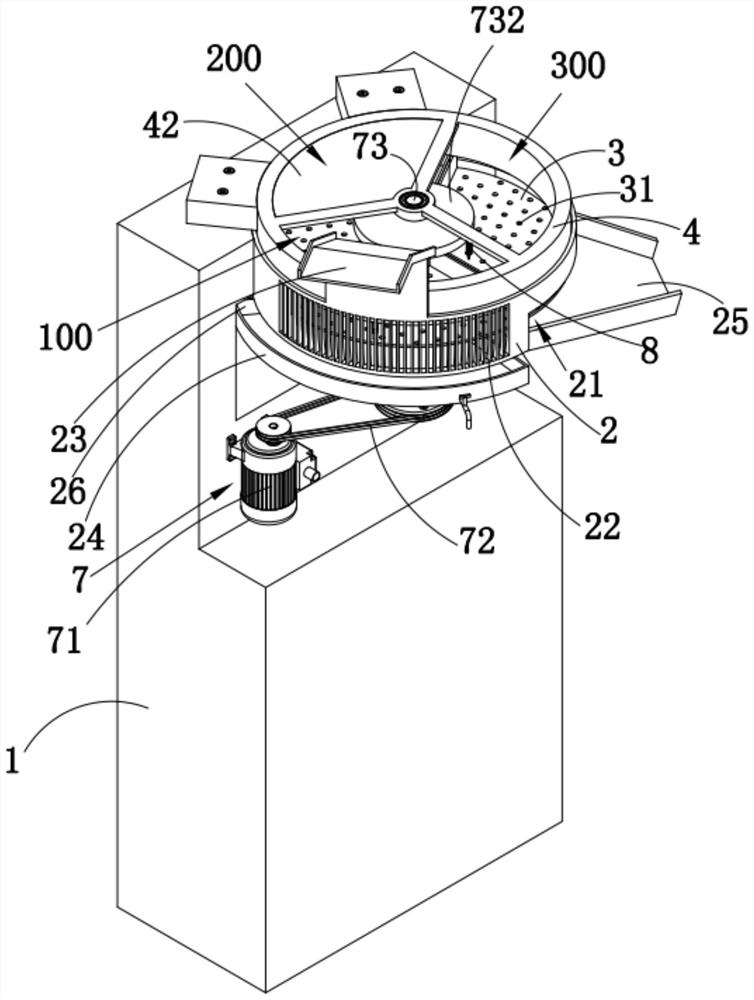

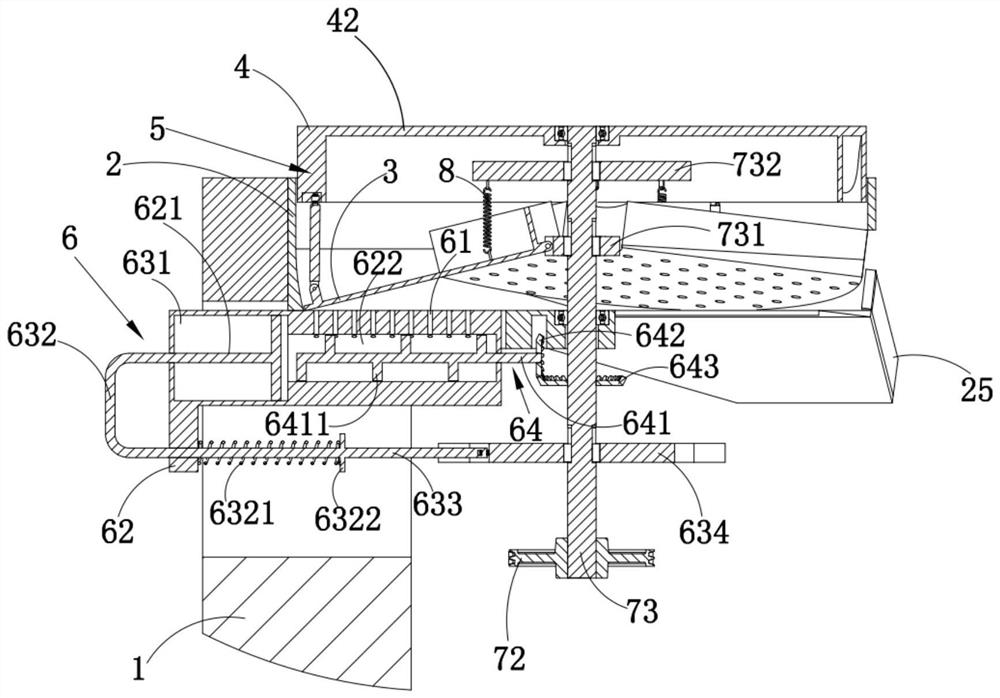

[0074] Such as Figure 2-9 As shown, a method for frying peanuts, draining oil and sprinkling salt, includes a rack 1, and also includes:

[0075] An annular support 2, which is installed on one side of the frame 1, and the side is provided with a discharge port 21;

[0076] Fan-shaped material tray 3, said fan-shaped material tray 3 is provided with three and evenly distributed ring is arranged in the inside of annular support 2, forms three mutually independent spaces between these three fan-shaped material trays 3 and the side wall of annular support 2, The three mutually independent spaces along the direction of rotation of the fan-shaped tray 3 are the feeding space 100, the seasoning spraying space 200, and the discharge space 300; A number of drain holes 31 are evenly opened on the tray 3;

[0077] Ring-shaped guide frame 4, the ring-shaped guide frame 4 is arranged on the top of the ring-shaped support 2, and its lower end surface is provided with an annular track gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com