Cooking and extruding technology in instant rice noodle production

A technology of ripening and rice noodles, which is applied in the production process of instant rice noodles, can solve the problems of insufficient ripening and high power consumption of frictional ripening, and achieve the effects of stable time and space, light load and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

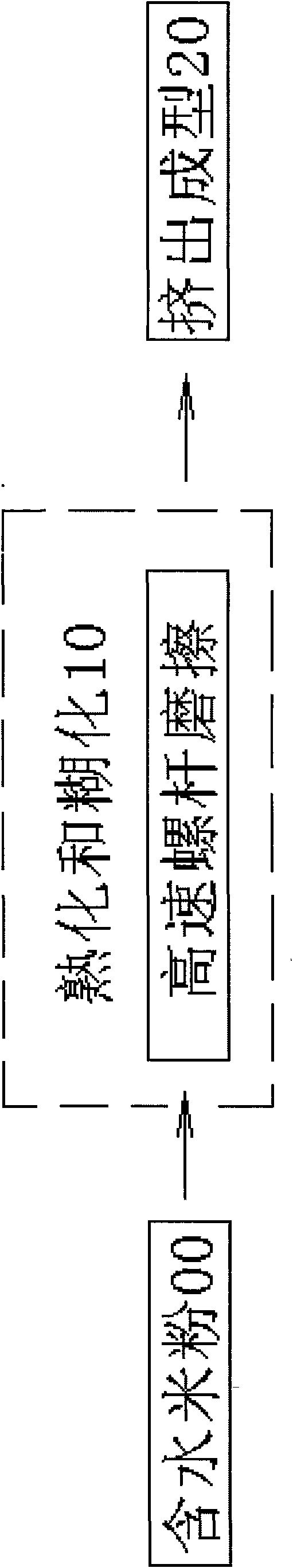

Method used

Image

Examples

Embodiment Construction

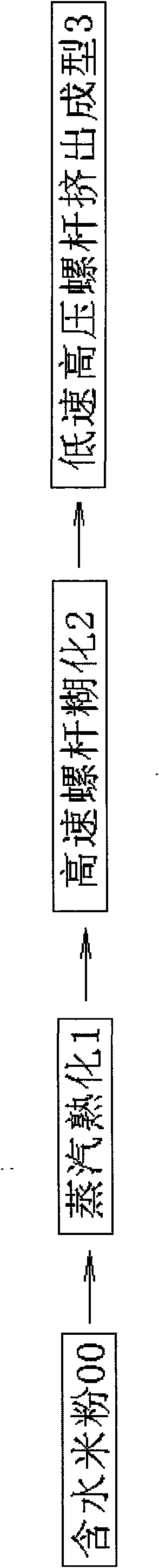

[0014] Such as figure 2 As shown, a ripening and extruding process of instant rice noodles includes steam ripening 1, high-speed screw gelatinization 2, low-speed and high-pressure creep rod extrusion molding 3, and is characterized in that: steam ripening 1, high-speed screw gelatinization 2, low-speed The high-pressure screw extrusion molding 3 is completely separated and independent. Each exerts the best quality.

[0015] Specifically, the whole technological process is as follows: figure 2 As shown, first obtain rice flour (powder) (00) in water with water content, such as: 70% stem rice flour, 25% cornstarch, 5% potato starch, and a total water content of 30%, and evenly feed it into a steam aging strip forming machine Steam heating 1, rush into high temperature steam to make it mature (steam pressure range: 3 ~ 5kgf / cm 2 ;Temperature range: 120~160℃);

[0016] The cured rice noodles are evenly extruded into strips and output, and then enter the high-speed screw mach...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com