Electromagnetic heating high vacuum oil diffusion pump

A technology of oil diffusion pump and electromagnetic heater, which is applied in the direction of diffusion pumps, pumps, non-volume pumps, etc., can solve the problems of inability to produce high-vacuum oil diffusion pumps, limited production, processing and manufacturing, and low ultimate vacuum, so as to provide The effect of contact area and water flow, avoiding secondary evaporation, and short heating time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

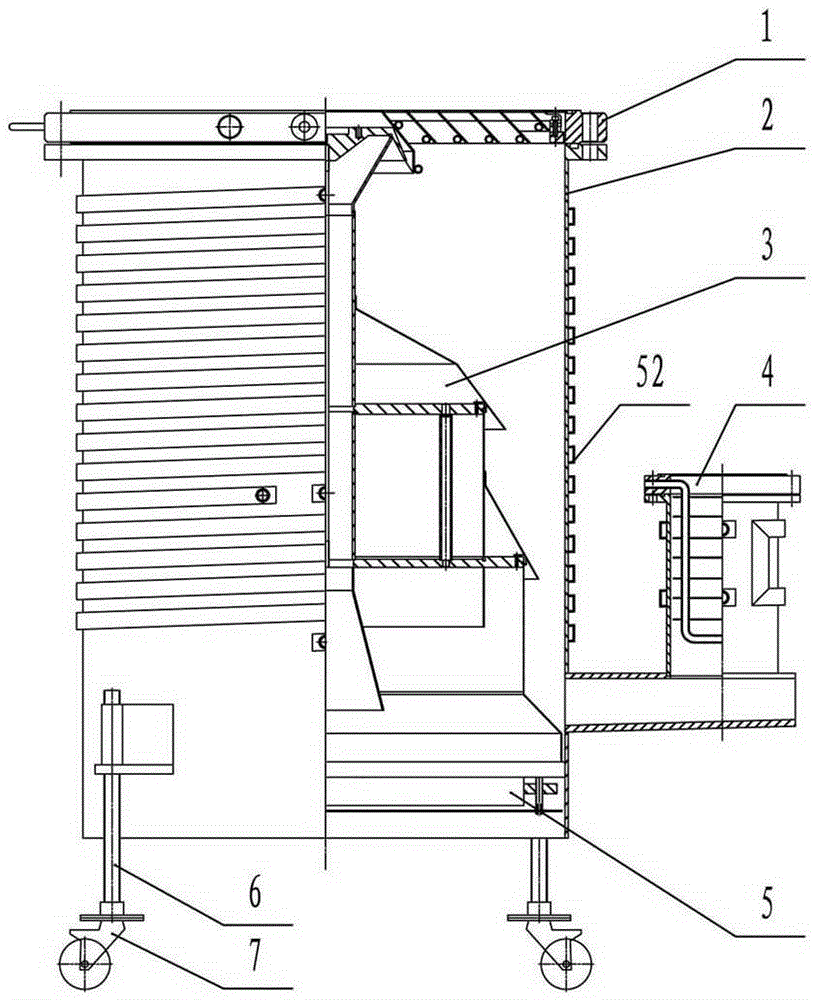

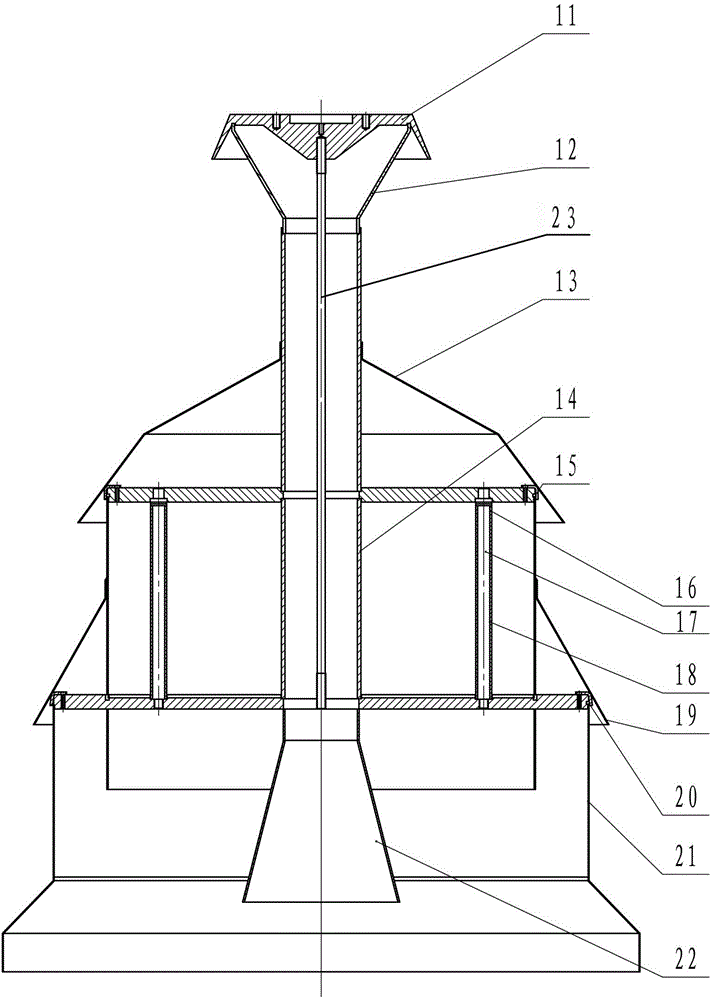

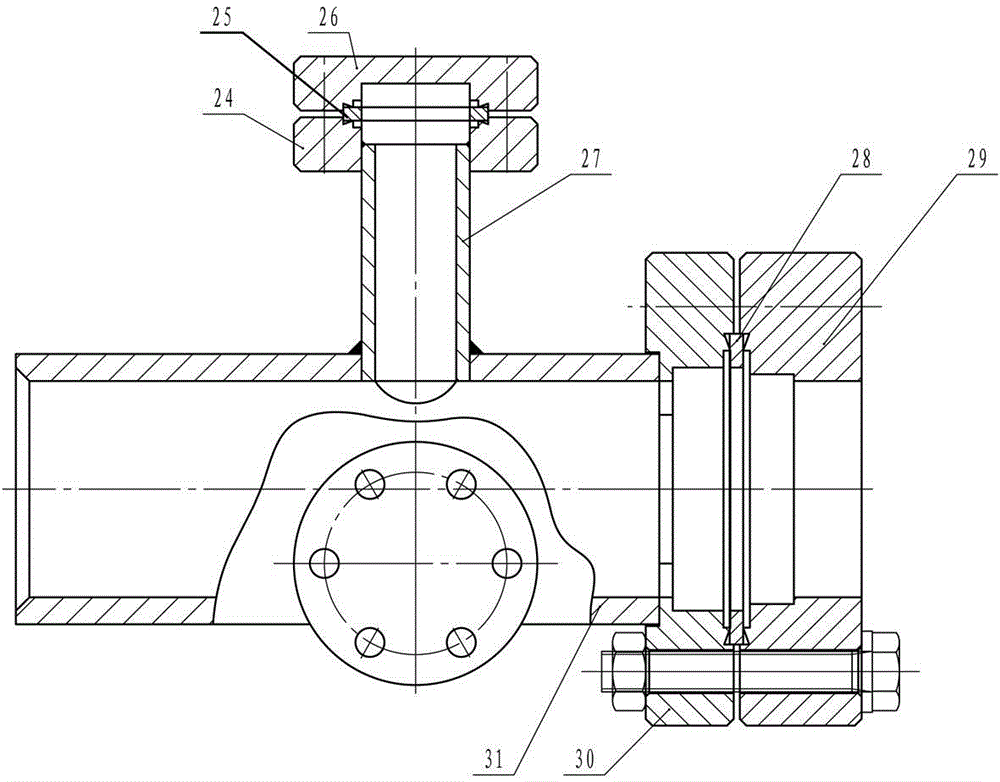

[0031] It includes a pump body and a pump core assembly set in the pump body. It is characterized in that the electromagnetic heater is set at the bottom of the pump body, and a water-cooled oil retaining device is installed at the exhaust port of the pump body. The pump body adopts a straight cavity structure. There is a sink-type cooling jacket, and the pump core assembly is vertically installed in the center of the pump body. The structure of the pump core assembly is provided with an umbrella-shaped first-stage nozzle cap, an umbrella-shaped second-stage nozzle cap, and an umbrella-shaped third nozzle cap from the inside to the outside. The first-stage nozzle cap and the third-stage guide pipe constitute the overall structure. The nozzle caps of the umbrella caps at all levels are equipped with guide pipes. The first-stage diffuser guide pipe is welded vertically at the center of the third-stage guide pipe. The height of the flow tube is higher than that of the secondary fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com