Oil pan structure

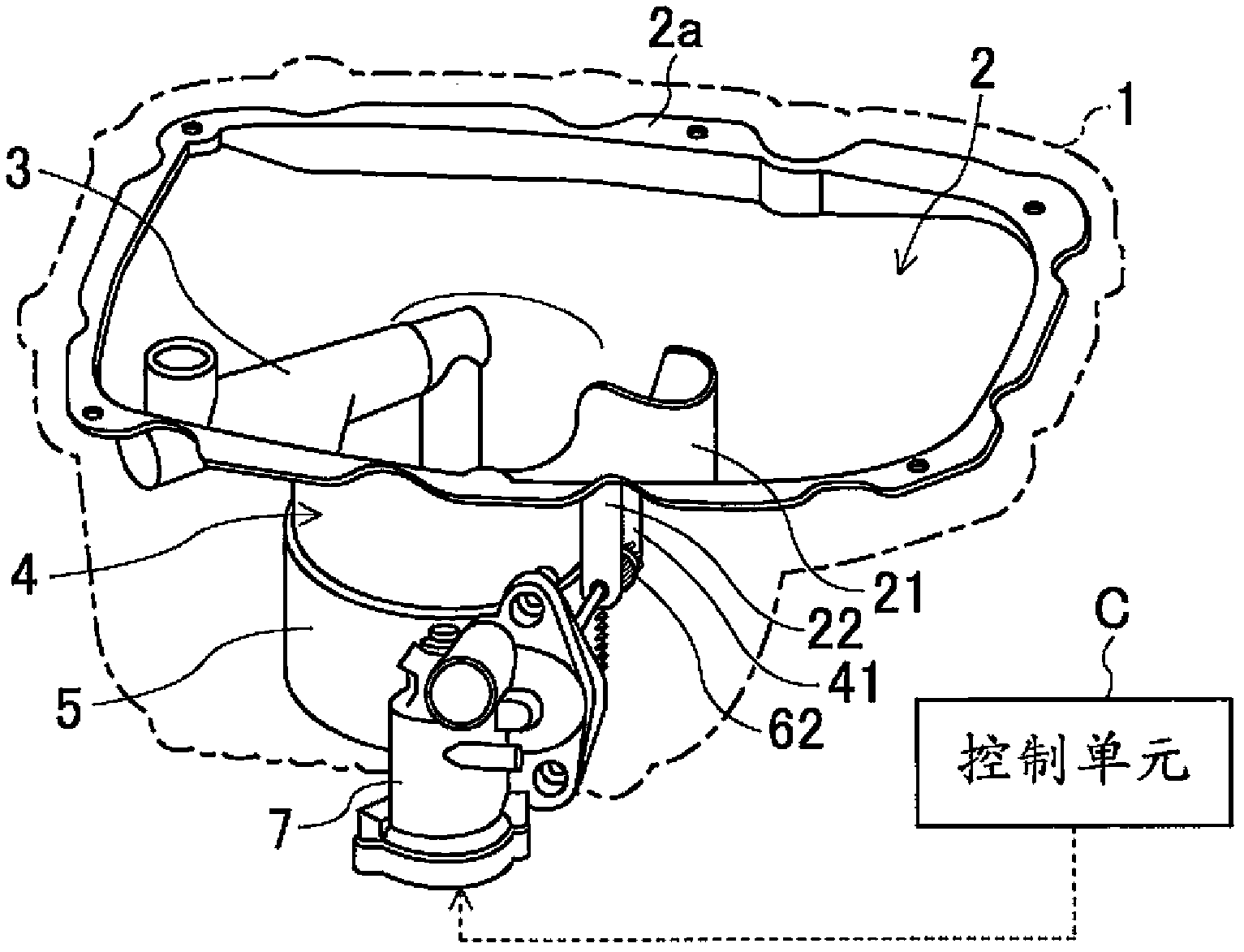

A technology of oil pan and structure, applied in the direction of engine components, machine/engine, engine lubrication, etc., can solve the problems of engine speed increase, oil cut-off, etc., to speed up temperature rise, prevent burns, and shorten warm-up running time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

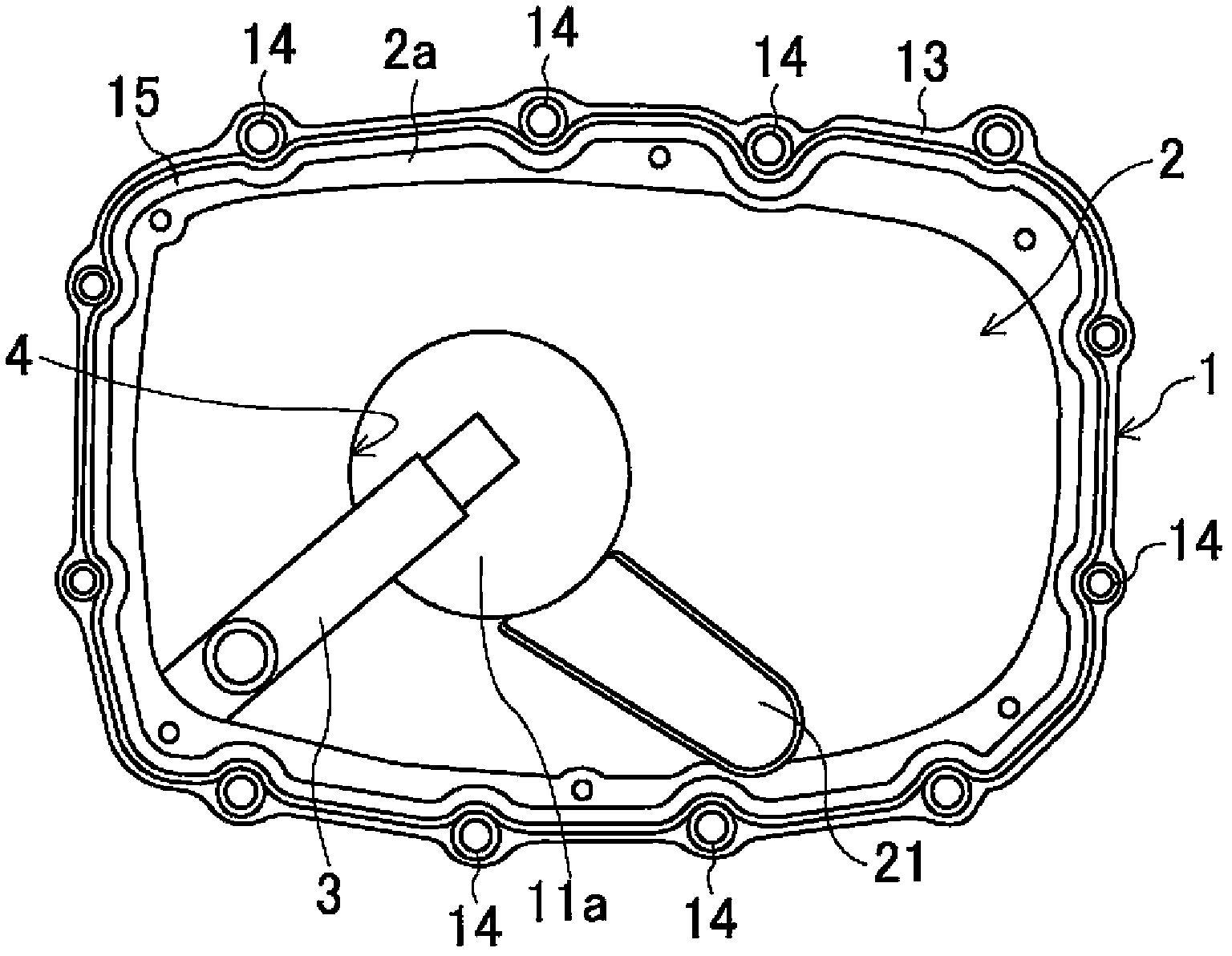

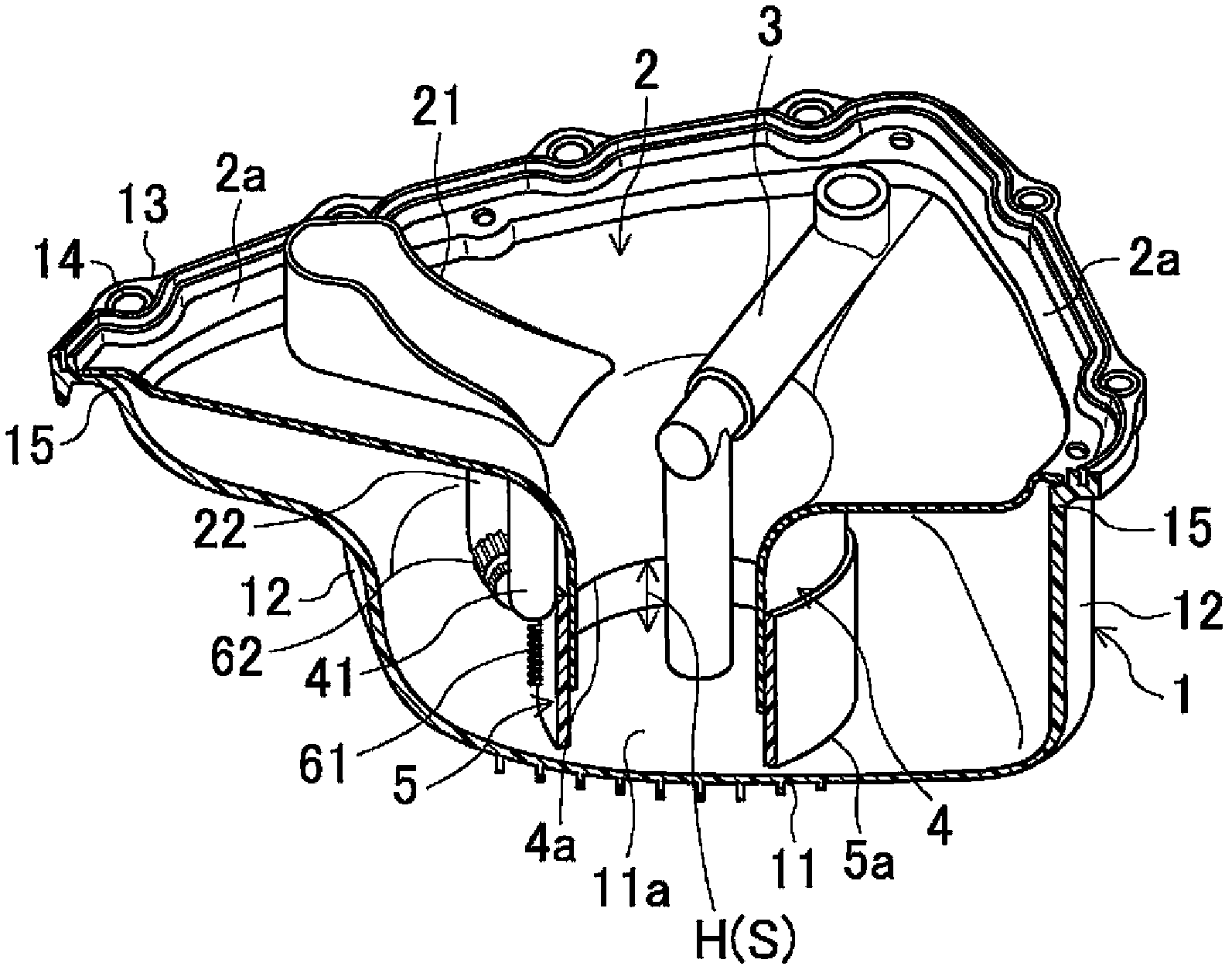

Embodiment approach 1

[0115] Like the first embodiment, the electric actuator 107 of the second embodiment is also configured to receive a control signal from the control unit C to generate a rotational force, and the rotational force is applied to the worm 106 b via the shaft 73 .

[0116] The opening area adjusting mechanism M adjusts the opening area S of the communication port 9 between the oil passage body 4 and the bottom surface 11a of the oil pan 1 by using the above-mentioned structure. Specifically, the opening area S is increased or decreased by rotating and moving the partition wall body 105 in the circumferential direction.

[0117] In addition, although the specific control flow is not described, it actually controls using the same control flow as that of 1st Embodiment.

[0118] Therefore, substantially the same effect as that of the first embodiment can be obtained in this second embodiment as well. In particular, in the second embodiment, the opening area S is adjusted by rotating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com