Oil injector fault checking method and device

A fuel injector and fault detection technology, which is applied to fuel injection devices, measuring devices, instruments, etc., can solve the problems of high labor intensity, cumbersome procedures, complex structure, etc., and achieve the goal of reducing labor intensity, simple operation and improving work efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The core of the present invention is to provide a fuel injector fault detection method to realize on-line fault detection and effectively avoid the defects existing in off-line measurement. The present embodiment will be described in detail below in conjunction with the accompanying drawings.

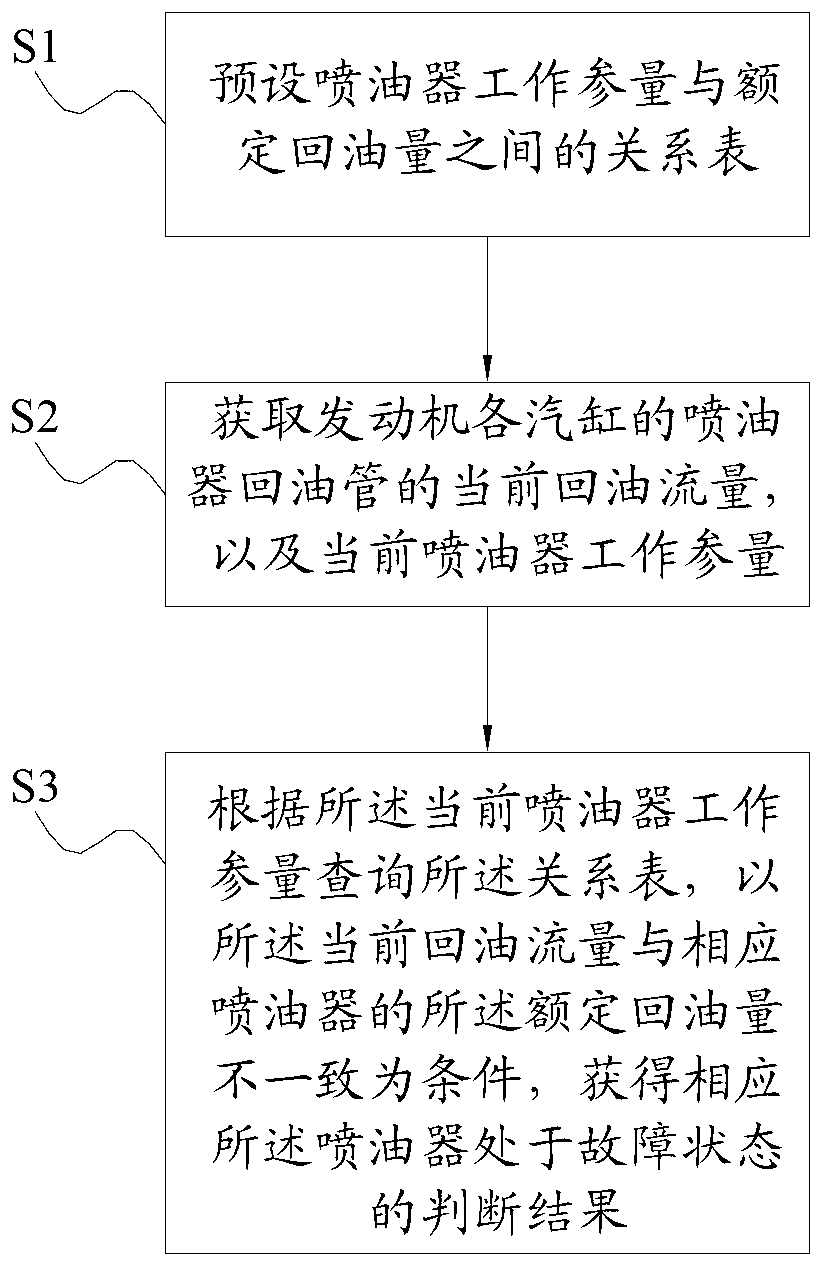

[0025] See figure 1 , which is a flow chart of the fuel injector fault detection method described in this embodiment.

[0026] This detection method is used to judge the fault of the fuel injector when the engine is running. Such as figure 1 As shown, the detection method comprises the following steps:

[0027] S1, the relationship table between the preset operating parameters of the injector and the rated oil return; here, the rated oil return is the threshold obtained by theoretical calculation. It should be understood that the rated oil return volumes corresponding to the operating parameters of the injectors are different for different models of engines and under differen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com