Calculating method of fresh return air mixed type air adjusting system with fixed secondary mixing ratio

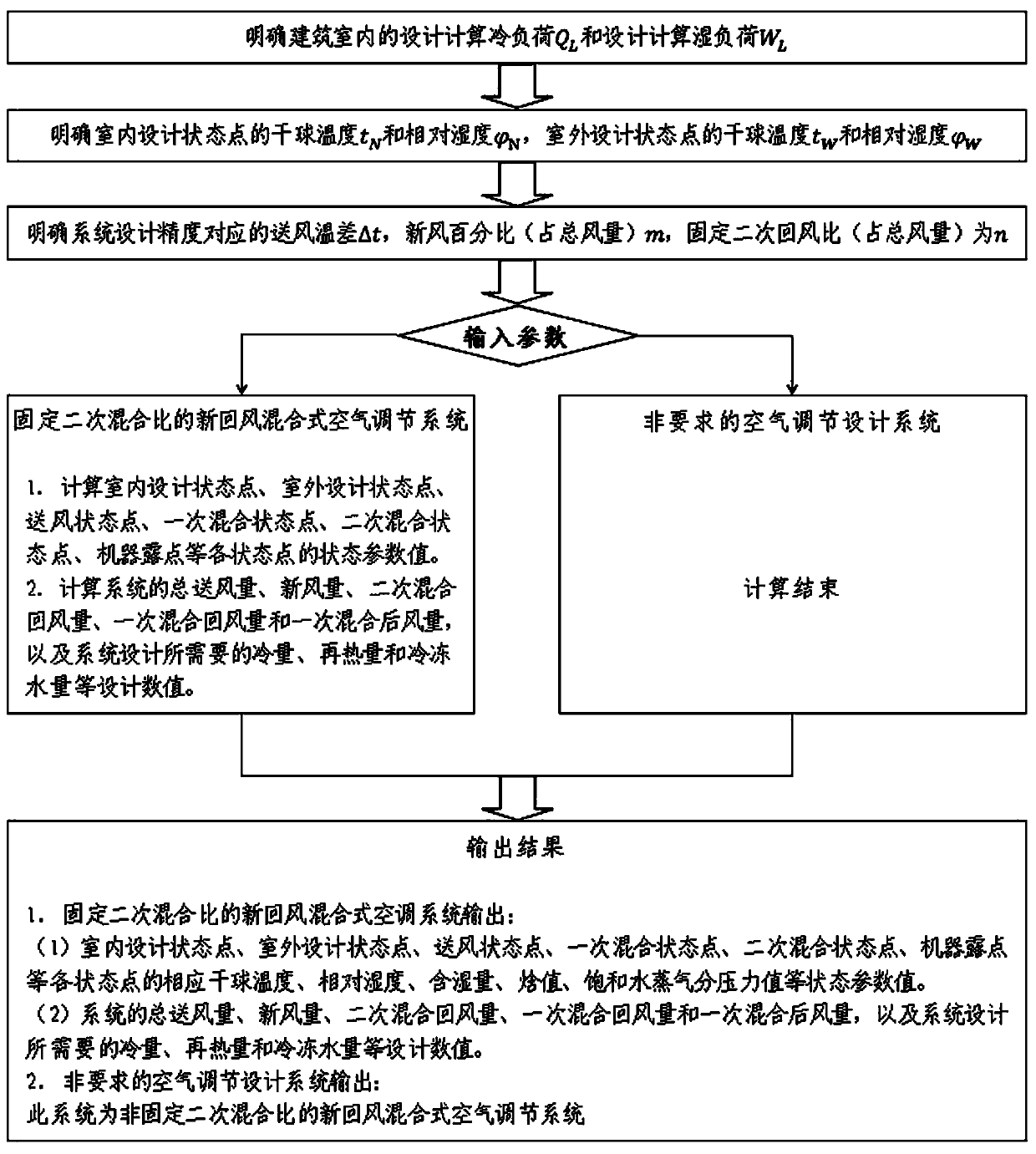

An air conditioning system, secondary mixing technology, applied in the direction of calculation, computer-aided design, design optimization/simulation, etc., can solve the problems of insufficient dehumidification capacity, waste of cold and heat energy, and less application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described through specific embodiments below in conjunction with the accompanying drawings.

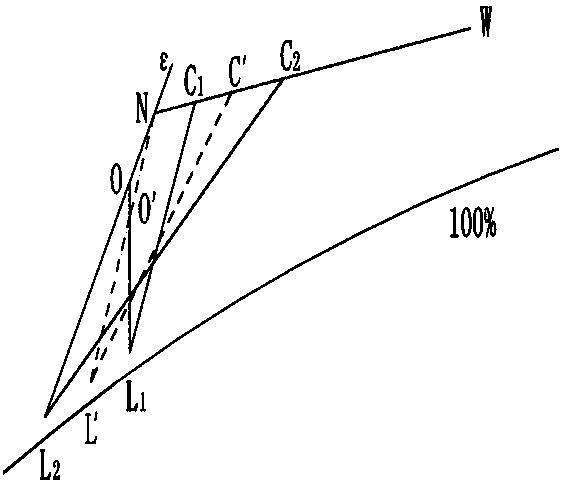

[0032] Such as figure 1 As shown in the figure, the ε line is the heat-humidity ratio line of the indoor load of the air conditioning system; the O point is the air supply state point of the air conditioning system; the N point is the indoor design state point of the air conditioning system; the W point is the outdoor design state of the air conditioning system point; C 1 The mixed state point of the primary mixed new return air hybrid air-conditioning system; C 2 The primary mixing state point of the new return air hybrid air conditioning system with secondary mixing; C' the primary mixing state point of the new return air hybrid air conditioning system with a fixed secondary mixing ratio; O' the new return air conditioning system with a fixed secondary mixing ratio Secondary mixing state point of wind mixing air conditioning system; L ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com