Patents

Literature

45results about How to "Practical engineering application value is great" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

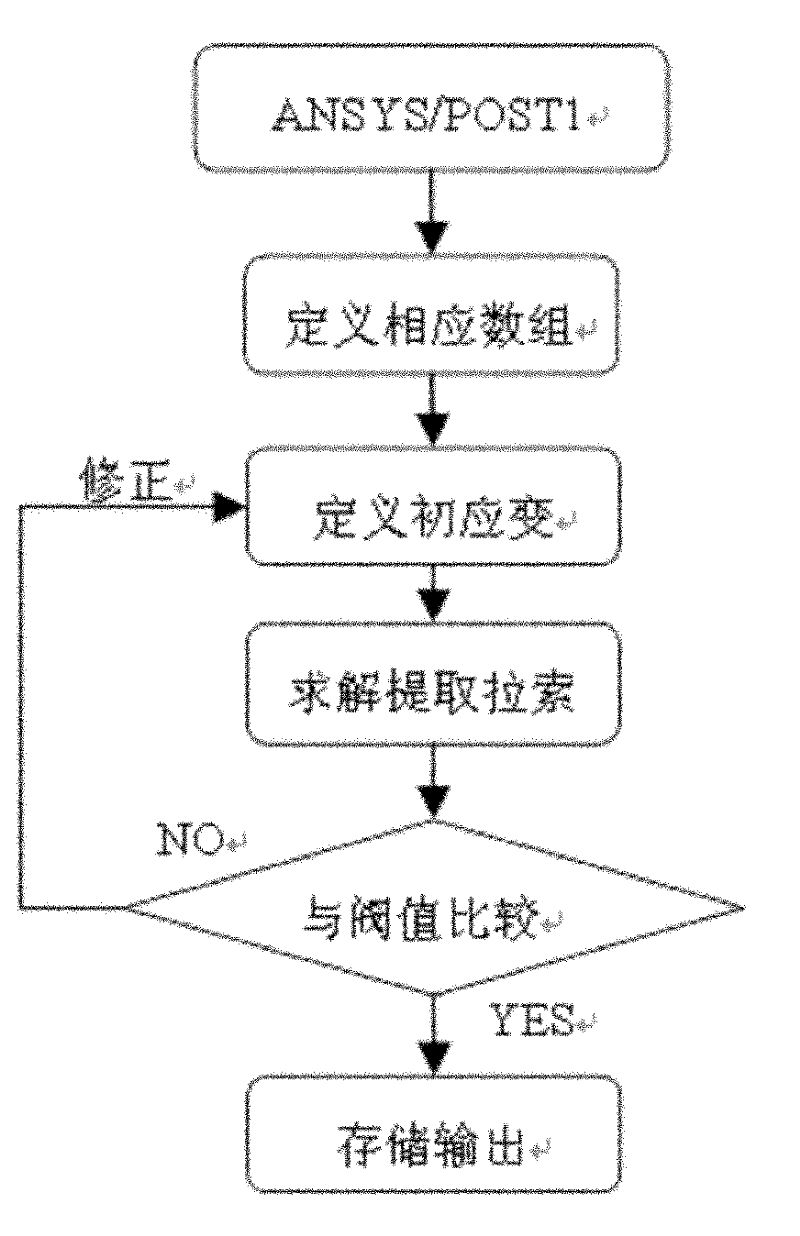

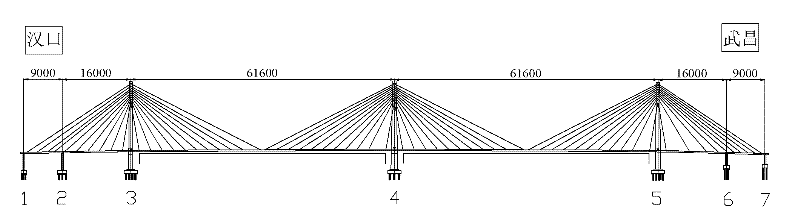

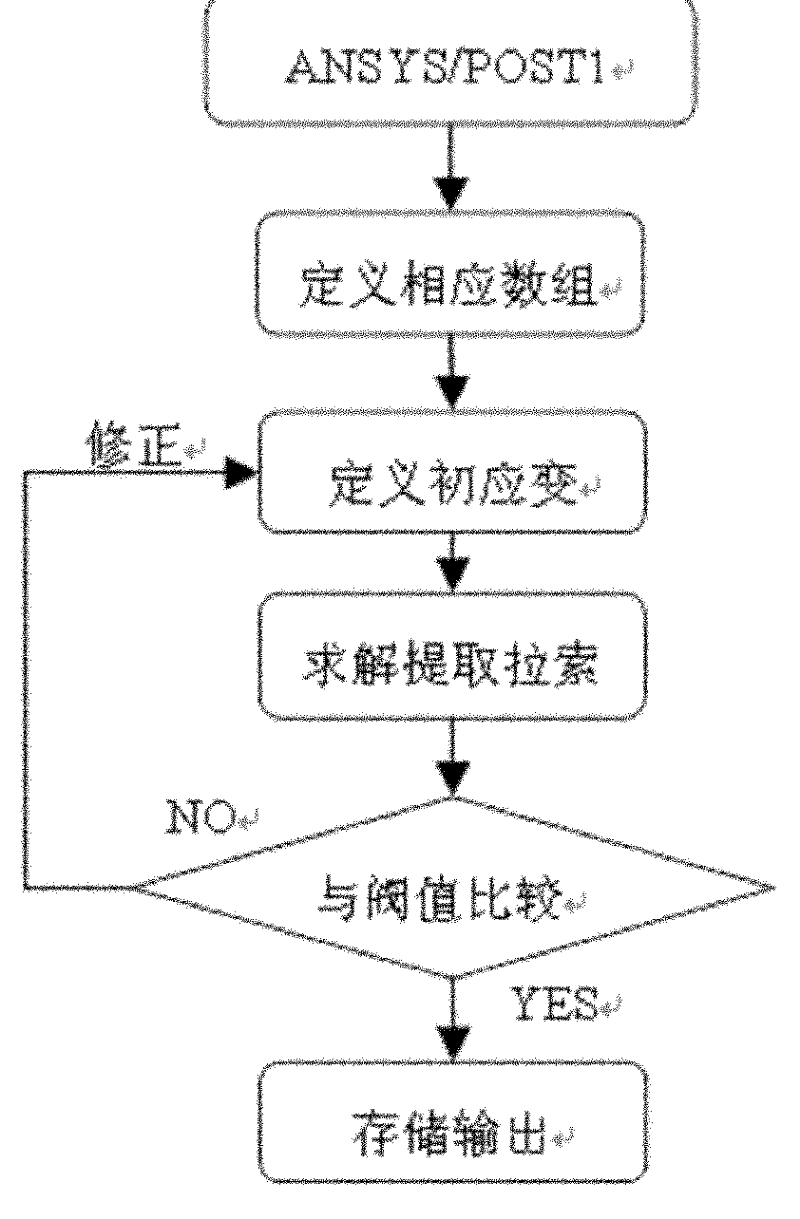

Determination method of initial completion initial cable force of cable-stayed bridge

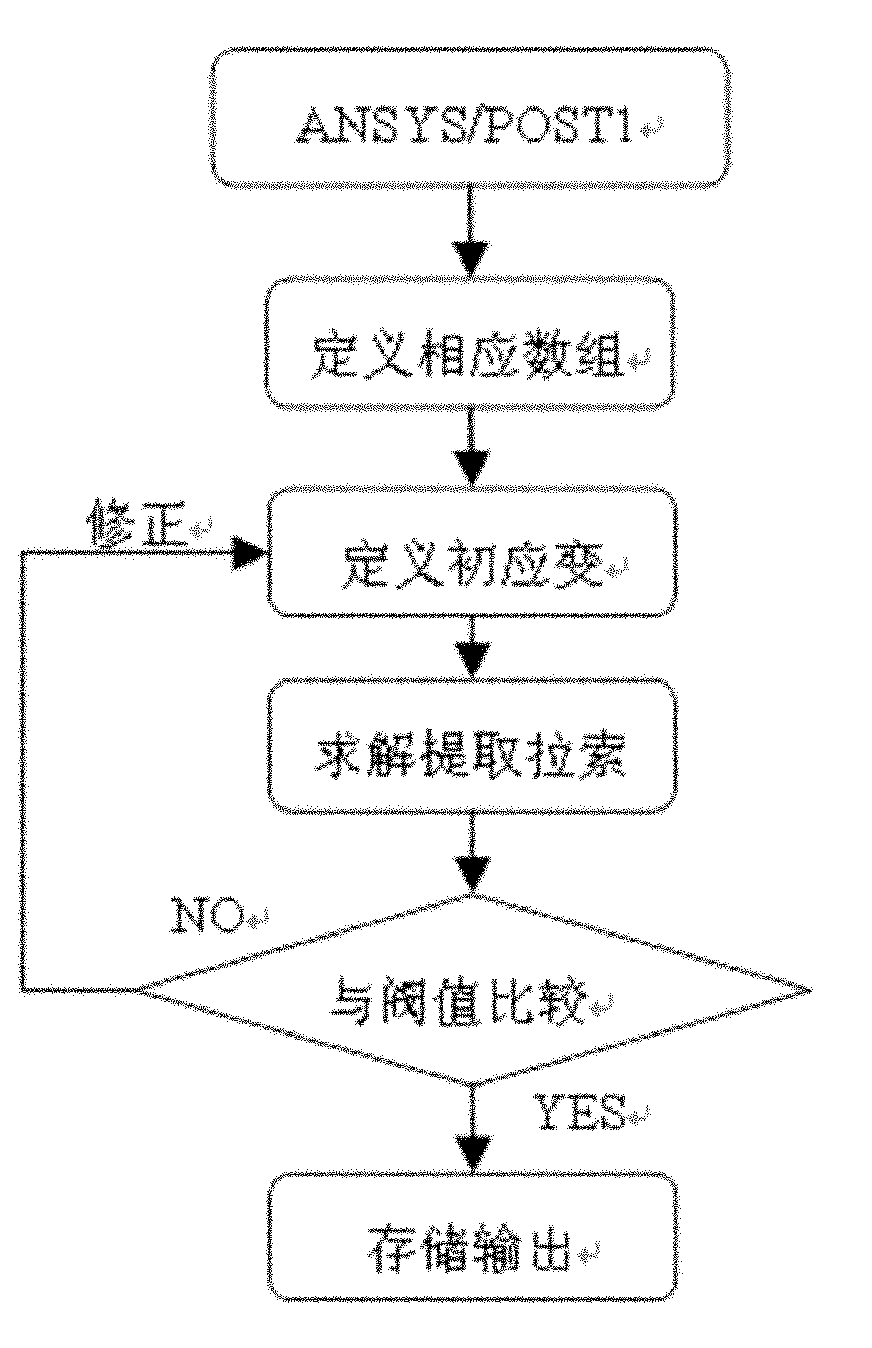

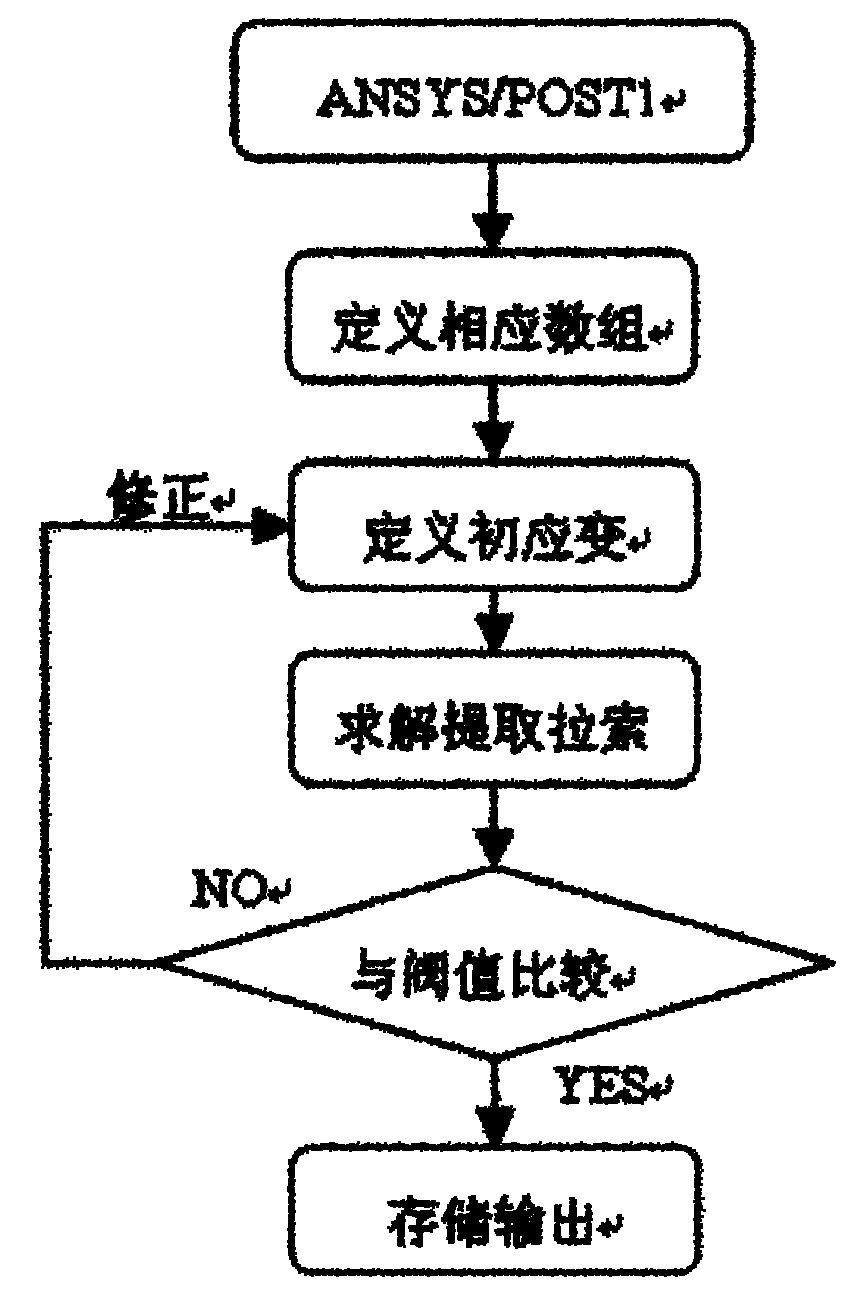

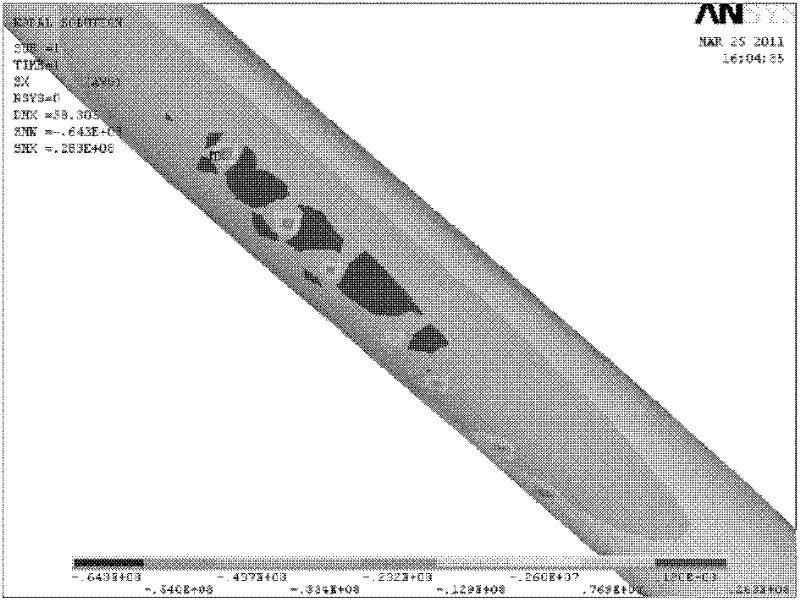

ActiveCN101937485AFast convergenceReduce calculation errorsSpecial data processing applicationsCable stayedCommand language

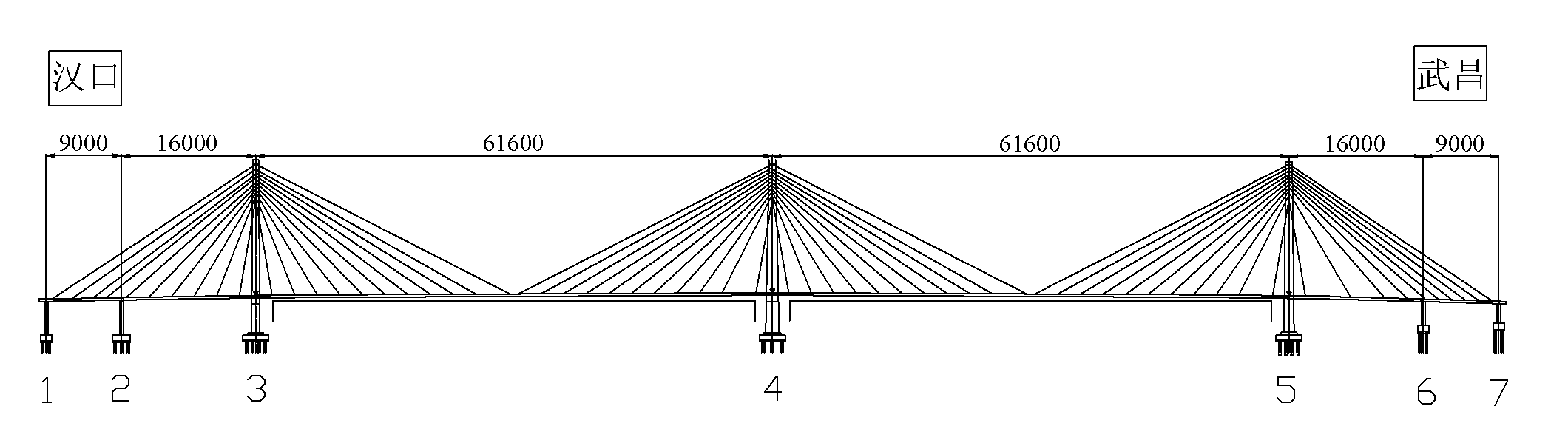

The invention relates to a determination method based on an ANSYS second development platform of the initial completion initial cable force of a cable-stayed bridge. The method uses the design cable force as the target value, considers the geometric non-linear effect and performs iteration for solving and correcting the cable initial strain under the action of dead load. The method comprises the following specific steps: any group of cable forces is assumed to be added on the stay cable in the mode of initial strain, dead load is added to calculate, the *do-loop command language is used to extract the calculated cable force of the stay cable and check whether the error between the cable force and the target completion cable force is within an available limit; if the error is large, the indifference method is used to correct the stay cable initial strain, then the error is calculated again until the error is within the available limit; and the initial completion initial cable force can be obtained by multiplying the last calculated group of stay cable initial strains by the elastic modulus of the stay cable which is corrected by considering the vertical effect. By using the method, the solving time of the completion initial cable force of the cable-stayed bridge can be reduced and the precision can be increased, thus the method has large practical engineering application value.

Owner:WUHAN UNIV OF TECH

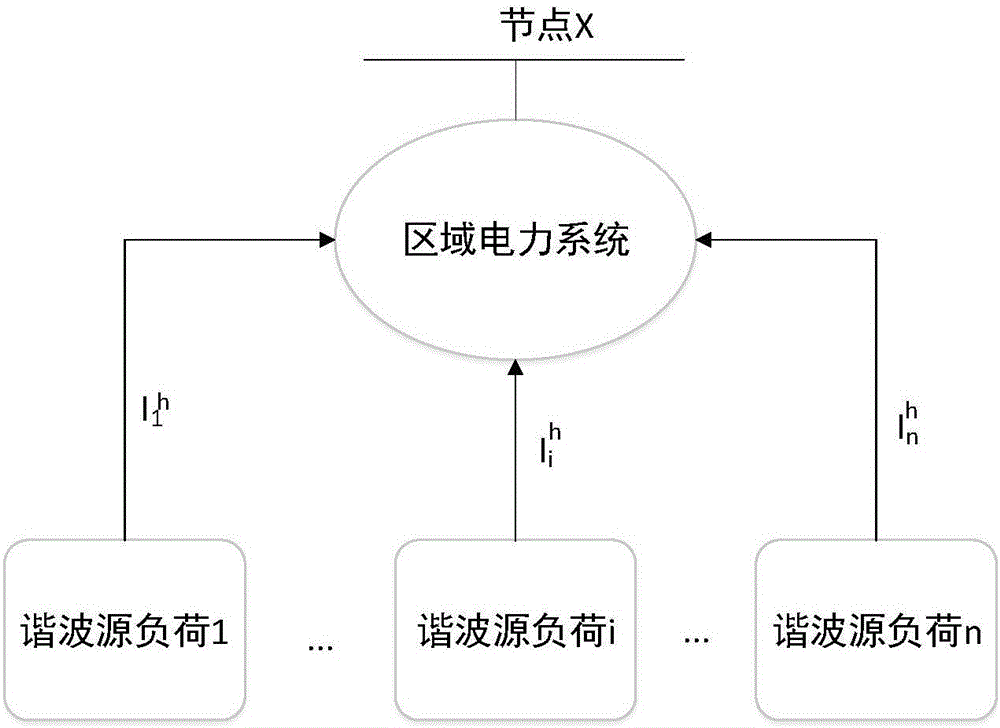

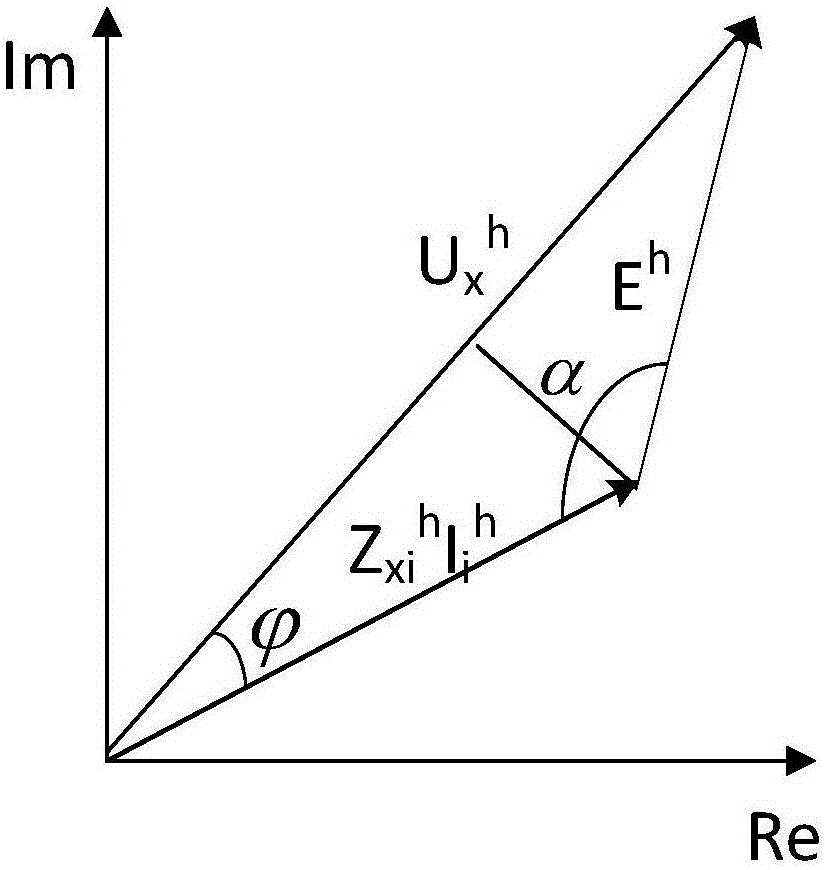

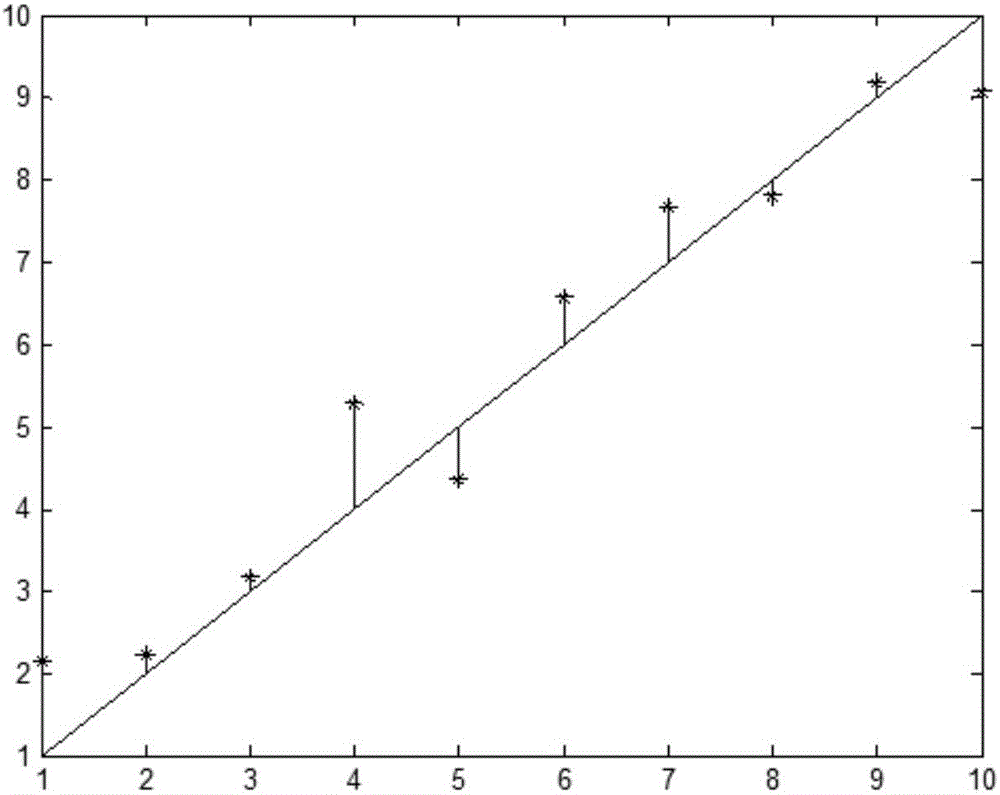

Multi-harmonic-source harmonic contribution quantitative analysis method based on total-least square method

ActiveCN106443285AOvercome errorThe result is accurateData processing applicationsElectrical testingTotal least squaresSingular value decomposition method

The invention discloses a multi-harmonic-source harmonic contribution quantitative analysis method based on a total-least square method. The multi-harmonic-source harmonic contribution quantitative analysis method includes: selecting harmonic voltage as the index for evaluating harmonic contribution, and determining the joint action of the harmonic source of each node; sectioning measured data according to time, and calculating the harmonic contribution in each time section according to the projection of the harmonic voltage of one harmonic source at one node on the total harmonic voltage at the node; using the total-least square method to solve harmonic impedance and the harmonic voltage, namely background harmonic voltage, of other harmonic sources at the node, and using a singular value decomposition method to obtain the solution of the total-least square method to obtain the quantitative data of each harmonic source at each node at each harmonic time. The multi-harmonic-source harmonic contribution quantitative analysis method has the advantages that the total-least square method is applied to the harmonic quantitative analysis field, the defect that a traditional method only considers variable harmonic voltage measuring errors and does not consider the independent variable harmonic current measuring errors is overcome, and obtained results are accurate.

Owner:UNIV OF JINAN

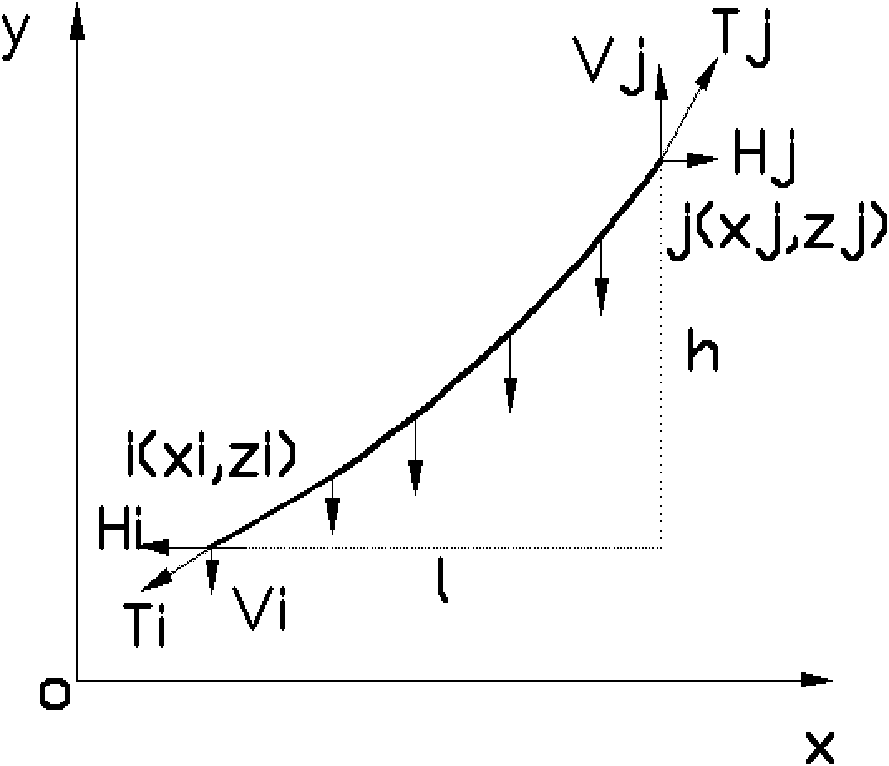

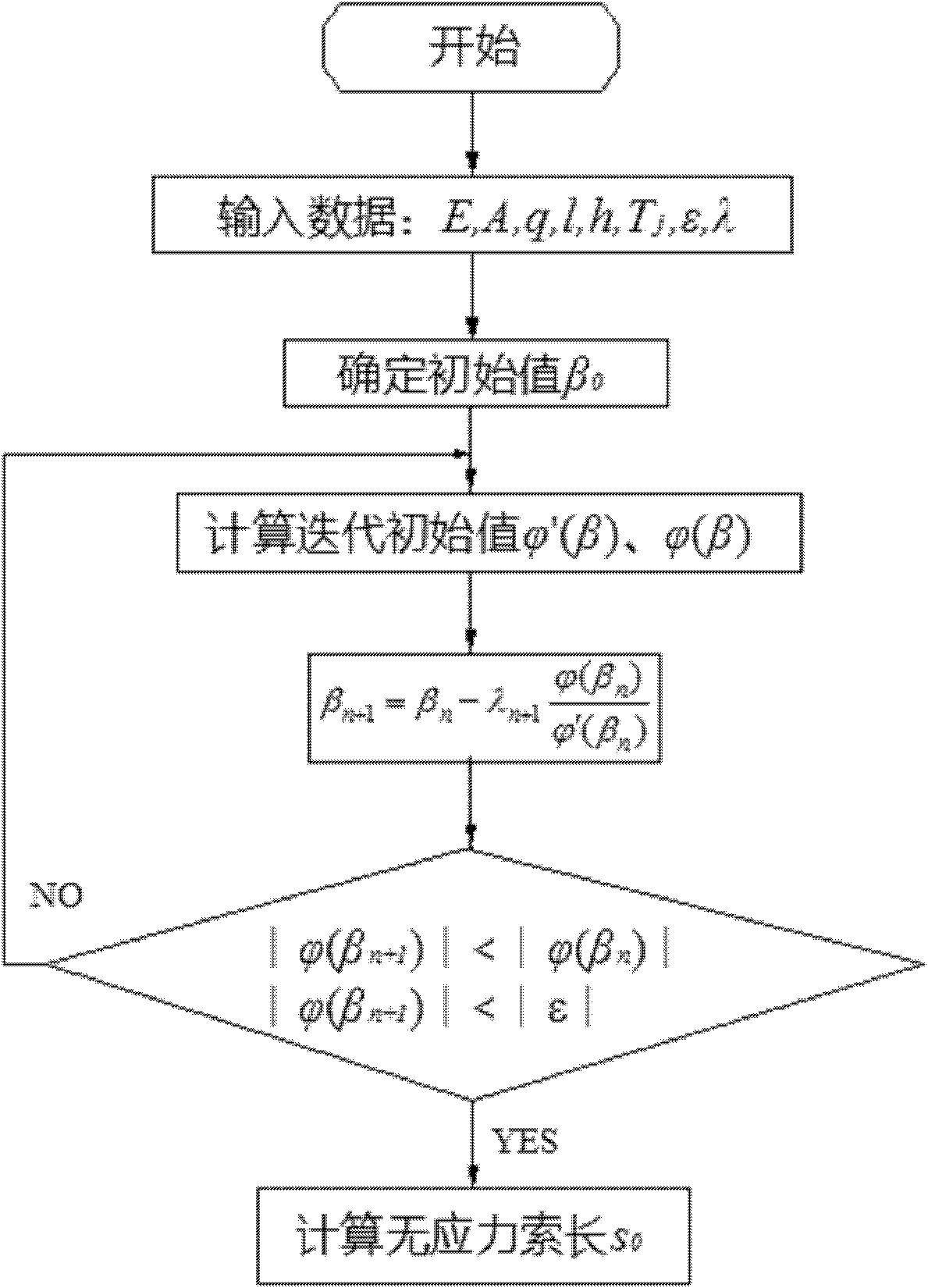

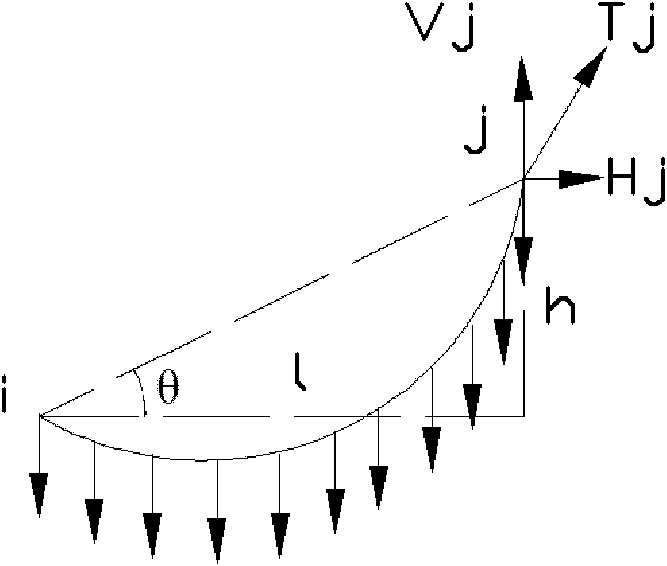

Method for precisely solving length of unstressed cable of cable-stayed bridge

InactiveCN101852600AFast convergenceReduce calculation errorsMeasurement devicesComplex mathematical operationsCable stayedCalculation error

The invention provides a method for precisely solving the length of an unstressed cable of a cable-stayed bridge. The length of the unstressed cable is solved by substituting the average value of the nodal force at the end of the stayed cable with a precise calculation method for the force at the end of the stayed cable, and by building a precise expression s0 of the length of the unstressed stayed cable and a characteristic parameter beta constraint equation of the stayed cable when a tensile force at the end of a tower is known without selecting the primary value of the length of the unstressed cable. The method comprises the following steps of: building the precise expression of the length of the unstressed stayed cable and the characteristic parameter beta constraint equation of the stayed cable when the tensile force Tj at the end of the tower is known, and solving the length of the unstressed stayed cable. The method has the advantages of solving the problem on the selection of the primary value of the length of the unstressed cable, with high convergence rate and small calculation error. Compared with the linear search, the dichotomy and the improved chord secant method for iteratively solving the length of the unstressed cable, the method of the invention greatly improves the solution precision and solution efficiency of the length of the unstressed stayed cable, so the method is of relatively high application value in practical projects.

Owner:WUHAN UNIV OF TECH

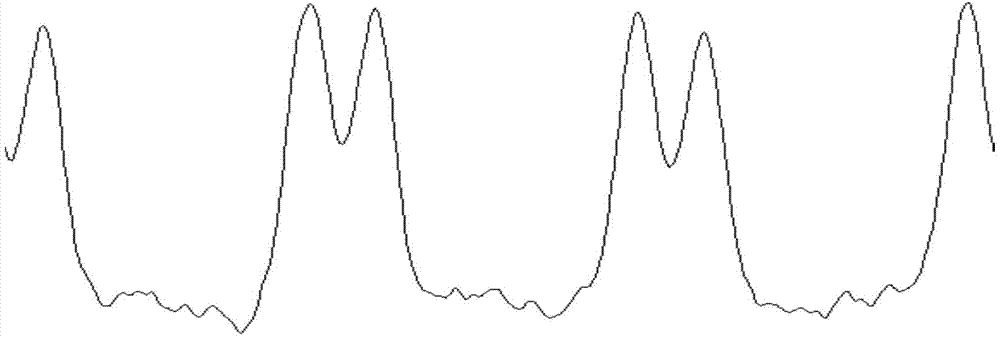

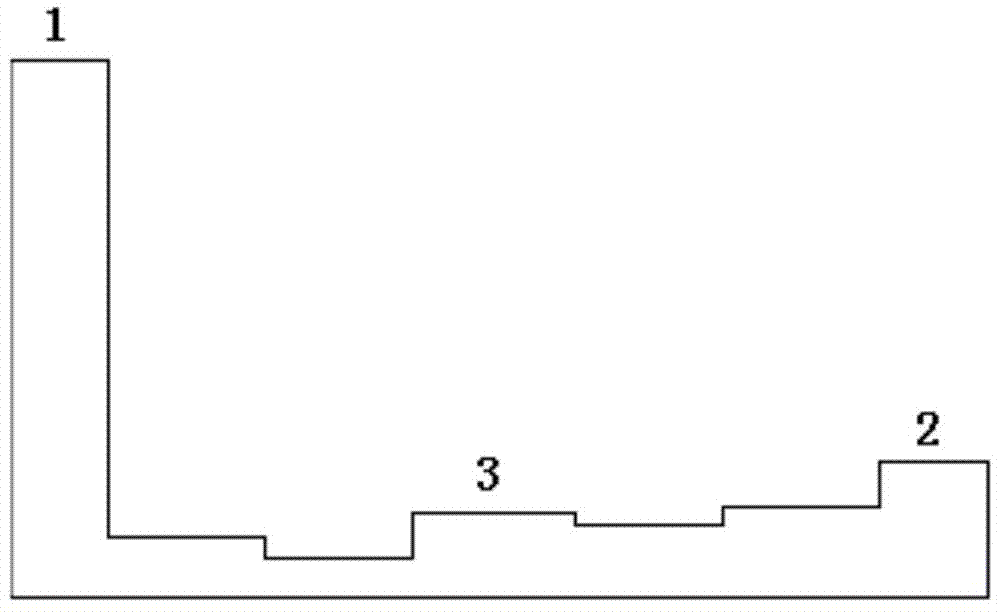

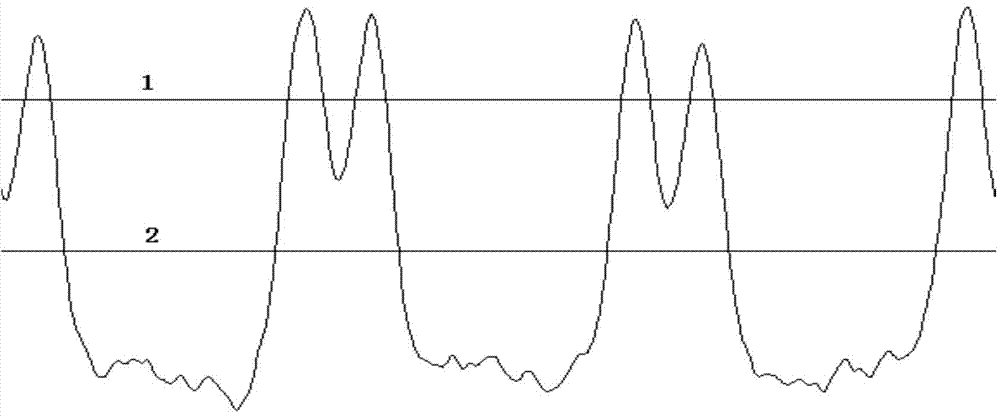

Method for measuring tip clearance of turbine concave cavity blades

ActiveCN104296714AEnables tip clearance measurementSimple designMeasurement devicesEngineeringTip clearance

The invention belongs to a blade clearance measuring technology, and particularly relates to a method for measuring the tip clearance of turbine concave cavity blades. Disclosed by the invention is a method for measuring the tip clearance of the turbine concave cavity blades, which comprises the steps of firstly acquiring original blade tip signals and carrying out filtering and smoothing processing, then setting high and low threshold levels according to the shape of the concave cavity blades, enabling the high level to be between the peak of original blade tip clearance signals and the concave cavity valley, enabling the low level to be between inter-blade valley signals and concave cavity valley signals, differentiating different blades according to the low level, identifying two peaks according to the high level, extracting peak level, and then determining tip clearance values at a blade back side and a blade basin side according to a fitting relation between clearance and voltage. According to the invention, blade tip signals at the blade back and the blade basin of turbine concave cavity blades can be identified and extracted based on a full-period sampling technology based tip clearance measuring algorithm, variations in tip clearance at the back and the basin are monitored visually in real time, and whether collision occurs or not between the blade tip and a casing can be judged precisely.

Owner:AECC SICHUAN GAS TURBINE RES INST

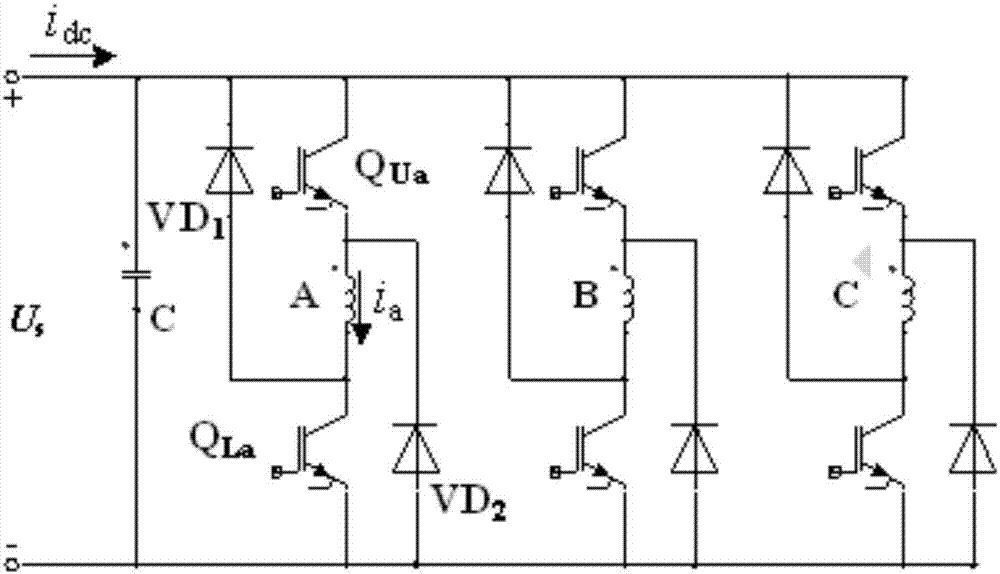

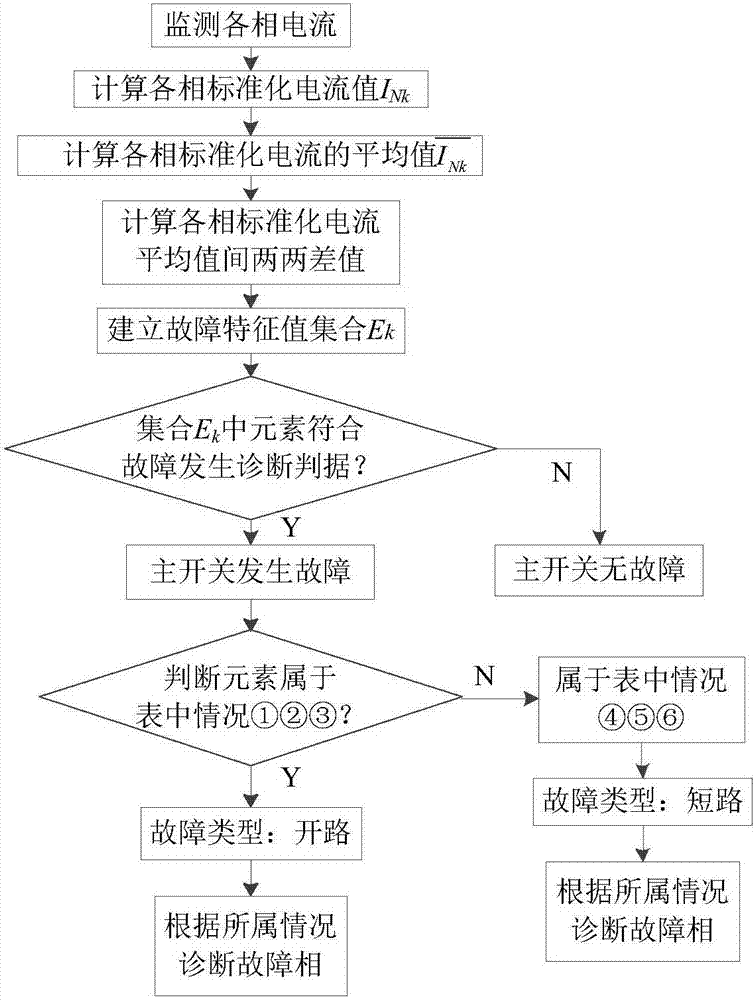

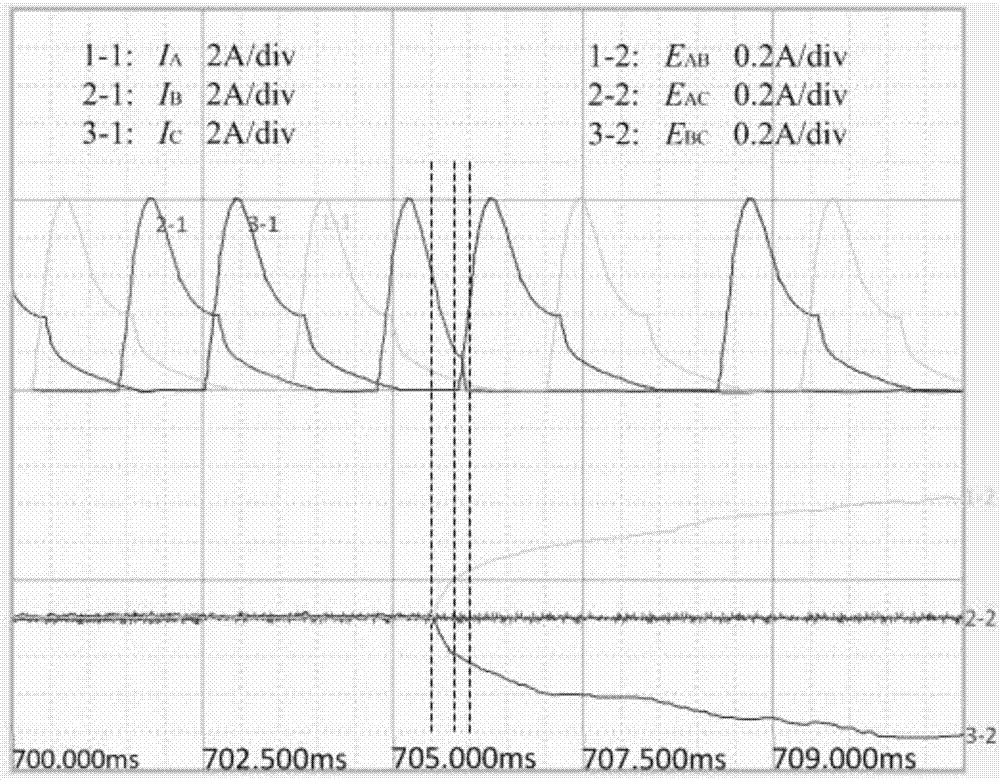

Main switch fault detection method for asymmetric half-bridge-type power converter of switched reluctance motor

PendingCN106896323AThe detection method is simple and fastLow costDynamo-electric machine testingEngineeringStandardization

The invention discloses a main switch fault detection method for an asymmetric half-bridge-type power converter of a switched reluctance motor. The method comprises the following steps: detecting the instantaneous value of each phase current of the switched reluctance motor power converter, calculating the difference between the two of the normalized current averages, and treating each difference as an element to construct the fault feature quantity set Ek; determining the condition which the element in the set belongs to in the fault diagnosis table by comparing the relationship between the elements in the set and the diagnostic threshold; detecting the fault occurrence, the fault type and the fault phase according to condition details in the table; if the fault type is open, identifying the fault element by calculating the demagnetization time of the fault phase current; and if the fault type is short circuit, identifying the faulty element by judging the main switch on and off state. The method can precisely and rapidly detect the fault details, is suitable for a variety of phases of switched reluctance motor power converters without adding any additional sensors, and is high in versatility, high in reliability and good in implementation effect.

Owner:TIANJIN UNIV OF COMMERCE

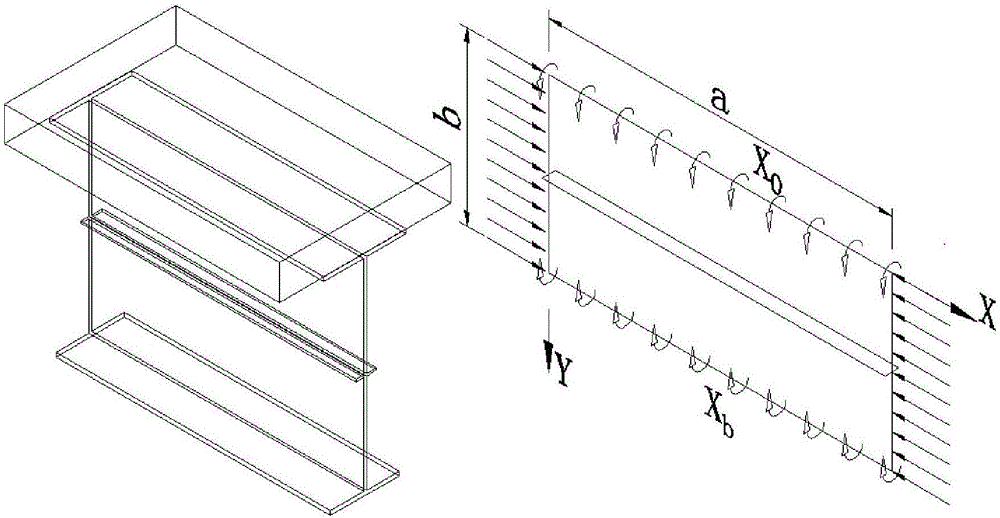

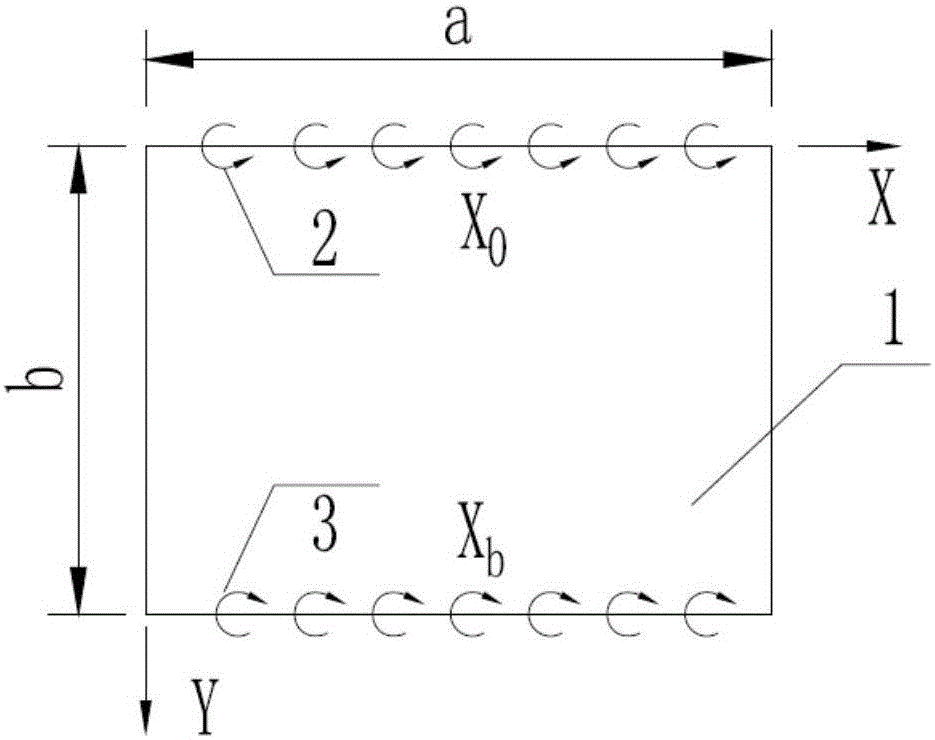

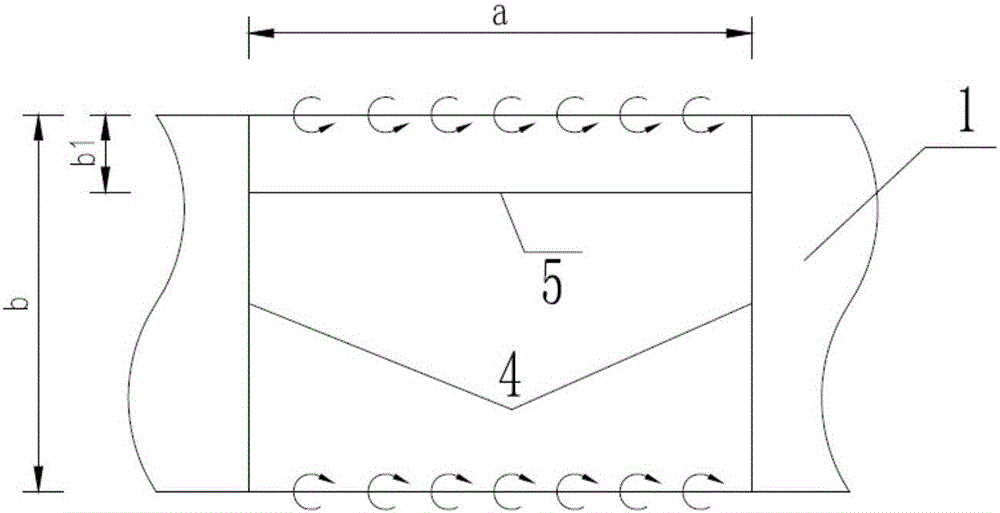

Method for setting longitudinal stiffening rib of high web of elastic rotation constrained boundary steel-concrete composite beam

ActiveCN106758738AAccurate calculation of critical buckling stressImprove rationalityBridge materialsEngineeringEnergy method

The invention relates to a method for setting a longitudinal stiffening rib of a high web of an elastic rotation constrained boundary steel-concrete composite beam. The method comprises the following steps: firstly building a displacement function equation with the elastic rotation constrained boundary and the boundary condition, deriving buckling stress calculation expression of the stiffening rib under two states of the rigid stiffening and flexible stiffening based on an energy method, and obtaining a calculation formula of the elastic rotation constrained boundary longitudinal stiffening rib critical rigidity; and then, considering external work and a minimum potential energy principle, presenting a critical buckling stress calculation formula of a non-uniform pressing plate under the elastic rotation constrained boundary; and finally, according to a buckling safety degree equal principle, obtaining the optical position of setting the longitudinal stiffening rib under the elastic rotation constrained boundary. The method is capable of, according to the actual stress situation, accurately setting the longitudinal stiffening rib of the high web of the steel-concrete composite beam, solving the problems of the current steel-concrete composite bridge bream stiffening rib that the design is conservative and the amount of the steel products is large, and remarkably improving the rationality and economy of the stiffening rib setting of the high web.

Owner:WUHAN UNIV OF TECH

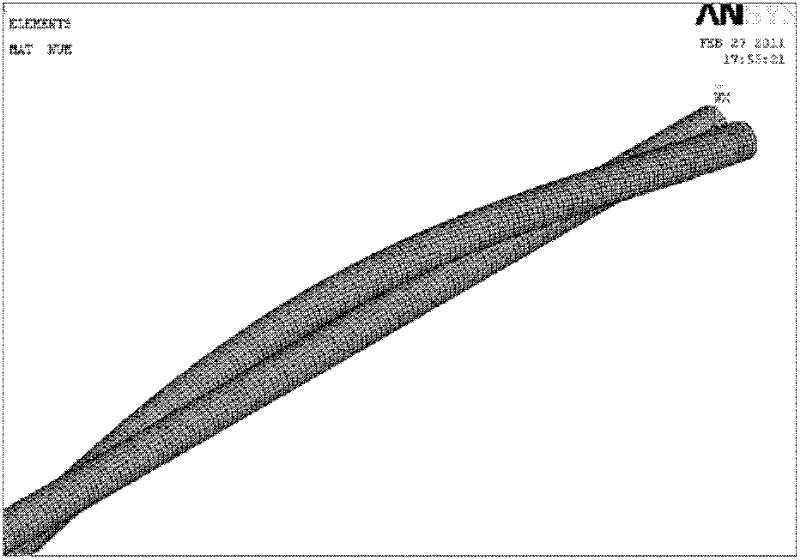

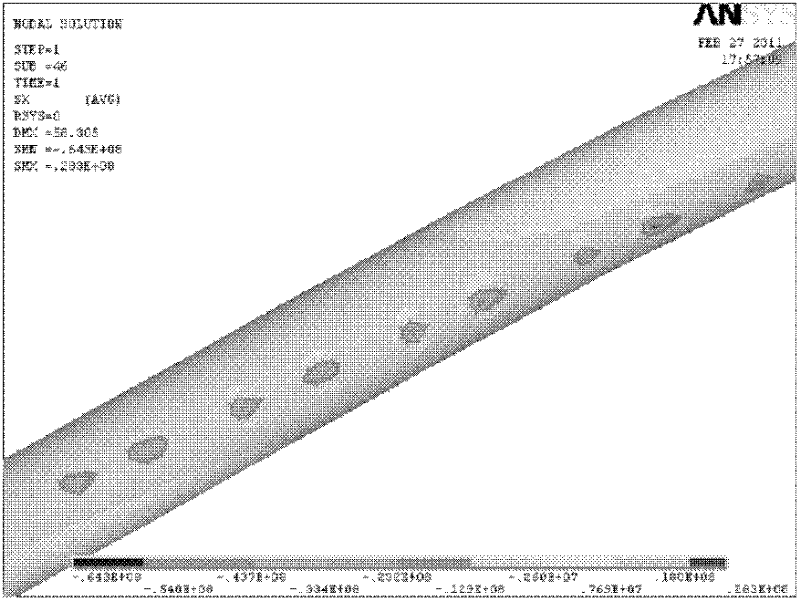

Method for evaluating resistance deterioration of stay cable of steel strand of cable-stayed bridge taking fretting fatigue

ActiveCN102375925AComprehensive assessmentAccurate assessmentSpecial data processing applicationsArchitectural engineeringEngineering

The invention provides a method for evaluating the resistance deterioration of a stay cable of a steel strand of a cable-stayed bridge taking fretting fatigue. The method comprises the following steps of: sampling practical parameters of steel wires of the stay cable of the cable-stayed bridge on site; obtaining a fretting fatigue depth fitting formula among steel wires of the stay cable of the steel strand of the cable-stayed bridge; dividing resistance deterioration phases of the stay cable; and substituting the actual fretting fatigue depth among the steel wires into the deterioration process of the stay cable of the steel strand of the cable-stayed bridge according to division of different phases to obtain a resistance deterioration equation of the stay cable of the steel strand of the cable-stayed bridge taking the fretting fatigue, and evaluating the situation of the resistance deterioration of the stay cable. The method describes the deterioration process of the stay cable of the steel strand more comprehensively and more accurately, and the evaluation process is simple and practical.

Owner:WUHAN UNIV OF TECH

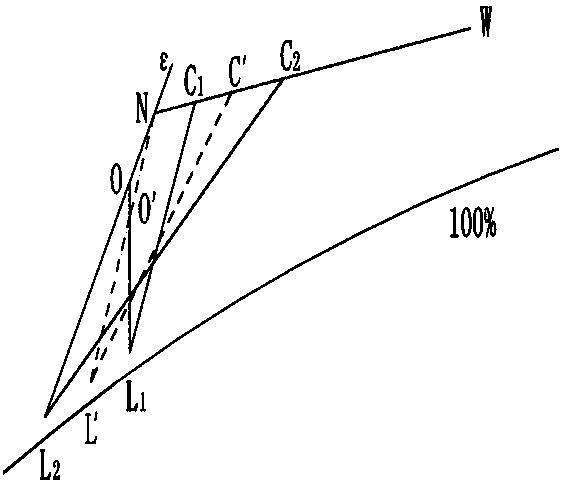

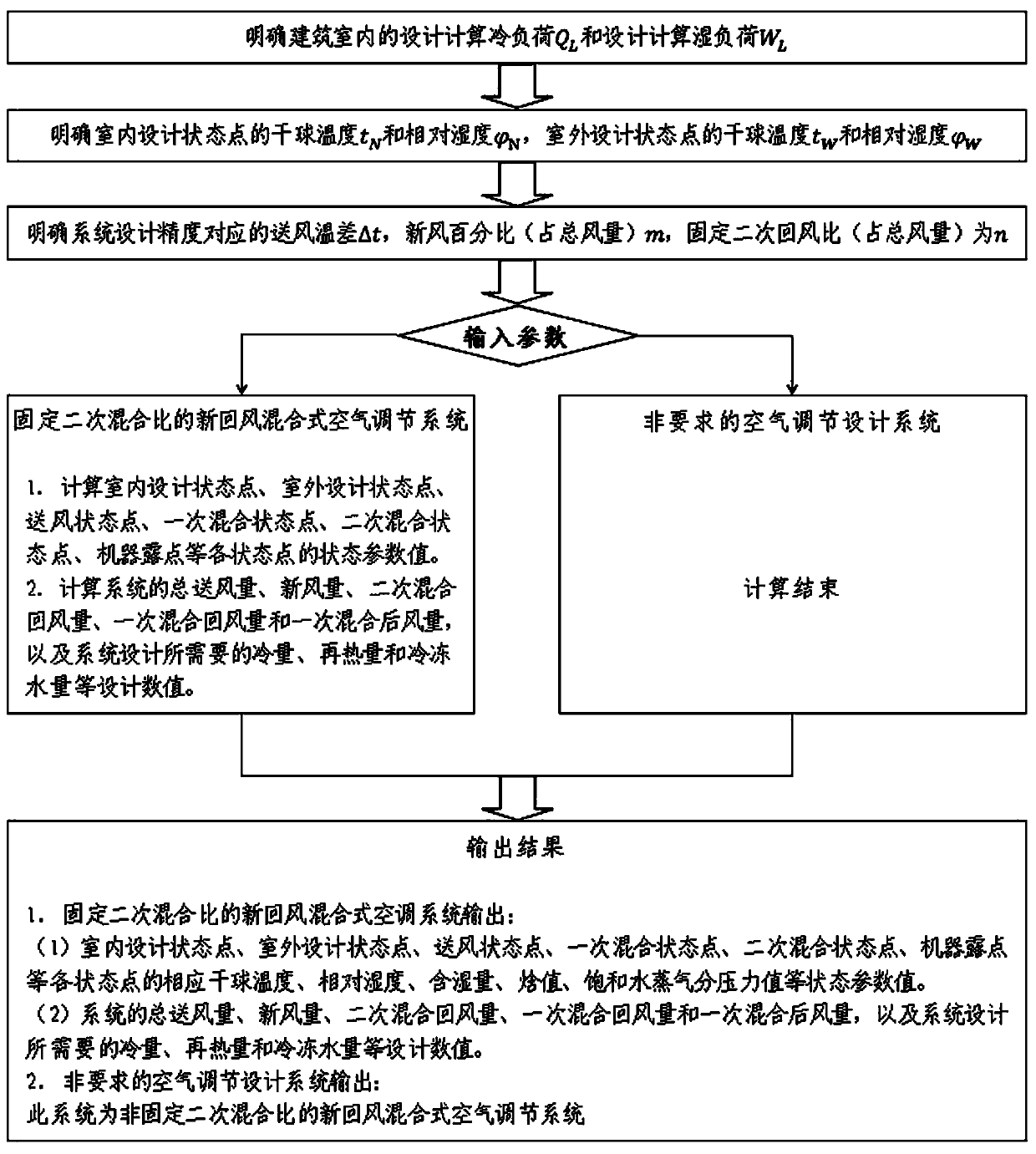

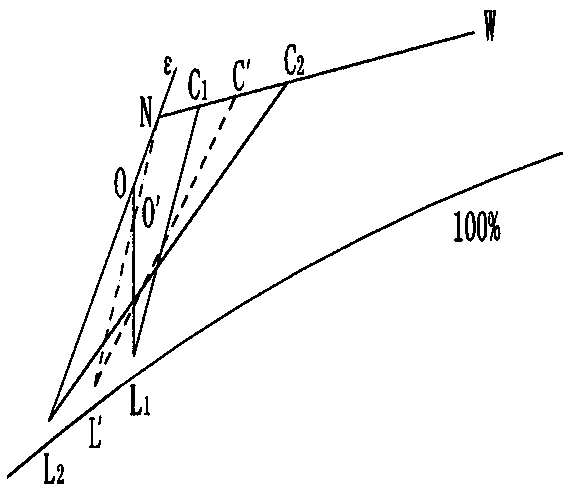

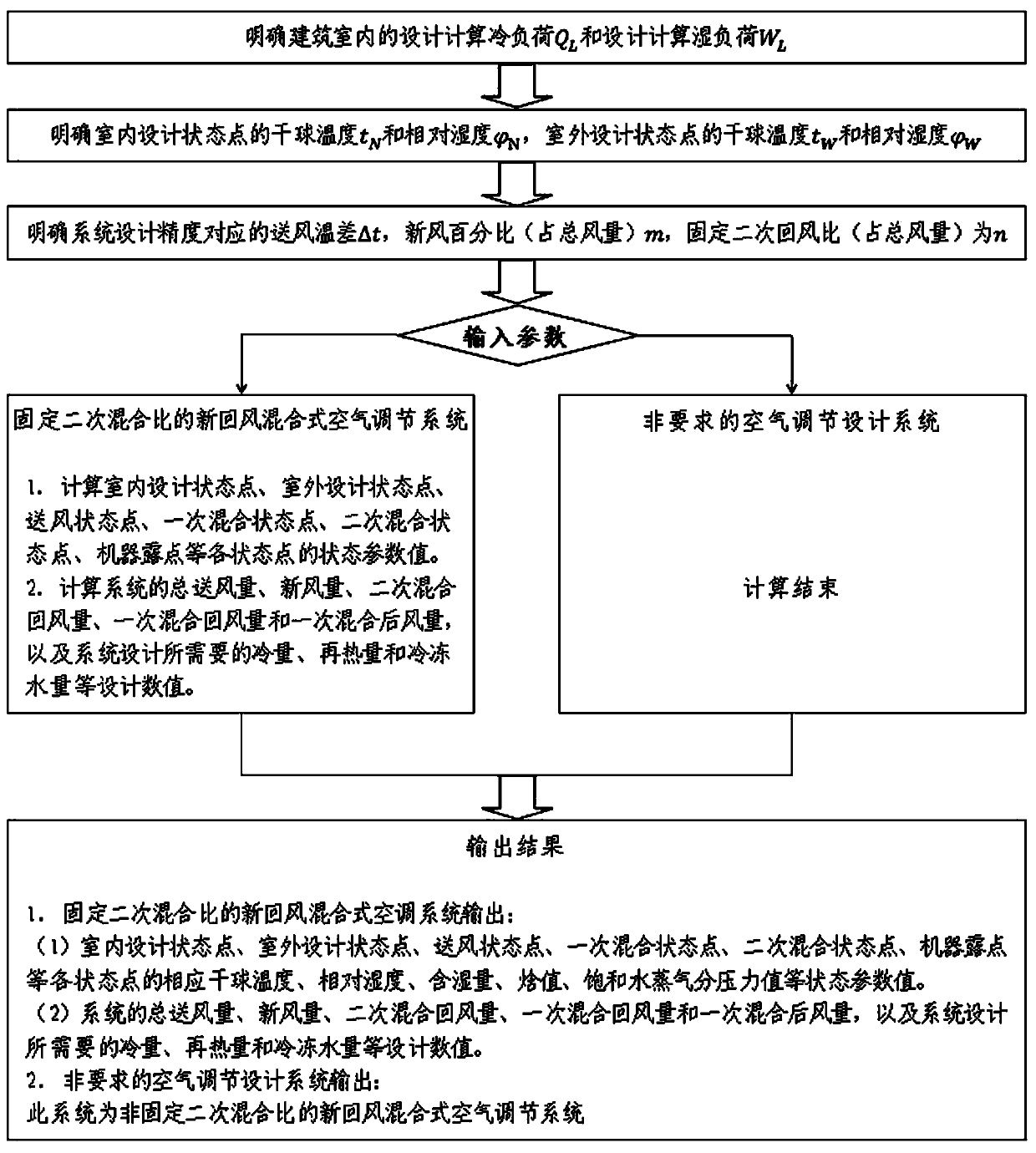

Calculating method of fresh return air mixed type air adjusting system with fixed secondary mixing ratio

ActiveCN107702272AImprove stabilityReduce energy wasteMechanical apparatusDesign optimisation/simulationSystems designAir volume

The invention relates to a calculating method of a fresh return air mixed type air adjusting system with a fixed secondary mixing ratio. The method comprises the following steps of: determining the dry-bulb temperature and relative humidity of an indoor design state point, the dry-bulb temperature and relative humidity of an outdoor design state point and the blowing temperature difference corresponding to the system design precision by determining the design calculating cold load and the design calculating wet load architectural indoors, wherein the fresh air percentage and the fixed secondary mixing ratio are target variables; acquiring the numerical values to calculate state parameter values of the indoor design state point, the outdoor design state point, a blowing state point, a primary mixing state point, a secondary mixing state point and state points of a dew point of a machine; and establishing a calculating mathematical model to calculate the general air volume, the fresh airvolume, the secondary mixing air return amount, the primary mixed return air amount and the primary mixed air volume of the system as well as a cooling capacity, quantity of reheat and refrigerationwater amount design numerical values needed by system design. The calculating method provided by the invention simplifies system control and operation complexity, and has relatively wide actual engineering application value.

Owner:JIANGSU VOCATIONAL INST OF ARCHITECTURAL TECH

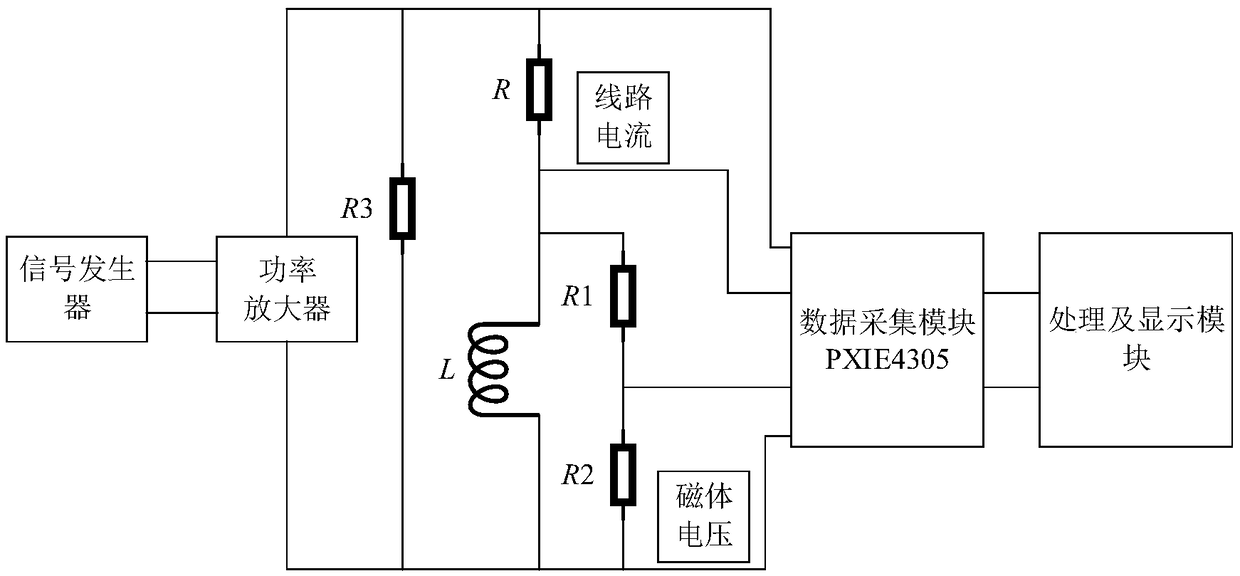

Device and method for measuring superconducting magnet alternating current losses

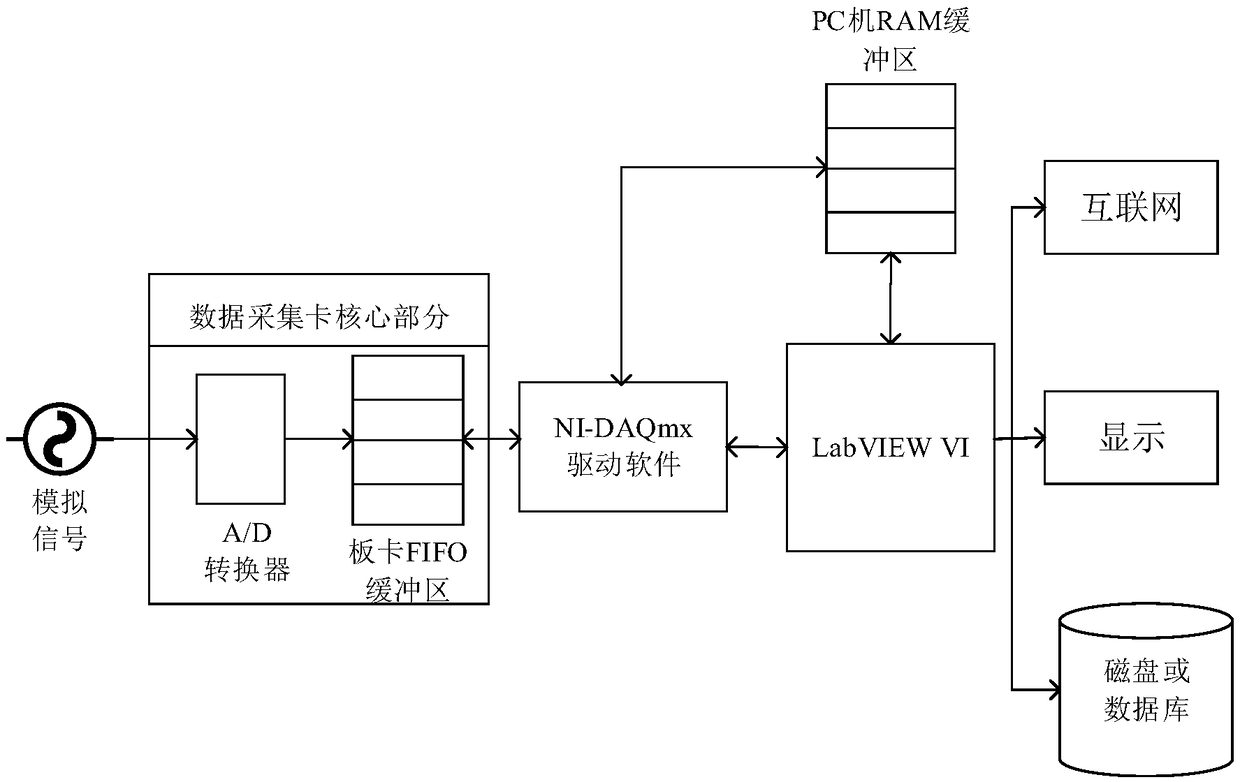

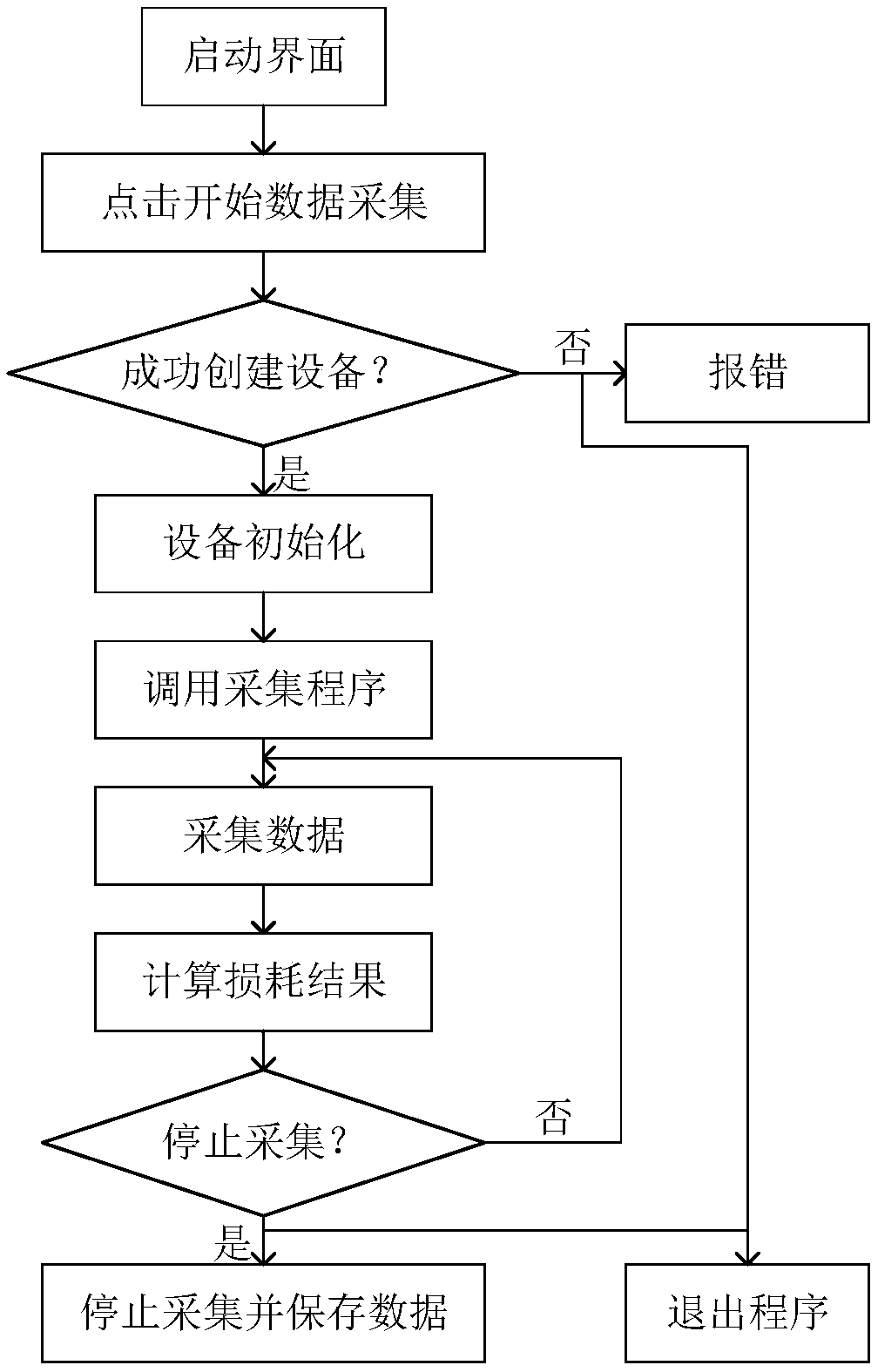

PendingCN108802499AEasy to operateMeasuring AC LossDielectric property measurementsSuperconductor elements usagePower flowLabview software

The invention discloses a device and a method for measuring alternating current losses under a superconducting magnet alternating current condition. The device mainly comprises a data acquisition module and a processing and display module. The core component of the data acquisition module is a data acquisition card used for collecting voltage and current signals when a superconducting magnet to bedetected works. Through LabVIEW software, the software and hardware online control of the data acquisition card and the processing and display module is realized, and the collected voltage and current signals are transmitted to the processing and display module. In the processing and display module, an energy calculating formula which is a voltage and current integral formula is used to process received data, the total energy change of the superconducting magnet acquired through calculation is used to subtract the energy change of the equivalent inductance of the superconducting magnet to bedetected so as to acquire the alternating current loss measurement result of the superconducting magnet to be detected. In the invention, problems that a speed is slow, operation is complex, only small coils can be measured and so on in an existing alternating current loss measurement method are solved.

Owner:HUAZHONG UNIV OF SCI & TECH

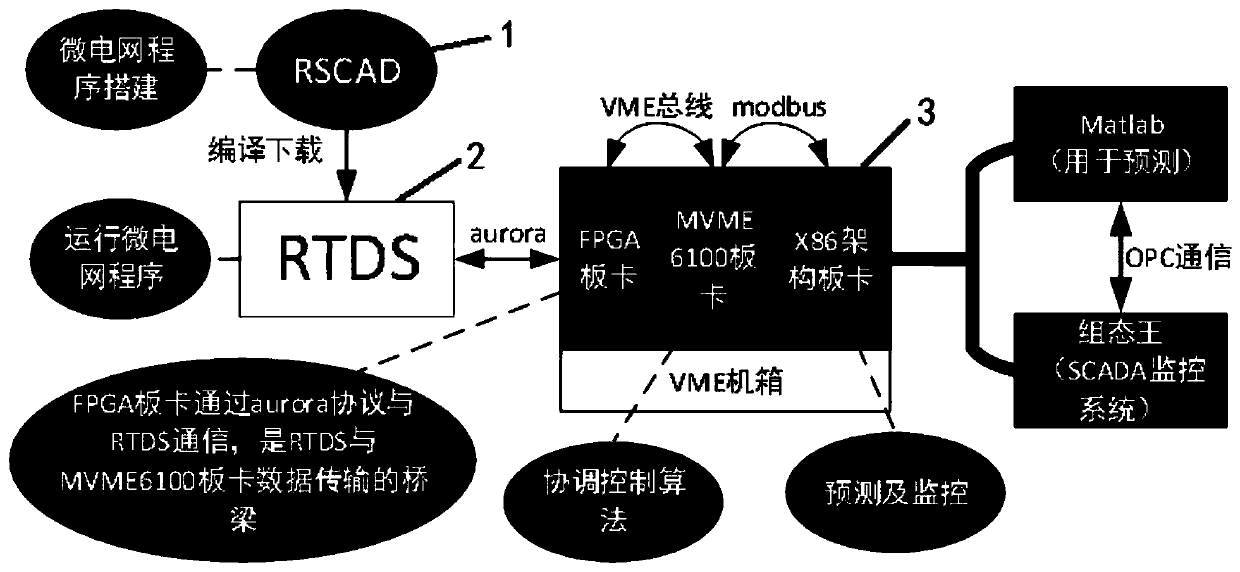

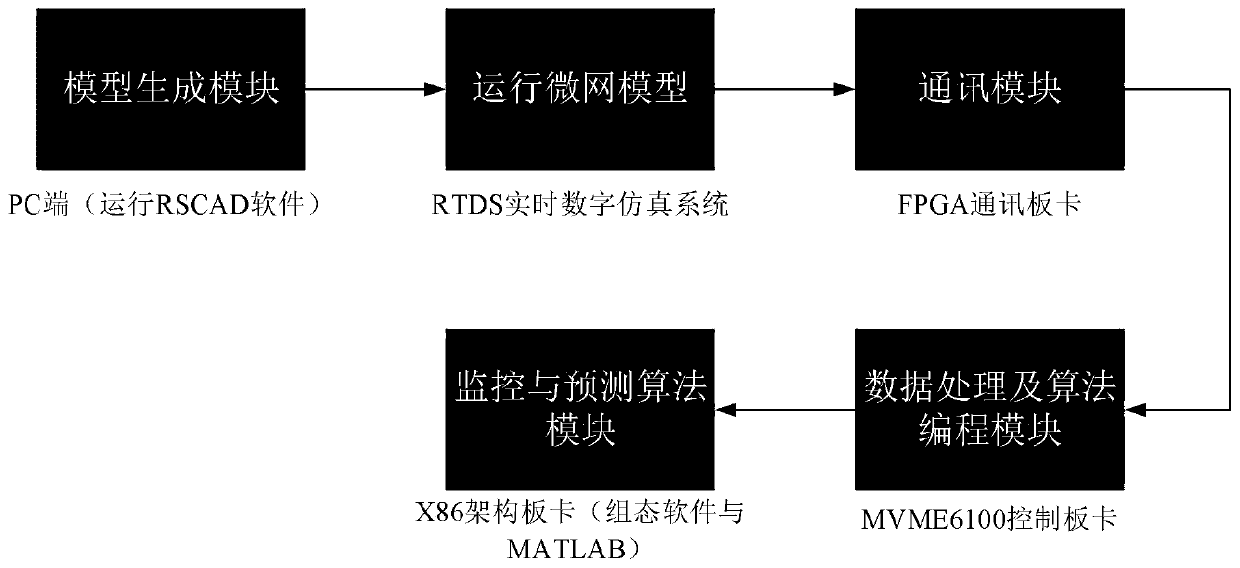

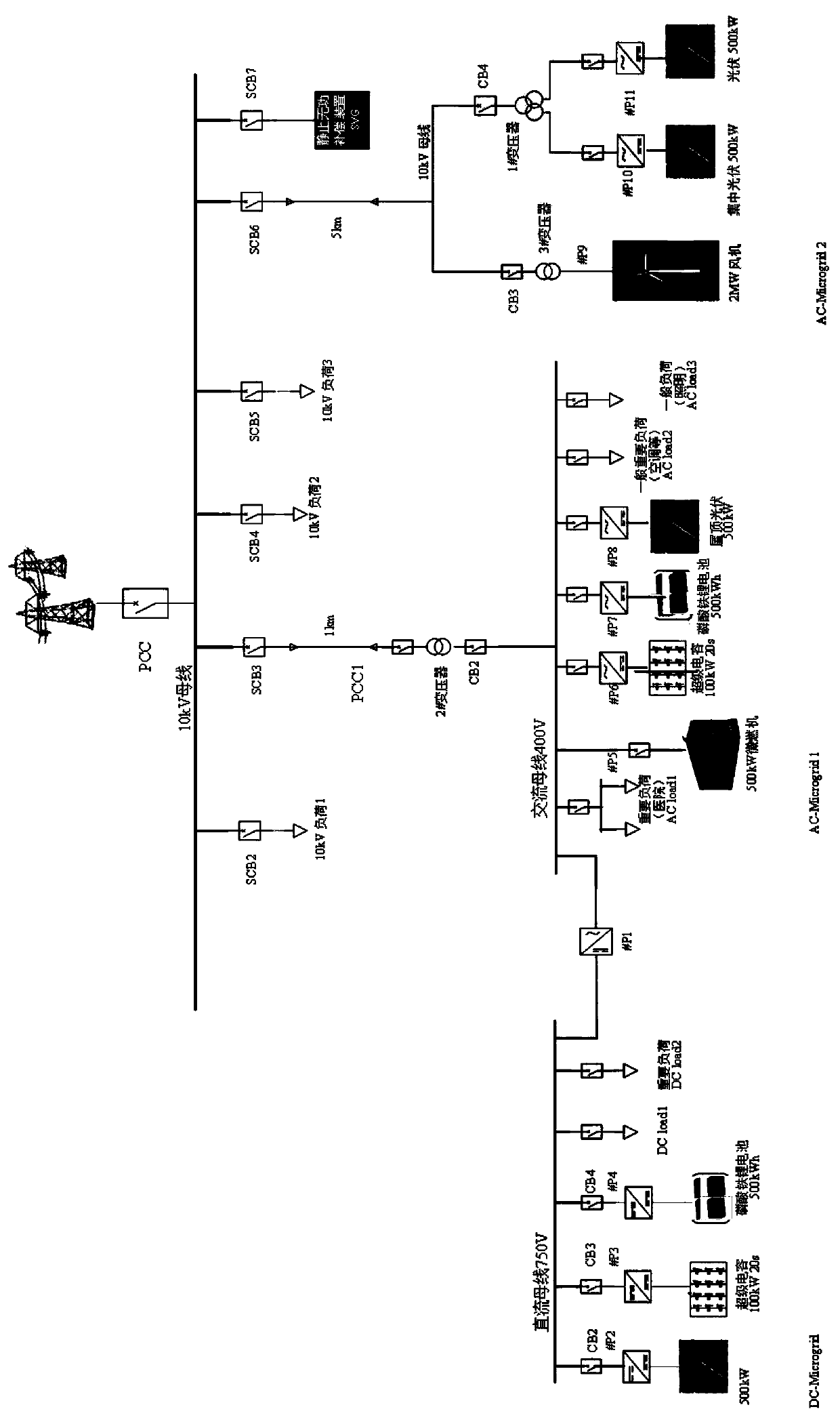

Integrated energy microgrid control experiment system based on semi-physical simulation

ActiveCN110286606AGuaranteed stabilitySolve the economic dispatch problem of power gridSimulator controlData transmissionForms of energy

The invention discloses an integrated energy microgrid control experiment system based on semi-physical simulation. The integrated energy microgrid control experiment system realizes coordinated and optimized operation of various forms of energy in an AC / DC hybrid microgrid based on an RTDS system to ensure stability, accuracy and rapidity of data transmission and control signals. The purpose of developing a VME controller is to deal with the increasingly complex integrated energy microgrid system, to achieve multi-energy complementarity, grid-source-load coordinated and optimized operation and to solve the power grid economic dispatching problem. The invention aims at developing the experiment system of the integrated energy microgrid system and performing simulation and effect verification of the microgrid structure and the operation control strategy thereof. The application of the semi-physical simulation platform can more truly reflect the operating state of the actual microgrid system and can provide ideas and methods to solve the problems in the actual engineering so as to have great practical engineering application value.

Owner:NORTH CHINA UNIVERSITY OF TECHNOLOGY

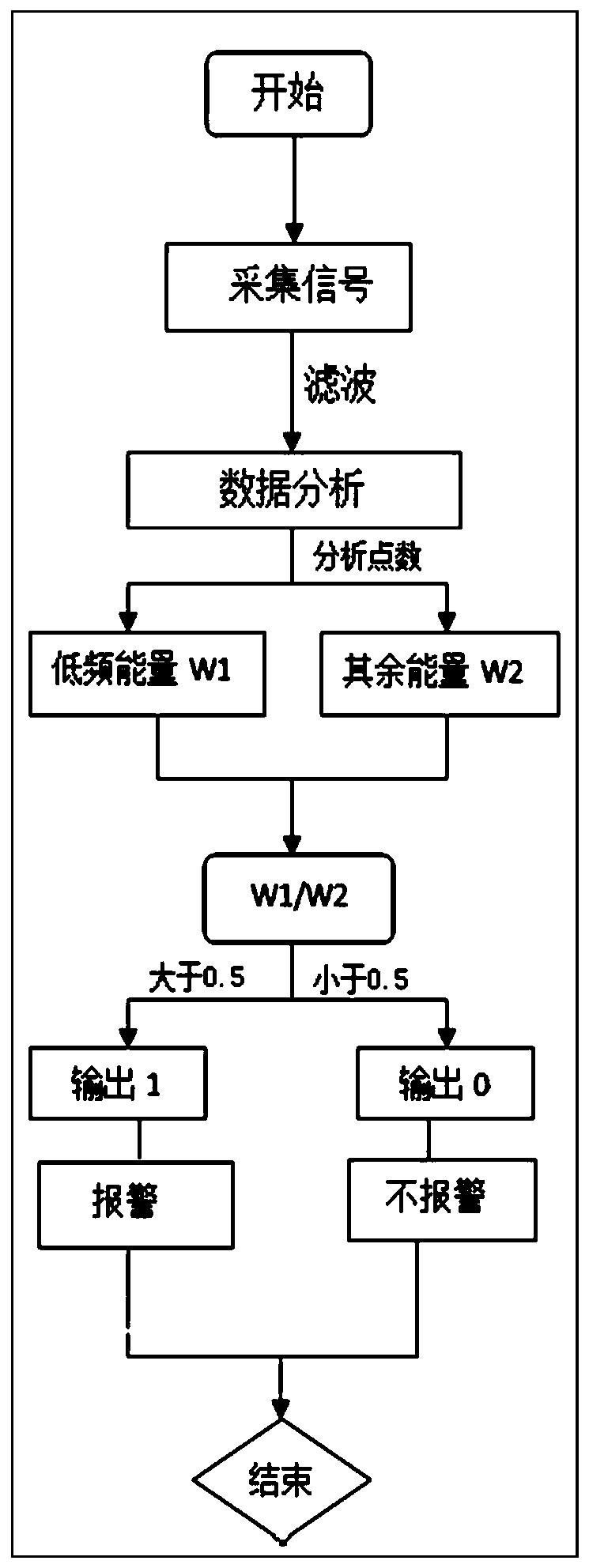

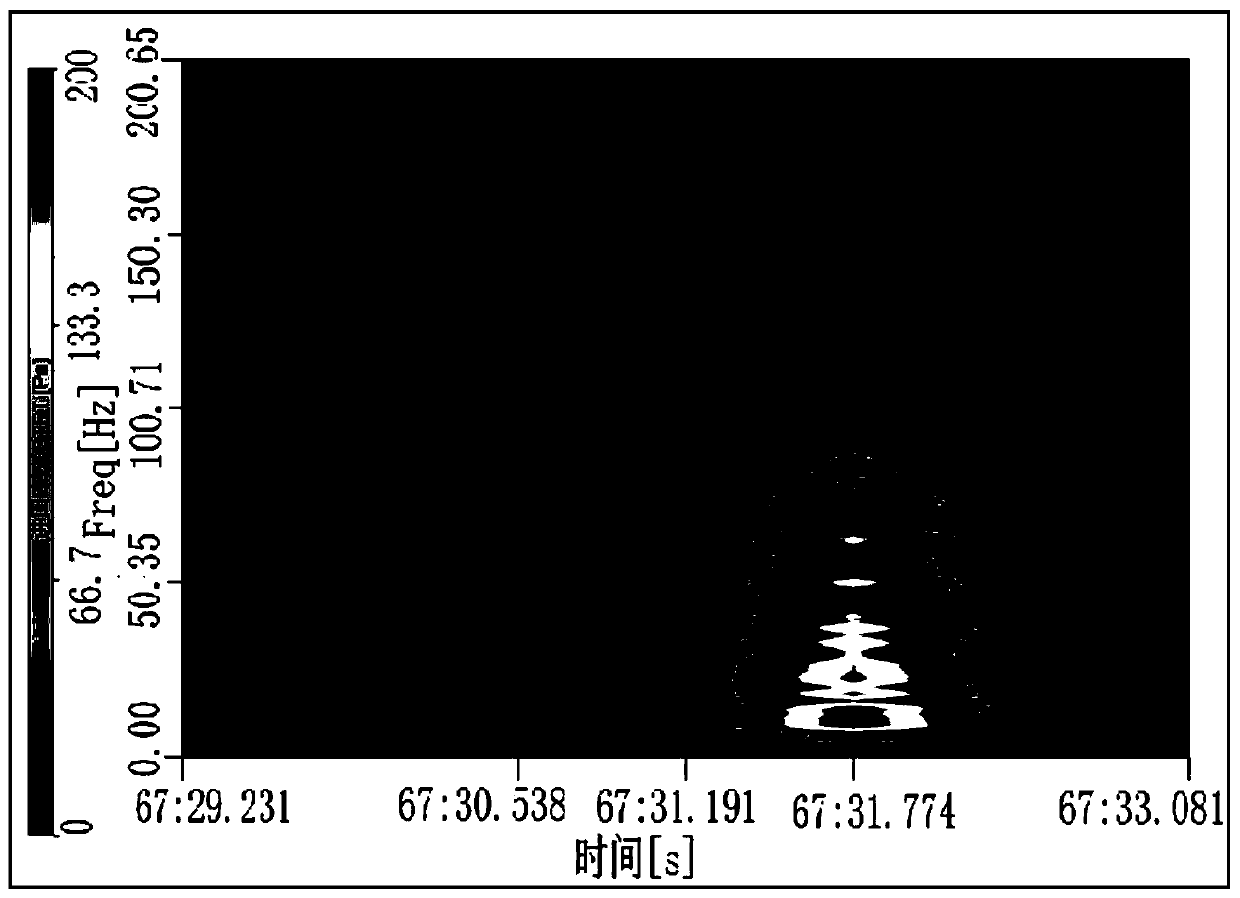

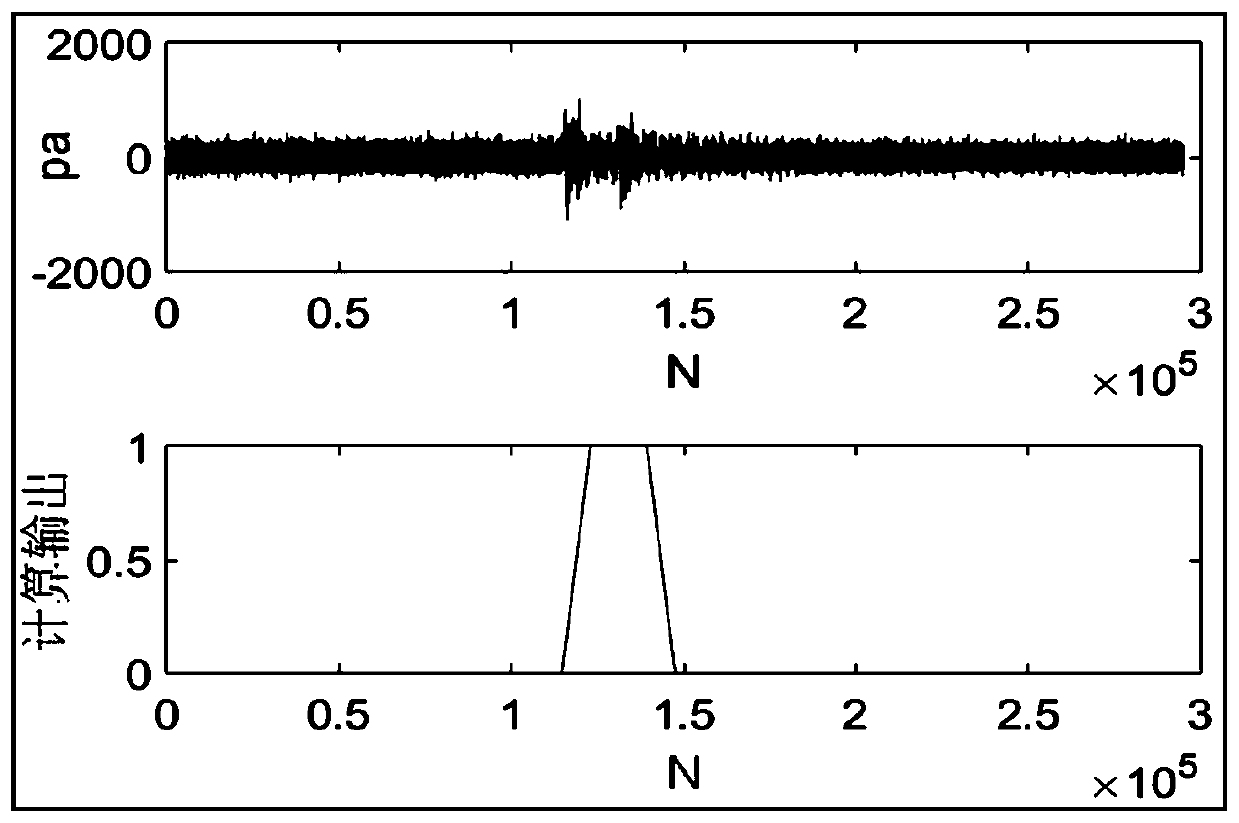

Compressor surge fault diagnosis method based on acoustic signals

InactiveCN110925233AAccurate diagnosisThe testing process is simplePump controlNon-positive displacement fluid enginesControl engineeringControl theory

The invention provides a compressor surge fault diagnosis method based on acoustic signals. The compressor surge fault diagnosis method includes the following steps that (1), a sound pressure sensor is installed on a compressor casing; (2), signals obtained by the sound pressure sensor are subjected to filtering and energy spectrum analysis; (3), the energy ratio calculating is carried out on analysis results; and (4), threshold judgment is carried out, and determining signals are output. According to the compressor surge fault diagnosis method and the low frequency acoustic characteristic phenomenon at the time of compressor surge occurring, the acoustic signals at the time of compressor surge occurring are captured by using an acoustic testing method, and a calculation method of energy ratio is used to successfully implement accurate diagnosis of compressor surge faults. The compressor surge fault diagnosis method can be applied to the on-line diagnosis of the compressor surge faults, is simple in testing and accurate in diagnosis, can be popularized and applied on compressors, and has good economic benefits and great practical engineering application value.

Owner:AECC SICHUAN GAS TURBINE RES INST

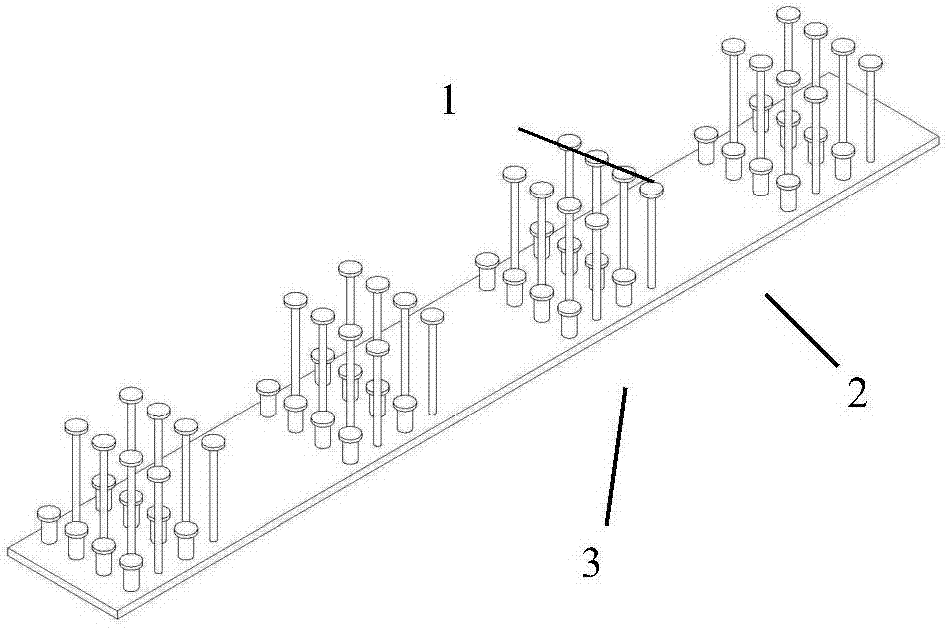

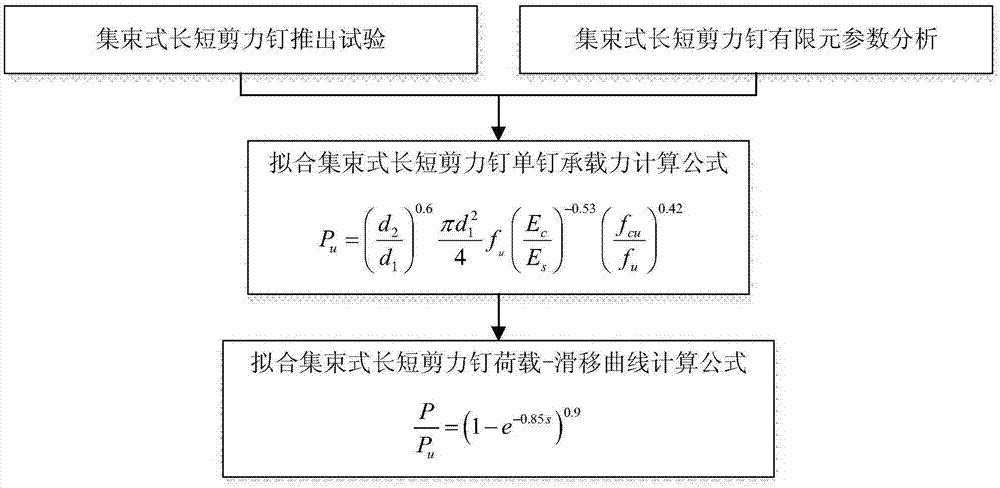

Calculation method for ultimate shear-carrying capacity of bundled long and short shear nails

ActiveCN107515975AAccurate calculation of ultimate shear capacityAccurately determine the load-slip variation relationshipGeometric CADSpecial data processing applicationsElement analysisEngineering

The present invention provides a calculation method for an ultimate shear-carrying capacity of bundled long and short shear nails. The method comprises: firstly, launching a push-out test and finite element analysis of long and short shear nails to obtain an average single nail ultimate shear-carrying capacity, studying rules of effects of parameters of long and short shear nails, such as diameter, length, strength, elastic modulus and concrete strength, on shear-carrying capacity of a shear nail, performing non-linear regression analysis on ultimate shear-carrying capacity of the shear nail by a differential evolution method, and establishing a calculation formula of the ultimate shear-carrying capacity of the bundled long and short shear nails; and then, studying load, ultimate shear-carrying capacity and a relative slip value between a steel beam and a concrete slab of the long and short shear nails, and performing regression analysis to obtain a calculation formula of a load-slip curve of the bundled long and short shear nails. The method provided by the present invention solves the problem that the prior specification cannot consider staggered arrangement of different lengths and diameters of the shear nails for calculation of capacity, and provides technical supports for design long and short shear nails in steel-mixed composite structures.

Owner:WUHAN UNIV OF TECH

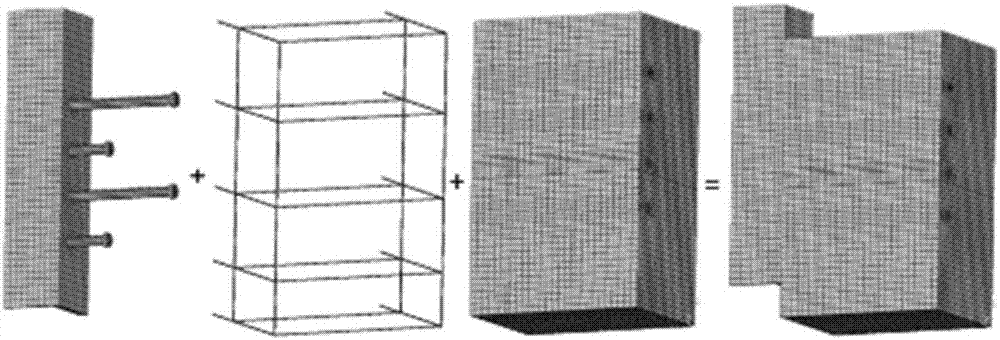

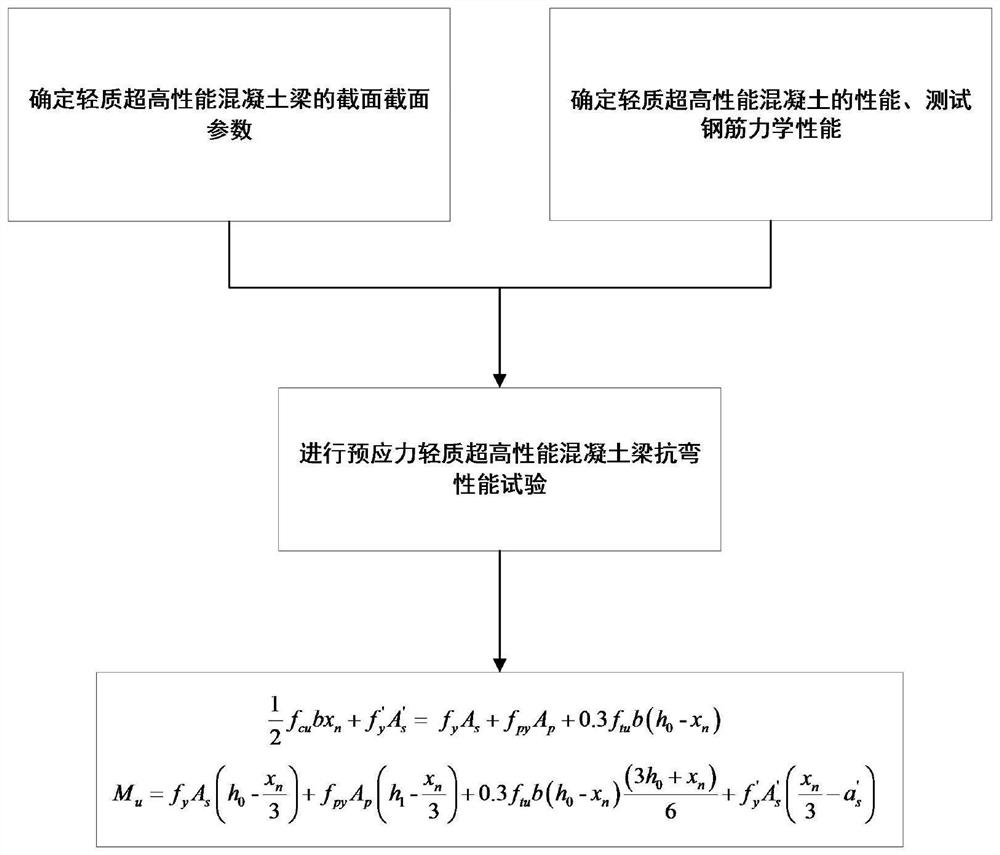

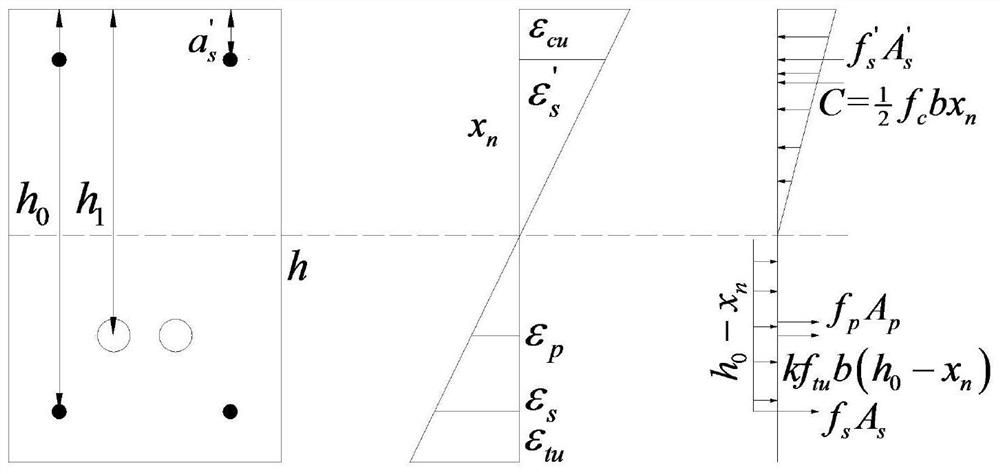

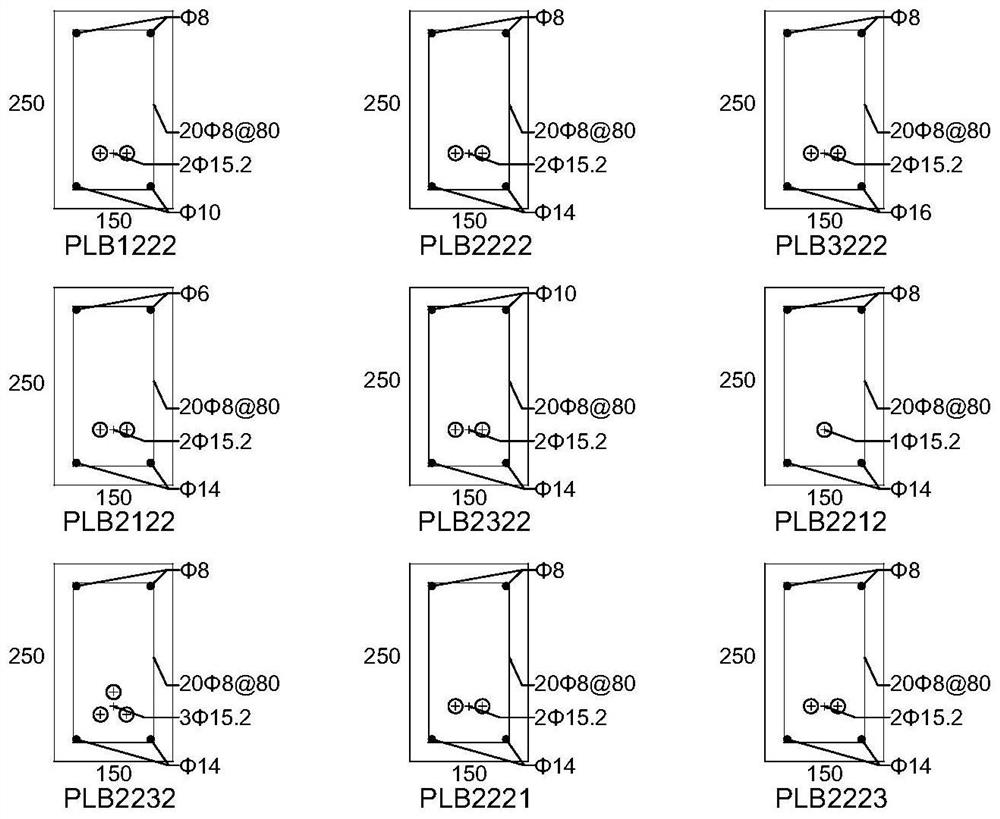

Method for determining flexural capacity of prestressed light ultra-high performance concrete beam

PendingCN113536418AEasy way to determinePractical engineering application value is greatGeometric CADDesign optimisation/simulationBridge engineeringPre stress

The invention belongs to the technical field of civil construction and transportation industry bridge engineering. The invention discloses a method for determining the flexural capacity of a prestressed light ultra-high performance concrete beam. The method is characterized by comprising the following steps: 1) determining basic parameters of the prestressed light ultra-high performance concrete beam; 2) determining the performance of the lightweight ultra-high performance concrete, and testing the mechanical properties of the reinforcing steel bar; (3) carrying out a bending test on the prestressed light ultra-high performance concrete beam to obtain a bending bearing capacity calculation formula of the prestressed light ultra-high performance concrete beam; and 4) substituting the corresponding data into a flexural capacity calculation formula of the prestressed light ultra-high performance concrete beam to determine the flexural capacity of the prestressed light ultra-high performance concrete beam. According to the method, the problem that an existing standard flexural capacity formula is not suitable for the prestressed light ultra-high performance concrete beam is solved, and theoretical and test basis is provided for application of LUHPC new materials in bridge engineering.

Owner:WUHAN UNIV OF TECH

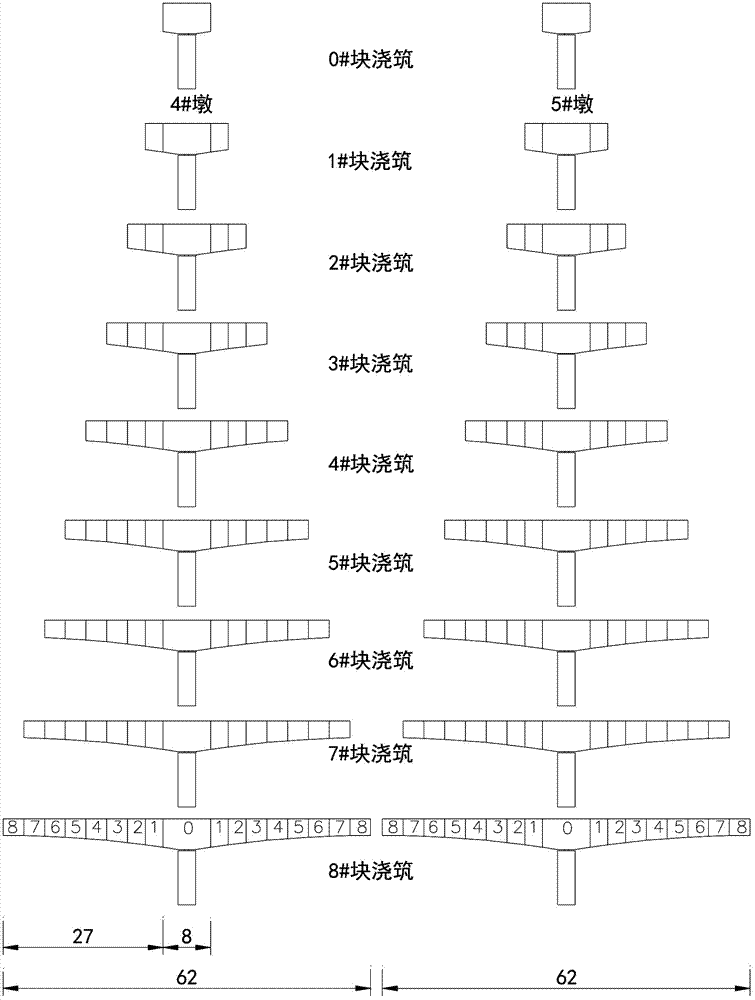

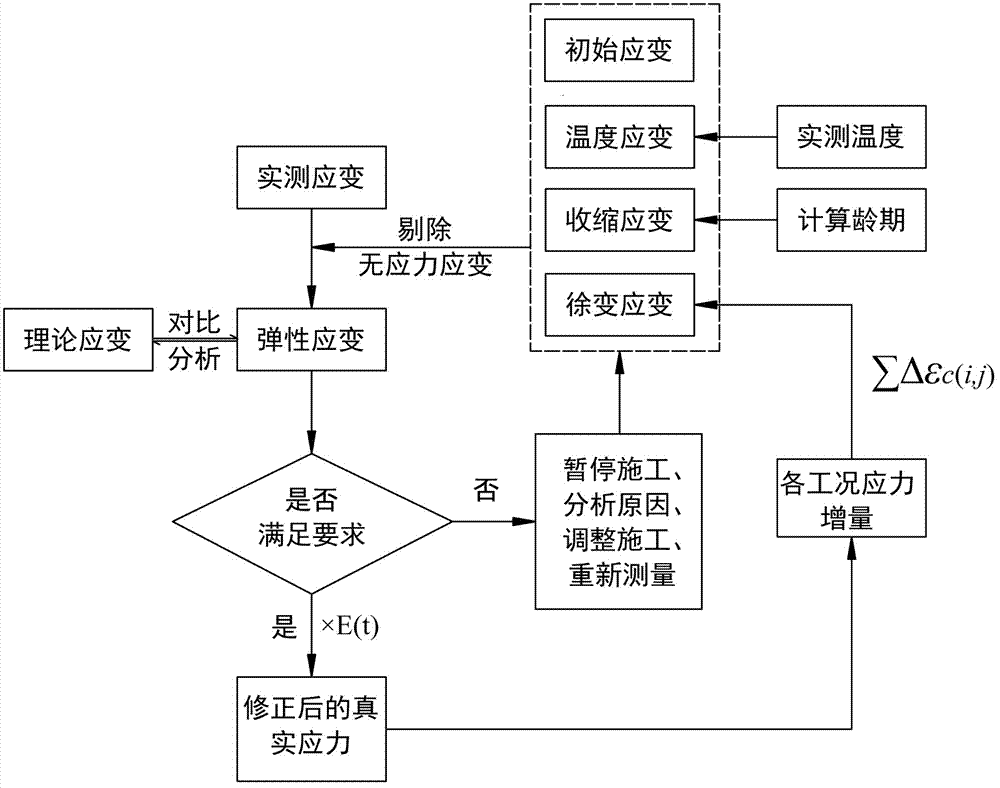

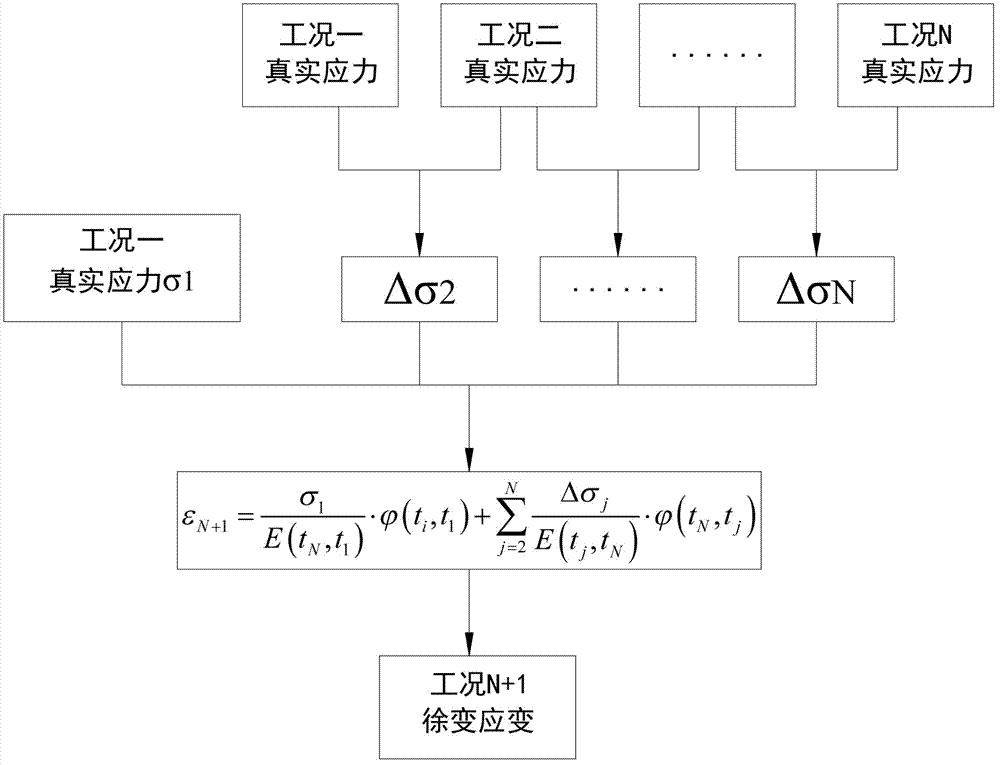

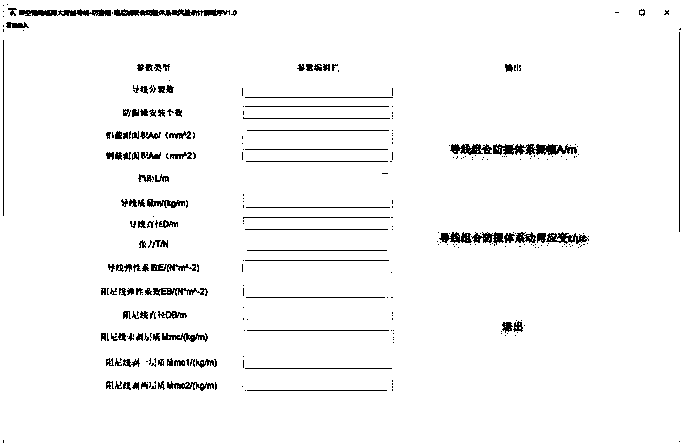

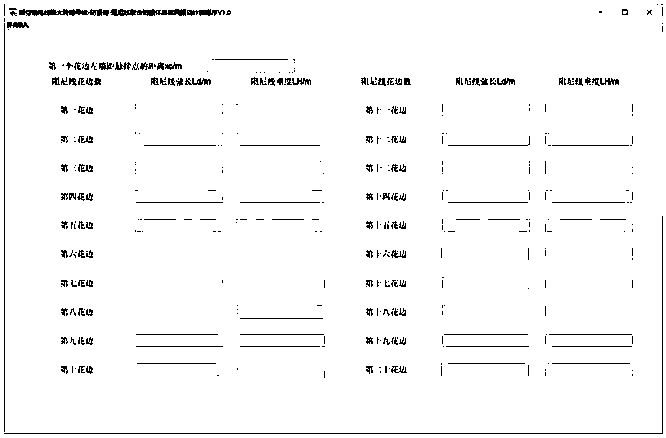

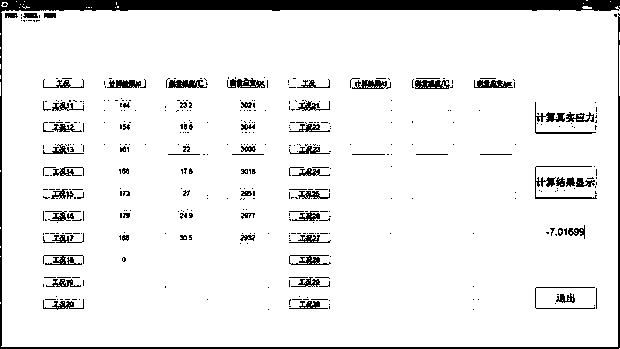

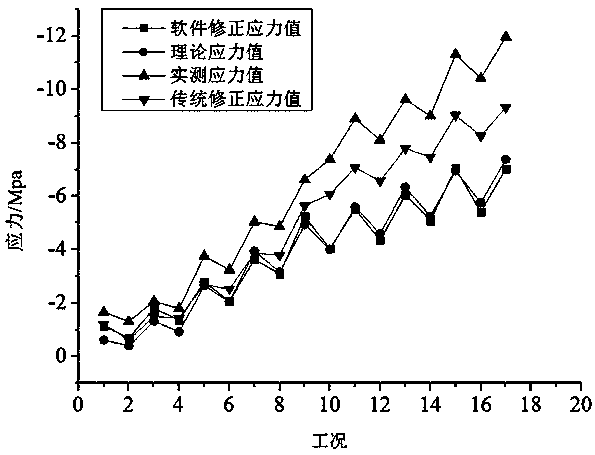

Method for correcting main girder stress of large-span prestressed concrete cantilever construction bridge

ActiveCN107423500AHigh solution accuracyImprove solution efficiencyGeometric CADDesign optimisation/simulationCreep strainPre stress

The invention relates to a method for correcting a main girder stress of a large-span prestressed concrete cantilever construction bridge. In a creep strain calculation method considering a section construction characteristic of the large-span bridge, a time-varying elastic modulus and an equivalent elastic modulus between any two age periods are introduced; non-stress strain generated by creep is more accurately removed; and a corresponding secondary development technology is selected for performing secondary development on MATLAB, so that parametric interface operation is realized. The method comprises the following steps of Step 1: calculating a strain value caused by concrete creep; Step 2: calculating the influence of the time-varying elastic modulus on strain correction; Step 3: calculating a strain value caused by a temperature difference; Step 4: calculating a strain value caused by concrete shrinkage; and Step 5: based on secondary development of a MATLAB platform, compiling a main girder stress correction calculation program, and performing calculation. According to the method, the real main girder stress in the bridge construction process can be accurately calculated; the stress calculation and analysis efficiency in construction control can be improved; and the development of a large-span bridge construction control technology can be better served.

Owner:CHINA THREE GORGES UNIV

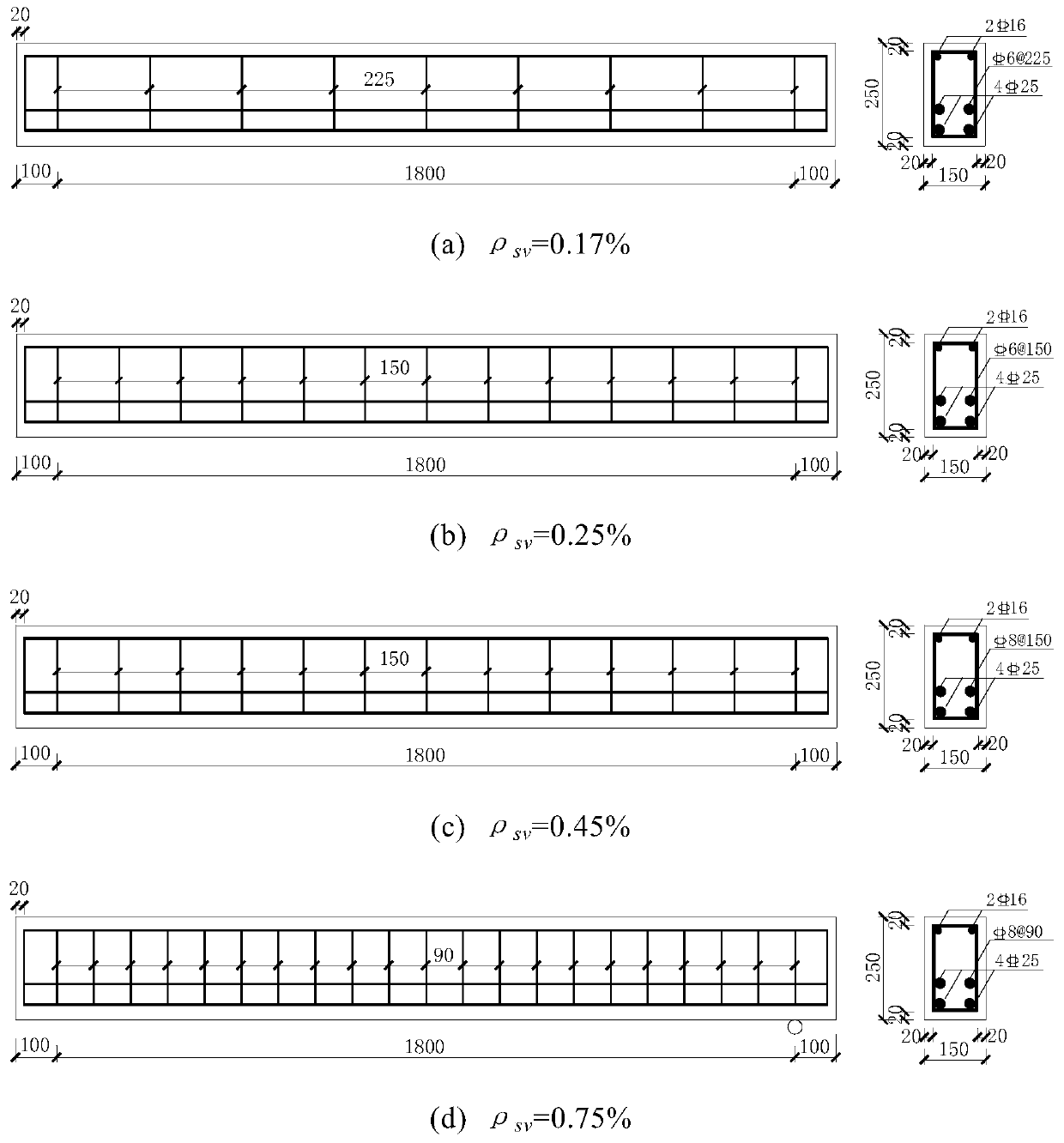

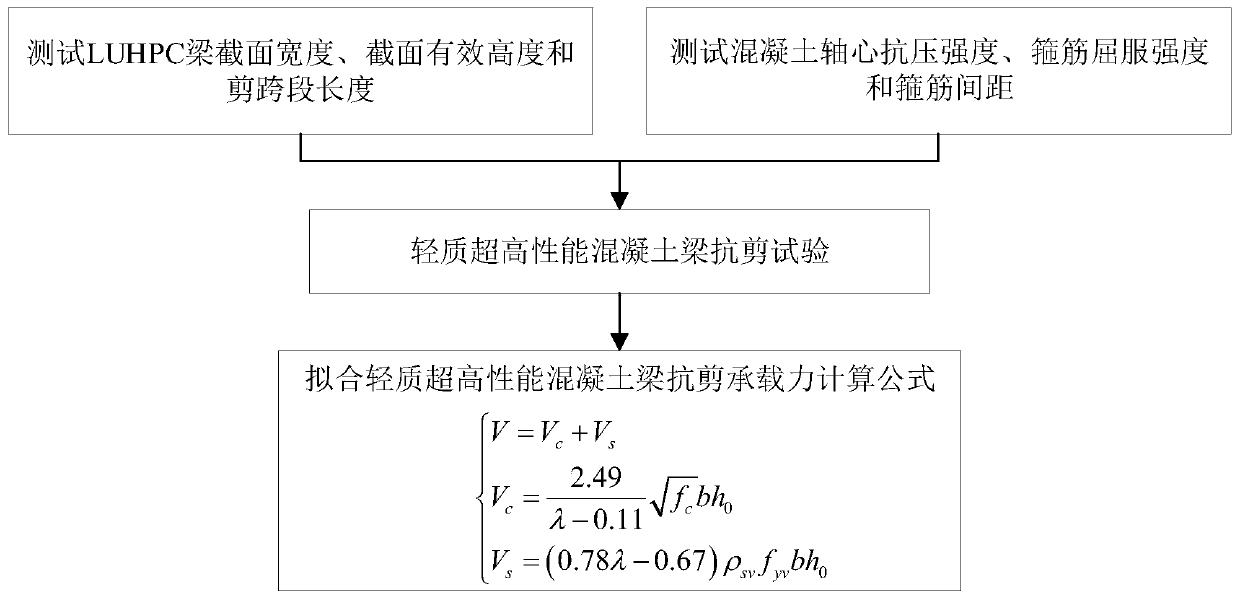

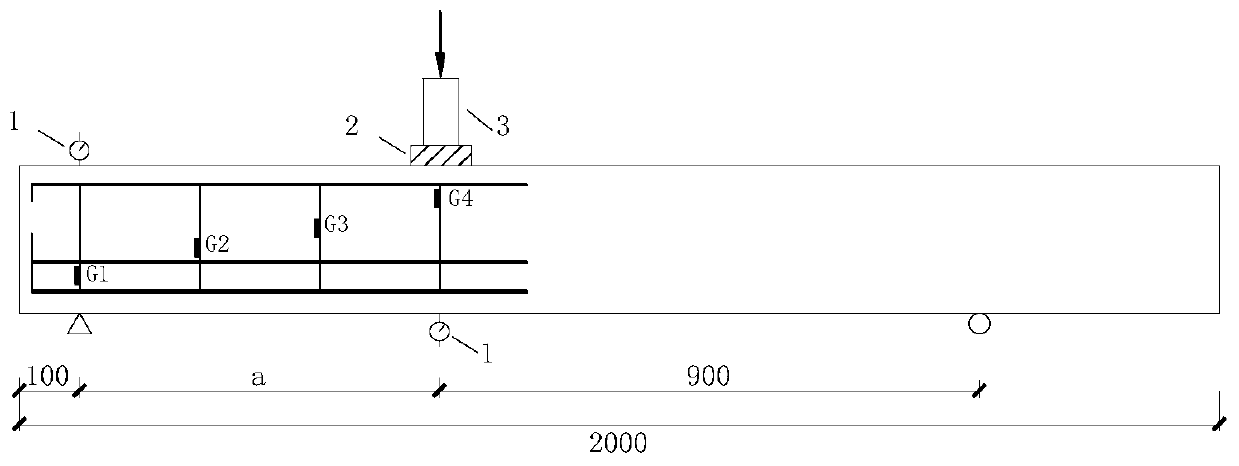

Method for determining shear capacity of light ultra-high performance concrete beam

PendingCN111400801AAccurate determination of shear capacitySimple method for determining shear capacityGeometric CADCompressive resistanceTest beam

The invention discloses a method for determining the shear capacity of a light ultra-high performance concrete beam. The method is characterized by comprising the following steps: testing the sectionwidth, the section effective height and the shear span section length of the LUHPC beam; testing the axial compressive strength, the stirrup yield strength and the stirrup spacing of the concrete; carrying out an LUHPC beam shear test, obtaining the shear bearing capacity of the test beam, studying the influence rule of the shear span ratio and the hooping rate on the LUHPC beam shear bearing capacity, carrying out the nonlinear regression analysis on the LUHPC beam shear bearing capacity through a differential evolution method, and establishing a shear bearing capacity calculation formula ofthe LUHPC beam; and substituting the required data into a calculation formula to obtain the shear capacity of the light ultra-high performance concrete beam. According to the method, the problem thatan existing standard shear capacity formula is not suitable for the LUHPC beam is solved, and technical support is provided for shear design of the LUHPC beam. According to the method, the shear capacity of the LUHPC beam can be accurately determined, and the determination method is simple and easy to implement.

Owner:WUHAN UNIV OF TECH

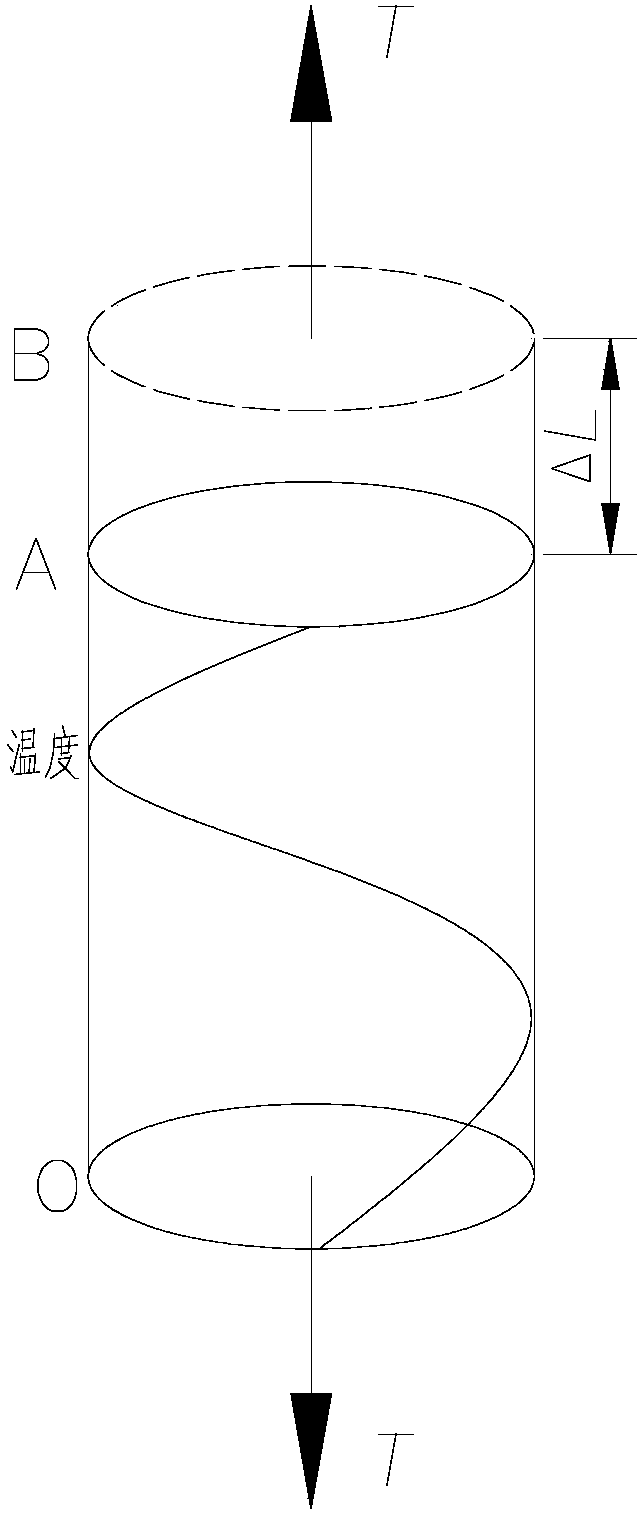

Method considering influence of multiple factors for predicting fatigue life of large span power transmission wire

InactiveCN108444823AReflect the real stress stateProcessing speedData processing applicationsMaterial strength using tensile/compressive forcesCarrying capacityEnergy balance equation

A method considering influence of multiple factors for predicting fatigue life of a large span power transmission wire is disclosed; first, considering the influence of wind speed, ambient temperatureand current carrying capacity on the temperature of the wire, and calculating the actual temperature of the wire; then establishing a mechanical equilibrium equation of the power transmission wire, considering the influence of the temperature on the stress of the wire, and calculating the stress of a steel core aluminum strand of the wire under tension and temperature effects; using an energy method to establish an energy balance equation of the power transmission wire, and calculating the dynamic stress amplitude of the power transmission wire; calculating the equivalent alternating stress of the power transmission wire, and calculating the number of times of vibration resistance of the power transmission wire; calculating the annual vibration cycle number of the power transmission wireunder different frequencies according to the probability distribution of wind speeds and wind directions at each level; and finally, improving a traditional Miner method, considering the influence ofthe interaction between stresses of each level of the wire on the fatigue of the wire, and calculating and evaluating the fatigue life of the wire. The method for calculating the fatigue life of the large span power transmission wire is high in precision and high in speed, and is more in line with the engineering practice of the power transmission wire.

Owner:CHINA THREE GORGES UNIV

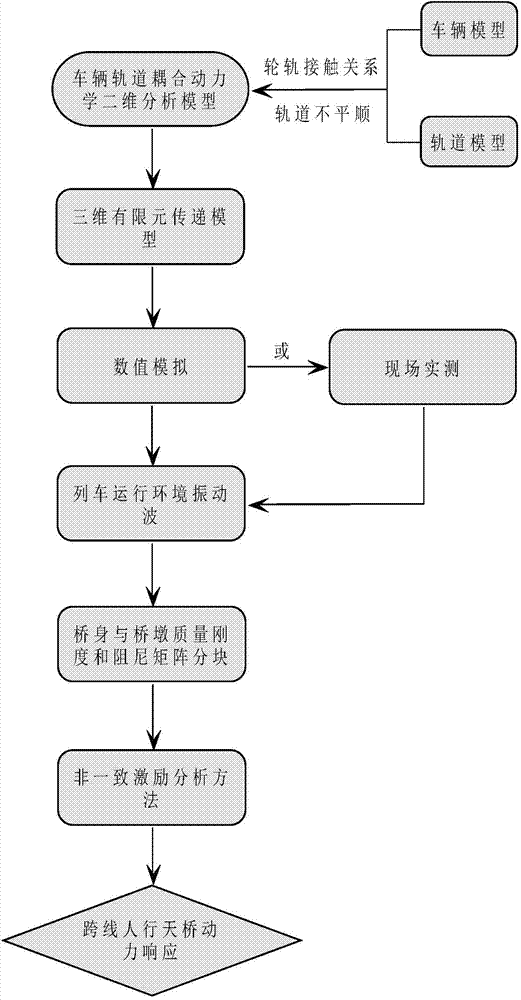

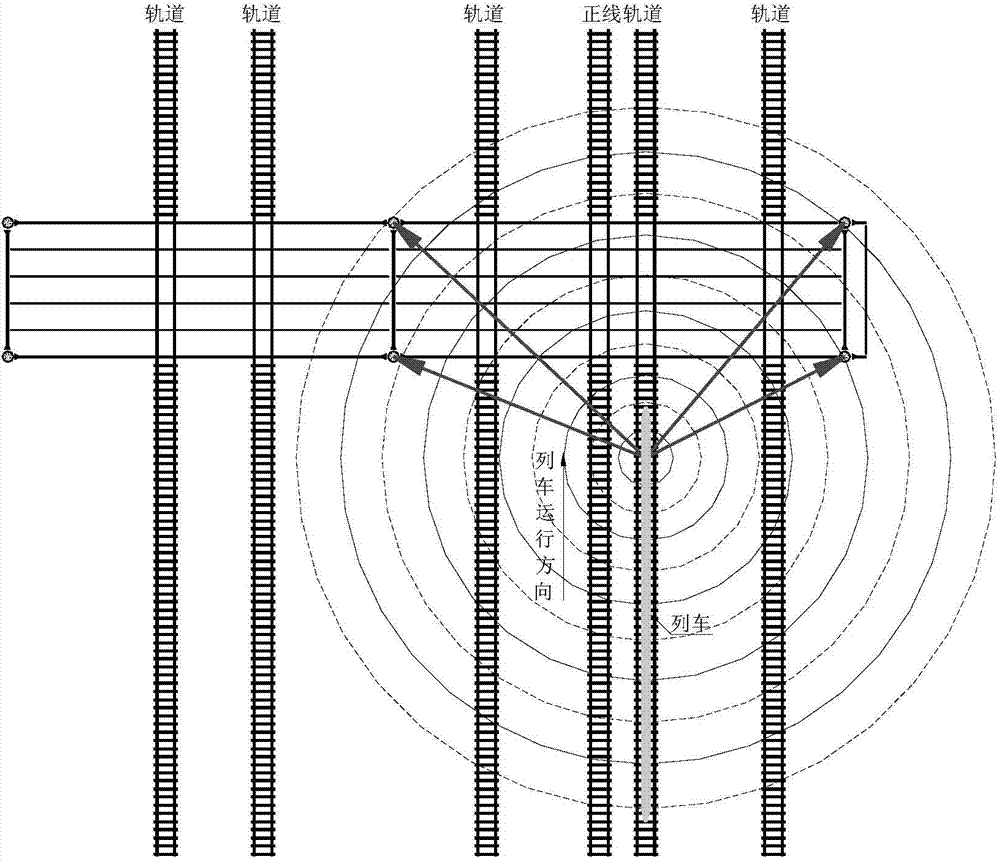

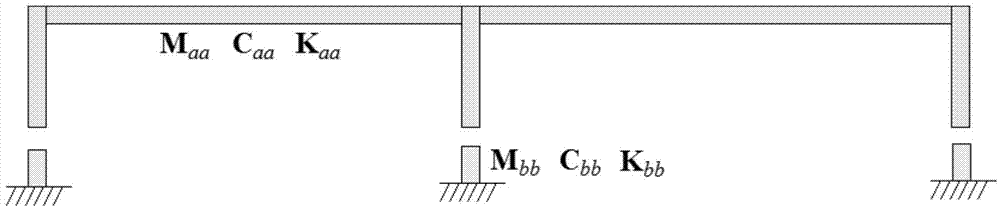

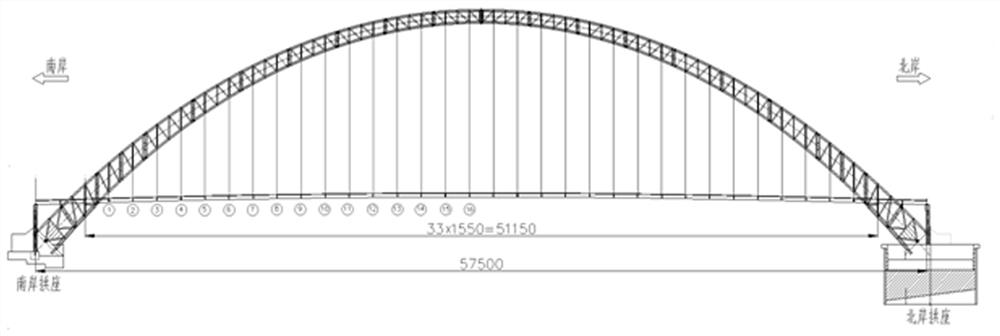

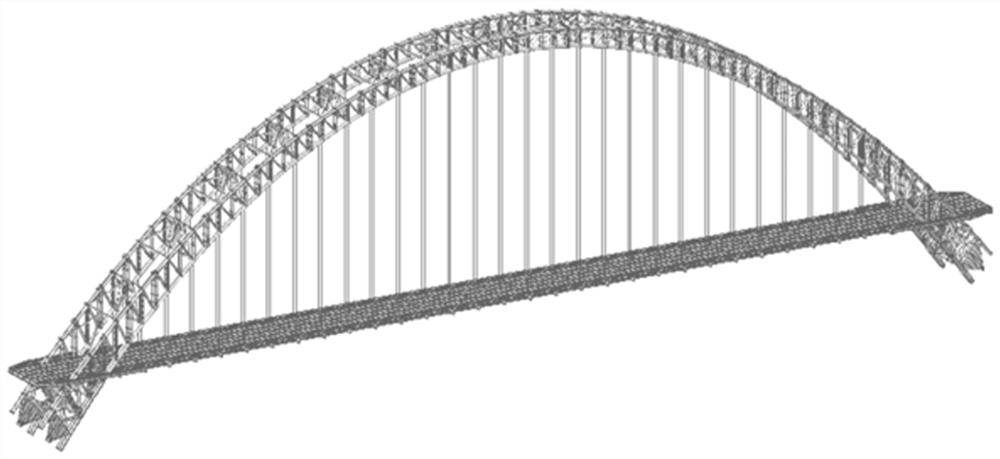

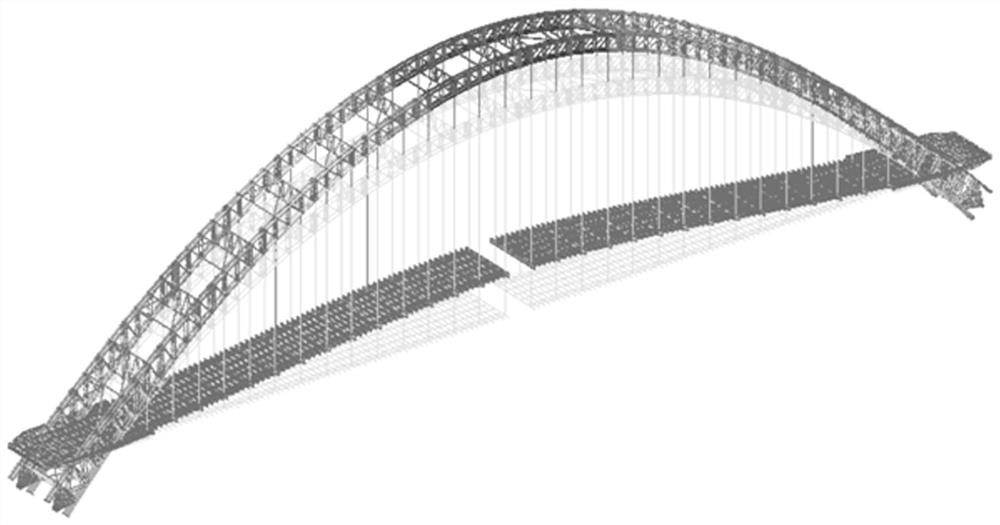

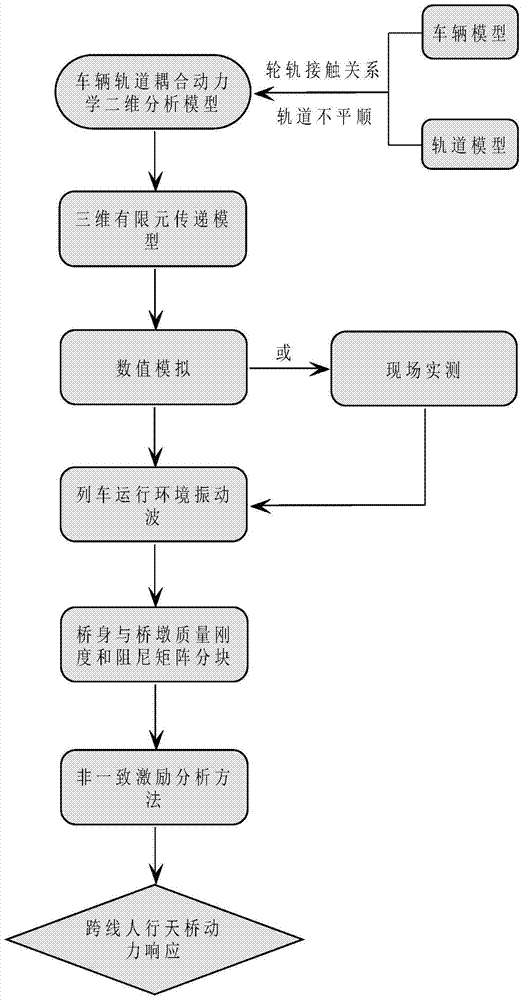

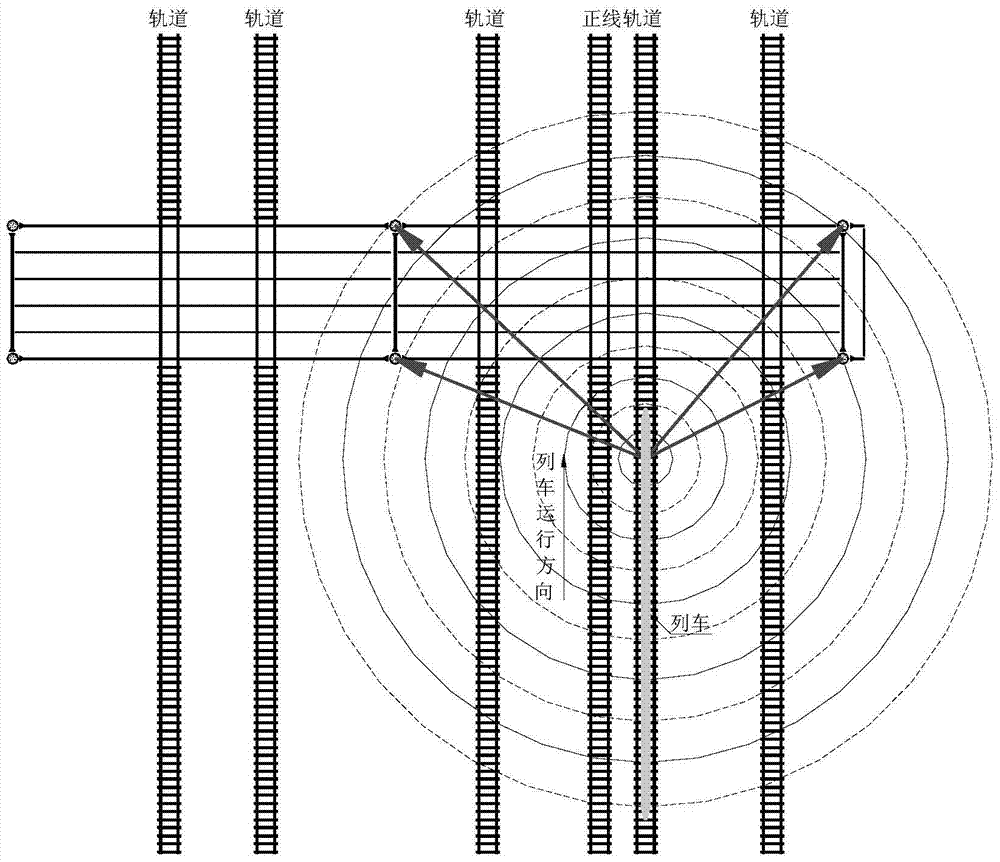

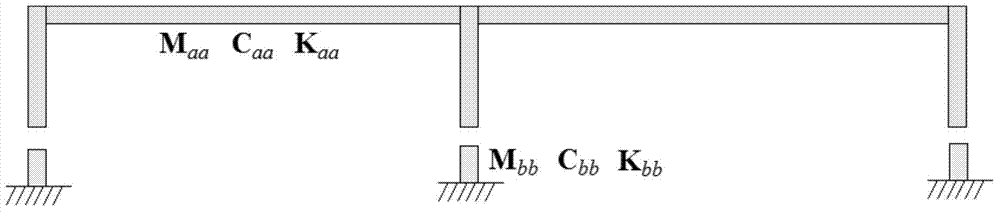

Computing method of dynamic response under nonuniform excitation of overline overbridge

InactiveCN104731998APractical engineering application value is greatSpecial data processing applicationsAnalysis methodComputer science

The invention relates to a computing method of dynamic response under nonuniform excitation of an overline overbridge. The computing method of dynamic response under the nonuniform excitation of the overline bridge relates to the computing method of dynamic response of the overline pedestrian overbridge under the action of the nonuniform excitation of a main-line train, the dynamic response of the overline pedestrian overbridge serves as a target value, considering that the nonuniform excitation is generated at the position of a bridge pier of the overline pedestrian overbridge during the high-speed running process of the train, the equation of motion of the overline pedestrian overbridge under the action of the nonuniform excitation is deduced, and the response of the overline pedestrian overbridge under the action of the train can be obtained according to a numerical integration. According to the computing method of dynamic response under the nonuniform excitation of the overline bridge, the analytic method of the nonuniform excitation is brought out creatively to be used for calculating the vibration response under the nonuniform excitation acting on the position of the bridge pier of the overline pedestrian overbridge when the main-line train passing through at a high speed under the overline pedestrian overbridge, the computing method of dynamic response under the nonuniform excitation of the overline bridge is suitable for dynamic response analyses of all overline pedestrian overbridges under the action of the main-line trains and has a comparatively large practical engineering application value and innovativeness.

Owner:WUHAN UNIV OF TECH

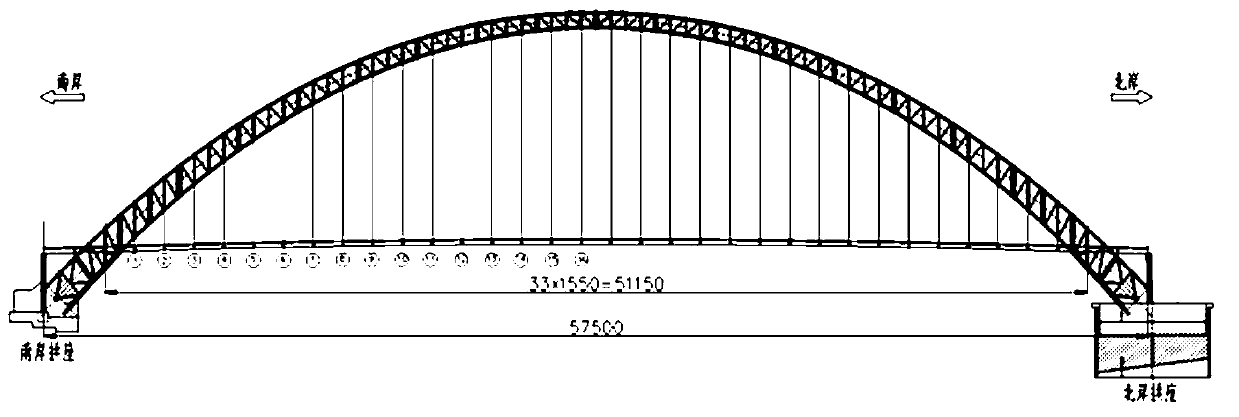

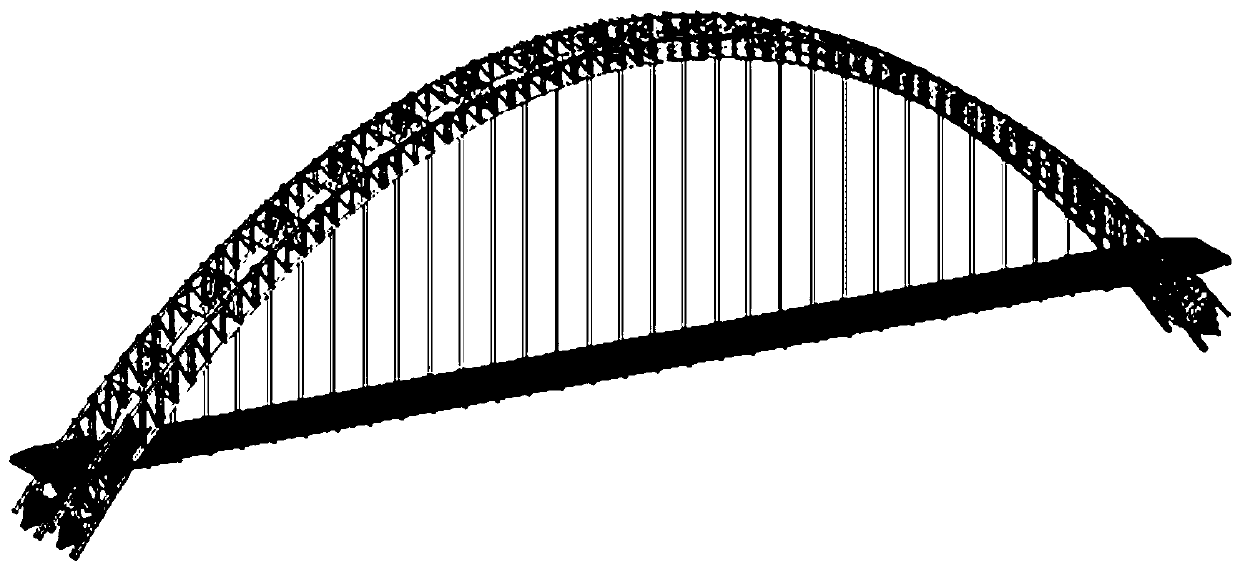

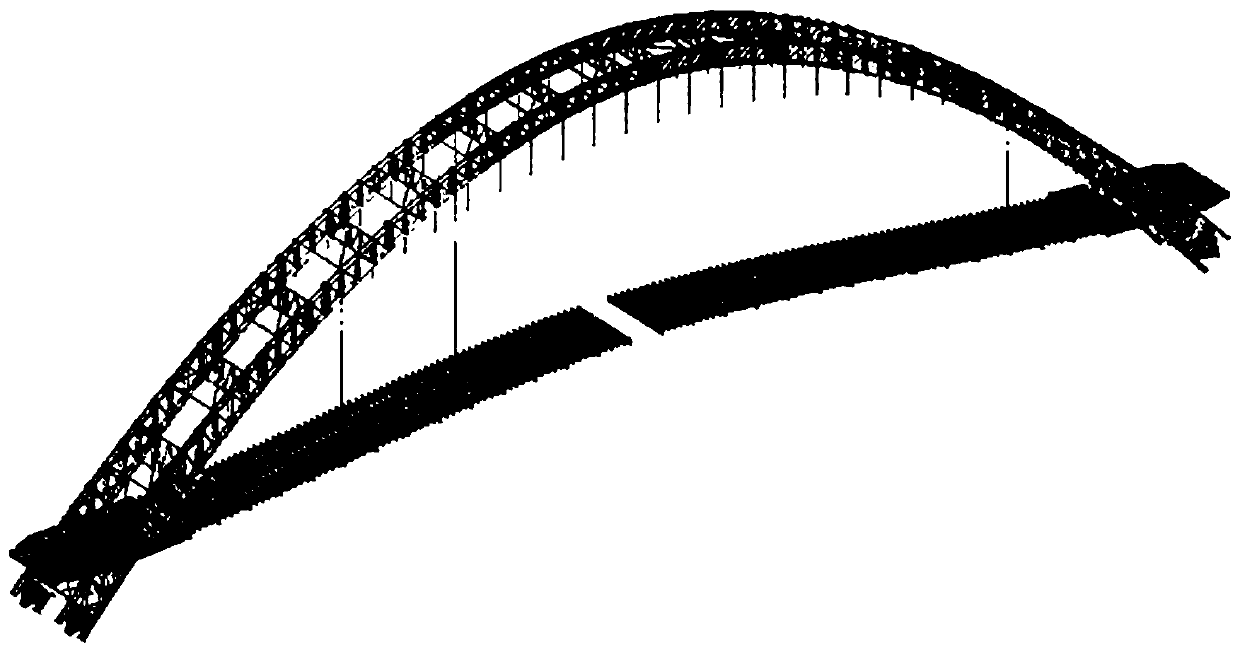

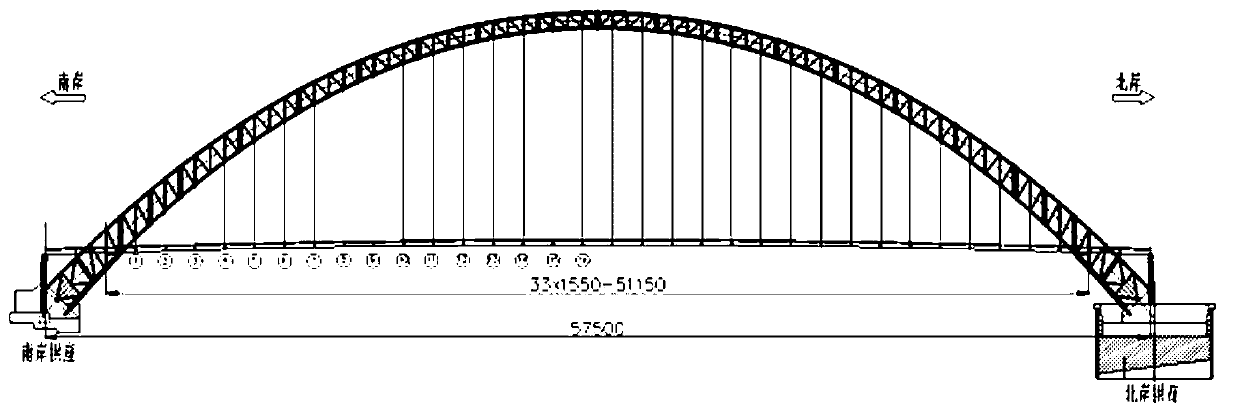

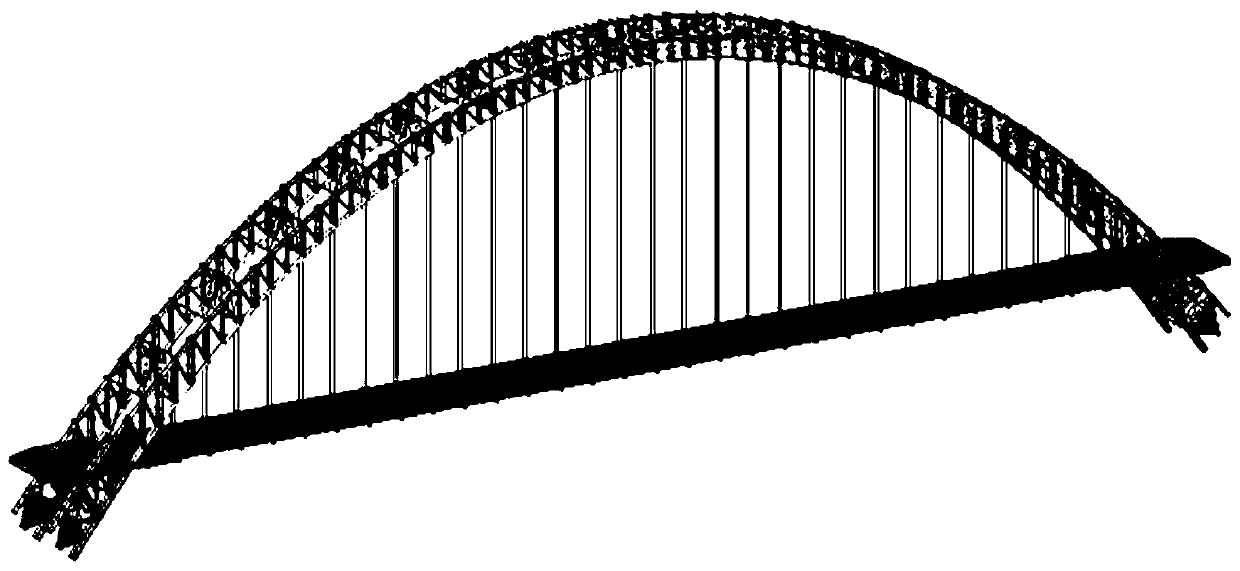

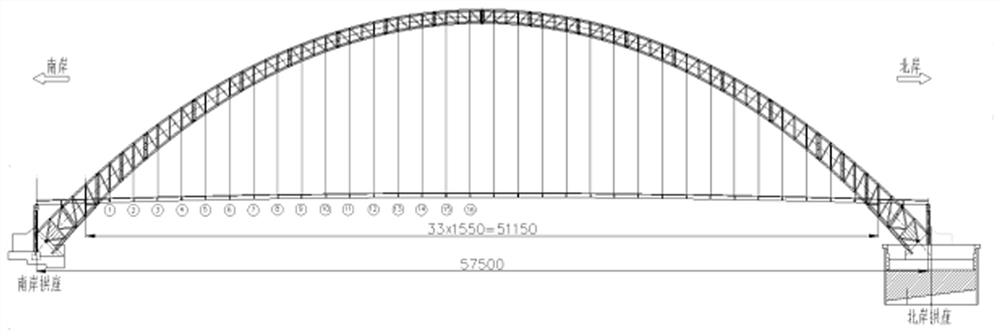

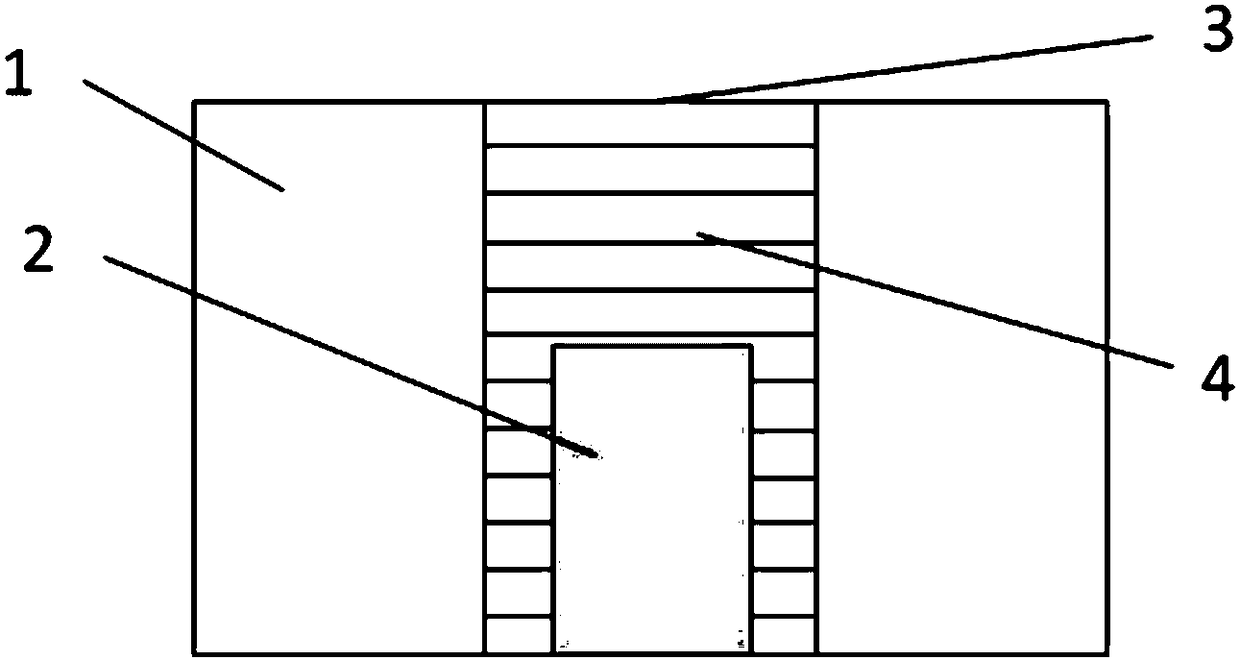

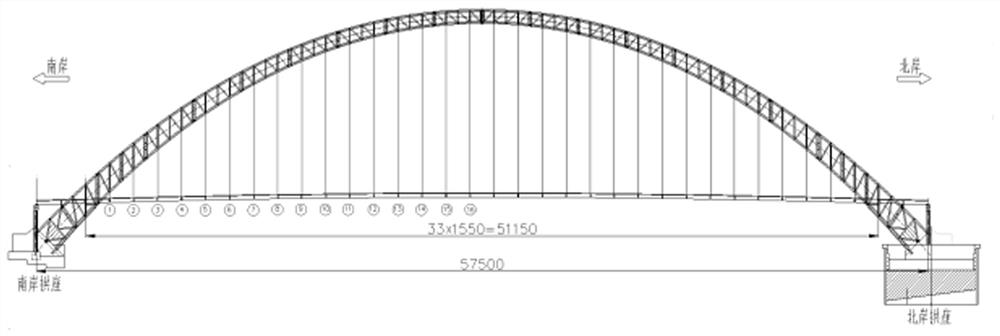

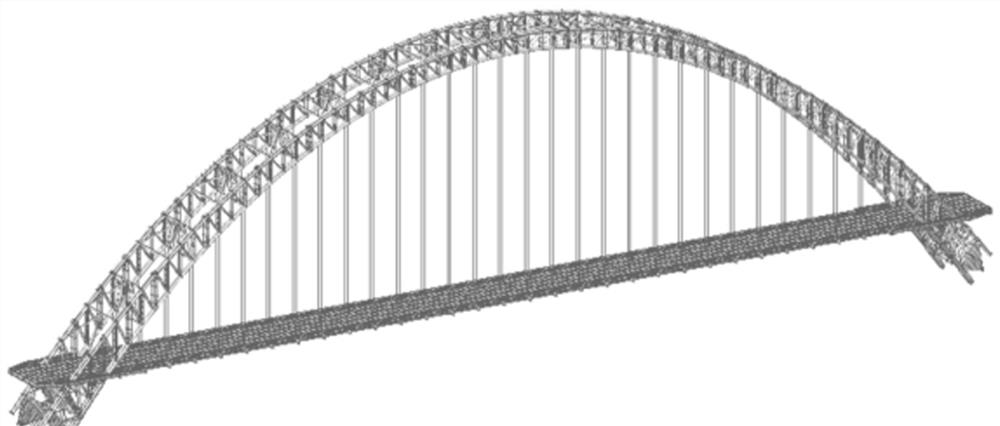

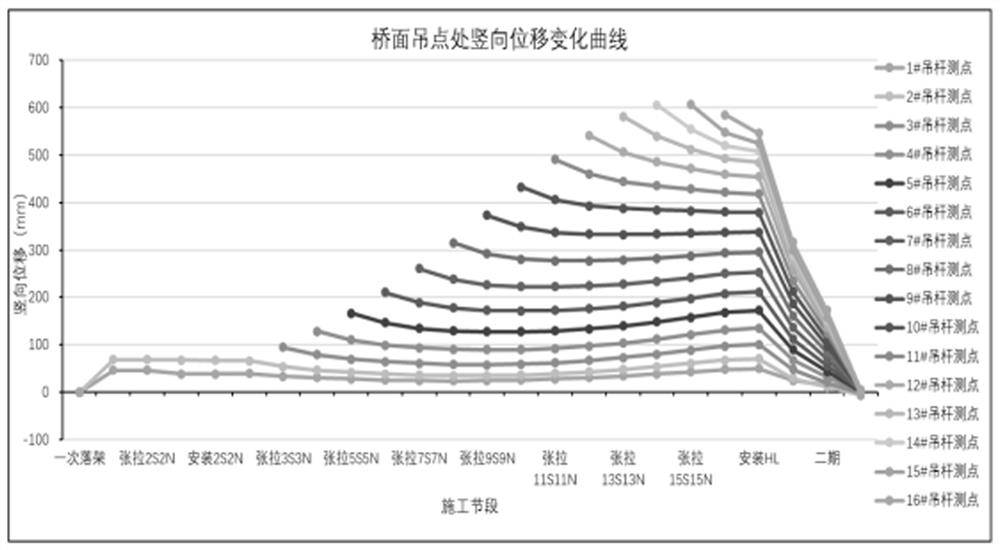

Arch bridge grid beam hoisting displacement control method capable of eliminating temperature influence

ActiveCN111576229ALittle influence of temperatureEliminate displacement cumulative error valueGeometric CADDesign optimisation/simulationEconomic benefitsBridge deck

The invention discloses an arch bridge grid beam hoisting displacement control method capable of eliminating temperature influence. Displacement control in the process is carried out by taking an archbridge with a suspender as an engineering object; a temperature correction factor is introduced, the displacement of the hoisting construction of the arch bridge grid beam is controlled,the influenceof the temperature on the displacement of the grid beam is eliminated,the minimum temperature influence of the hoisting grid beam is used as a target function,analysis is conductedby taking the displacement for controlling bridging closest to a reasonable bridging state as a constraint condition,the problem that the displacement of the grid beam is not easy to control due to the influence of temperature is well solved,the problems that the bridge floor is not smooth, the driving comfort is poor, the vehicle speed cannot meet the design requirement, and the traffic capacity is poor are solved,the arch bridge grid beam hoisting construction period is greatly shortened, the risk of forcibly selecting night construction is reduced, the economic cost is saved, wide application and popularization prospects are achieved, and huge economic benefits are brought.

Owner:GUANGXI TRANSPORTATION SCI & TECH GRP CO LTD +1

Determination method of initial completion initial cable force of cable-stayed bridge

ActiveCN101937485BFast convergenceReduce calculation errorsSpecial data processing applicationsStructural engineeringControl theory

Owner:WUHAN UNIV OF TECH

Median-value average filtering-based digital speed measuring method

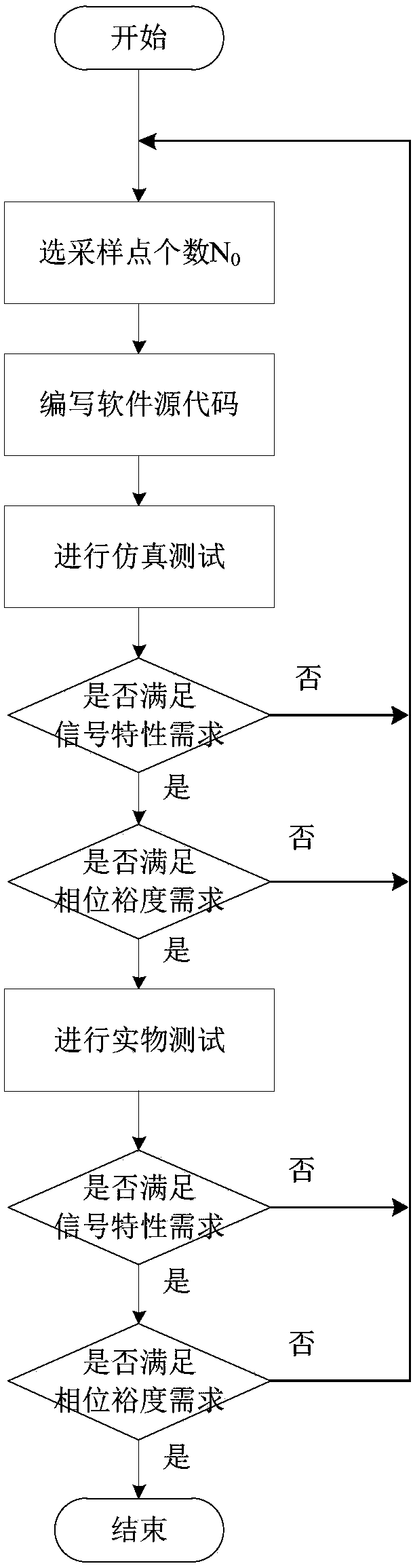

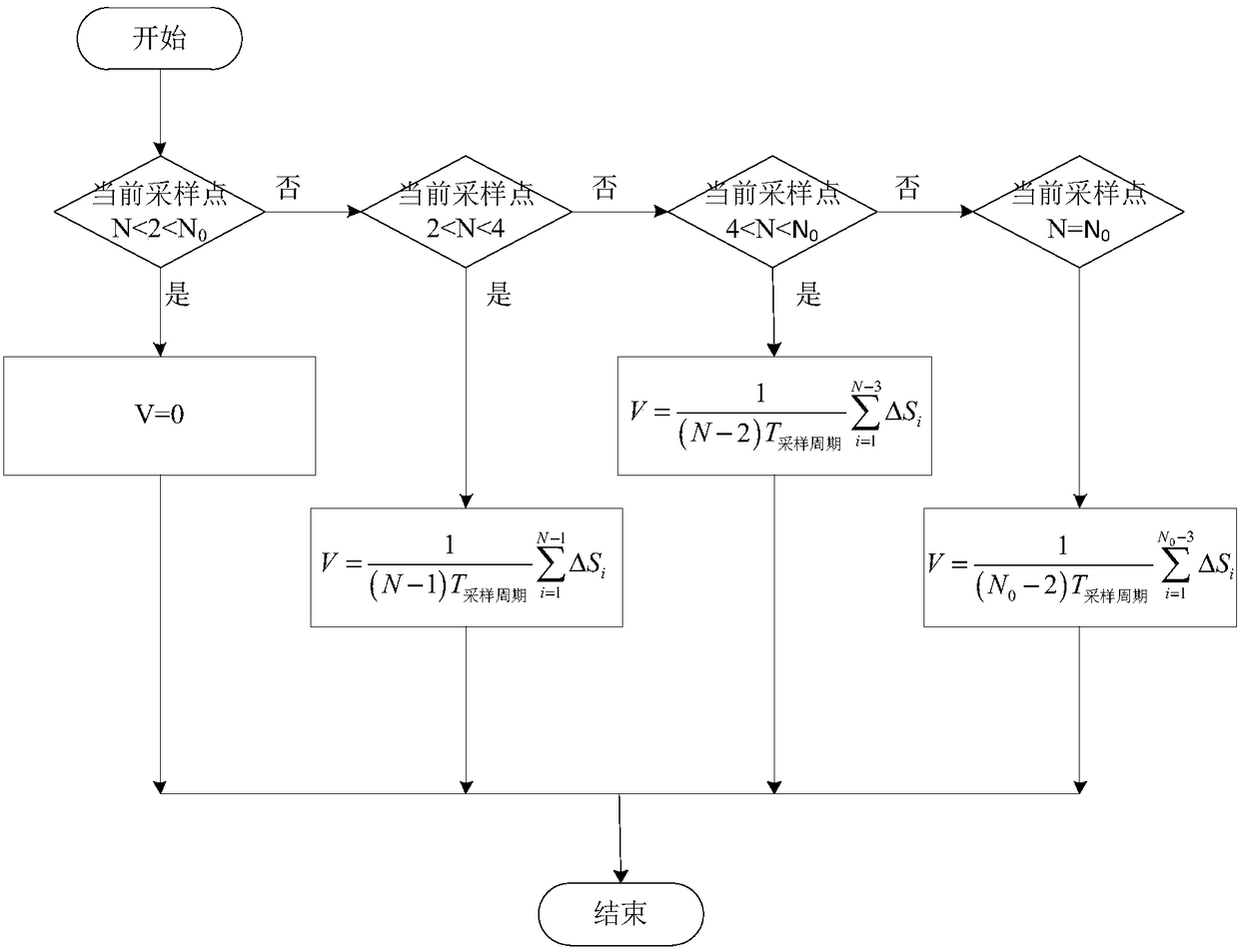

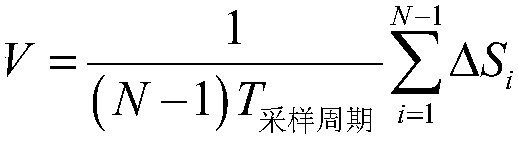

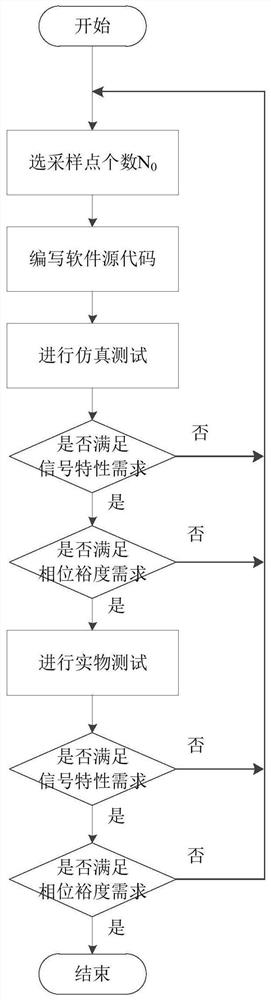

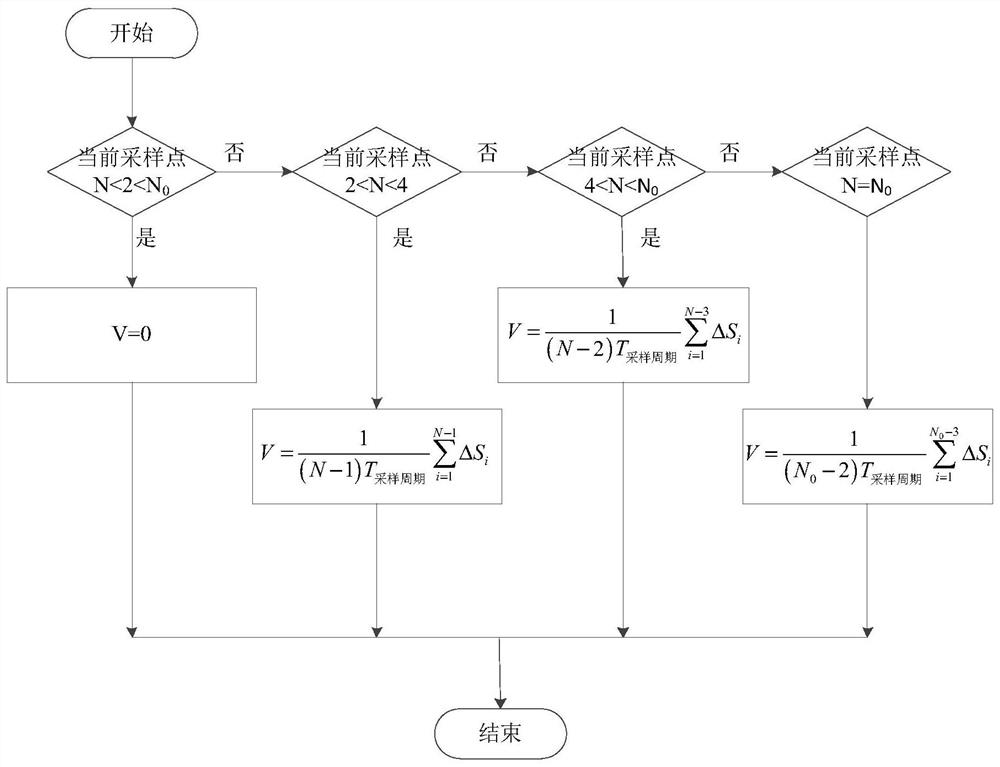

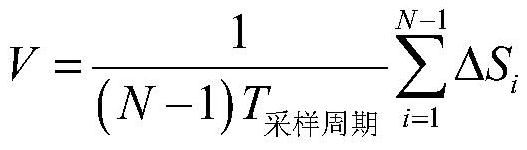

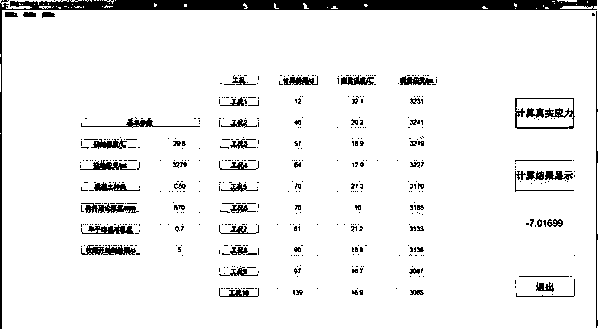

ActiveCN108152527AReduce phase lagImprove errorDevices using time traversedAverage filterMathematical simulation

The invention belongs to the field of the digital speed measuring technology and particularly relates to a median-value average filtering principle-based digital speed measuring method, wherein a speed feedback value is resolved based on the displacement. According to the median-value average filtering principle-based digital speed measuring method provided in the invention, firstly, the number N0of sampling points is selected, and a median-value average filtering-based digital speed measuring scheme is determined. The speed measuring scheme is subjected to mathematical simulation test. In this way, whether the signal characteristic and the phase margin characteristic of the speed measuring scheme meet the requirements at the same time or not can be verified. After that, the entity test is carried out on a motor connected with an absolute displacement sensor, wherein whether the characteristic of the speed feedback signal of the motor and the characteristic of the phase margin of thecontrol loop meet the requirements at the same time or not are verified. According to the invention, the method overcomes the defects of a traditional method in an initial operation stage and reducesthe resolution error. Meanwhile, the introduced phase lag is reduced. The control characteristic in the initial acceleration stage is improved. The method is suitable in all application scenes whereincorresponding speeds need to be resolved by using linear displacement values or angular displacement measurement values. The method has great practical engineering application value.

Owner:BEIJING QINGYUN AVIATION INSTR CO LTD

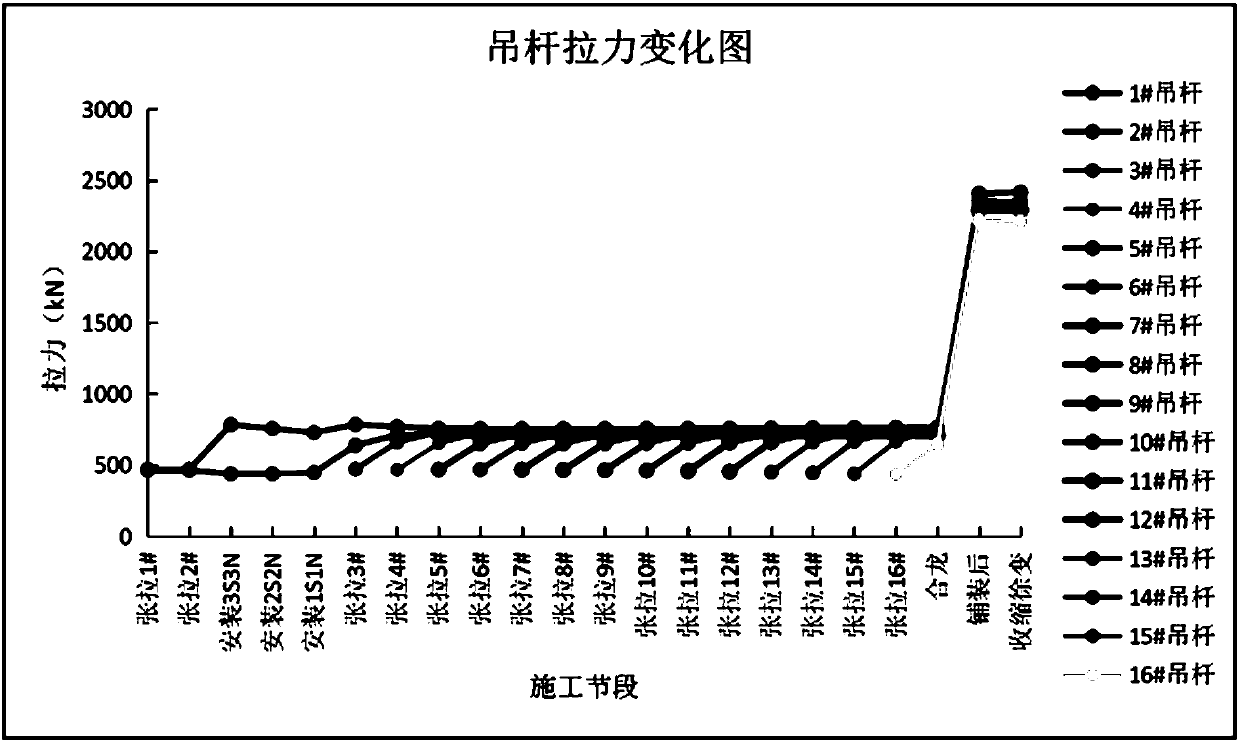

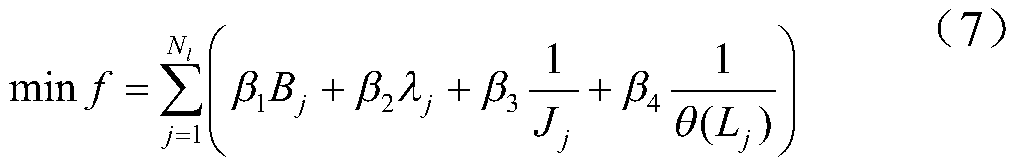

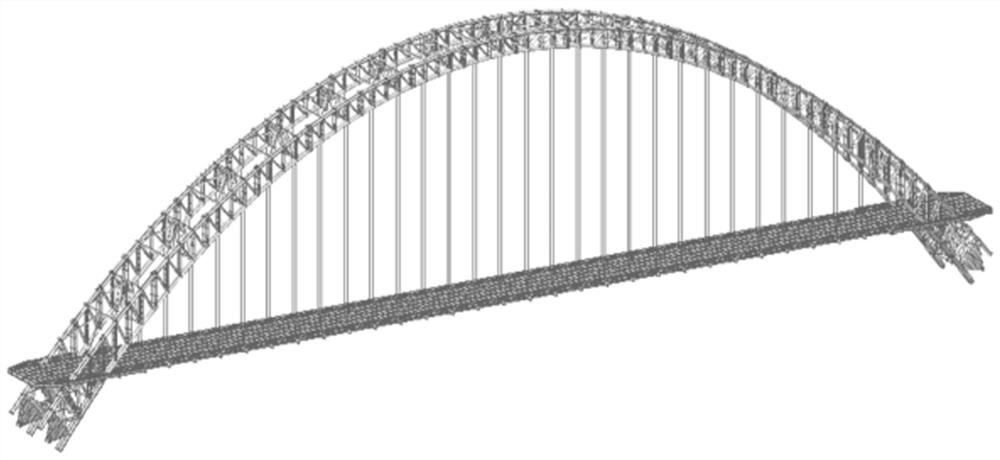

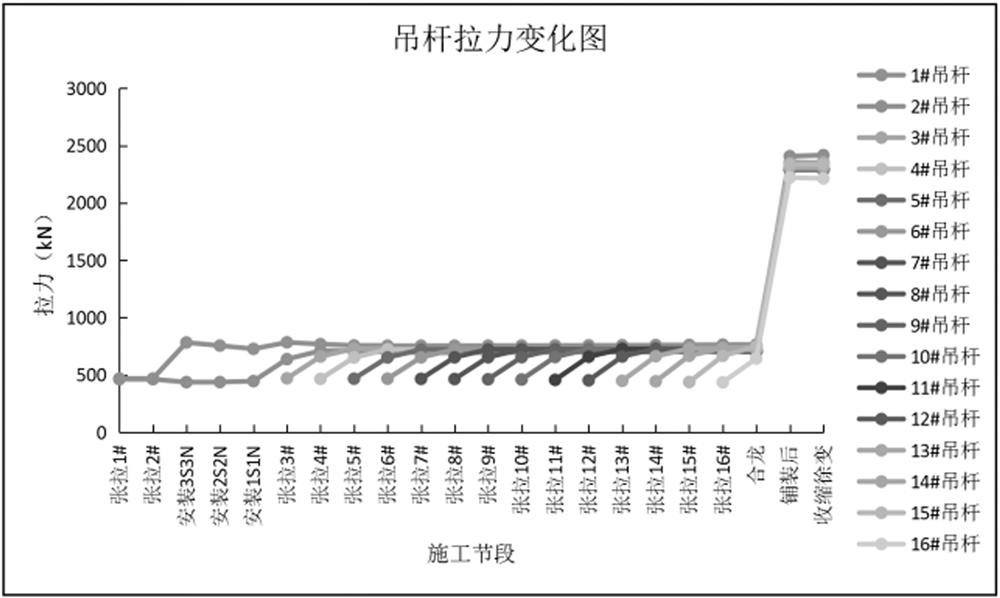

Arch bridge suspender tension optimization method for rectifying deviation in construction process

ActiveCN111581714AUniform tensionLittle change in tensionGeometric CADDesign optimisation/simulationElement modelStructural engineering

The invention discloses an arch bridge suspender tension optimization method for construction process deviation rectification, and the method comprises the steps: building a finite element model, andenabling the material characteristics, geometric characteristics and boundary conditions in the finite element model to be consistent with the external load information and the corresponding data of adesign drawing; substituting the determined group of suspender initial tension into a built finite element model to carry out normal installation analysis in a construction stage to obtain each initial value vector; and establishing an optimization model, and substituting each parameter into the optimization model to obtain a final tensioning force. The actually measured weight is corrected in time in the construction process, so that the suspender is tensioned only once and is not adjusted any more after a bridge is formed, and meanwhile it is ensured that the tension of the suspender is changed uniformly and slightly in the hoisting process; compared with a traditional tension calculation method, the method has the advantages that repeated iteration is not needed, tedious calculation isavoided, and a tension result can be obtained at a time. The method is suitable for arch bridges with different construction sequences and spans, and the application range is very wide.

Owner:GUANGXI TRANSPORTATION SCI & TECH GRP CO LTD +1

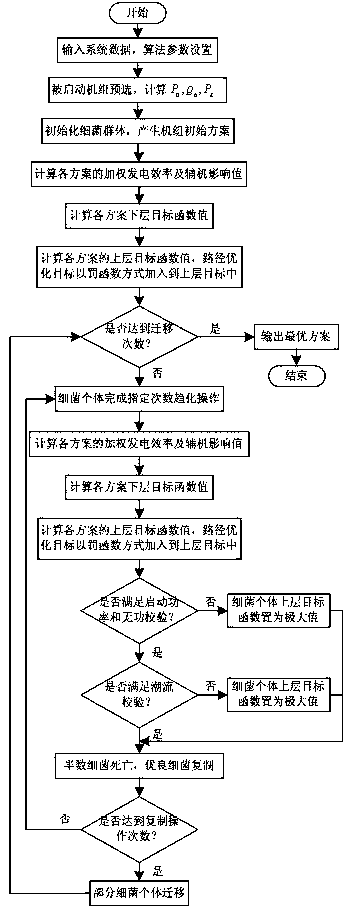

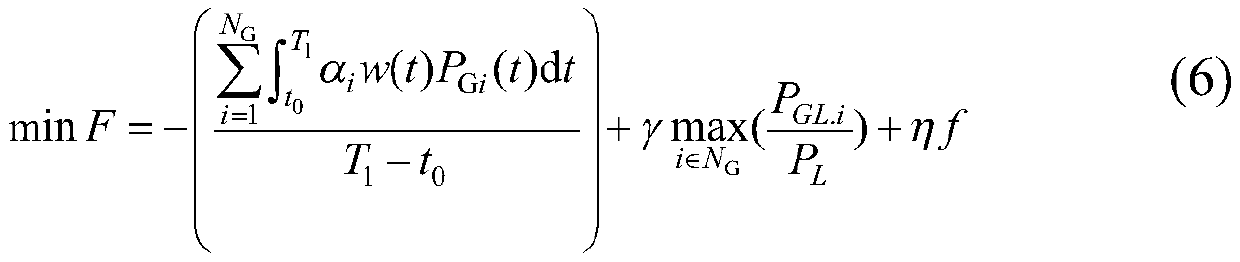

Two-layer planning optimization method of extended black start scheme to improve the security of recovery process

ActiveCN108539781BHigh weighted power generation efficiencyImprove securitySingle network parallel feeding arrangementsSafety propertyBacteria foraging algorithm

Owner:STATE GRID JIANGSU ELECTRIC POWER CO ELECTRIC POWER RES INST +2

Optimizing method of arch bridge suspender pull force for deviation correction in construction process

ActiveCN111581714BUniform tensionLittle change in tensionGeometric CADDesign optimisation/simulationElement modelStructural engineering

Owner:GUANGXI TRANSPORTATION SCI & TECH GRP CO LTD +1

Displacement control method for arch bridge lattice girder hoisting to eliminate temperature influence

ActiveCN111576229BLittle influence of temperatureEliminate displacement cumulative error valueGeometric CADDesign optimisation/simulationEconomic benefitsBridge deck

The invention discloses a method for controlling the hoisting displacement of an arch bridge lattice girder eliminating the influence of temperature. Taking the arch bridge with suspenders as the engineering object to carry out displacement control in the process, by introducing a temperature correction factor, the displacement of the hoisting construction of the arch bridge lattice girder is controlled, so as to eliminate the influence of temperature on the displacement of the lattice girder and reduce the temperature of the hoisting lattice girder The least impact is used as the objective function, and the displacement of the controlled bridge is closest to the reasonable bridge state as the constraint condition for analysis, which solves the problem that the displacement of the lattice girder is not easy to control due to the influence of temperature, and avoids the unevenness of the bridge deck and the driving comfort It greatly shortens the construction period of arch bridge lattice girder hoisting, reduces the risk of being forced to choose night construction, saves economic costs, has broad promotion and application prospects, and brings huge economic benefits. benefit.

Owner:GUANGXI TRANSPORTATION SCI & TECH GRP CO LTD +1

Calculation method of dynamic response of flyover under non-uniform excitation

InactiveCN104731998BPractical engineering application value is greatSpecial data processing applicationsAnalysis methodComputer science

The invention relates to a computing method of dynamic response under nonuniform excitation of an overline overbridge. The computing method of dynamic response under the nonuniform excitation of the overline bridge relates to the computing method of dynamic response of the overline pedestrian overbridge under the action of the nonuniform excitation of a main-line train, the dynamic response of the overline pedestrian overbridge serves as a target value, considering that the nonuniform excitation is generated at the position of a bridge pier of the overline pedestrian overbridge during the high-speed running process of the train, the equation of motion of the overline pedestrian overbridge under the action of the nonuniform excitation is deduced, and the response of the overline pedestrian overbridge under the action of the train can be obtained according to a numerical integration. According to the computing method of dynamic response under the nonuniform excitation of the overline bridge, the analytic method of the nonuniform excitation is brought out creatively to be used for calculating the vibration response under the nonuniform excitation acting on the position of the bridge pier of the overline pedestrian overbridge when the main-line train passing through at a high speed under the overline pedestrian overbridge, the computing method of dynamic response under the nonuniform excitation of the overline bridge is suitable for dynamic response analyses of all overline pedestrian overbridges under the action of the main-line trains and has a comparatively large practical engineering application value and innovativeness.

Owner:WUHAN UNIV OF TECH

Calculation Method of New Return Air Hybrid Air Conditioning System with Fixed Secondary Mixing Ratio

ActiveCN107702272BImprove stabilityReduce energy wasteMechanical apparatusDesign optimisation/simulationAir volumeMathematical model

Owner:JIANGSU VOCATIONAL INST OF ARCHITECTURAL TECH

A Digital Velocimetry Method Based on Median Average Filter

ActiveCN108152527BReduce phase lagImprove errorDevices using time traversedAverage filterMathematical simulation

The invention belongs to the field of the digital speed measuring technology and particularly relates to a median-value average filtering principle-based digital speed measuring method, wherein a speed feedback value is resolved based on the displacement. According to the median-value average filtering principle-based digital speed measuring method provided in the invention, firstly, the number N0of sampling points is selected, and a median-value average filtering-based digital speed measuring scheme is determined. The speed measuring scheme is subjected to mathematical simulation test. In this way, whether the signal characteristic and the phase margin characteristic of the speed measuring scheme meet the requirements at the same time or not can be verified. After that, the entity test is carried out on a motor connected with an absolute displacement sensor, wherein whether the characteristic of the speed feedback signal of the motor and the characteristic of the phase margin of thecontrol loop meet the requirements at the same time or not are verified. According to the invention, the method overcomes the defects of a traditional method in an initial operation stage and reducesthe resolution error. Meanwhile, the introduced phase lag is reduced. The control characteristic in the initial acceleration stage is improved. The method is suitable in all application scenes whereincorresponding speeds need to be resolved by using linear displacement values or angular displacement measurement values. The method has great practical engineering application value.

Owner:BEIJING QINGYUN AVIATION INSTR CO LTD

A Stress Correction Method for Main Girder of Long-span Prestressed Concrete Cantilever Construction Bridge

ActiveCN107423500BHigh solution accuracyImprove solution efficiencyGeometric CADDesign optimisation/simulationPre stressCreep strain

The invention relates to a method for correcting a main girder stress of a large-span prestressed concrete cantilever construction bridge. In a creep strain calculation method considering a section construction characteristic of the large-span bridge, a time-varying elastic modulus and an equivalent elastic modulus between any two age periods are introduced; non-stress strain generated by creep is more accurately removed; and a corresponding secondary development technology is selected for performing secondary development on MATLAB, so that parametric interface operation is realized. The method comprises the following steps of Step 1: calculating a strain value caused by concrete creep; Step 2: calculating the influence of the time-varying elastic modulus on strain correction; Step 3: calculating a strain value caused by a temperature difference; Step 4: calculating a strain value caused by concrete shrinkage; and Step 5: based on secondary development of a MATLAB platform, compiling a main girder stress correction calculation program, and performing calculation. According to the method, the real main girder stress in the bridge construction process can be accurately calculated; the stress calculation and analysis efficiency in construction control can be improved; and the development of a large-span bridge construction control technology can be better served.

Owner:CHINA THREE GORGES UNIV

High temperature resistant filling glue for encapsulating temperature measuring crystals

ActiveCN106673586BRealize the temperature measurement functionEasy to buyThermometer detailsPhysical chemistrySilicon oxide

Owner:AECC SICHUAN GAS TURBINE RES INST

Displacement control method for hoisting lattice girders of arch bridge with small construction disturbance

ActiveCN111576230BReduce disturbanceSmall and smooth control point displacement changesBridge erection/assemblyArch-type bridgeStructural deformationElement model

Owner:GUANGXI TRANSPORTATION SCI & TECH GRP CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com