High temperature resistant filling glue for encapsulating temperature measuring crystals

A technology with high temperature resistance and crystal, which is applied to parts of thermometers, thermometers, measuring heat, etc., to achieve the effects of convenient purchase, good economic benefits, and low cost of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

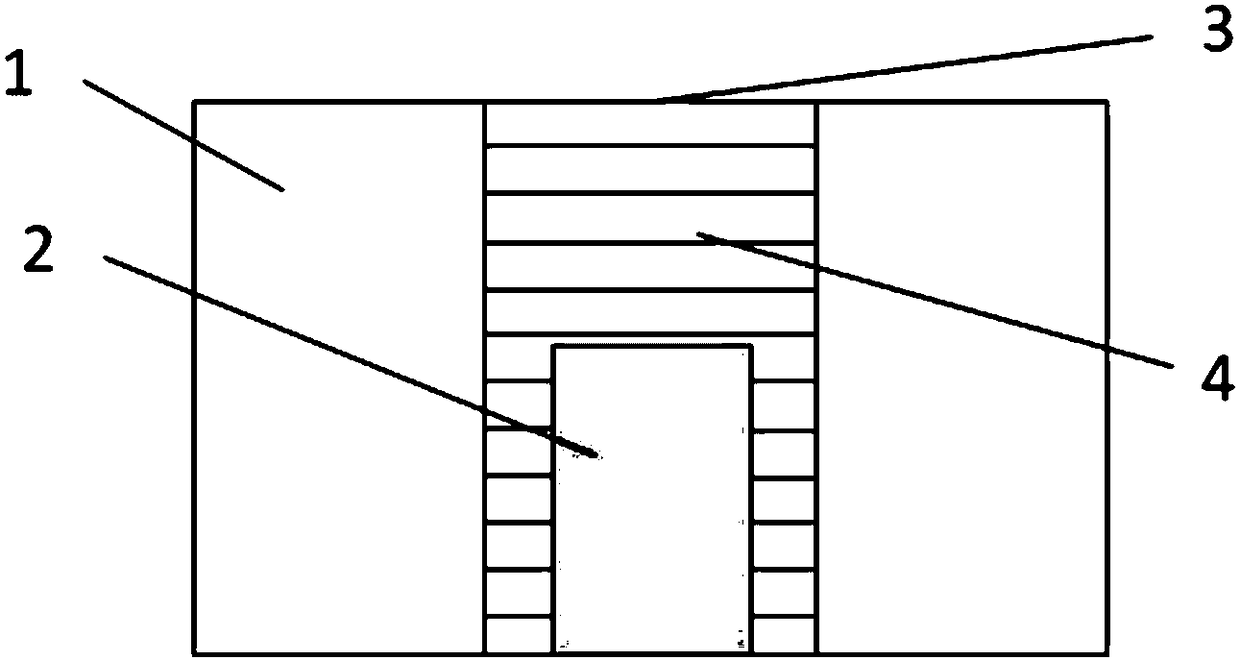

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below by specific embodiment:

[0015] The invention prepares a high-temperature-resistant filling glue for encapsulating temperature-measuring crystals by screening raw materials and their dissolved base material solvents and diluents, selecting raw materials from selected raw materials and formulating them in a certain proportion. In this embodiment, the prepared filling glue for packaging temperature measuring crystals is composed of sodium silicate with a mass ratio of 20%, silicon dioxide with a mass ratio of 35%, and zirconia with a mass ratio of 25%. Titanium dioxide with a proportion of 15% and ethanol with a concentration of 50% and a mass proportion of 5% are uniformly mixed and ground. Among them, the silicon dioxide, zirconia and titanium dioxide have good heat resistance, can maintain good protection properties under the action of heat, and can effectively protect the temperature measuring crystal. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com