Patents

Literature

40results about How to "Reduce R&D" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

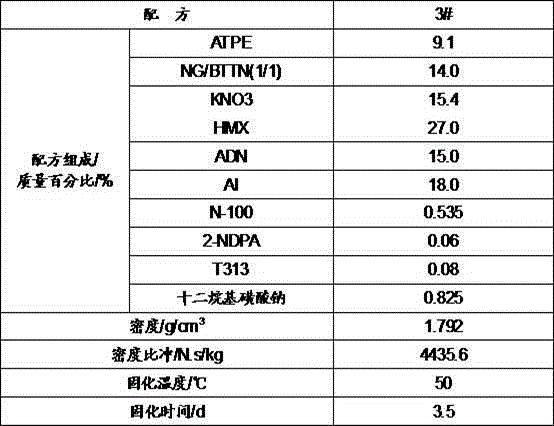

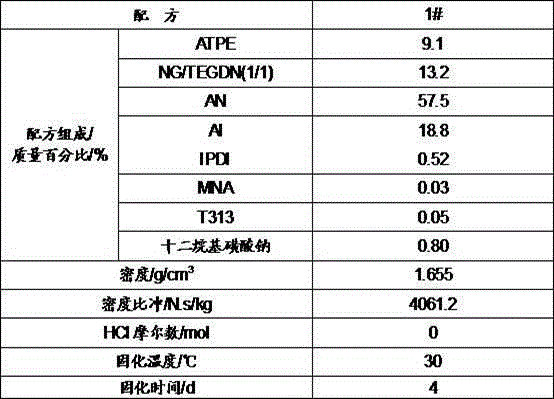

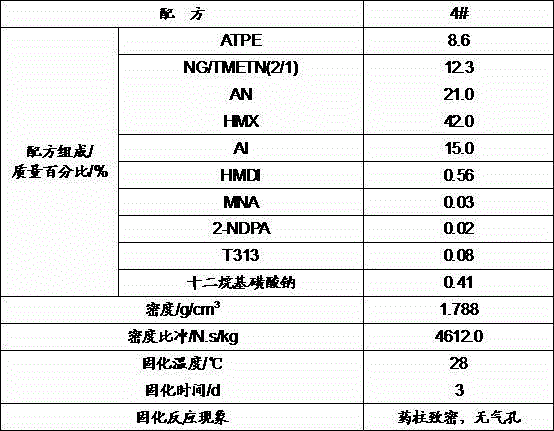

Room-temperature-cured-type clean solid propellant

The invention provides a room-temperature-cured-type clean solid propellant. The room-temperature-cured-type clean solid propellant is prepared from, by mass, 55%-70% of chlorine-free oxidizing agents, 5%-20% of metal fuels, 5%-15% of plasticizers, 5%-10% of amine-terminated polyether adhesives, 0.5%-1.0% of isocyanate curing agents and 0.01%-3% of function auxiliaries. According to the room-temperature-cured-type clean solid propellant, the detect that in the prior art, due to the fact that an oxidizing agent ammonium perchlorate is used in a compound solid propellant, a large amount of HCl gas is contained in a combustion product, and atomospheric pollution is serious is overcome; the amine-terminated polyether adhesives with the high reaction activity are introduced into a compound solid propellant system, and a cross-linking and curing reaction of terminal amino groups and the isocyanate curing agents is utilized, so that room-temperature curing of the amine-terminated polyether propellant is achieved; no HCl gas exists in the combustion product by adding the chlorine-free oxidizing agents.

Owner:HUBEI INST OF AEROSPACE CHEMOTECHNOLOGY

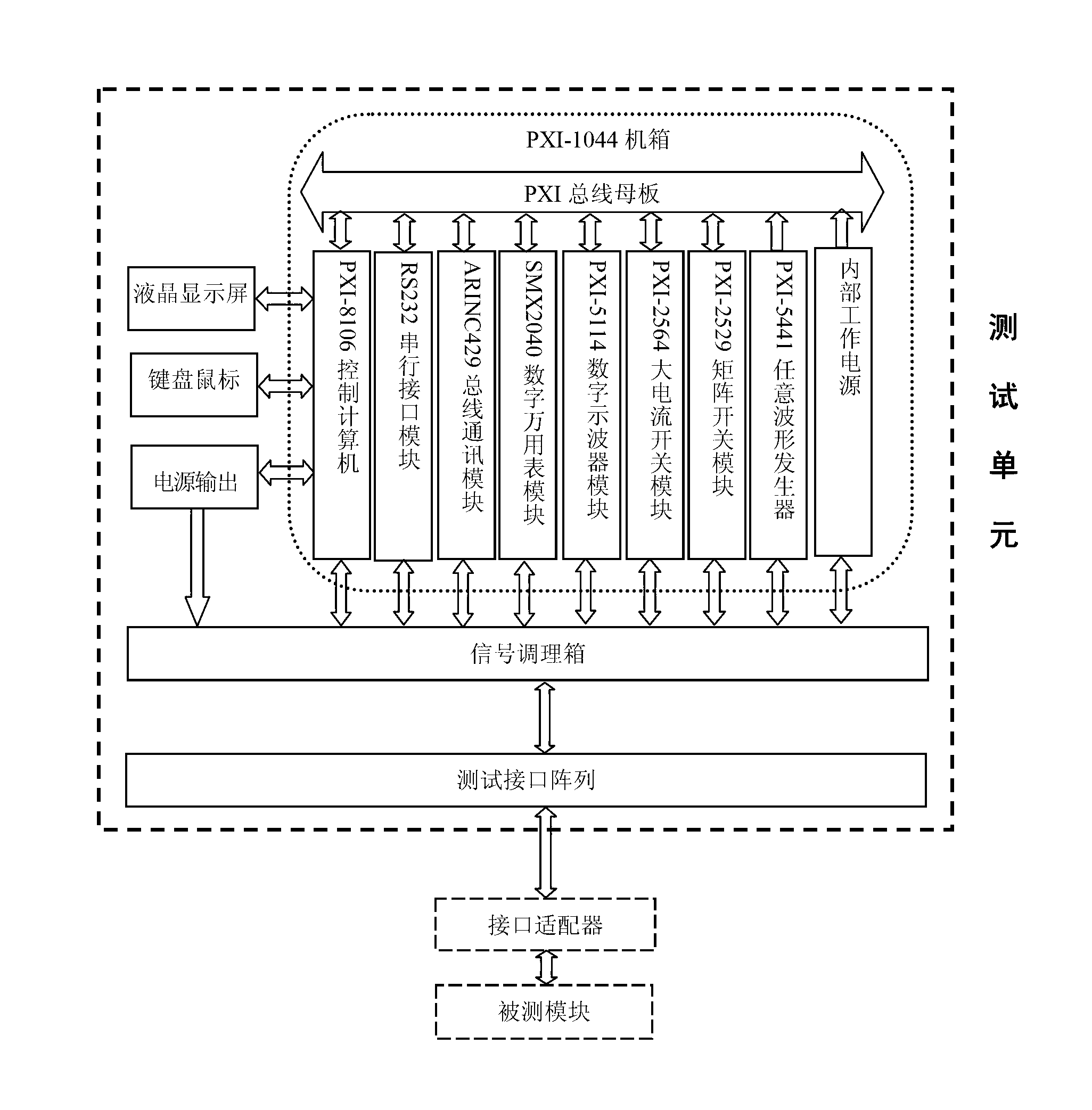

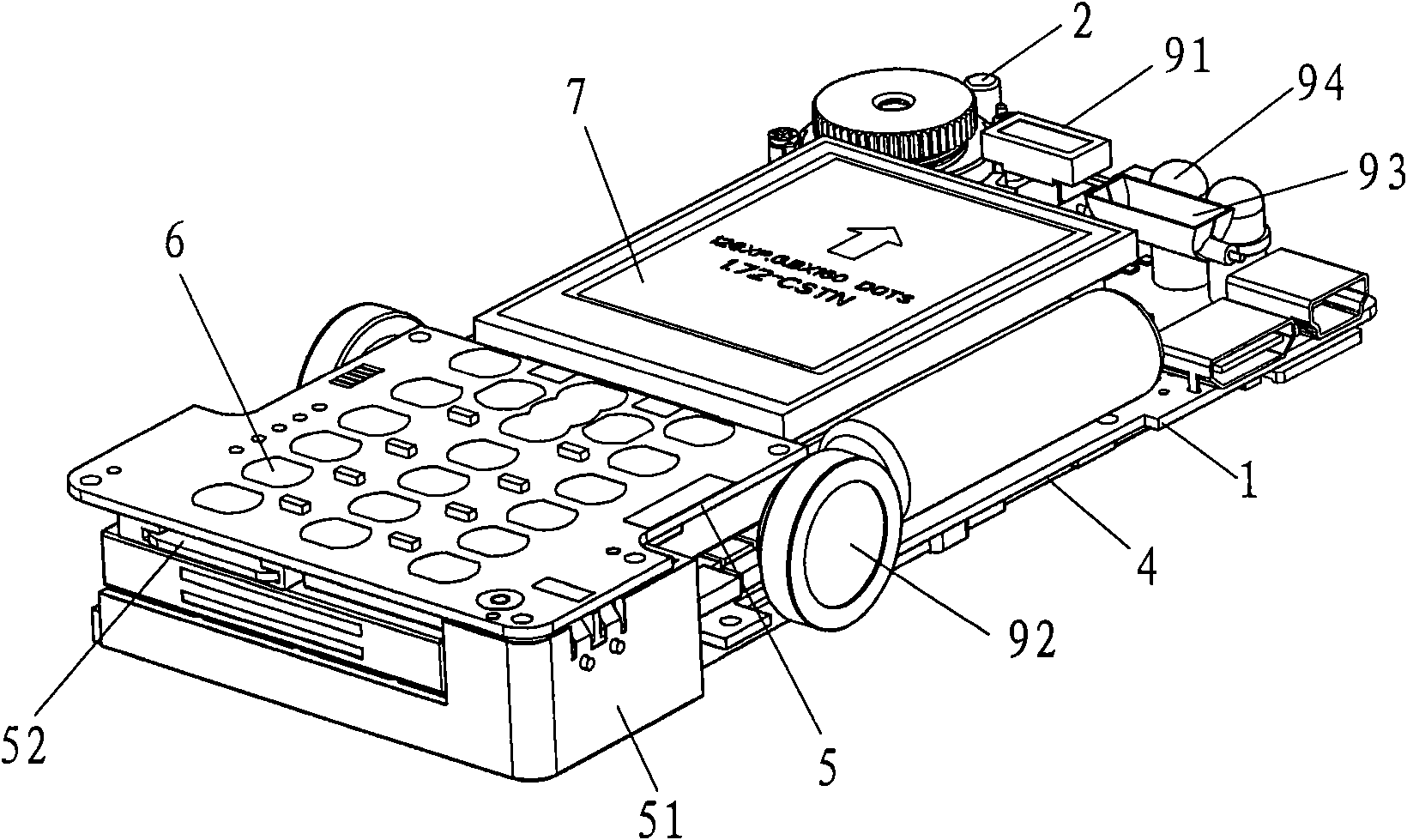

Automatic testing device and automatic testing method of ARINC 429 bus signal performance parameters

InactiveCN103019902AImprove quality levelImprove the level ofFunctional testingQuality levelTest fixture

The invention discloses an automatic testing device and an automatic testing method of ARINC 429 bus signal performance parameters; the device comprises a test unit, a test adapter and corresponding software program, wherein the test unit consists of a power control box, a PXI test case, a signal conditioning box, a test interface array and an input-output device; all resource modules in the test unit can be used for running a test program of the test unit by testing software under the control of a PXI control computer through a PXI bus; the adapter is meshed with an RCV end by an ITA end of a test array, and is connected with test resource modules on the test unit; and the testing software comprises two parts including testing software of the test unit and testing software specially used for the adapter. After the invention is adopted, the quality level of an ARINC 429 bus signal module product can be improved, the development of a special test device is omitted, and the development cost and the maintenance cost of the test device can be greatly lowered.

Owner:CHINESE AERONAUTICAL RADIO ELECTRONICS RES INST

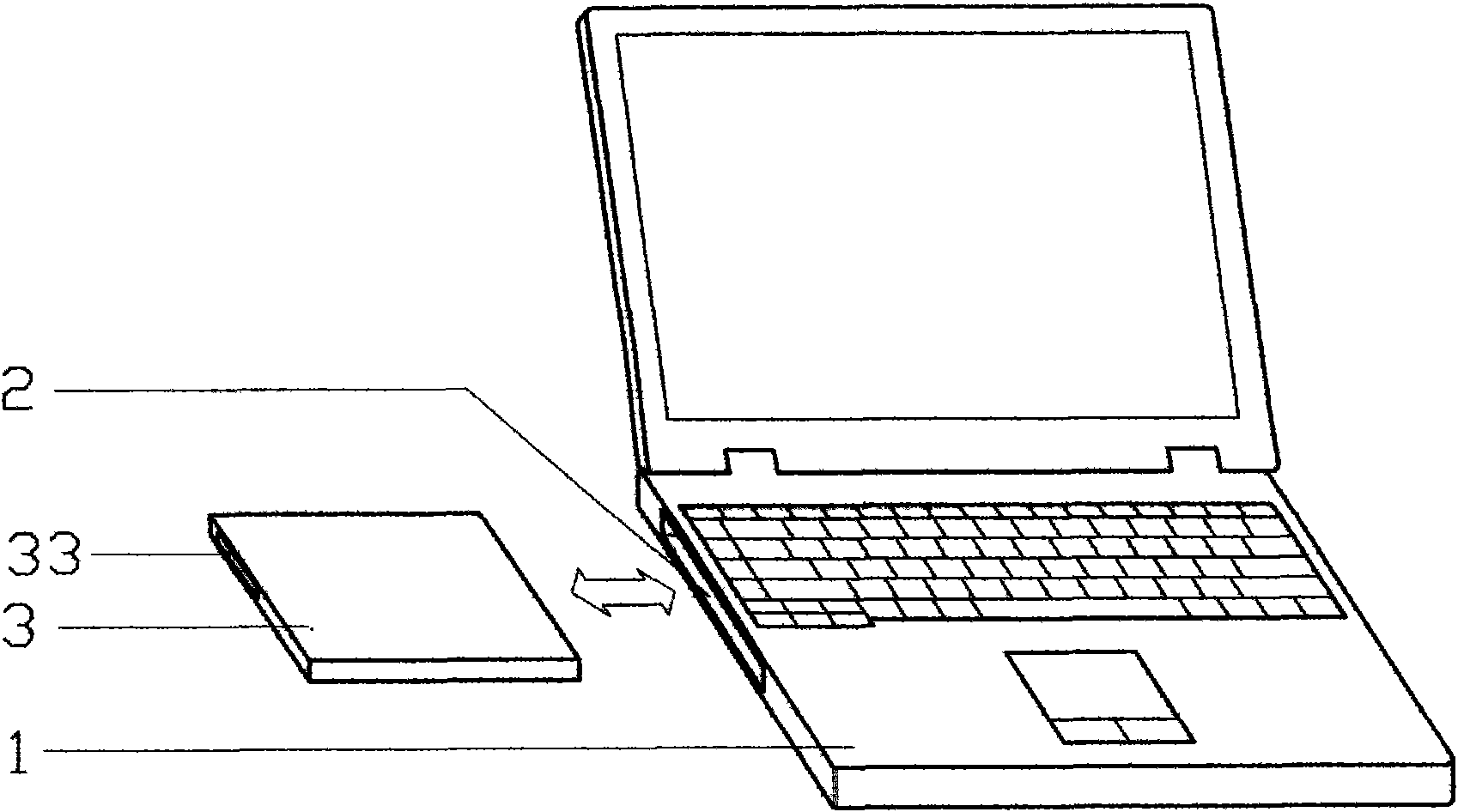

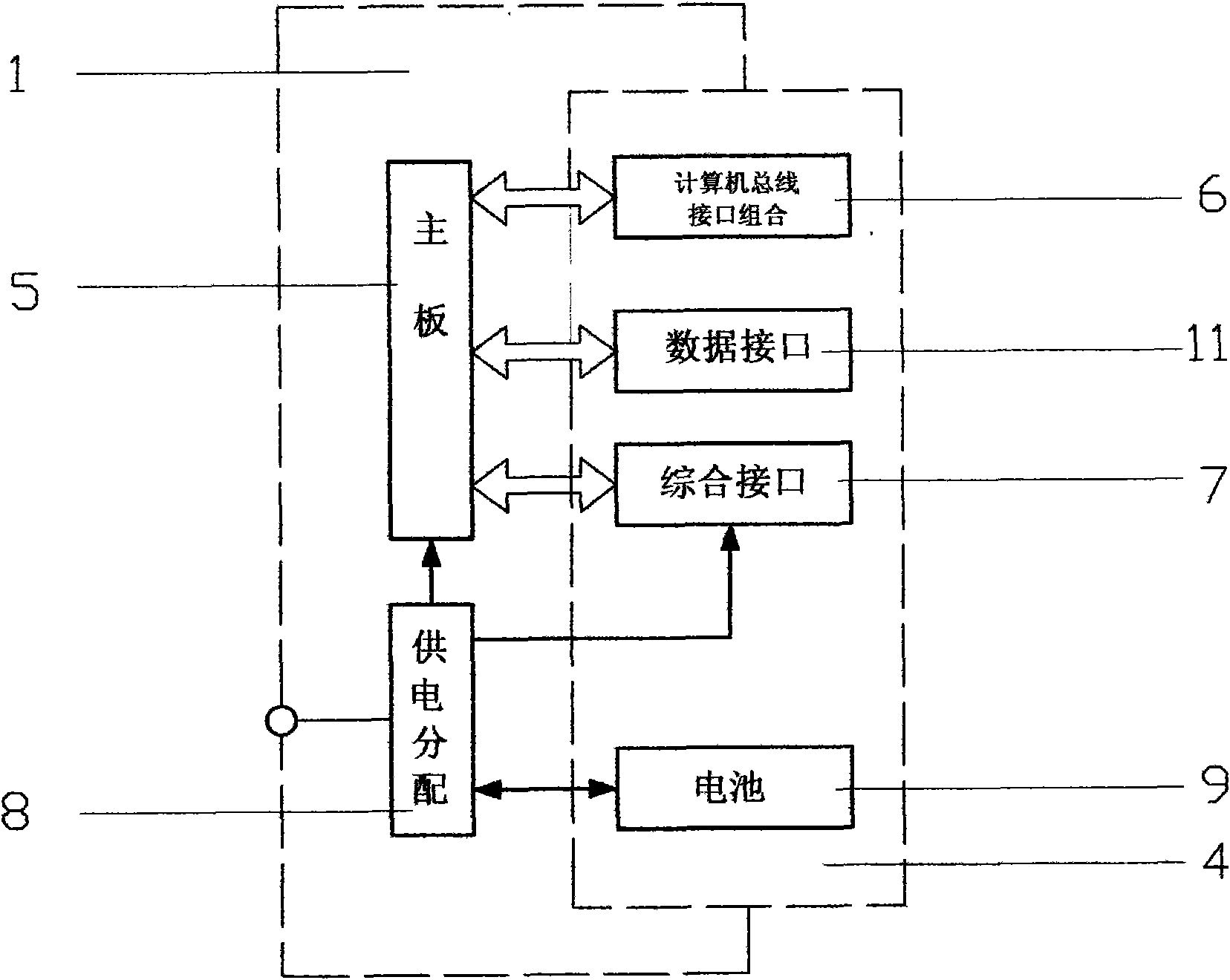

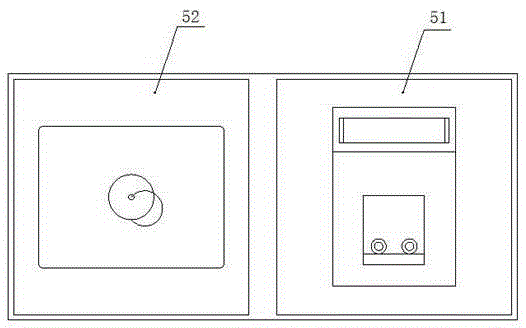

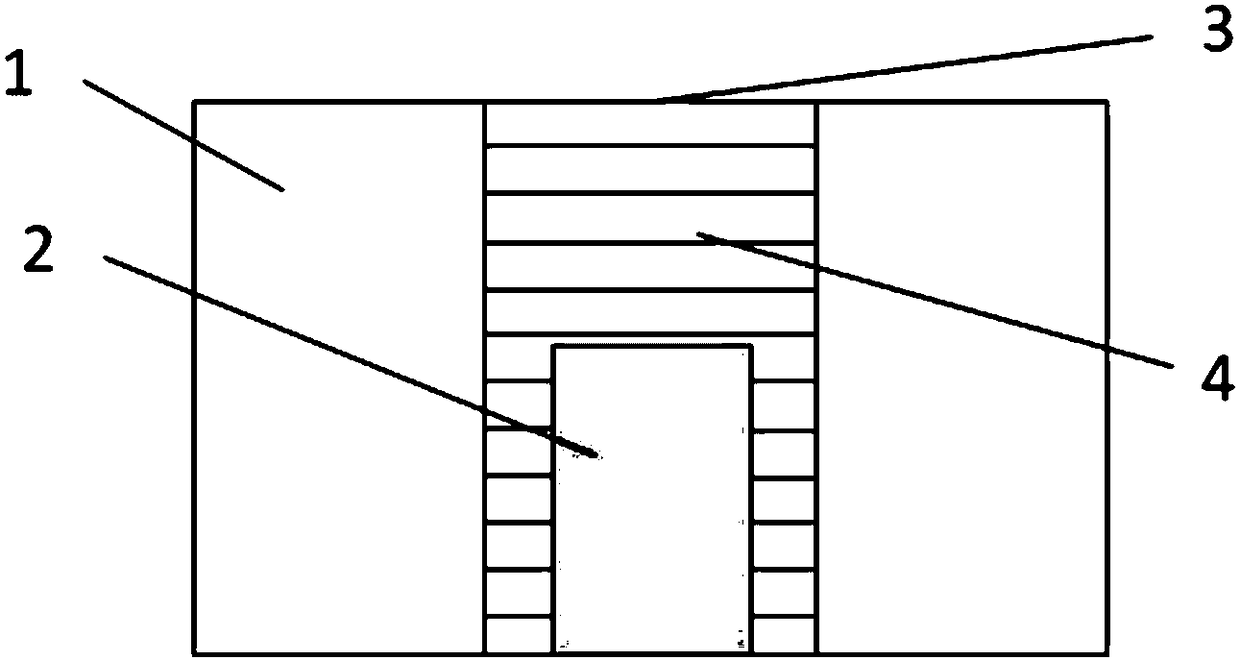

Notebook computer system with modular function expansion structure and removable functional expansion module

InactiveCN101620457ASolve thin and lightSolve functionDigital data processing detailsCommunication interfaceInterior space

A notebook computer system with a modular function expansion structure and a removable function expansion module comprise a modular removable function expansion module. The modular function expansion module comprises at least one function expansion bin, a removable function expansion module and an electrical interface, wherein the function expansion bin is embedded in a notebook computer mainframe; the removable function expansion module can be inserted in the function expansion bin and work; and the electrical interface is connected with the removable function expansion module and the mainframe. The function expansion bin is of a single-layered or double-layered or three-layered structure; and at least a computer bus communication interface, a battery power supply interface, a data interface and an integrated interface or a combination of the computer bus communication interface, the battery power supply interface, the data interface and the integrated interface are included in the electrical interface of the function expansion bin. The removable function expansion module consists of a function component enwrapped by a shell and a module connector connected with the electrical interface, the outer appearance of the removable function expansion module or the outer appearance of the removable function expansion module after being superimposed and combined is matched with the inside space of the function module expansion bin. The invention has the advantages of stronger function expansion, configuration update and interchange and universal performance and can provide various types of quick switching external interfaces and function expansion.

Owner:许文武

Band-shaped beam klystron outer tuning apparatus

InactiveCN103681176ASimple structureReduce volumeTransit-tube circuit elementsResonant cavityKlystron

The invention provides a band-shaped beam klystron outer tuning apparatus. The apparatus comprises an accommodation cavity, a tuning assembly, a trapezoid lever bracket and a control assembly. An inductance tuning mode is adopted, and a tuning piston is inserted into a band-shaped beam klystron tube body to form a cavity wall of a resonant cavity; and the motion of the tuning piston is controlled through a lever principle so as to change the size and distribution inductance of the resonant cavity and further change the resonant frequency of the resonant cavity. According to the invention, a flexible seal membrane sheet rather than a corrugated pipe is adopted for realizing tuning of the resonant cavity so that the cost is reduced, and the structure is simplified.

Owner:INST OF ELECTRONICS CHINESE ACAD OF SCI

Configuring and testing method and system in ATCA system

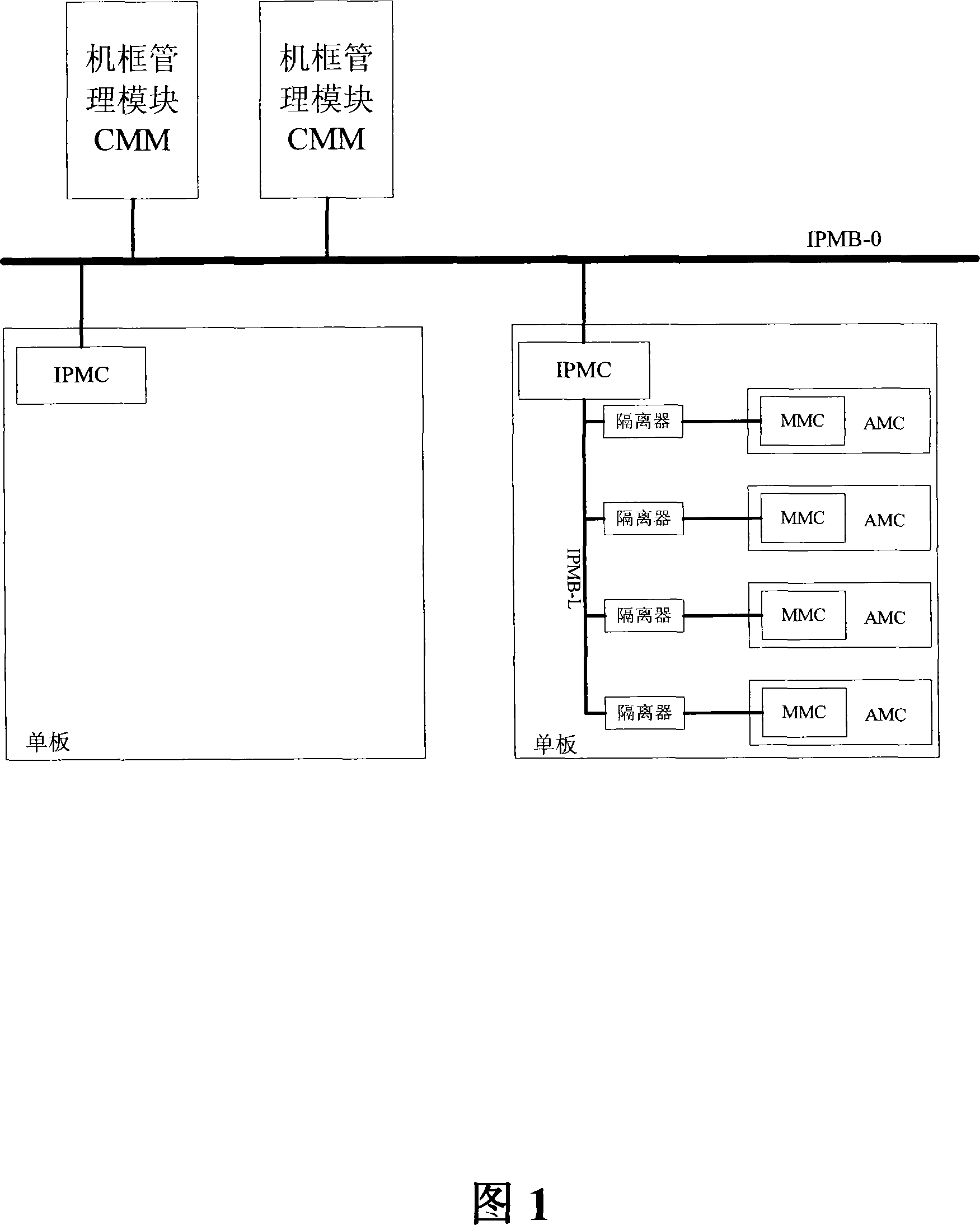

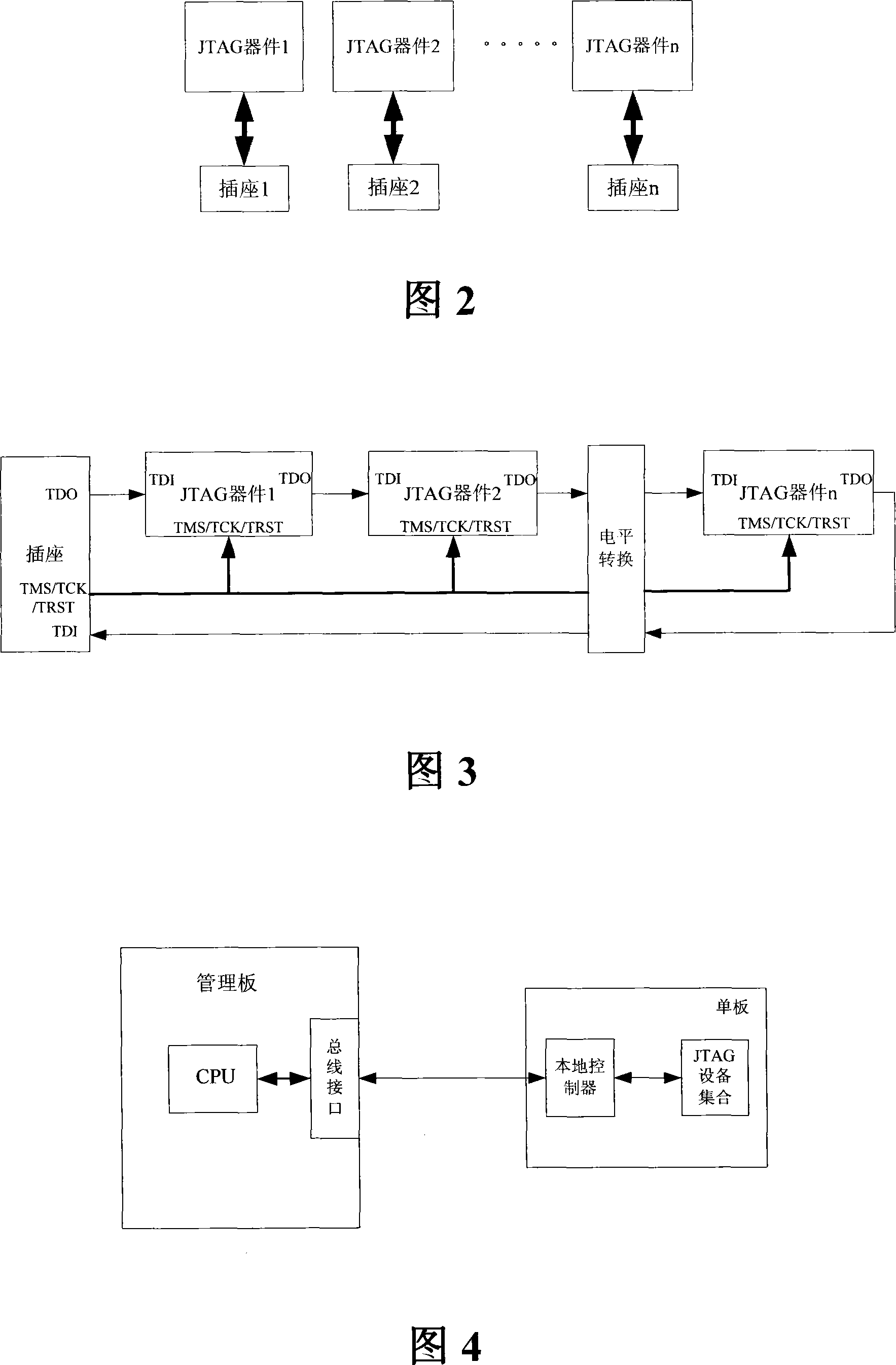

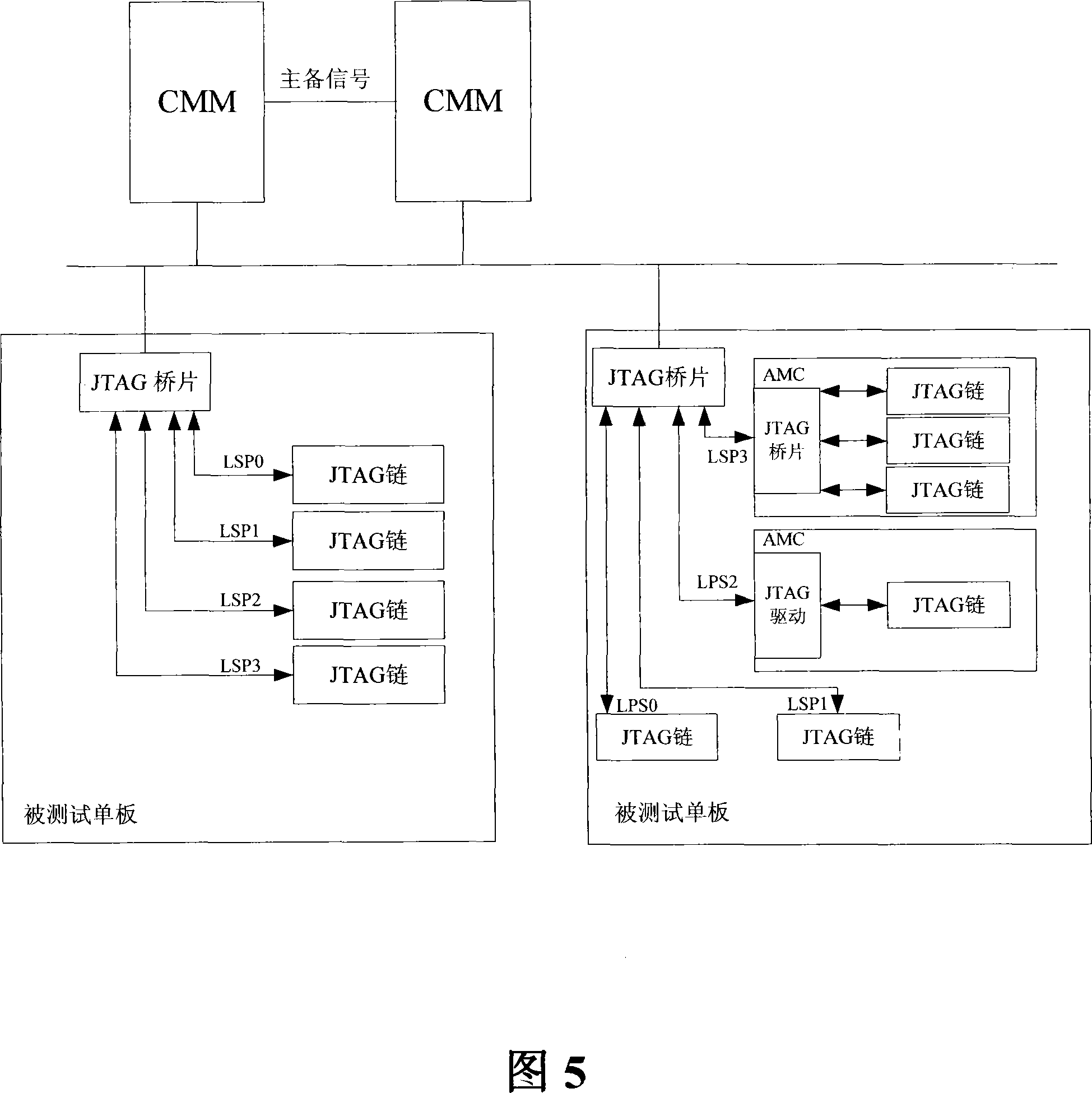

ActiveCN101179748AIncrease coverageReduce manual interventionSupervisory/monitoring/testing arrangementsSelection arrangementsCommunications systemPerformance computing

The invention discloses a configuration and testing system in a high-performance communication computing architecture system, comprising: a JTAG bridge, located on a single board to be tested, and used to gate the JTAG connected to the JTAG bridge under the control of a test control unit Device, JTAG chain, JTAG bridge and / or JTAG drive; test control unit, used to obtain test vectors for testing or configuration, and control the JTAG bridge to select the JTAG device and JTAG chain connected to the JTAG bridge , JTAG bridge chip and / or JTAG driver, so as to connect to the specified JTAG device and / or JTAG chain, and send the test vector to the specified JTAG device and / or JTAG chain for testing or configuration. Thereby, the test and configuration speed in ATCA are improved and the management board test and configuration can be performed.

Owner:ZTE CORP

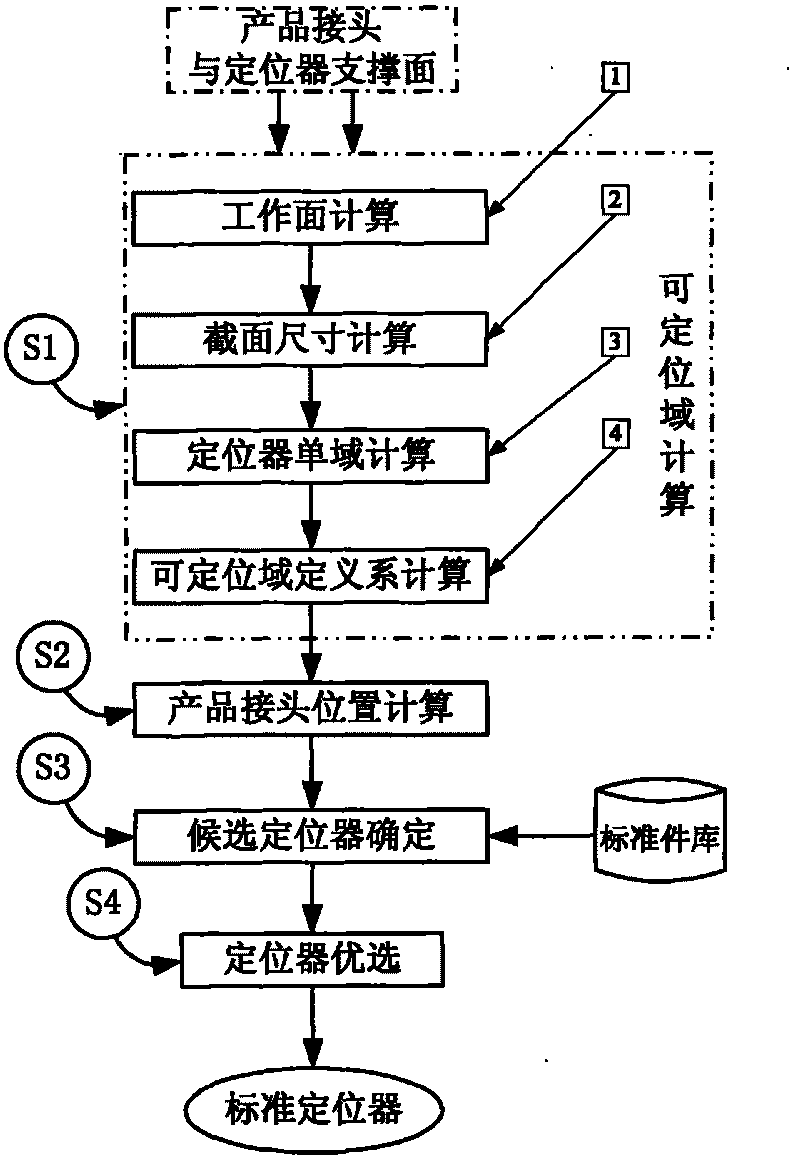

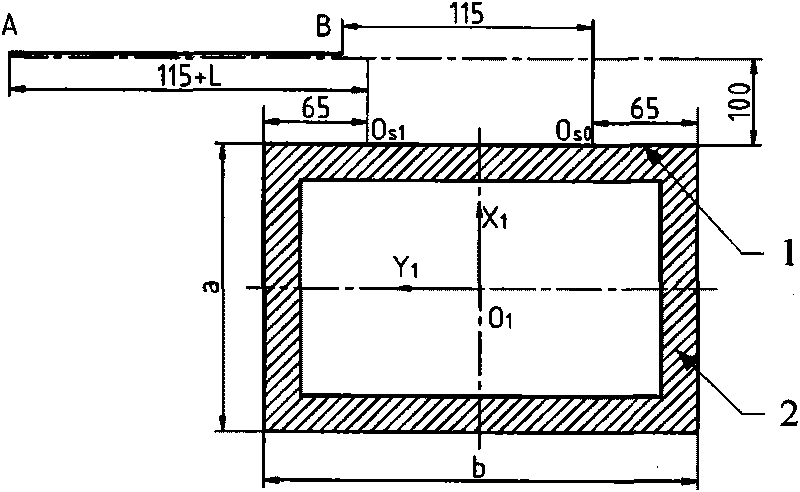

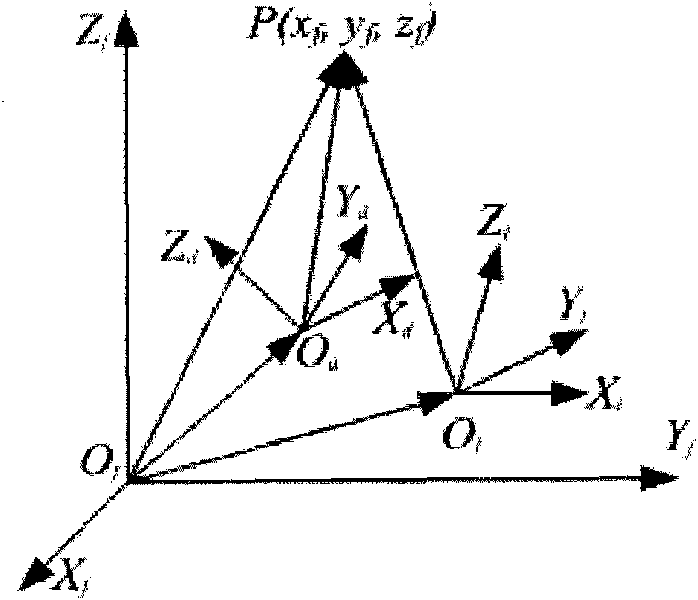

Airplane complex construction member numerical control processing tool standard locator automatically selecting method

InactiveCN101738983AImprove development cycleShorten the development cycleProgramme controlComputer controlAirplaneTool design

The invention provides an airplane complex construction member numerical control processing tool standard locator automatically selecting method. Domain definition system and product joint position can be defined by calculation, and a candidate locator and an optimal locator are determined, so as to determine the type and specification of the standard locator meeting the locating requirement. The method can be applied to development of 'tool rapid generating sub system' standard locator automatically selecting program in the 'airplane complex construction member rapid numerical control processing ready system'. Tool design efficiency is improved, tool development and even the whole production ready period is shortened, and application benefit is favourable. Besides, the invention can be applied to automatic calling of airplane manufacturing tool and other special standard component. When applying the method, only manual selection of product joint and locator supporting surface is required, the standard locator can be automatically selected, automation, intellectualization and rapid design of locator can be realized, and design efficiency and quality of complex construction member numeric control processing tool is improved, thus shortening airplane development period.

Owner:SHENYANG AIRCRAFT CORP +1

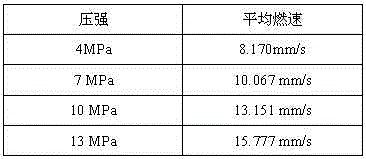

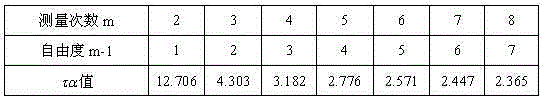

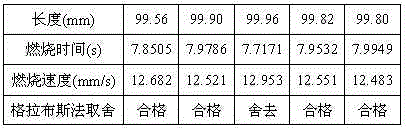

Combustion speed testing method for gel propellant

InactiveCN103604905AEasy to prepareEasy to promoteChemical analysis using combustionAutomotive engineeringThin walled

The invention discloses a combustion performance testing method for a gel propellant. The method comprises the following steps: directly taking a prepared gel propellant as a sample to be tested and injecting the sample into a thin-wall straight plastic pipe of which the inner diameter is 8mm-10mm and one end is closed to prepare a powder pipe to be detected; fixing the powder pipe to be detected on a powder rack of a combustion room; placing ignition powder on one unclosed end and fixing by using a nickel-chrome wire; coating an end face by using a coating agent; and putting the powder rack of the combustion room, which carries the fixed powder pipe to be detected, into an underwater acoustic emission combustion speed meter to test a combustion speed and finally calculating an average combustion speed, a combustion speed pressure index and a combustion speed temperature sensitivity coefficient. The method is simple and easy to operate and short in testing period, and can rapidly and accurately test the combustion performance of the gel propellant.

Owner:XIAN MODERN CHEM RES INST

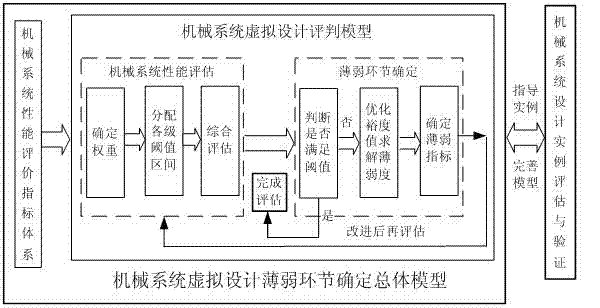

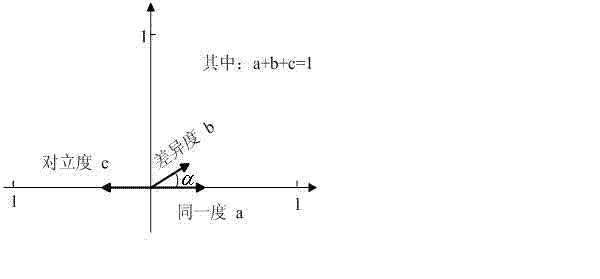

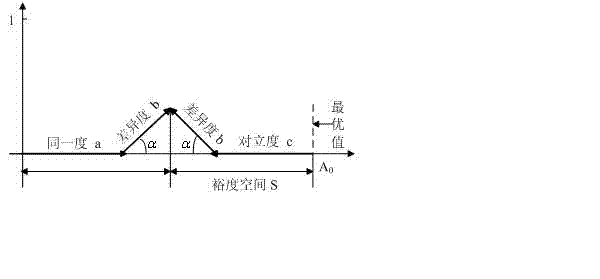

Method for determining weak links in mechanical system virtual design

InactiveCN102521458AImprove applicabilityImprove performanceSpecial data processing applicationsAssessment methodsWeakness

The invention discloses a method for determining weak links in mechanical system virtual design, which includes the following steps: (1) establishing a mechanical system virtual model machine; (2) building a mechanical system overall performance index evaluating system according to the mechanical system virtual module machine; (3) structuring a mechanical system design performance evaluating model based on the extension superiority theory; and (4) determining the weak links of the mechanical system design scheme. The method has the advantages that on the basis of the extension superiority evaluation method, quantification of quantitative indexes can be solved well by building correlation function, the problems of related many factors, nonlinearity and uncertainty of the mechanical system performance can be solved well, weakest indexes can be determined by structuring an index weakness model, and the integral performance of a mechanical system is improved conveniently. In addition, by the method, design efficiency and overall performance of the mechanical system are improved, waste of resources is reduced, and the cycle for research, development and experiment is shortened.

Owner:ORDNANCE TECH RES INST OF THE GENERAL ARMAMENT DEPT PLA

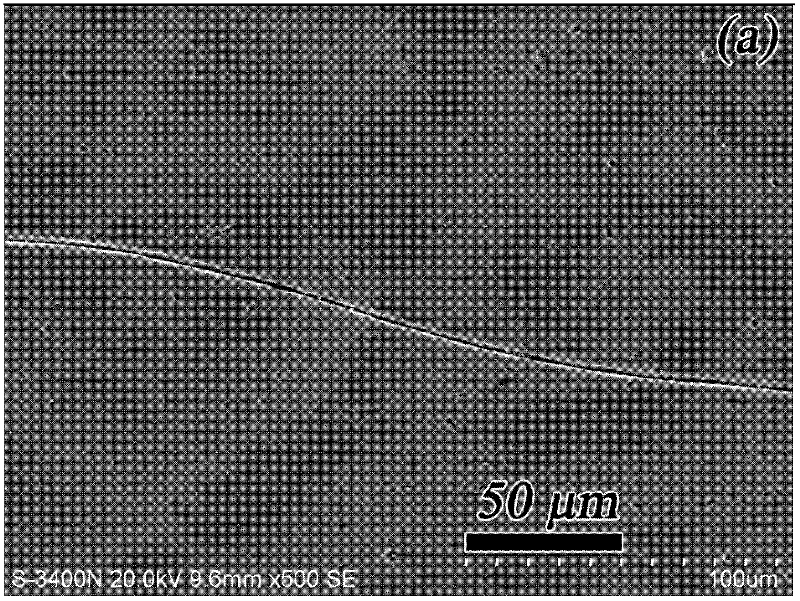

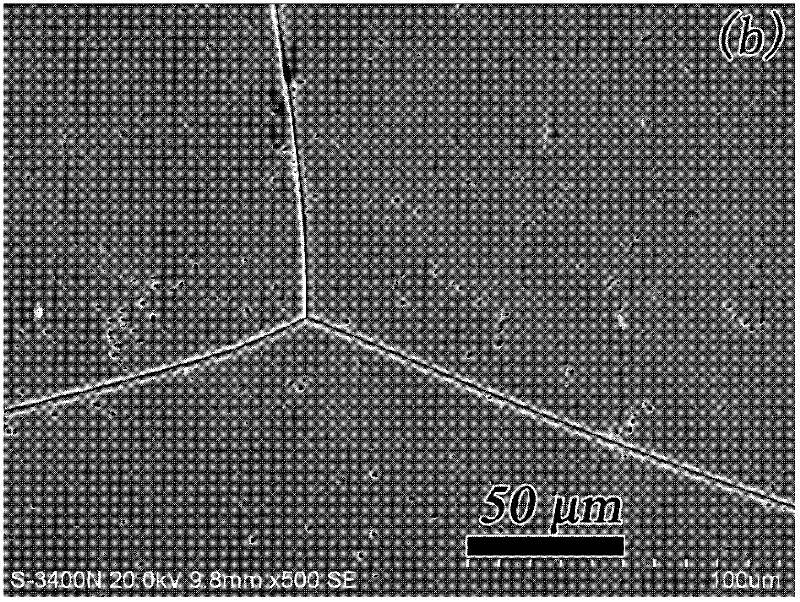

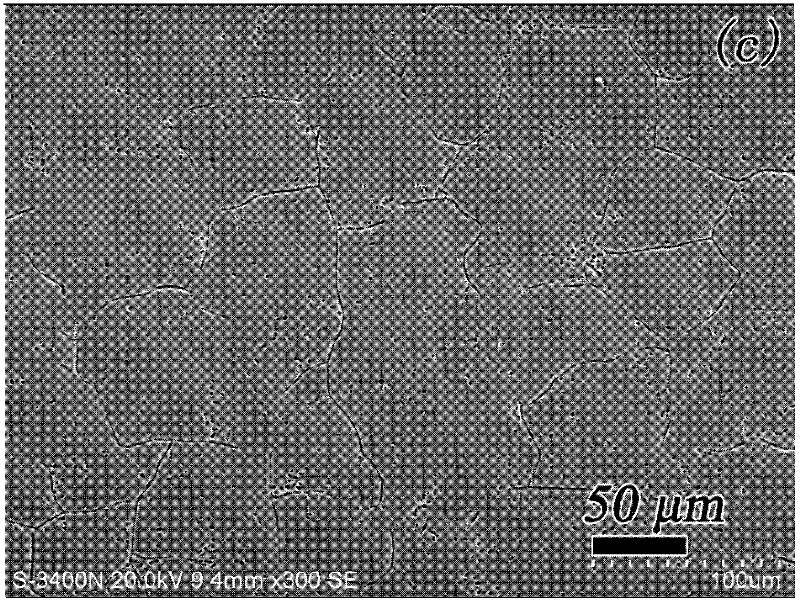

Metastable beta-type Ti-Mo-Si system biomedical alloy and preparation method thereof

The invention discloses a metastable beta-type Ti-Mo-Si system biomedical alloy and a preparation method thereof. The metastable beta-type Ti-Mo-Si system biomedical alloy comprises the following raw material components in percentage by weight: 88.00-90.00 percent of sponge titanium, 0.00-2.00 percent of silicon and 9.5-10.50 percent of molybdenum. The preparation method comprises the following steps of: firstly, respectively weighing raw material according to the weight percentage of the raw material components; secondly, uniformly mixing the raw materials and melting the raw materials by using non-consumable arc; and finally, cooling to obtain an alloy cast ingot with a uniform structure. According to the metastable beta-type Ti-Mo-Si system biomedical alloy and the preparation method thereof disclosed by the invention, the non-poisonous molybdenum and low-price silicon are added to improve the phase composition and the mechanical property of a titanium alloy, so that the mechanical property of the alloy is better matched with that of natural bone of a human body. The low-price silicon is used as one of alloying elements, so that the production cost of the alloy is effectively reduced.

Owner:GUANGXI UNIV

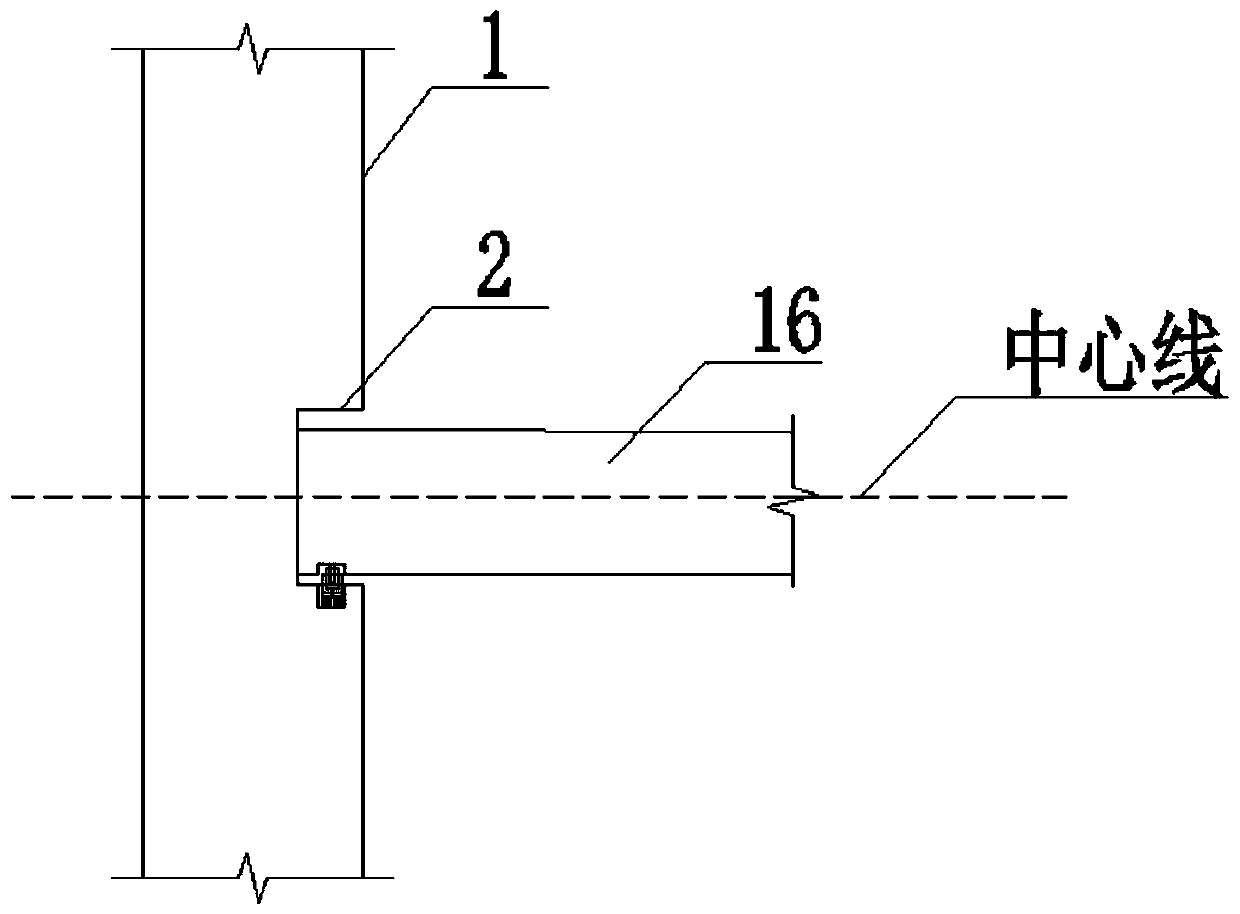

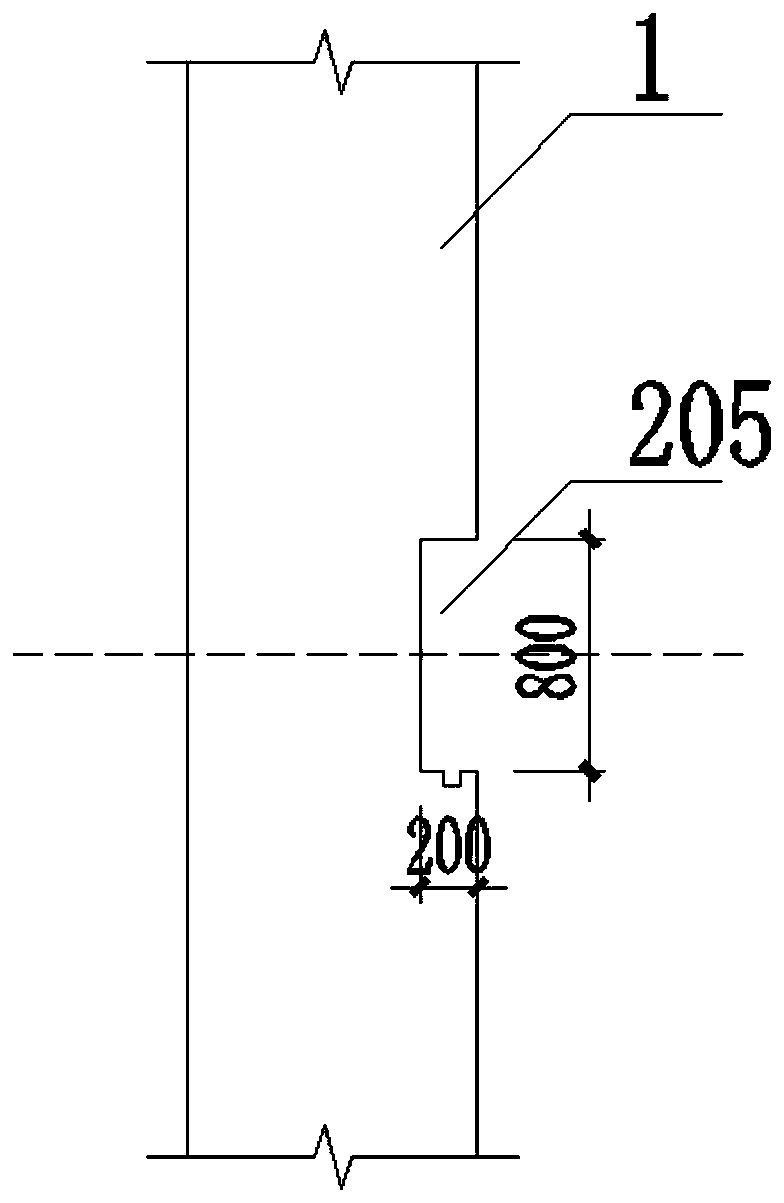

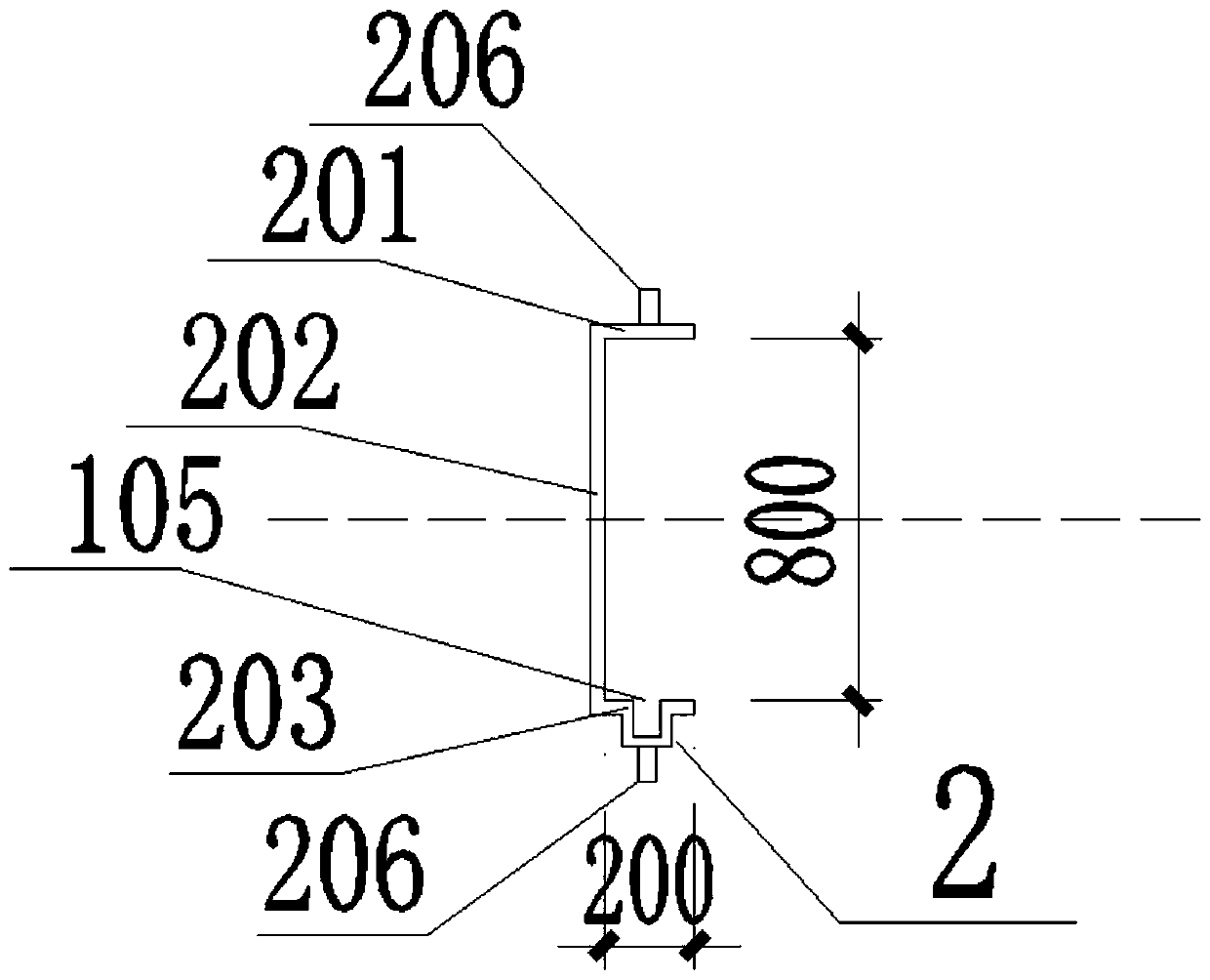

Full composite fabricated metro station underground wall and prefabricated middle plate joint and construction method

PendingCN110042863AAccurate placementSimple structureArtificial islandsLifting devicesMetro stationArchitectural engineering

The invention discloses a full composite fabricated metro station underground wall and prefabricated middle plate joint structure. The full composite fabricated metro station underground wall and prefabricated middle plate joint structure comprises an underground wall, a steel structure clamping groove and a prefabricated middle plate; the steel structure clamping groove is pre-embedded in the underground wall; the steel structure clamping groove is a U shape in the whole, a lower clamping groove is pre-formed on a lower wing plate, and an upper clamping groove is pre-formed in the corresponding position of the lower part of the prefabricated middle plate; a sliding lifting device is mounted in a gap formed by the upper clamping groove and the lower clamping groove, and the prefabricated middle plate can be supported and driven to move along a metro station longitudinally; and a plurality of reinforced junction connecting devices are fixed to the upper part of the upper wing plate andthe lower part of the lower clamping groove of the lower wing plate, and correspondingly matched with underground wall longitudinal bars in the underground wall. According to the full composite fabricated metro station underground wall and prefabricated middle plate joint structure, the error problem of prefabricated underground wall hoisting and mounting is solved, and it is guaranteed that the prefabricated middle plate can accurately be in place; and by using the rigidity and the reserved reinforced junction connecting devices, longitudinal reinforcing steel bars of the underground wall arefurther connected, and weakening damage of the prefabricated underground wall is prevented.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

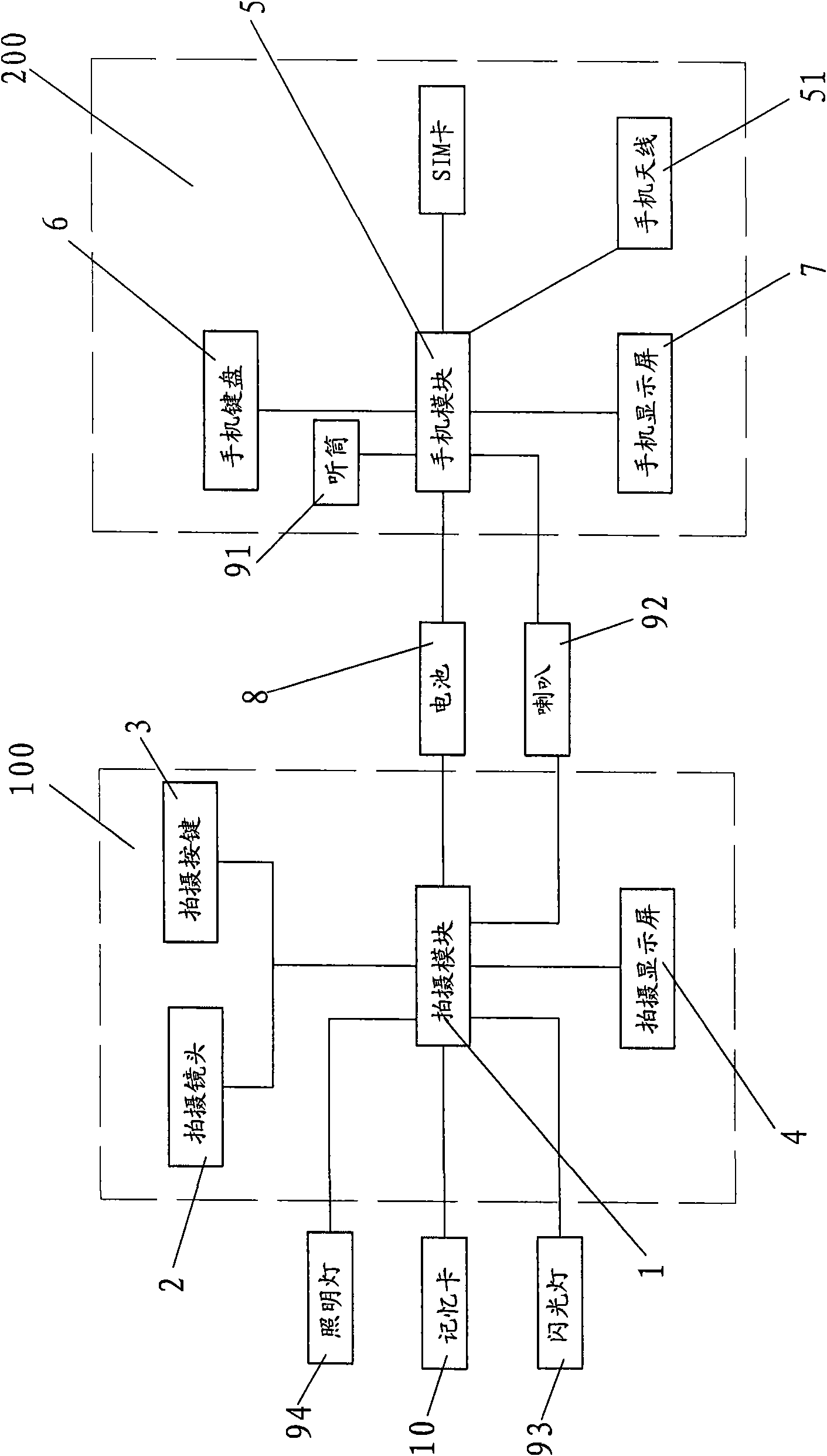

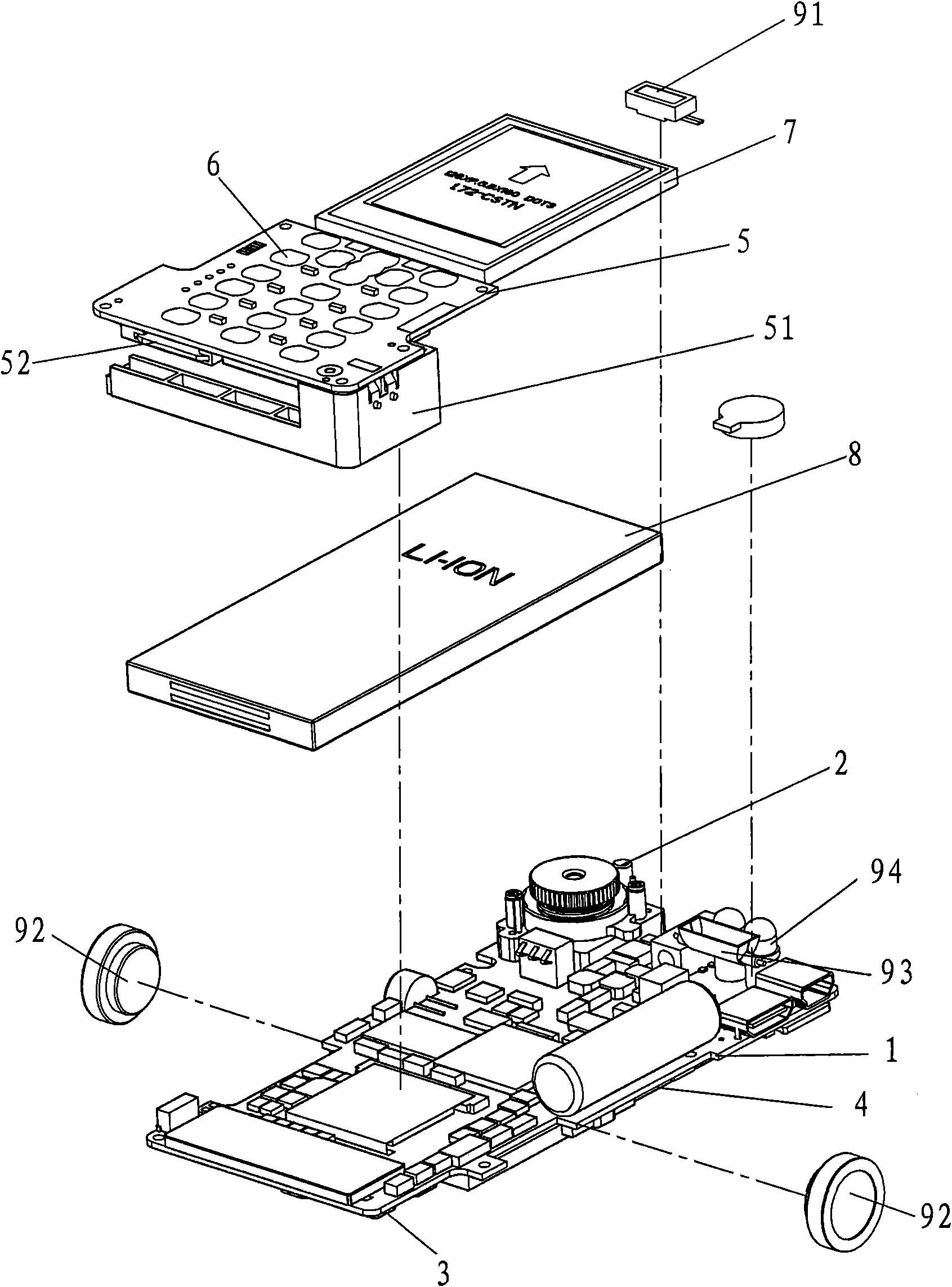

Cellphone control system with camera function

InactiveCN101600007AFunction increaseEnhanced shooting functionTelephone set constructionsCommunications systemControl system

The invention discloses a cellphone control system with a camera function, which comprises a camera system for realizing the camera function and a communication system for realizing the cellphone function, wherein the camera system and the communication system are mutually independent and share or independently use a power supply and a set of loudspeakers. The invention can respectively improve the cellphone function and the camera function, enables the cellphone to have appropriate camera pixel, imaging pixel and cellphone function and has a low cost.

Owner:QUEEN LINES XIAMEN CAMERA

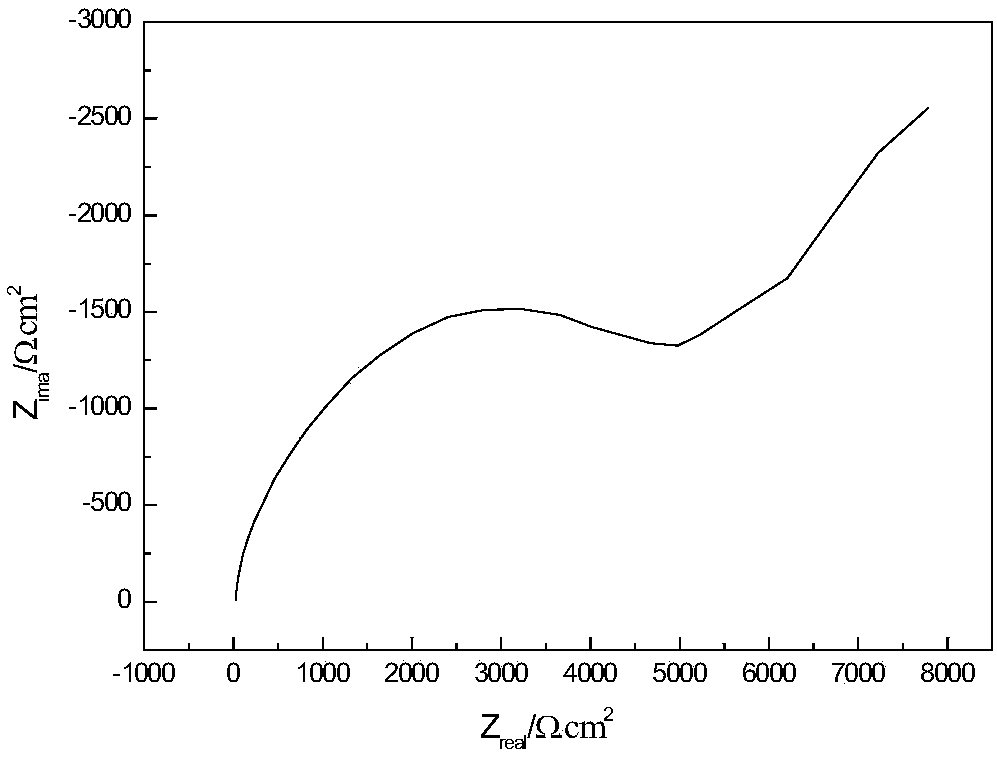

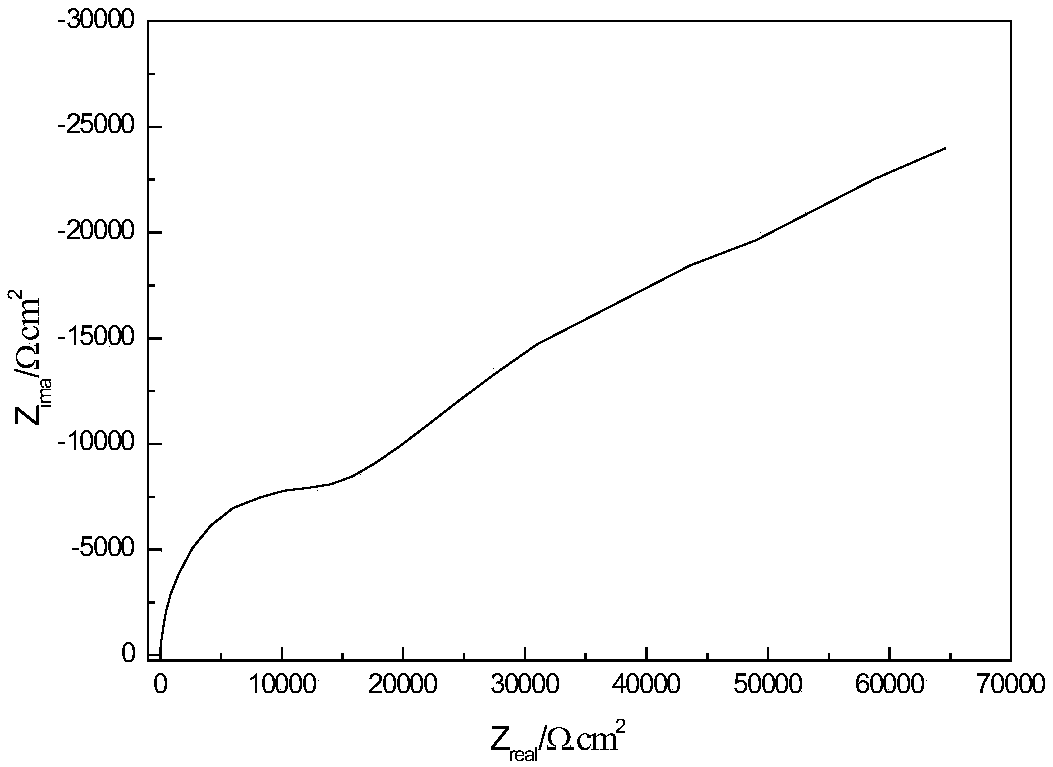

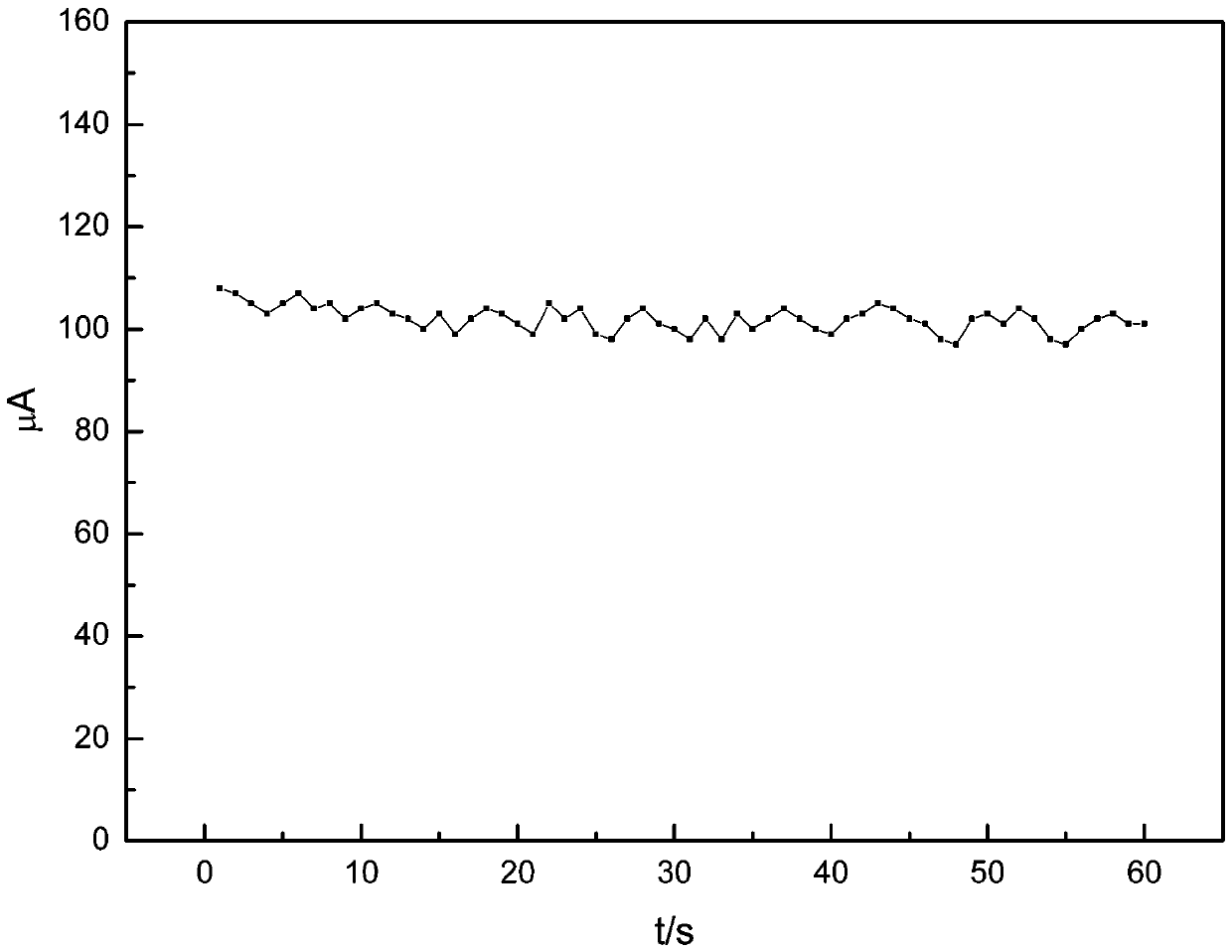

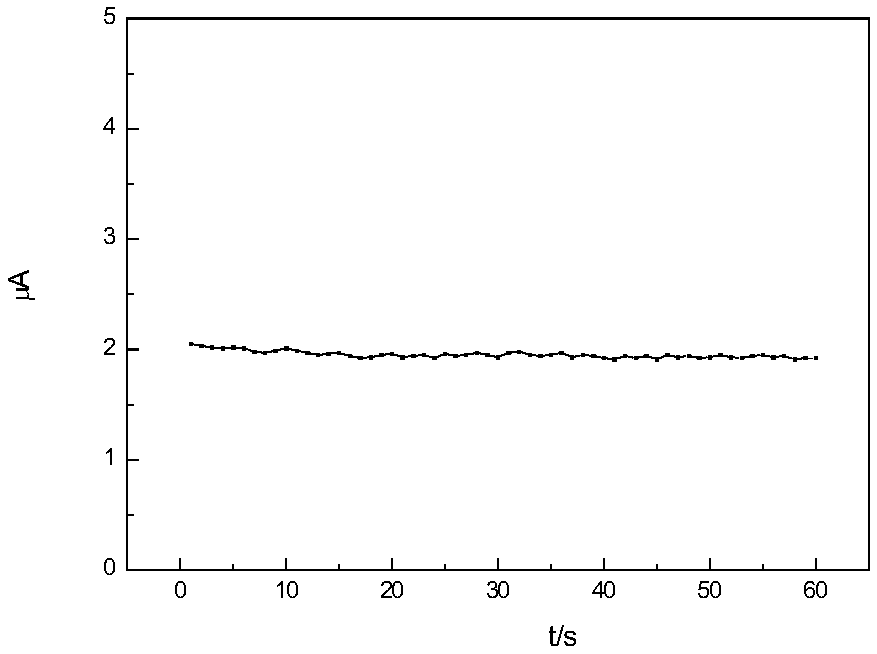

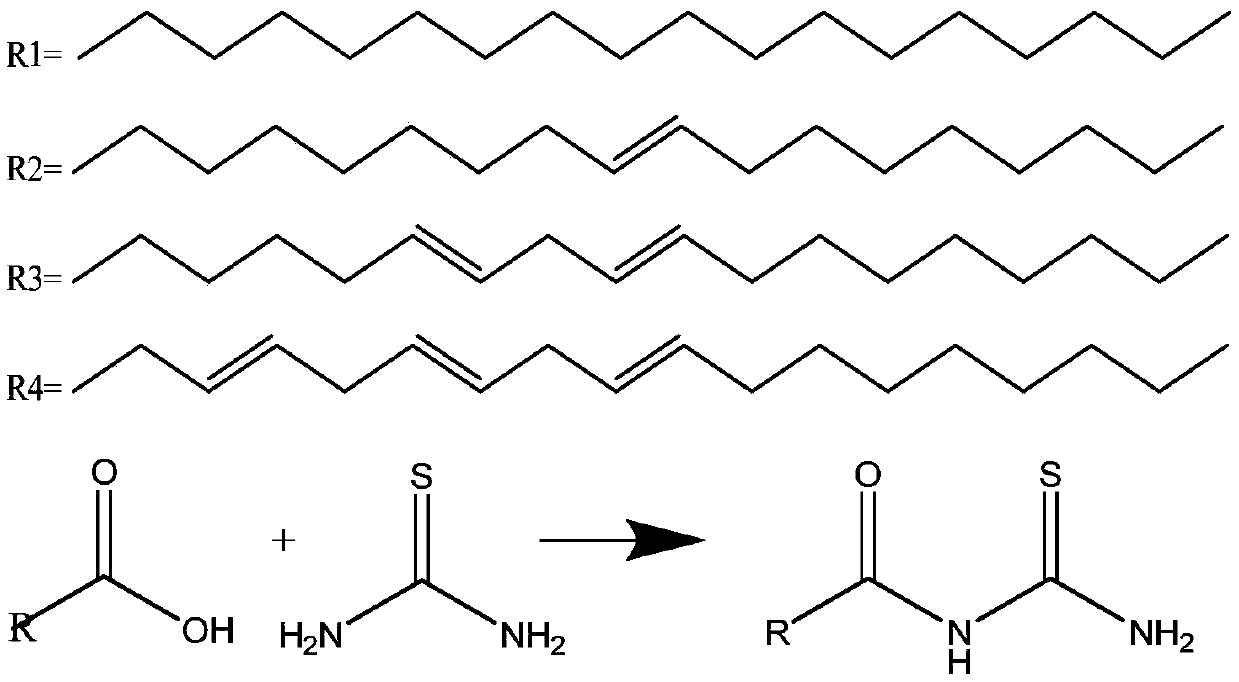

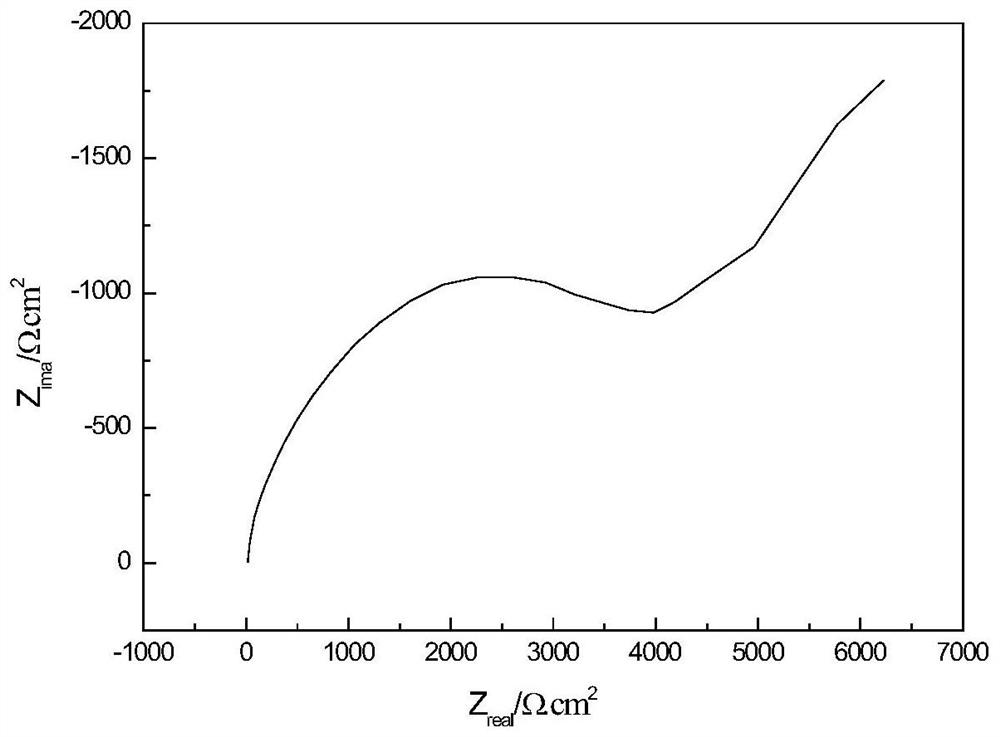

Compound corrosion inhibitor of B10 copper-nickel alloy suitable for seawater medium and preparation method of compound corrosion inhibitor

The invention belongs to the field of metal material corrosion and protection, and relates to a compound corrosion inhibitor of a B10 copper-nickel alloy suitable for a seawater medium and a preparation method of the compound corrosion inhibitor. The compound corrosion inhibitor of the B10 copper-nickel alloy suitable for the seawater medium is composed of benzotriazole linseed oleamide derivatives, sodium molybdate and absolute ethyl alcohol. The compound corrosion inhibitor has the following advantages that on the one hand, the raw materials of the base, namely the benzotriazole linseed oleamide derivatives, of the corrosion inhibitor are wide in source, linseed oil is green vegetable oil, environment friendliness is achieved, a synthetic method is simple, and products do not need purification aftertreatment; and on the other hand, the base, namely the benzotriazole linseed oleamide derivatives, of the corrosion inhibitor has the independent excellent corrosion inhibition performanceto copper and nickel. Uniform corrosion and corrosive pitting of a B10 copper-nickel alloy material can be suppressed at the same time when the compound corrosion inhibitor is used by being compounded with other reagents again.

Owner:BINZHOU UNIV

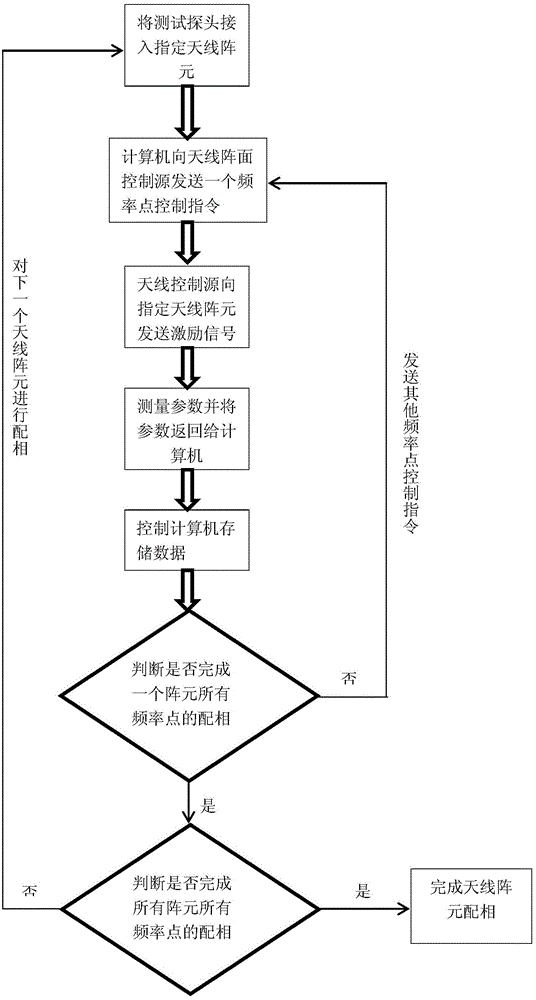

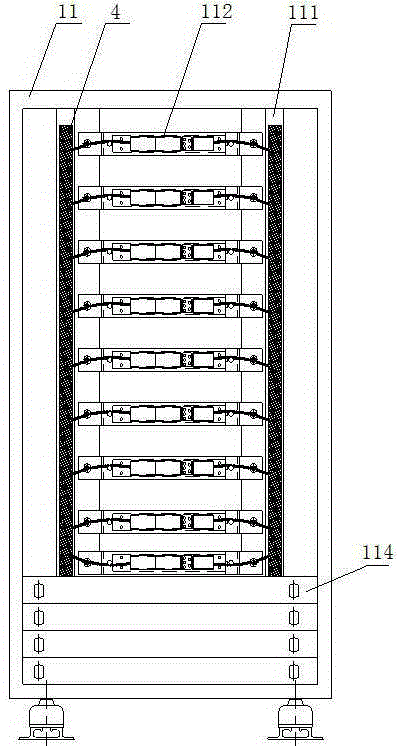

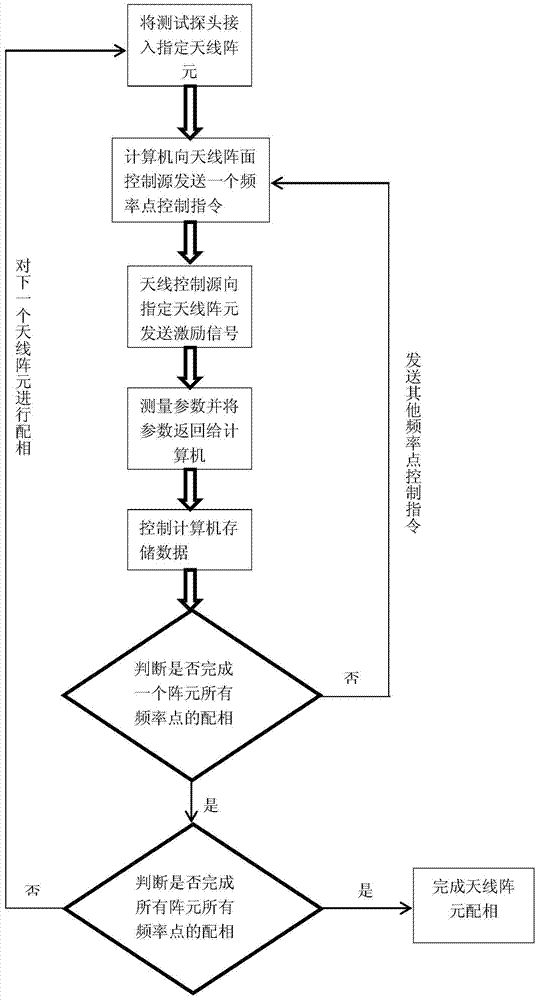

Multi-frequency point phase distribution method for radar antenna array elements

ActiveCN104681987AReduce the number of plugging and unpluggingShorten test timeAntenna arraysPhase distribution methodGeneral purpose

The invention belongs to the field of microwave measurement, and relates to a multi-frequency point phase distribution method for radar antenna array elements. The multi-frequency point phase distribution method comprises the following steps: S1, connecting a test probe into an appointed antenna array element; S2, sending control information corresponding to a frequency point of the appointed antenna array element to an array plane control source by a control computer; S3, measuring data corresponding to the frequency point by using a vector network analyzer, and transmitting the data to the control computer through a GPIB (general purpose interface bus) cable; S4, storing the data in a corresponding database after the data under the frequency point is received by the control computer and corresponding data processing is performed; S5, judging whether the phase distribution of all the frequency points of one array element is finished or not; S6, judging whether the phase distribution of all the frequency points of all the array elements is finished or not. The plug time of each frequency point is greatly reduced, so the plug time of a whole phase distribution cycle is further shortened, manpower, material resources and financial resources in the phase distribution process are saved, and the development cycle and the production cycle are greatly shortened.

Owner:LEIHUA ELECTRONICS TECH RES INST AVIATION IND OF CHINA

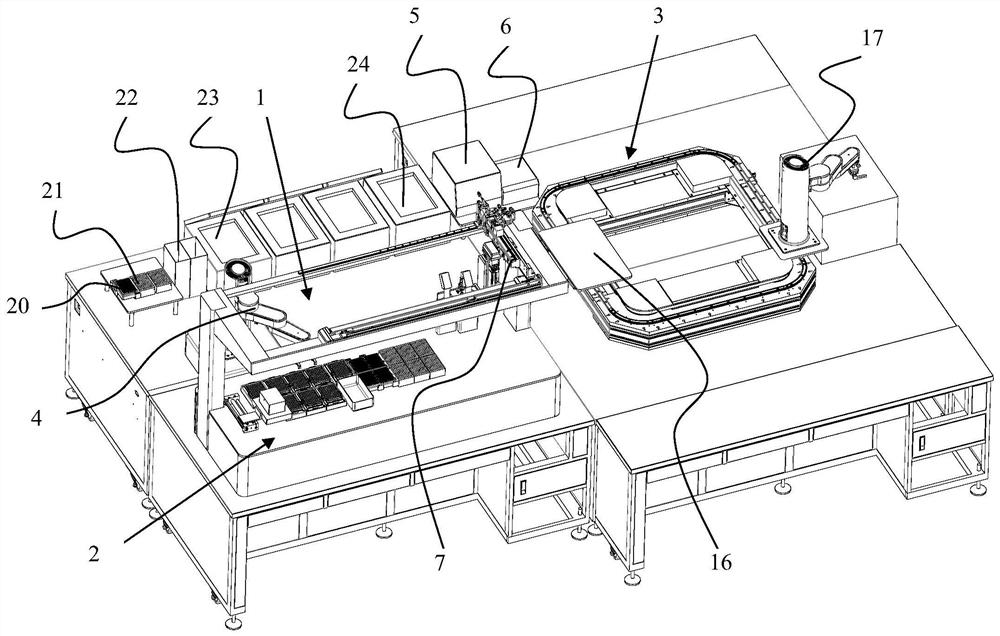

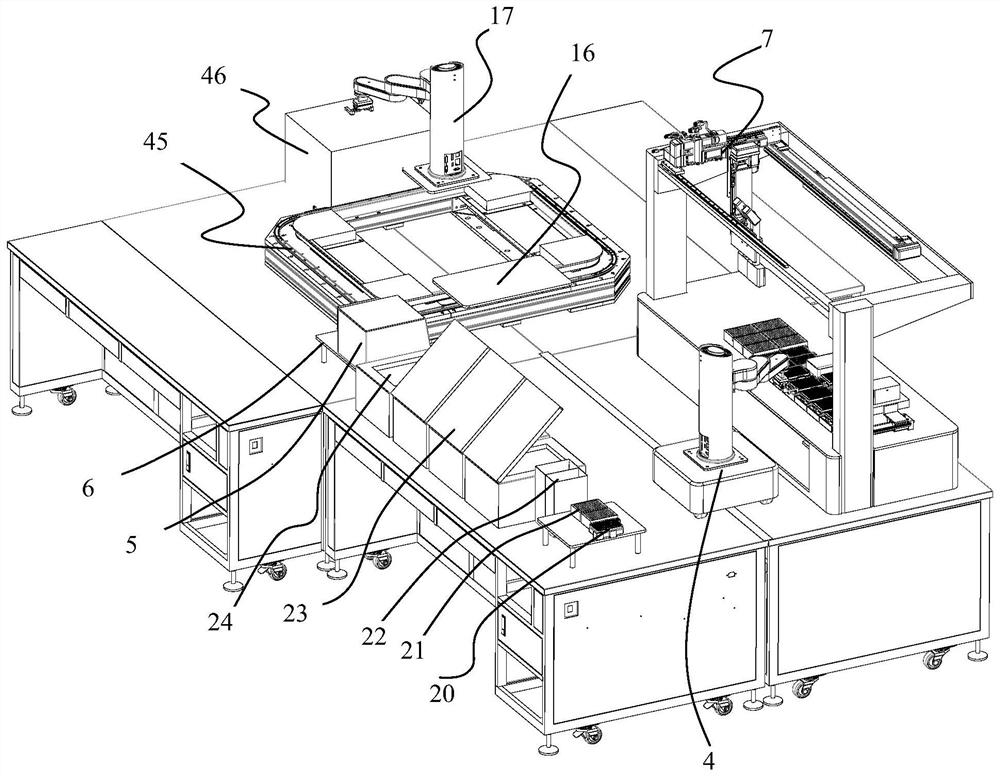

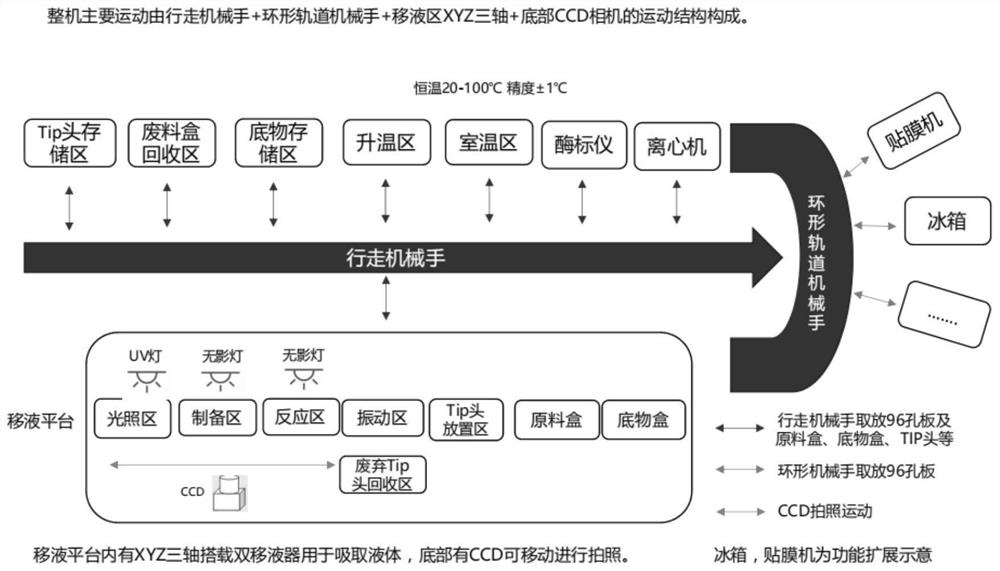

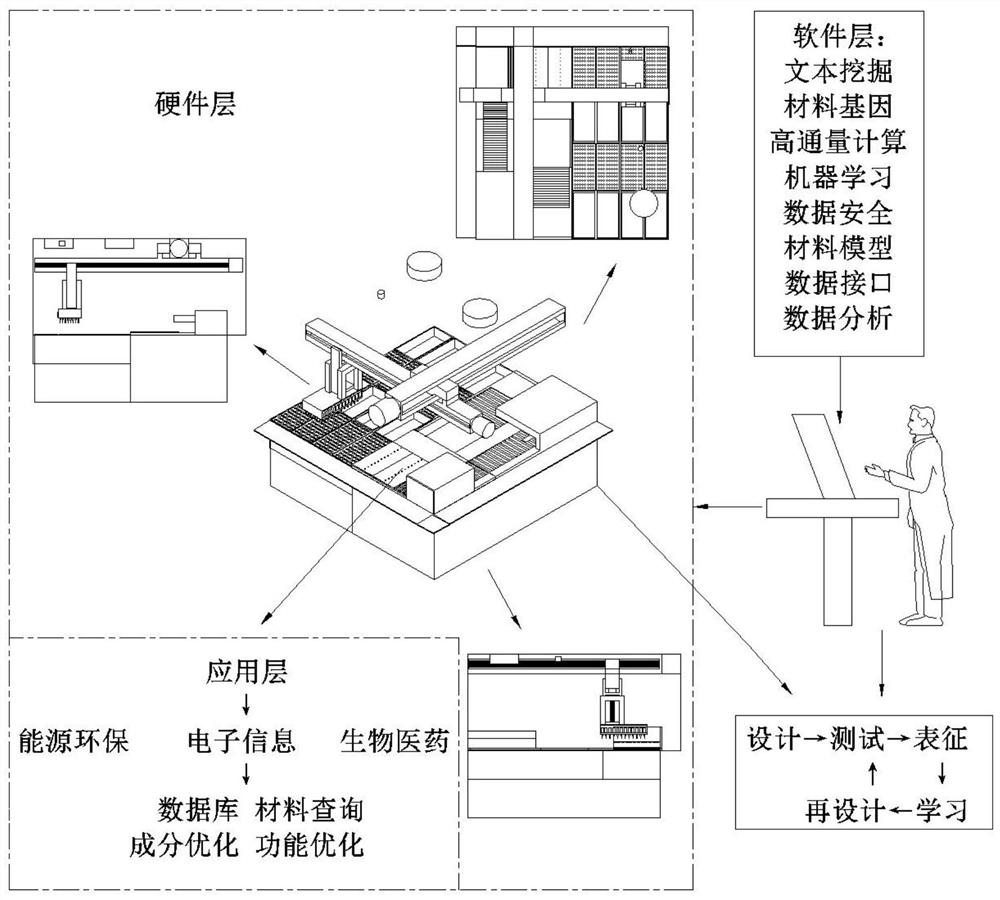

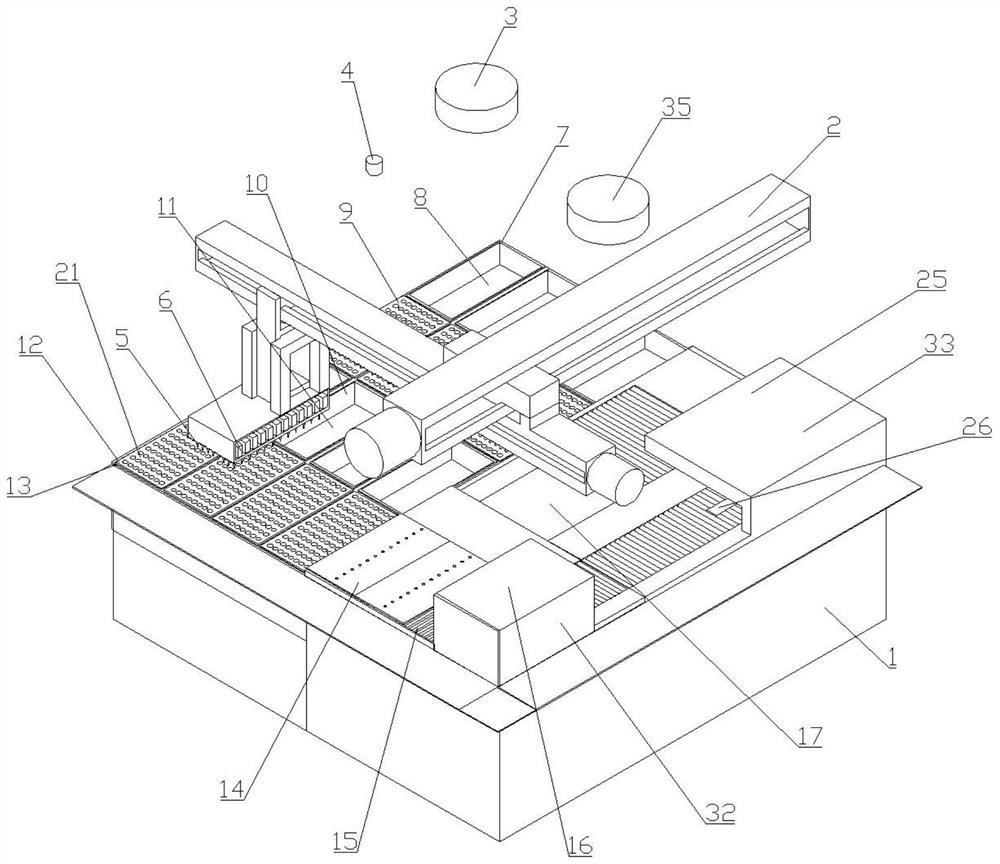

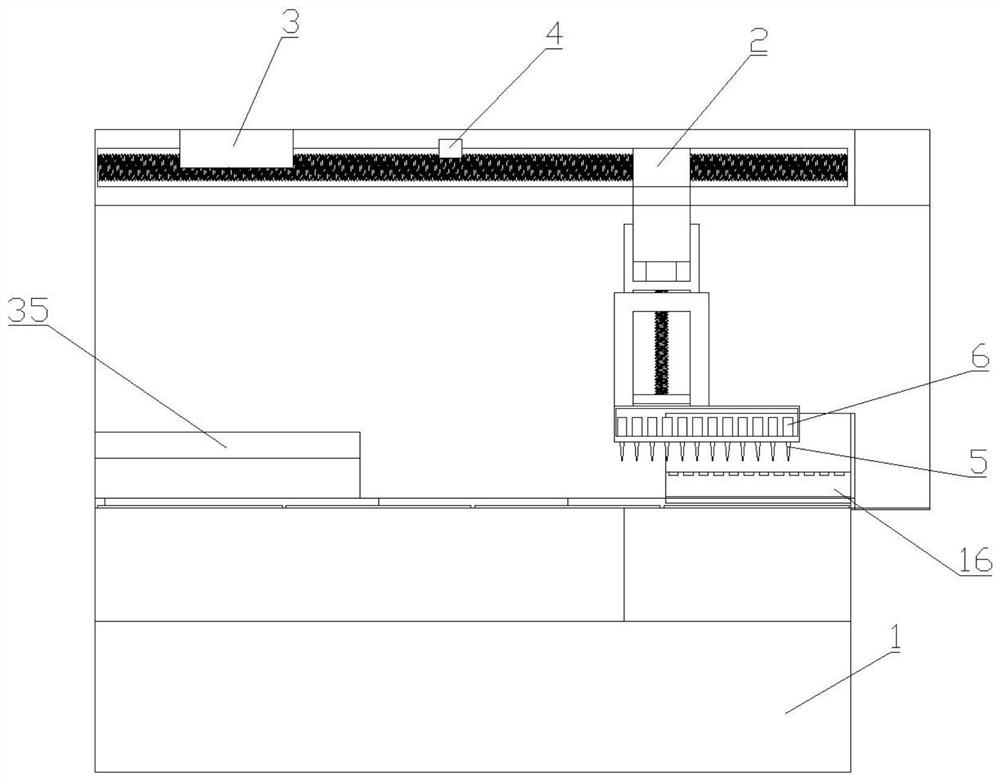

Functional material digital design, preparation and evaluation automation platform

PendingCN112697706AReduce labor intensityImprove accuracyMaterial analysis by optical meansPeptide preparation methodsRobot handDigital manufacturing

The invention belongs to the field of high-end equipment manufacturing, new materials, intelligent manufacturing, new-generation information technologies and biotechnologies and relates to a functional material digital design, preparation and evaluation automation platform. The platform comprises a first operation area, a second operation area, a third operation area, a first manipulator, a second manipulator and a third manipulator; the first manipulator transfers materials among the three operation areas; the second manipulator is used for extracting, transferring and mixing the materials in the second operation area; and the third manipulator is used for extracting, transferring and mixing the materials in the third operation area. The manipulators are adopted to replace an operator; material extraction, functional material formula screening, design, preparation and evaluation are carried out through person-human artificial intelligence-robot cooperation, and therefore, the labor intensity is reduced, time is saved, the experiment accuracy can be improved, and design, test, characterization, learning and redesign are completed; and digital manufacturing and iterative innovation of a novel functional material are realized.

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI

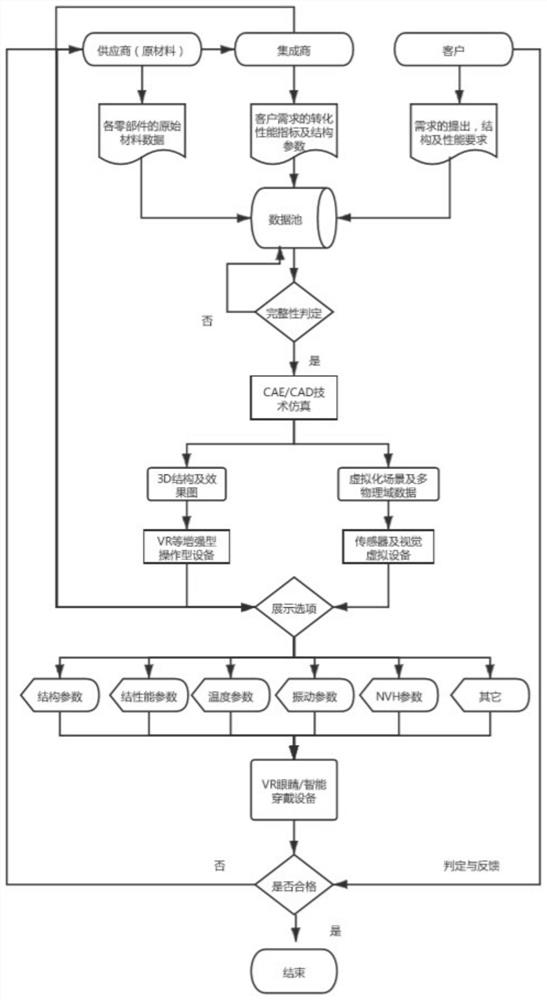

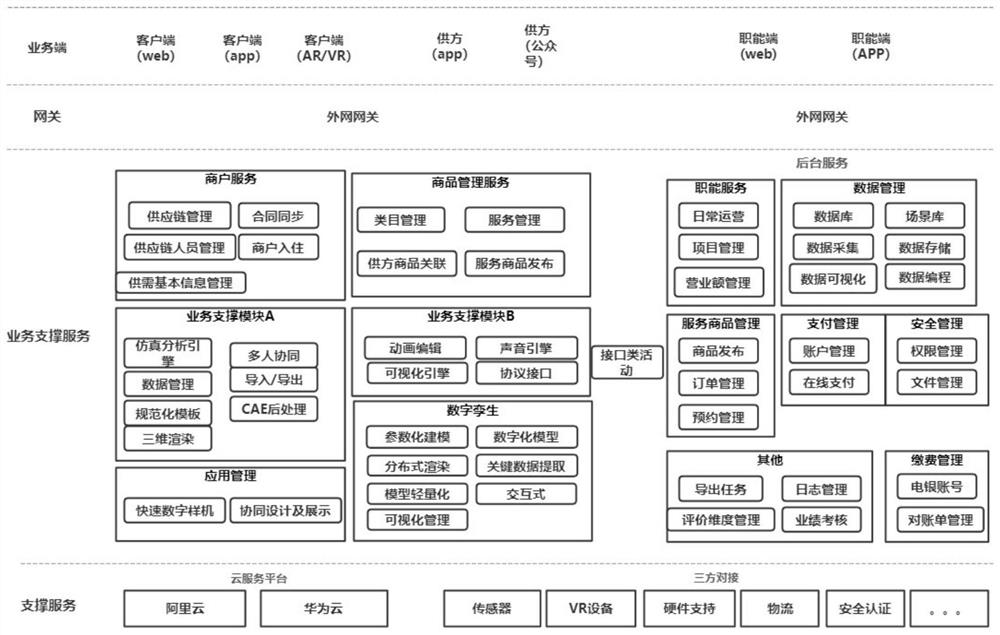

Supply chain system based on simulation and digital prototype

ActiveCN114549124AReduce R&DReduce riskDesign optimisation/simulationBuying/selling/leasing transactionsModel selectionElectric machinery

A supply chain system based on simulation and a digital prototype comprises a supply chain platform running on a server, and the supply chain platform is provided with a motor release module, a simulation module, a motor integration module, a search module, a wearable device connection module, a user management module and an online transaction module. According to the invention, a customer can search a required motor product on the supply chain platform, and visually check the appearance 3D model, function and performance simulation of the digital motor. The digital motor has consistent functions and characteristics with a physical prototype, and a client can directly sense the vibration, temperature rise, temperature and other conditions of the digital motor through the wearable device with the sensor, so that the digital prototype is realized. The electrical parameters of the digital motor displayed by the supplier on the platform all cover each working condition, and are more visual. A virtual-real combination mode is adopted, and model selection and matching of electromechanical products such as a motor by a user are facilitated.

Owner:杭州麦科斯韦网络科技有限公司

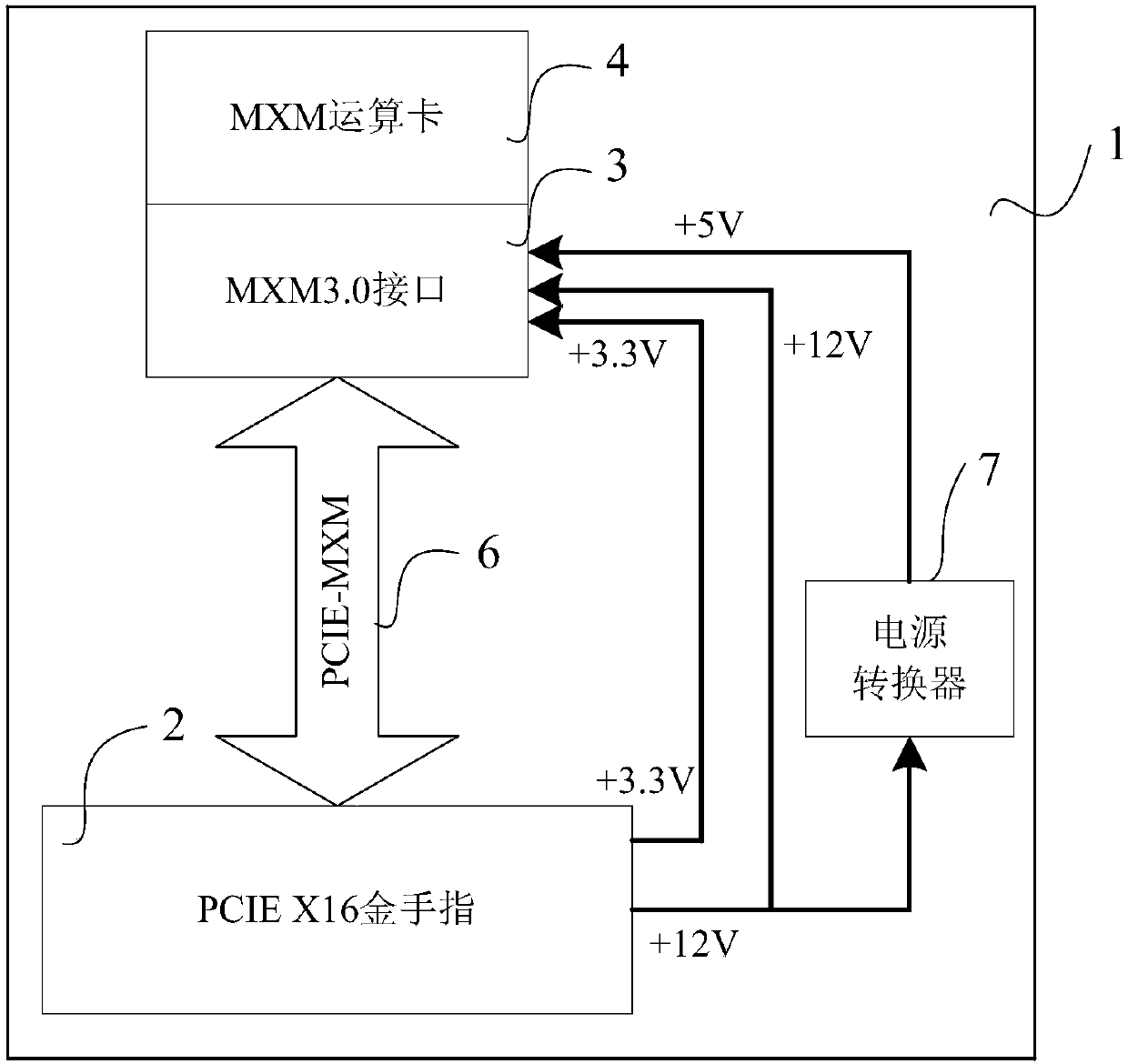

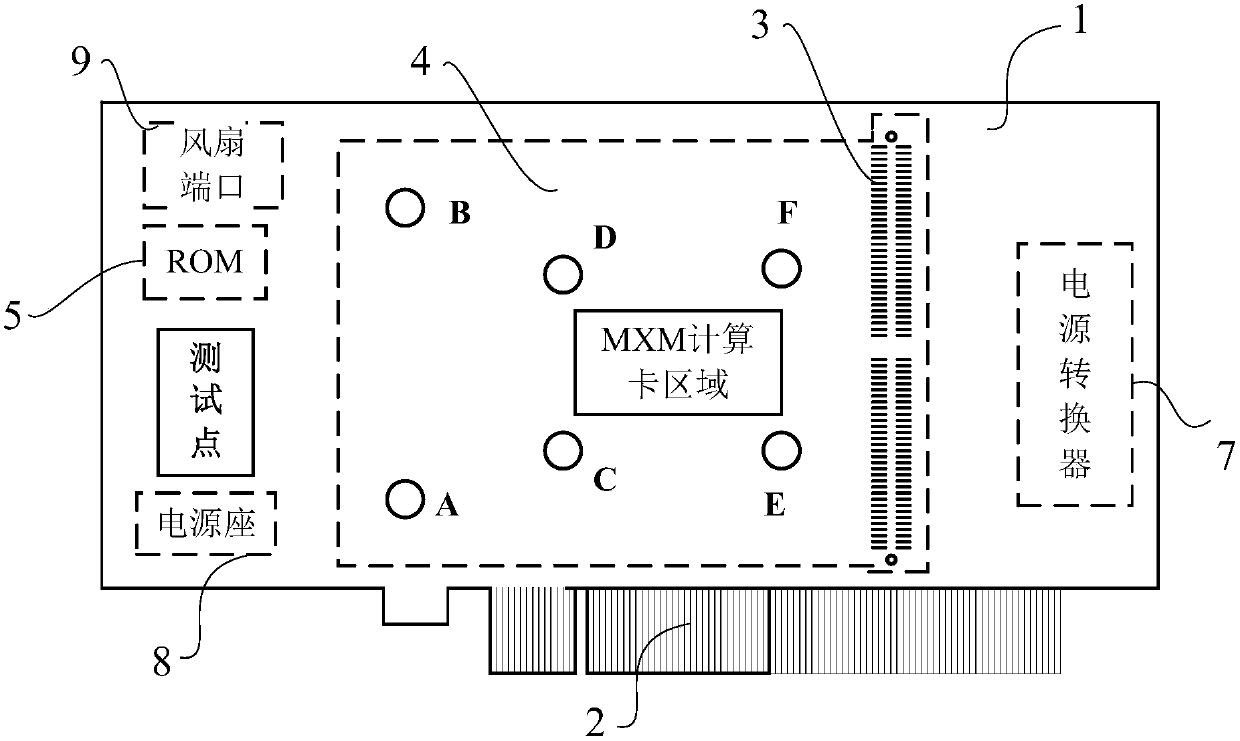

Operation switching device based on PCIE X16-MXM

The invention discloses an operation switching device based on PCIE X16-MXM, and belongs to the technical field of operation switching plate design. The invention aims to solve the problems that the current MXM computing card cannot be directly used on a desktop PC and a server, and the development and use cost of a user is relatively high. The PCIE X16 golden finger adapter comprises an adapter plate, a PCIE X16 golden finger, an MXM 3.0 interface, an MXM operation card, an I2C ROM interface and a PCIE-MXM signal line. A PCIE X16 golden finger is arranged on the adapter plate, and the PCIE X16 golden finger can be inserted into a server with a PCIE X16 slot; The adapter plate is further provided with an MXM 3.0 interface and an I2C ROM interface, the MXM 3.0 interface carries an MXM operation card, and the I2C ROM interface is used for storing firmware programs; PCIE-X16 golden finger between MXM 3.0 interface and PCIE X16 golden finger And the MXM signal lines are connected. The invention is used for realizing the direct connection use of the MXM operation card and the PC or the server.

Owner:哈尔滨工大雷信科技有限公司

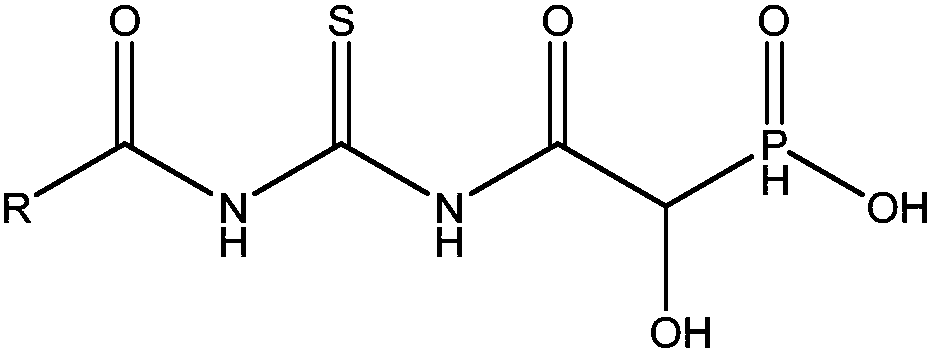

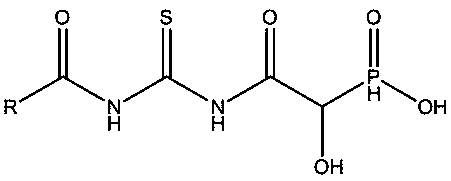

Compounded corrosion inhibitor suitable for electric coupling of N80 steel and stainless steel and preparation method thereof

The invention belongs to the field of metal material corrosion and protection, and particularly relates to a compounded corrosion inhibitor suitable for electric coupling of N80 steel and stainless steel and a preparation method thereof. The compounded corrosion inhibitor comprises the following components in percentage by mass: 50%-60% of phosphonyl carbamido flaxseed oil derivatives, 10%-20% ofpolyaspartic acid, 10%-20% of sodium molybdate and 10%-30% of isopropyl alcohol, wherein the sum of the mass percentages of the components is 100%. The compounded corrosion inhibitor suitable for electric coupling of N80 steel and stainless steel and the preparation method thereof have the benefits as follows: the corrosion inhibition efficiency is high, the production cost is low, and the compounded corrosion inhibitor further has the characteristics that the environmental friendliness is achieved, and the normal operation of the equipment is not affected.

Owner:GUIZHOU MINZU UNIV

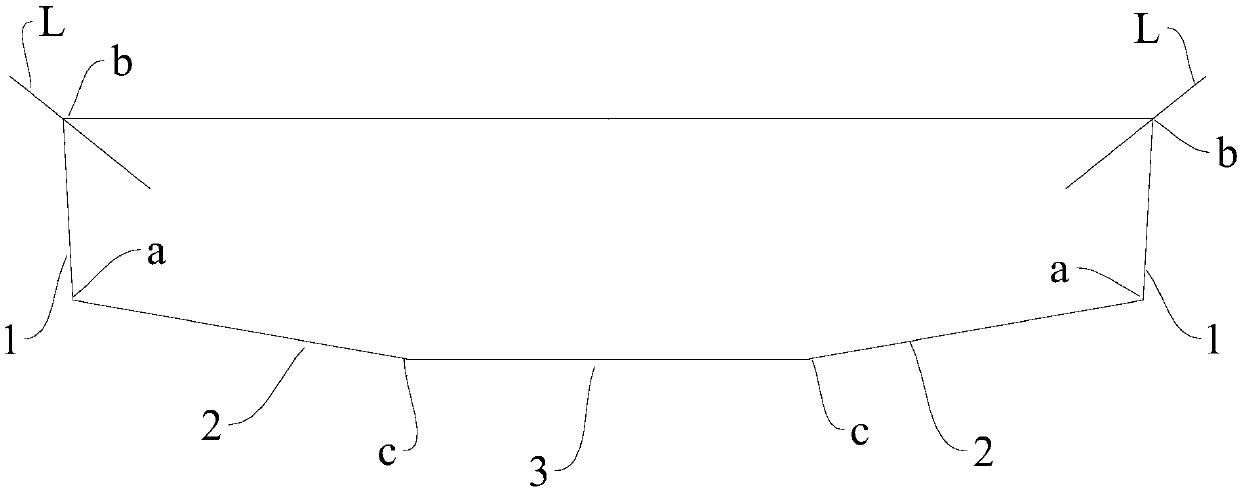

Platformization design method of steering trapezoids

ActiveCN108016495AReduce R&DShorten the development cycleSteering linkagesSteering angleDesign methods

The invention provides a platformization design method of steering trapezoids. A first steering trapezoid suitable for a first vehicle-type vehicle is designed, the first steering trapezoid makes themaximum internal steering angle of the first vehicle-type vehicle be alpha 1 and the maximum external steering angle be alpha 2, and the first steering trapezoid is provided with a first trapezoid arm; and a second steering trapezoid suitable for a second vehicle-type vehicle is designed, the maximum internal steering angle of the second vehicle-type vehicle is alpha 1, the maximum external steering angle is alpha 2, the second steering trapezoid is provided with a second trapezoid arm, and the second trapezoid arm and the first trapezoid arm are the same, wherein the first vehicle-type vehicle and the second vehicle-type vehicle are different, and the first steering trapezoid and the second steering trapezoid share a production platform. In this way, the second steering trapezoid can be designed according to the first steering trapezoid, research and development of the steering trapezoid of the new vehicle model can be reduced, the research and development time and cost can be reduced, design defects can be avoided, and the research and development cycle of the vehicles can be shortened.

Owner:GREAT WALL MOTOR CO LTD

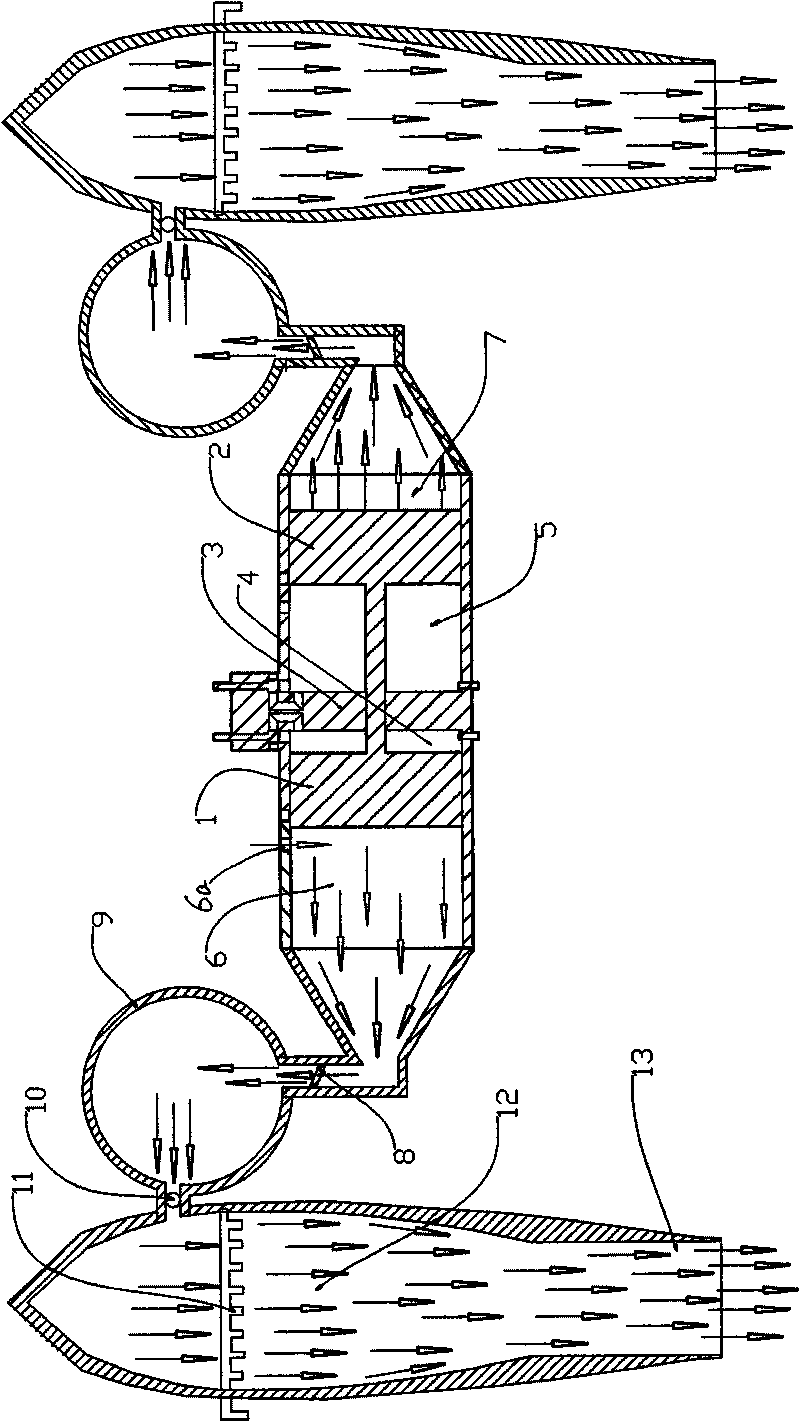

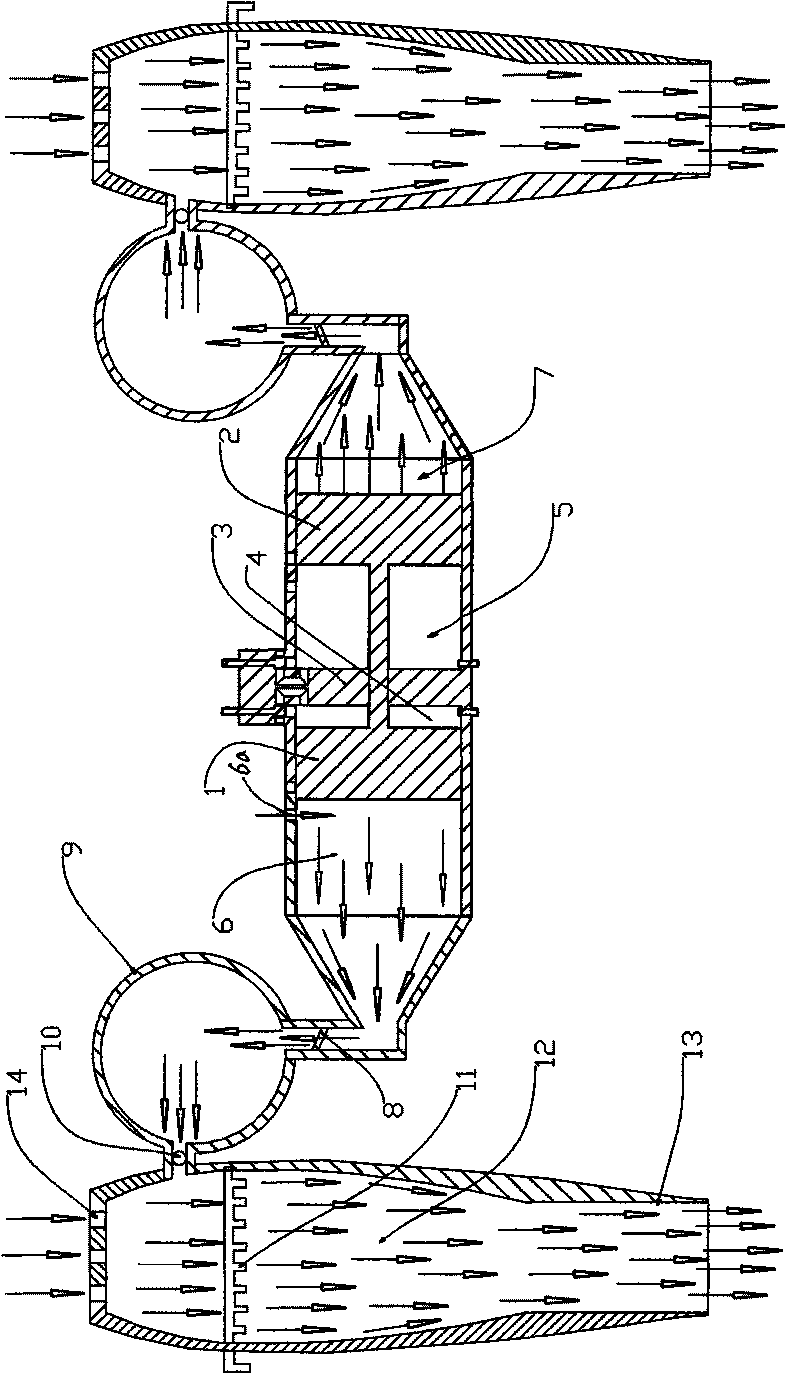

Air jet engine using piston engine as air compressor and application thereof

InactiveCN101709680AIncrease rotational powerHigh speedPower plants being motor-drivenContinuous jet plantsFree-piston engineCombustion chamber

The invention provides an air jet engine using a piston engine as an air compressor and application thereof. The air jet engine is characterized in that: by the motion of a piston in the piston engine, air entering an air cylinder is directly or indirectly compressed, and the compressed air and fuel are mixed and combusted in a combustion chamber and then jetted out from a jet pipe so as to generate a required propelling power. The piston engine and a ram jet are combined to form a ram pressure / piston jet engine. The gas jet pipes are arranged in all directions of an aircraft, so that the aircraft can obtain the abilities of vertical takeoff and landing, hovering and flexible turning. The gas is tangentially jetted by nozzles at the tail ends of aerovanes of the aircraft, so that the aerovanes can obtain higher rotary power and speed.

Owner:徐林波

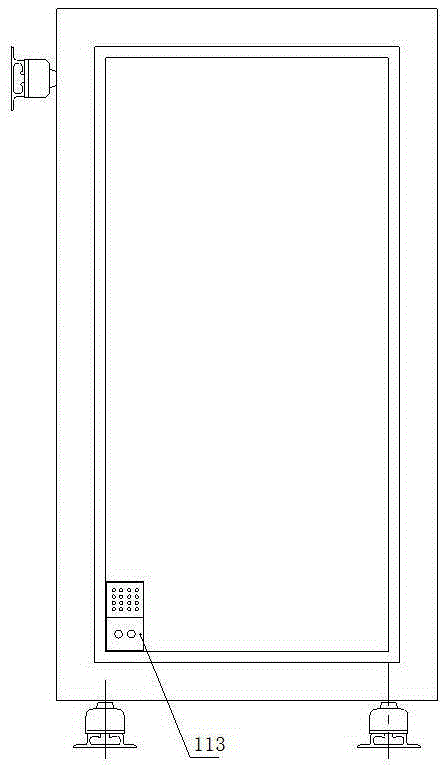

A square cabin platform based on optical fiber bus distribution

PendingCN105278067AImprove electromagnetic compatibilityReduce typesFibre mechanical structuresBus interfaceEngineering

The invention provides a square cabin platform based on optical fiber bus distribution. The square cabin platform comprises a cabin body and wall plates forming the cabin body in a surrounding manner. The wall plates include a front wall plate, a rear wall plate, a left wall plate and a right wall plate. Cabinets are arranged in the cabin body and are internally provided with signal bus apparatuses. The inner walls of the rear wall plate, the left wall plate and the right wall plate close to the cabinet side are provided with first wiring grooves. Signal buses are laid in the first wiring grooves. The first wiring grooves of the left wall plate and the right wall plate are internally provided with panel bus interfaces connected with the signal buses. The signal buses are led out via the signal bus apparatuses. The signal buses are optical fiber buses. Full-optical fiber bus wiring is adopted, so that the electromagnetic compatibility of task systems is improved, the number of types of signal cables and the number of signal cables for using are reduced, communication command platforms are lightened, and further the developing, manufacturing, using and maintaining costs are reduced.

Owner:衡阳泰豪通信车辆有限公司

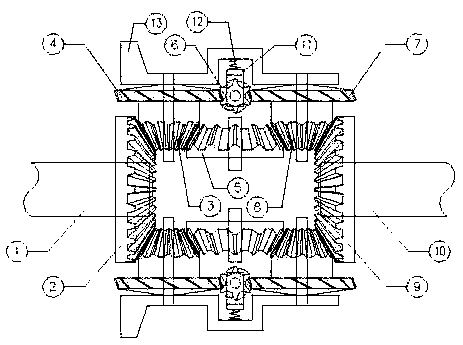

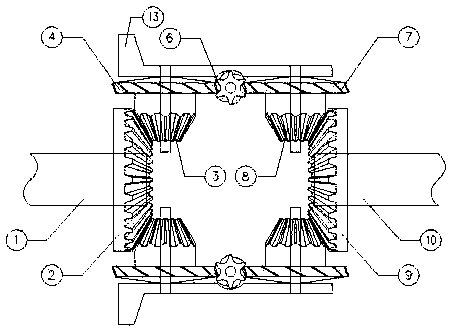

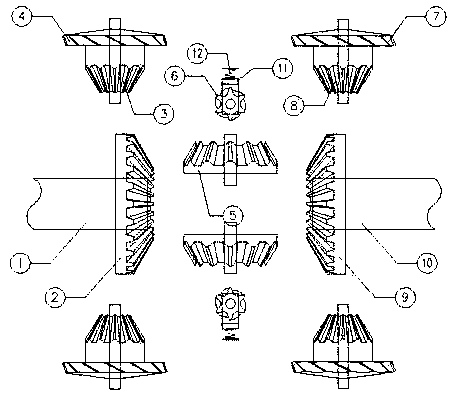

A mechanical limited-slip differential that can be used to drive the steering axle

InactiveCN105736672BImprove bearing capacitySmall sizeDifferential gearingsLimited-slip differentialRoad surface

The invention discloses a mechanical limited slip differential supportive of being used for driving a steering axle in the technical field of automobiles. A planet gear pair is used to replace a planet gear in an open differential, slip limiting effect of a worm and gear in the planet gear pair is utilized to realize a slip limiting function of the differential, wheel driving force changes linearly, and no impact force is generated. By the above mode, when a vehicle travels on a slippery road, the slip limiting function can be realized by utilizing self-locking performance of the worm and gear; when the vehicle utilizes an engine for braking, a central gear 6 slips to unload force, a central planet wheel 5 transmits force, and the differential is equivalent to an open differential at this moment, so that influence on a steering function due to locking of the limited slip differential is avoided, and the mechanical limited slip differential can be used for driving the steering axle. When the mechanical limited slip differential is used as a non-steering-axle differential or a central differential, the central planet wheel 5 can be omitted, and the central worm 6 is fixed on a planet gear bracket 13, so that structure is simplified while cost is saved.

Owner:朱靖栋

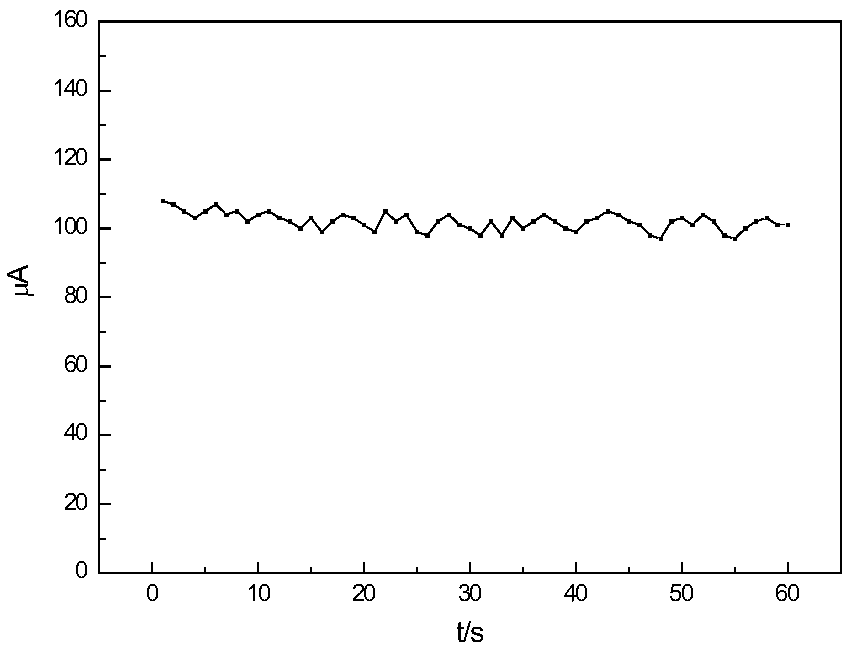

Automatic functional material biochemical synthesis workstation based on artificial intelligence

PendingCN112461822ARaise the ratioImprovement ingredientsMaterial analysis by observing effect on chemical indicatorPreparing sample for investigationVideo monitoringChemical synthesis

The invention relates to an automatic functional material biochemical synthesis workstation based on artificial intelligence. The workstation comprises a desktop robot hardware platform and an intelligent control analysis center which is in communication connection with the desktop robot hardware platform and includes a database and software. The desktop robot hardware platform is provided with araw material area, a reaction area, a test area, an evaluation area and a video monitoring area. The intelligent control analysis center can drive a three-axis mechanical arm to drive a pipette to prepare raw materials in a raw material area and can also inject the raw materials into a porous reaction plate and a porous microwell plate to be supplied to a visual module below a reaction area. A test detector in the test area and an evaluation detector in an evaluation area acquire data, the intelligent control analysis center performs calculation, analysis and machine learning, calculation andoutput are performed according to a preset model, and a high-throughput test, testing and iterative optimization of functional materials are realized. A closed loop of ''design-test-representation-learning-redesign'' is quickly completed in a low-cost and multi-cycle manner, and preparation and digital manufacturing of a novel functional material are realized.

Owner:武汉中科先进材料科技有限公司

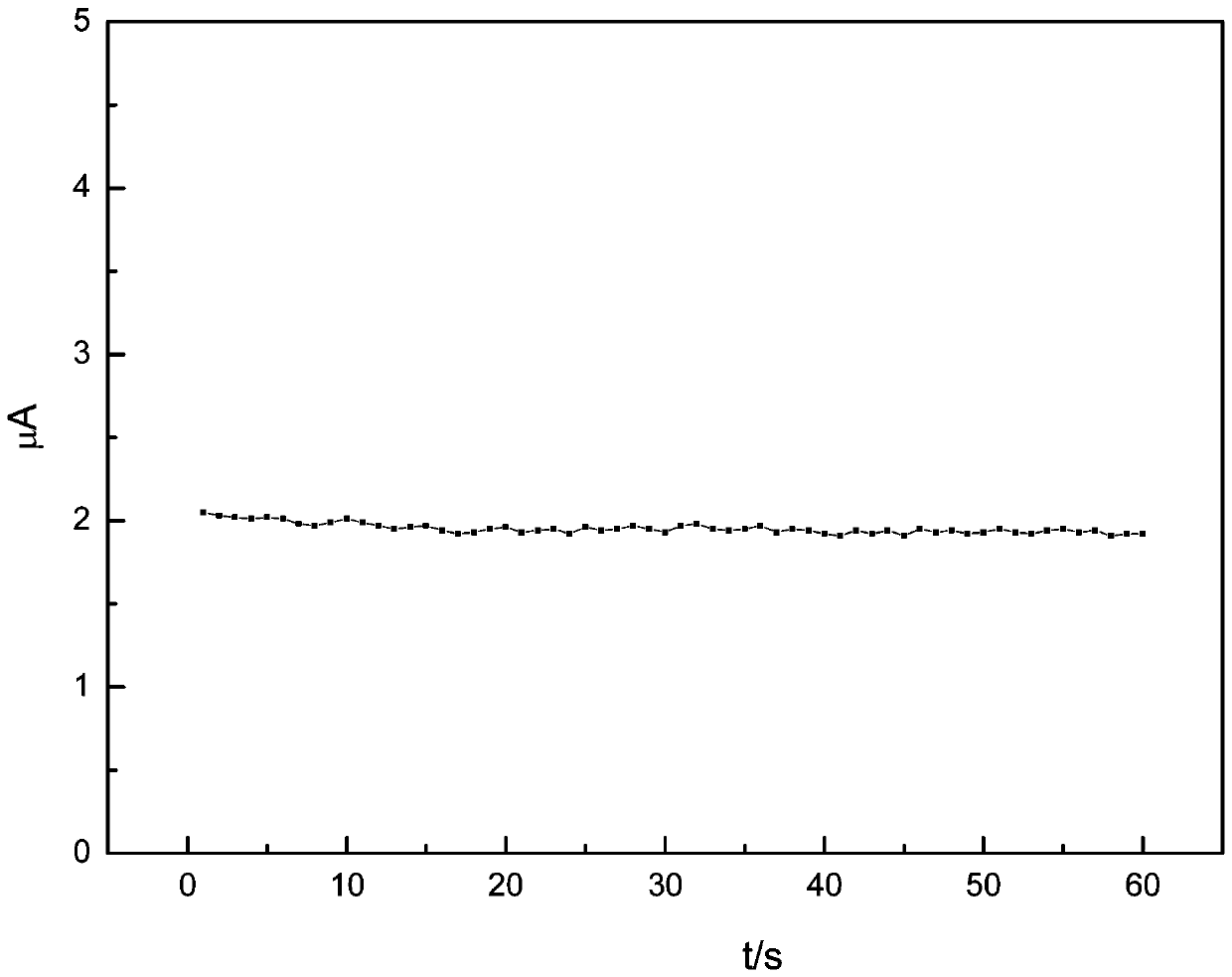

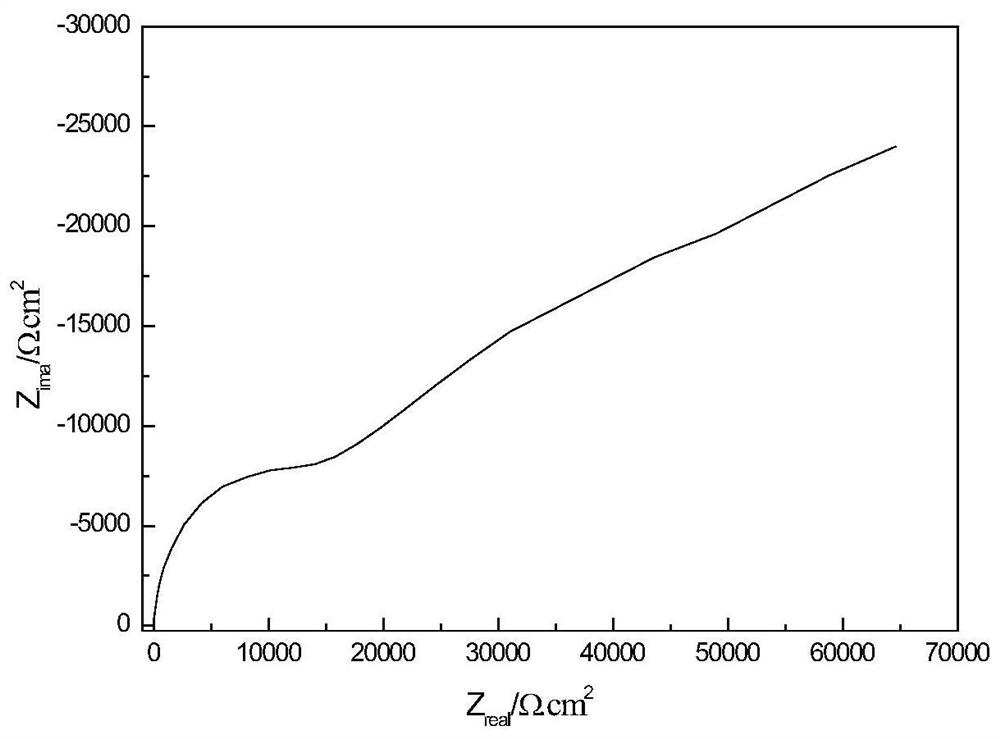

Compound corrosion inhibitor suitable for N80 steel and stainless steel galvanic couples in oilfield sewage medium and preparation method thereof

The invention belongs to the field of metal material corrosion and protection and relates to a compound corrosion inhibitor suitable for N80 steel and stainless steel galvanic couples in an oilfield sewage medium and a preparation method thereof. The compound corrosion inhibitor suitable for the N80 steel and stainless steel galvanic couples in the oilfield sewage medium comprises a phosphonyl ureido linseed oil derivative, polyaspartic acid, sodium molybdate and isopropyl alcohol. The compound corrosion inhibitor has the following advantages that on the one hand, the main component, the phosphonyl ureido linseed oil derivative, of the corrosion inhibitor has a wide source of raw materials, and the compound corrosion inhibitor has the environmental friendliness; the production process is simple, and a product does not need to be treated after purification; and on the other hand, the potential difference of the galvanic couples can be reduced obviously, the galvanic current of the N80 steel and stainless steel galvanic couples is remarkably reduced in the oilfield sewage medium again, and the corrosion inhibition efficiency reaches up to 97% and more.

Owner:BINZHOU UNIV

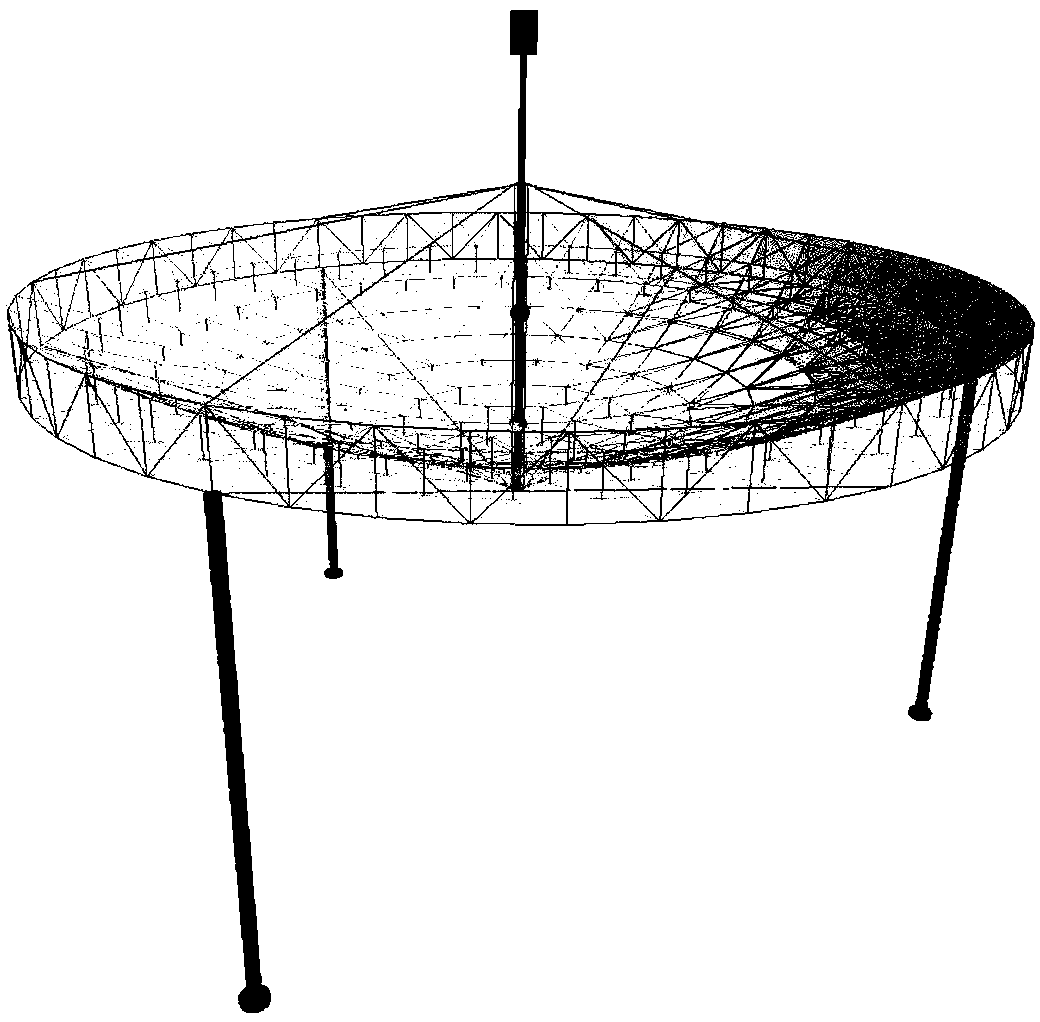

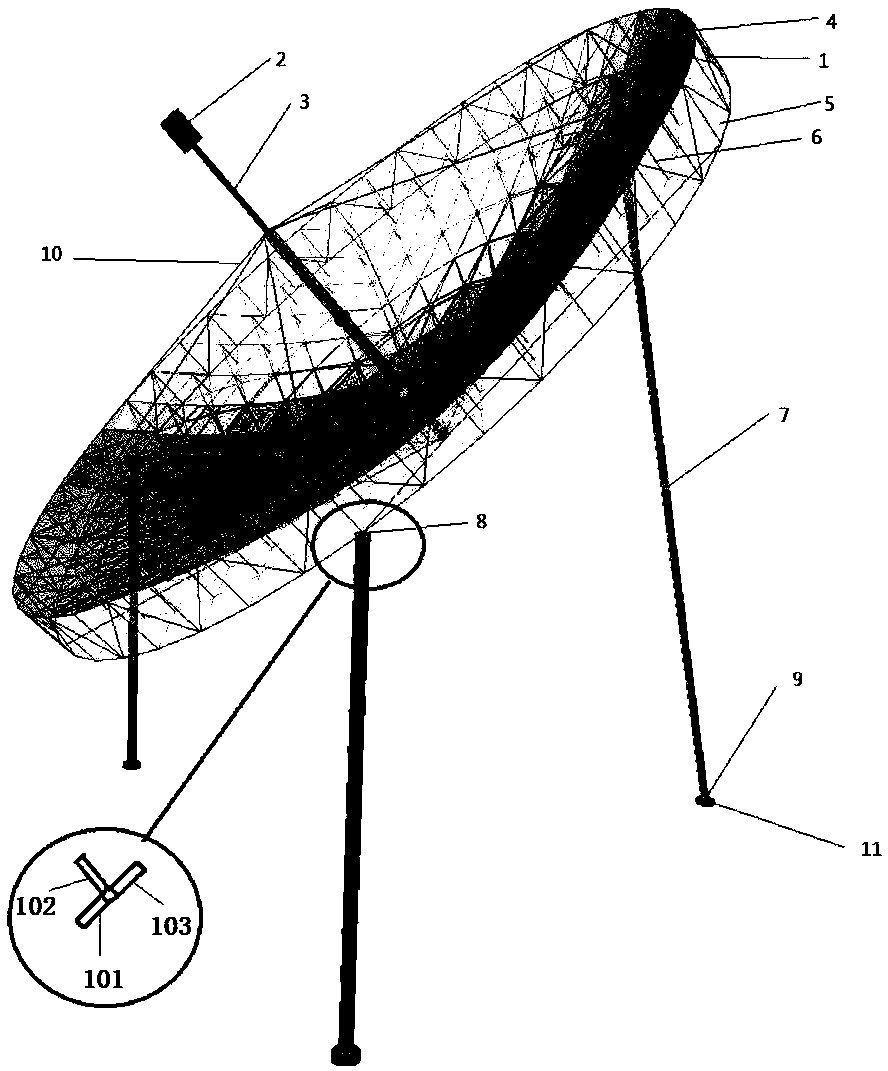

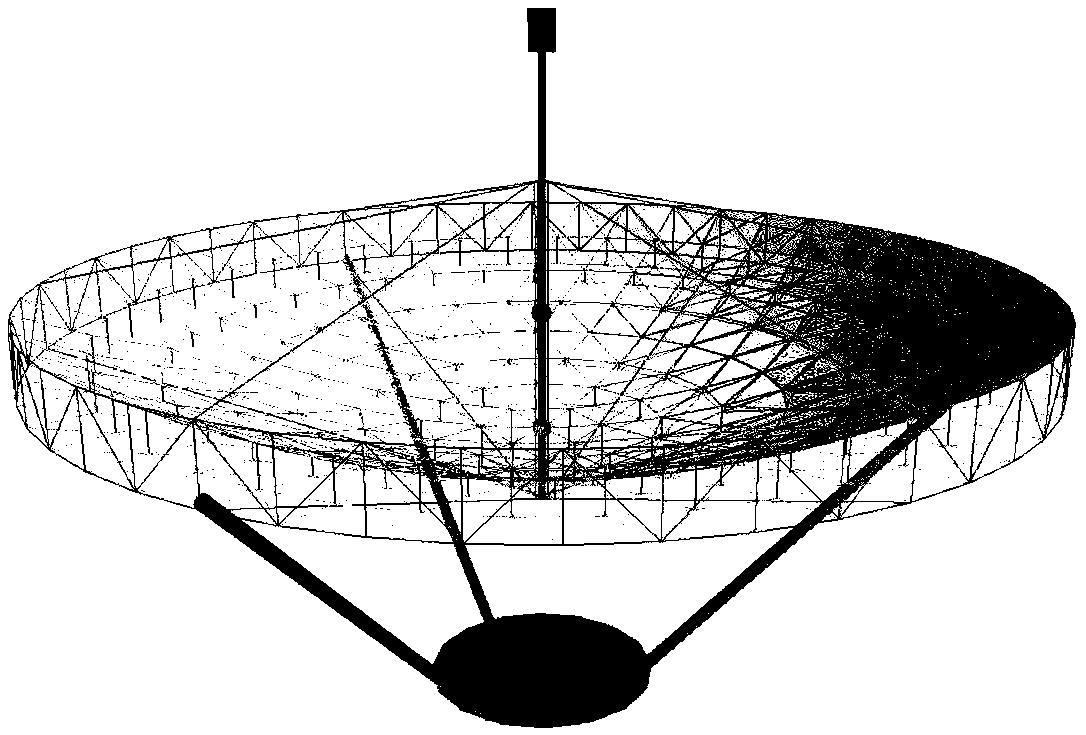

Ring frame column type cable net reflective system driven by three telescopic rods

ActiveCN106159458BTroubleshoot torsional instabilityRaise the fundamental frequency of the structureAntenna supports/mountingsMountingsElevation angleCable net

Owner:XIDIAN UNIV

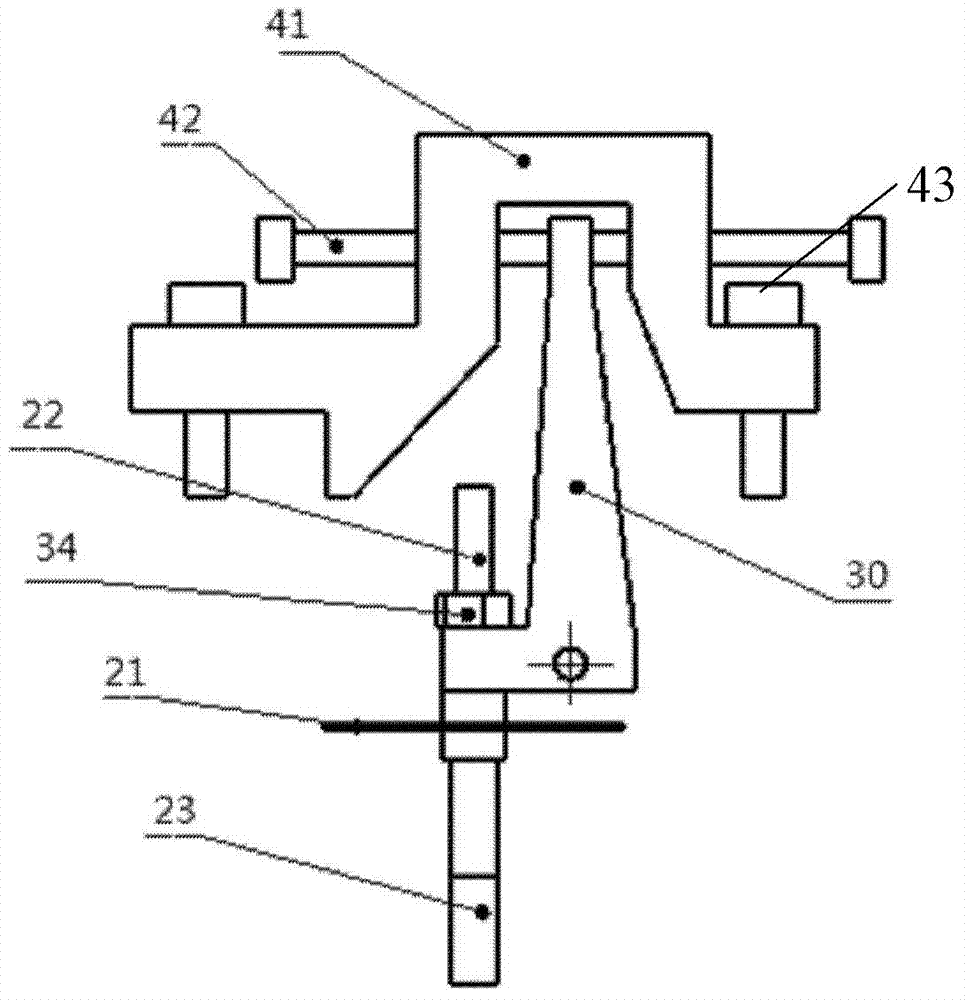

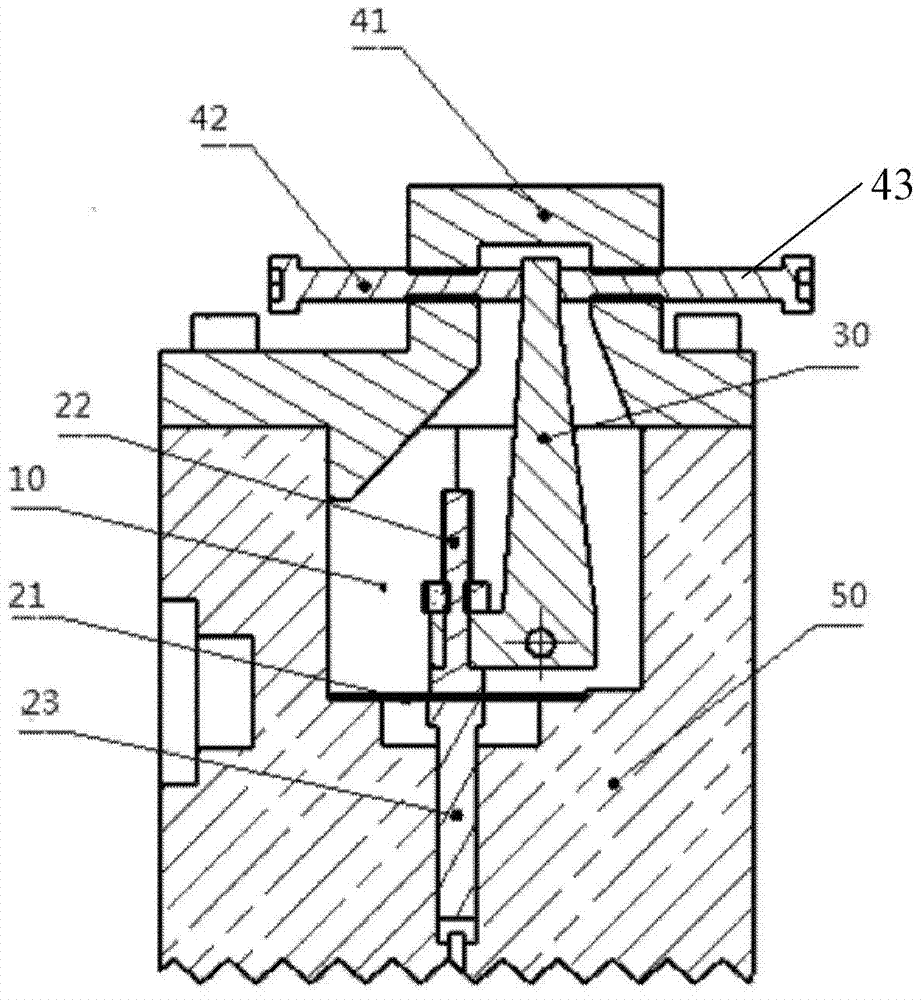

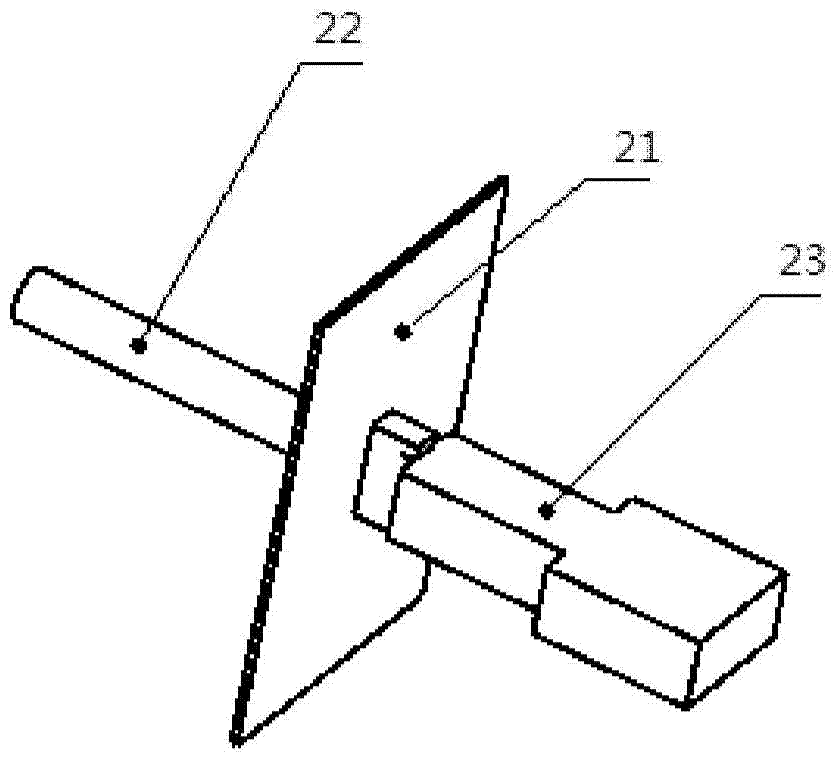

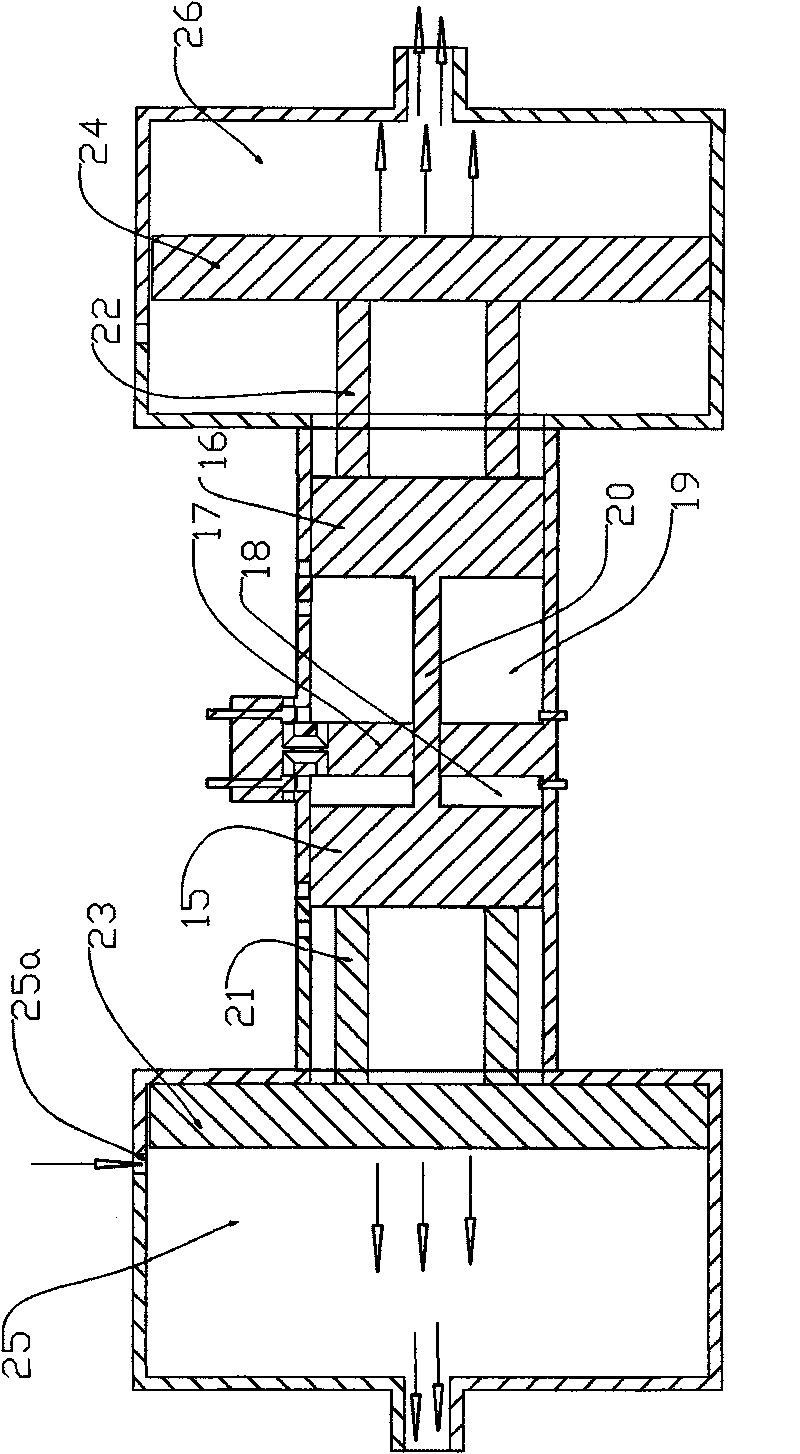

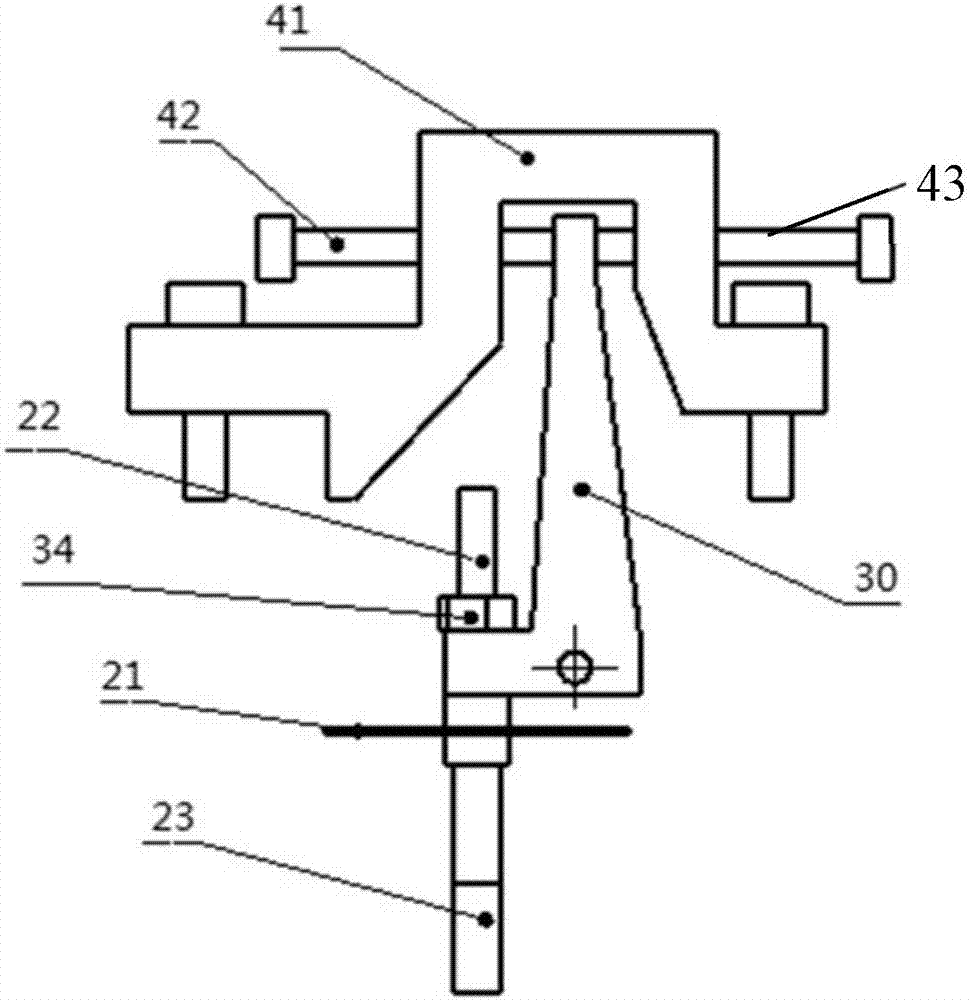

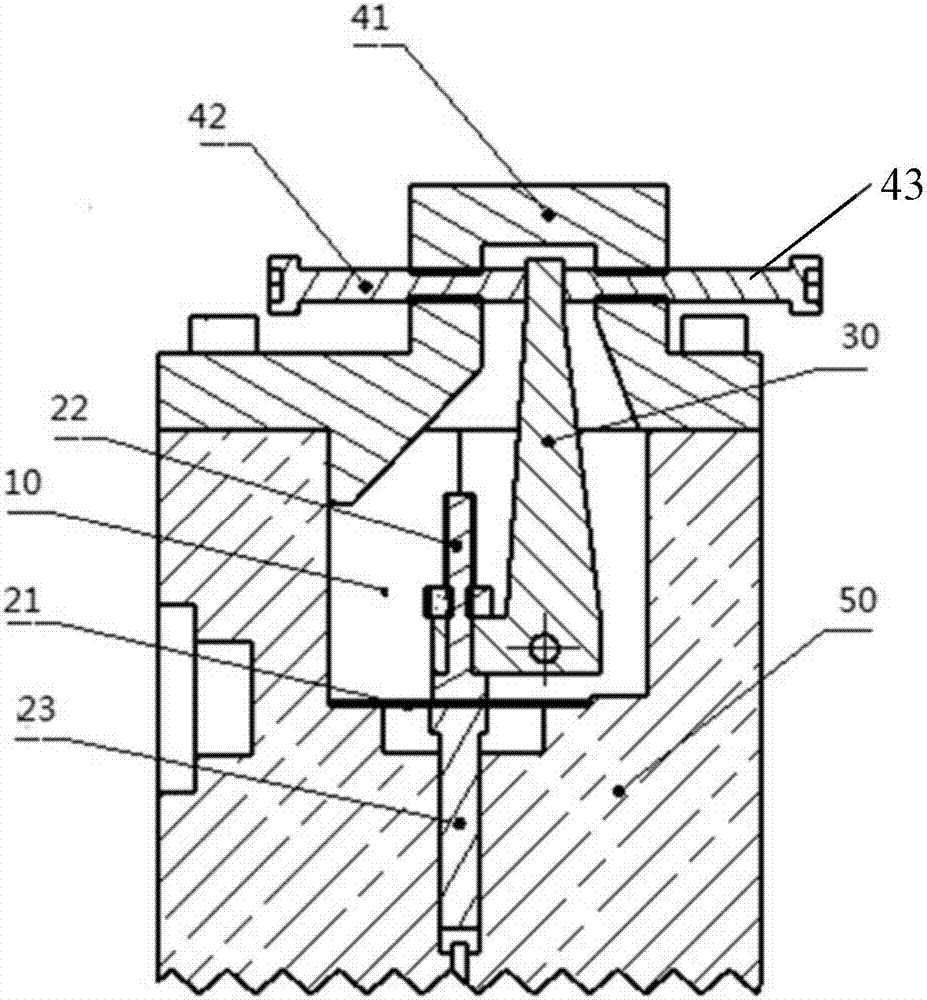

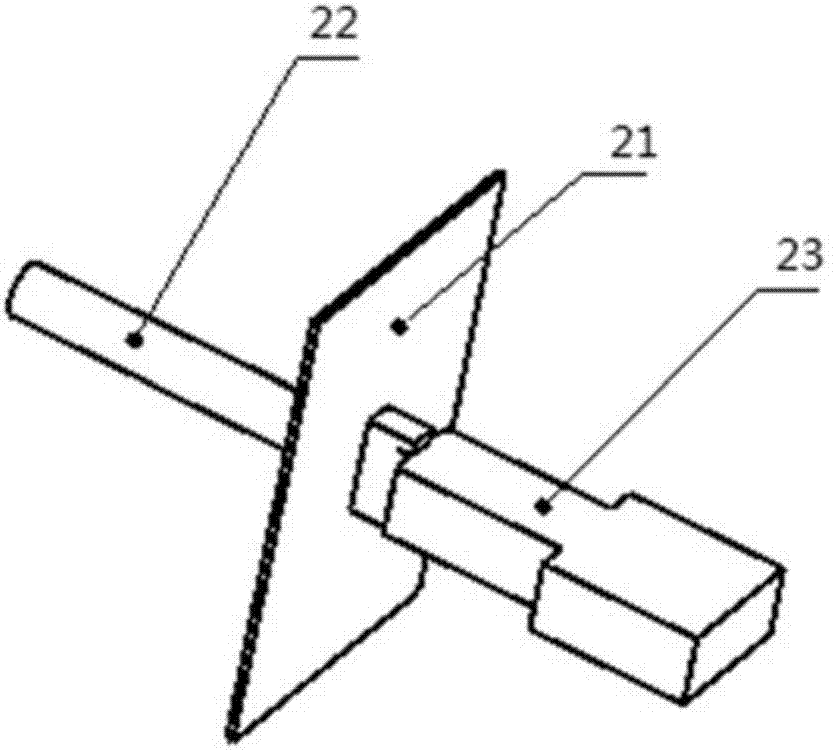

Ribbon injection klystron external tuning device

InactiveCN103681176BAchieve tuningReduce development costsTransit-tube circuit elementsKlystronResonant cavity

The invention provides an external tuning device for a strip-shaped injection klystron. The strip-shaped klystron external tuning device includes: accommodating cavity, tuning assembly, trapezoidal lever frame and control assembly, which adopts inductive tuning method, and the tuning piston is inserted into the strip-shaped klystron body to form a part of the resonance cavity. Cavity wall; the movement of the tuning piston is controlled by the lever principle, which changes the volume and distributed inductance of the resonant cavity, thereby changing the resonant frequency of the resonant cavity. The invention does not use a bellows, but uses a deformable sealing diaphragm to realize the tuning of the resonant cavity, thereby reducing the cost and simplifying the structure.

Owner:INST OF ELECTRONICS CHINESE ACAD OF SCI

High temperature resistant filling glue for encapsulating temperature measuring crystals

ActiveCN106673586BRealize the temperature measurement functionEasy to buyThermometer detailsPhysical chemistrySilicon oxide

Owner:AECC SICHUAN GAS TURBINE RES INST

A compound corrosion inhibitor suitable for q235 steel and copper alloy galvanic couple and preparation method thereof

Owner:GUIZHOU MINZU UNIV

A Radar Antenna Array Element Multi-frequency Matching Method

ActiveCN104681987BReduce the number of plugging and unpluggingShorten test timeAntenna arraysMicrowaveRadar

The invention belongs to the field of microwave measurement, and relates to a method for multi-frequency point matching of radar antenna array elements, which includes the following steps: Step 1: Connect a test probe to a designated antenna array element; The source sends the control information corresponding to a frequency point of the specified antenna element; Step 3: Measure the data of the corresponding frequency point with a vector network analyzer, and transmit it to the control computer through the GPIB cable; Step 4: The control computer receives the data at this frequency point The data is stored in the corresponding database after corresponding data processing. Step 5: Judging whether the matching of all frequency points of an array element is completed; Step 6: Judging whether matching of all frequency points of all array elements is completed. The number of times of plugging and unplugging at each frequency point is greatly reduced, thereby reducing the plugging and unplugging time of the entire matching cycle, saving manpower, material resources, and financial resources in the matching process, and greatly shortening the development and production cycle.

Owner:LEIHUA ELECTRONICS TECH RES INST AVIATION IND OF CHINA

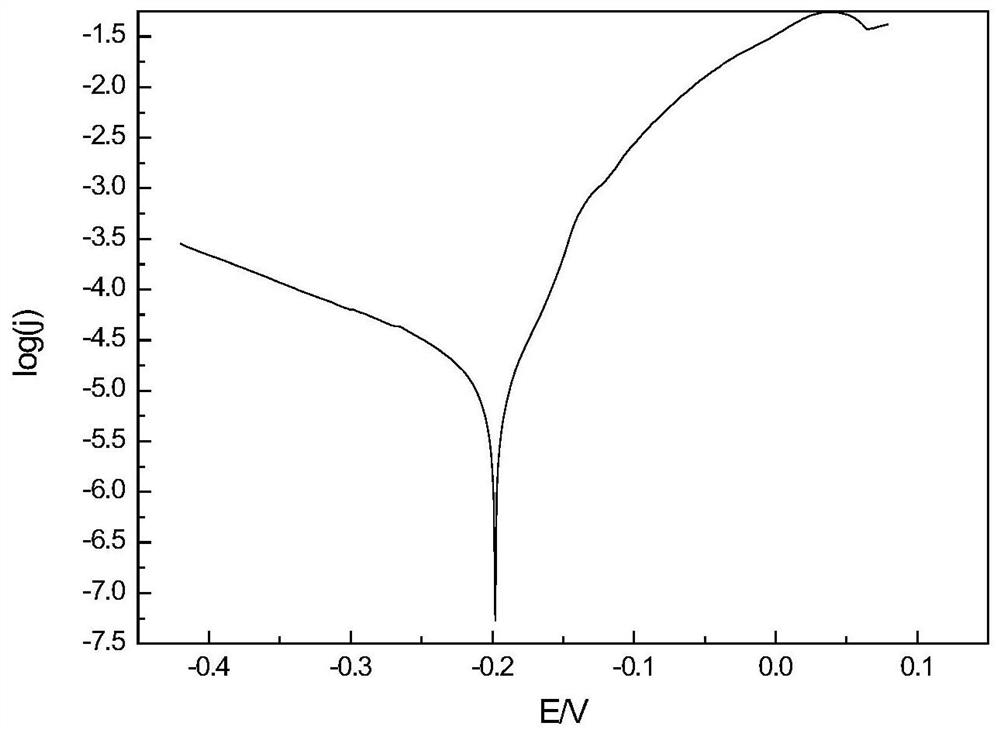

B30 copper-nickel alloy compound corrosion inhibitor suitable for strong acid medium and preparation method thereof

InactiveCN111690934AExcellent corrosion inhibition performanceImprove solubility and dispersibilityCopper nickel alloyStrong acids

The invention belongs to the field of metal material corrosion and protection, and relates to a B30 copper-nickel alloy compound corrosion inhibitor suitable for a strong acid medium and a preparationmethod thereof. The B30 copper-nickel alloy compound corrosion inhibitor suitable for the strong acid medium is prepared from a benzotriazole linseed oil amide derivative, carbamido linseed oil, sodium molybdate and isopropanol. The corrosion inhibitor has the following advantages that on the one hand, the benzotriazole linseed oil amide derivative, as a main agent of the corrosion inhibitor, haswide sources and is environmentally friendly; the production process is simple, and purification postprocessing of products is not required; and on the other hand, through compound use with other reagents, uniform corrosion and corrosive pitting of white copper B30 materials can be inhibited, and corrosion inhibition efficiency in the strong acid corrosive medium is over 98%.

Owner:BINZHOU UNIV

A compound corrosion inhibitor suitable for n80 steel and stainless steel galvanic couple and preparation method thereof

The invention belongs to the field of metal material corrosion and protection, and particularly relates to a compounded corrosion inhibitor suitable for electric coupling of N80 steel and stainless steel and a preparation method thereof. The compounded corrosion inhibitor comprises the following components in percentage by mass: 50%-60% of phosphonyl carbamido flaxseed oil derivatives, 10%-20% ofpolyaspartic acid, 10%-20% of sodium molybdate and 10%-30% of isopropyl alcohol, wherein the sum of the mass percentages of the components is 100%. The compounded corrosion inhibitor suitable for electric coupling of N80 steel and stainless steel and the preparation method thereof have the benefits as follows: the corrosion inhibition efficiency is high, the production cost is low, and the compounded corrosion inhibitor further has the characteristics that the environmental friendliness is achieved, and the normal operation of the equipment is not affected.

Owner:GUIZHOU MINZU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com