Combustion speed testing method for gel propellant

A technology of gel propellant and test method, which is applied in the direction of chemical analysis by combustion, etc., can solve the problems of long test period, large number of samples required for test, cumbersome operation steps, etc., and achieve the effect of easy promotion and simple preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

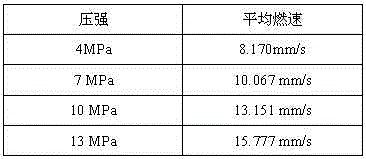

[0062] For a certain formulation of nano aluminum powder gel propellant at room temperature, the burning rate measured at 7MPa is as follows:

[0063]

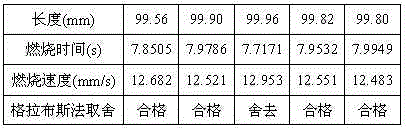

[0064] After selection by Grubbs method, 4 valid data are obtained. The average burning speed is 12.559mm / s calculated by formula (2), and the standard deviation S is calculated by formula (3) u =0.0864, the relative standard deviation (coefficient of variation) C is calculated by formula (4) v =0.69%, the combustion speed at this pressure can be expressed as 12.559±0.137mm / s from the formula (5).

Embodiment 2

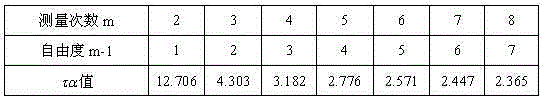

[0066] For a certain hand-mixed gel propellant, the initial pressure was tested at room temperature at 4MPa, 7MPa, 10MPa, and 13MPa. The average burning rate was calculated from equation (2). The specific values are shown in the following table:

[0067]

[0068] Substituting the values in the table into equation (7), the burning rate pressure index is calculated to be 0.560, and the constant term is calculated as 3.621 when substituting into equation (8). According to formula (6), the burning rate-pressure relationship of this formulation gel propellant in the range of 4~13MPa can be expressed as U=3.621P 0.560 .

Embodiment 3

[0070] For a certain high-energy gel propellant, the initial pressure is constant at 7MPa, and the initial temperature of the test sample is the burning rate of -40℃, 20℃ and 50℃ respectively. The average burning speed is calculated by formula (2). The specific values are as follows Shown:

[0071]

[0072] Substituting the values in the table into equation (10), the temperature sensitivity coefficient of the burning rate of the gel propellant when the pressure is 7MPa is calculated to be 9.551×10 -4 / ℃. Reference temperature T 0 Take it as 20°C and substitute it into formula (8) to calculate the corresponding constant term as 1.289. According to formula (9), the gel propellant of this formula is at 7MPa, the reference temperature T 0 Is the burning rate at 20℃—the initial temperature relationship can be expressed as u=1.289e 0.000955(T-20) .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com