Patents

Literature

41results about How to "Excellent corrosion inhibition performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

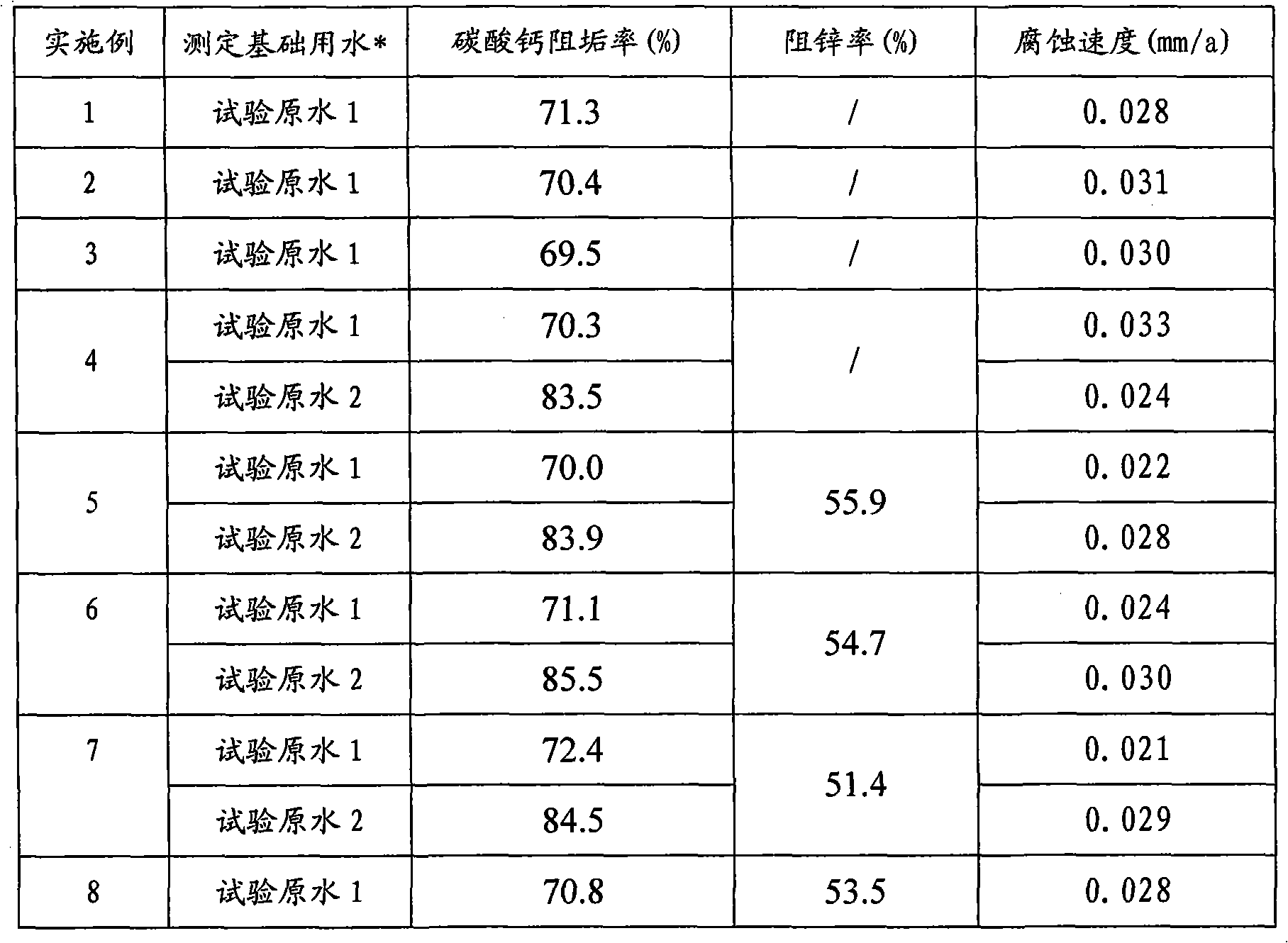

No-phosphate corrosion and scale inhibitor and its application

InactiveCN101066811AExcellent corrosion inhibition performanceIncrease polarityScale removal and water softeningNon-contaminated water treatmentPolyaspartic acidPhosphate

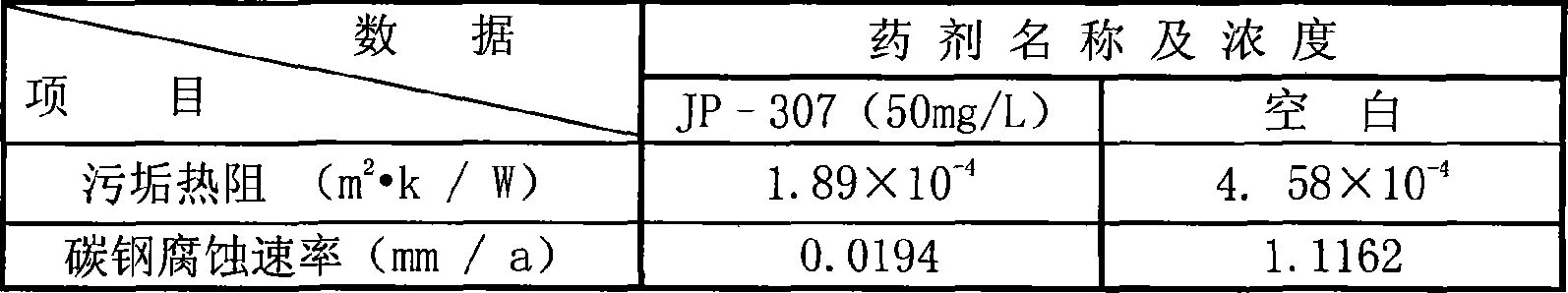

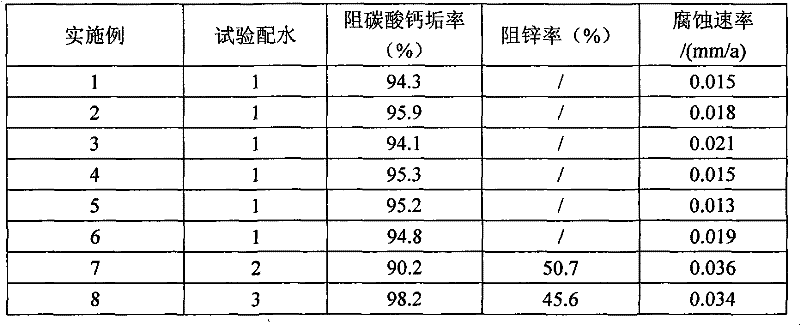

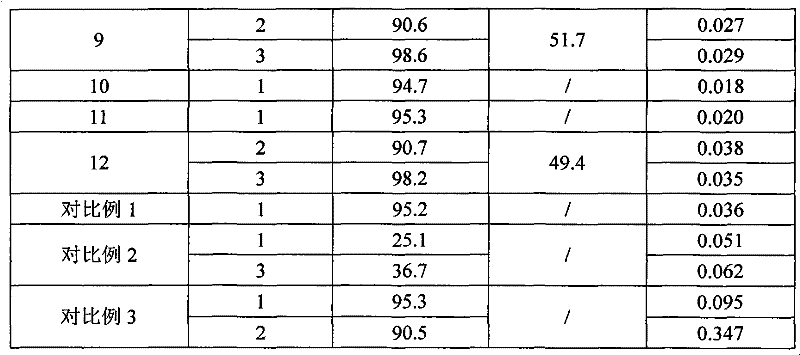

The present invention relates to no-phosphate corrosion and scale inhibitor and its application. The no-phosphate corrosion and scale inhibitor consists of polyaspartic acid and / or polyepoxy succinic acid 10-20 wt%, polymaleic anhydride 20-30 wt%, copolymer of acrylic acid and 2-acrylamido-2-methyl propenyl sulfonic acid 15-20 wt%, zinc salt 3-5 wt%, natural organic high molecular compound 5-12 wt%, molybdate 5-8 wt%, and other components 5-20 wt%. It has excellent corrosion retarding performance, high scale inhibiting performance and environment friendship.

Owner:WUHAN JINPO CHEM TECH

Non-Phosphorus composite anti incrustation eorrosion snhibiter and its application in water treatment

ActiveCN1785853AImprove performanceExcellent resistance to CaCO

<sub>3</sub>

Dirt performanceScale removal and water softeningMolybdatePolyaspartic acid

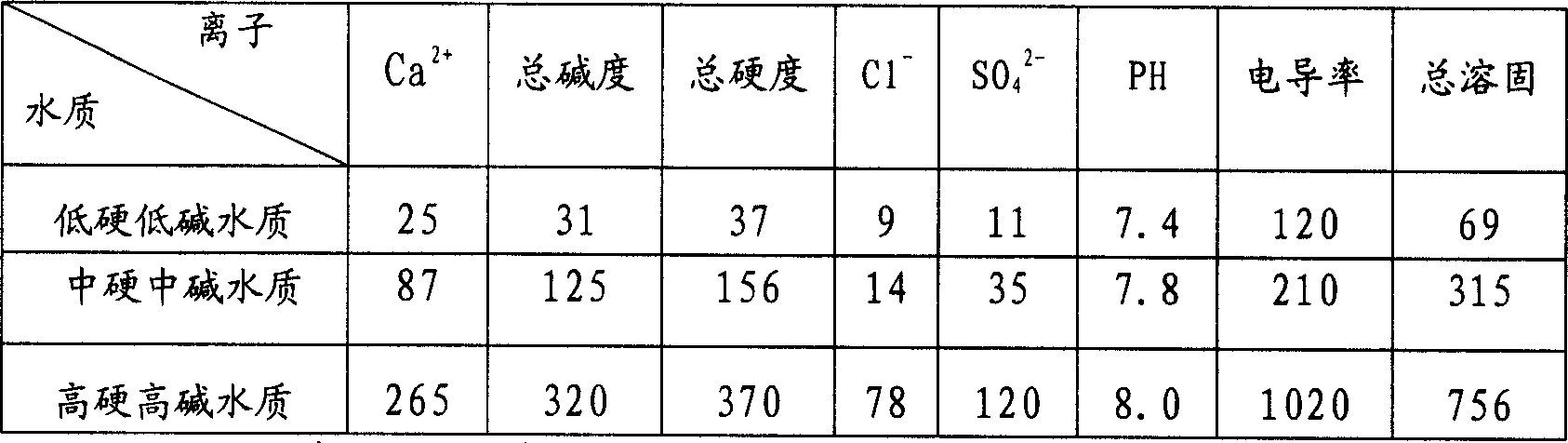

The present invention relates to a phosphorus-free composite antiincrustation corrosion inhibitor. It includes polyaspartic acid and / or polyepoxysuccinic acid and at least one kind of scale inhibition and dispersion agent, in which the scale inbibition and dispersion agent is polymer containing carboxylic acid group, or it includes polyaspartic acid and / or polyepoxysuccinic acid, zinc salt, molybdate or tungstate and polymer containing carboxylic acid group. Said invention is applicable to treatment of circulating cooling water.

Owner:BEIJING YANHUA PETRO CHEM

Low-phosphorus composite antiincrustation corrosion inhibitor and its use for water treatment

ActiveCN1743282AImprove performanceExcellent resistance to CaCO

<sub>3</sub>

Dirt performanceScale removal and water softeningPhosphorAspartic acid

This invention relates to a sort of low-phosphor scale-corrosion inhibitor which includes PBTCA, (and / or HPAA), poly-aspartic acid and / or polyepoxysuccinic acid and carboxyl-containing polymer. This inhibitor can be used to treat recirculated cooling water in ways such as inhibiting the forming of CaCO3 scale, inhibiting corrosion and stabilizing Zn2+ in water. Its phosphor concentration in recirculated water is no more than 1mg / L, reducing the hazard of phosphor discharge to environment.

Owner:BEIJING YANHUA PETRO CHEM +1

Composite scale-proof corrosion inbibitor containing poly epoxy succinic acid and its use

ActiveCN1616361AGood overall performanceExcellent corrosion inhibition performanceScale removal and water softeningCalcium EDTACorrosion inhibitor

The present invention relates to a kind of composite antiscale corrosion inhibitor containing polyepoxy succinic acid. The composite antiscale corrosion inhibitor includes two kinds of organic phosphonic acid and polyepoxy succinic acid, and may contain zinc salt and copper corrosion inhibitor, if necessary. The composite antiscale corrosion inhibitor is suitable for processing circular cooling water and can make the calcium hardness reach 1200 mg / L.

Owner:中国石油化工股份有限公司北京燕山分公司研究院

Molybdenum phosphine system composite anti-erosion anti-sludging agent and preparation method thereof

ActiveCN1990912AExcellent corrosion inhibition performanceInhibit oxidative decompositionScale removal and water softeningChemical inhibitorsMolybdatePhosphine

The invention provides a molybdate-phosphonate compound corrosion inhibitior and the method for preparing the same. Said corrosion inhibitior comprises of solidum molybdate 1-20 wt%, organic phosphine 1-40 wt%, oxidant 1-10 wt% and excipient 97wt%. The compound corrosion inhibitior is characterized by convenient operation and management and satable corrosion inhibition performance.

Owner:CHINA PETROLEUM & CHEM CORP +1

Corrosion inhibition foam water discharging agent for oil-gas well and preparation method of corrosion inhibition foam water discharging agent

ActiveCN103614129AExcellent bubble discharge performanceExcellent corrosion inhibition performanceDrilling compositionBorehole/well accessoriesAlkylphenolCorrosion inhibitor

The invention discloses a corrosion inhibition foam water discharging agent for an oil-gas well and a preparation method of the corrosion inhibition foam water discharging agent, solving the problem that the traditional single corrosion inhibitor or foaming agent is high in operating cost and can not be effectively synergically used. The corrosion inhibition foam water discharging agent comprises the following components in percentage by weight: 20%-40% of oleic acid based imidazoline quaternary ammonium salt, 1%-10% of dodecyl dimethyl benzyl ammonium chloride, 10%-30% of dodecyl dimethyl betaine, 5%-10% of alkylphenol polyoxyethylene and 10%-30% of water. The corrosion inhibition foam water discharging agent prepared through a formula has the advantages of excellent foam discharge property and excellent corrosion inhibition property.

Owner:成都华阳兴华化工有限公司

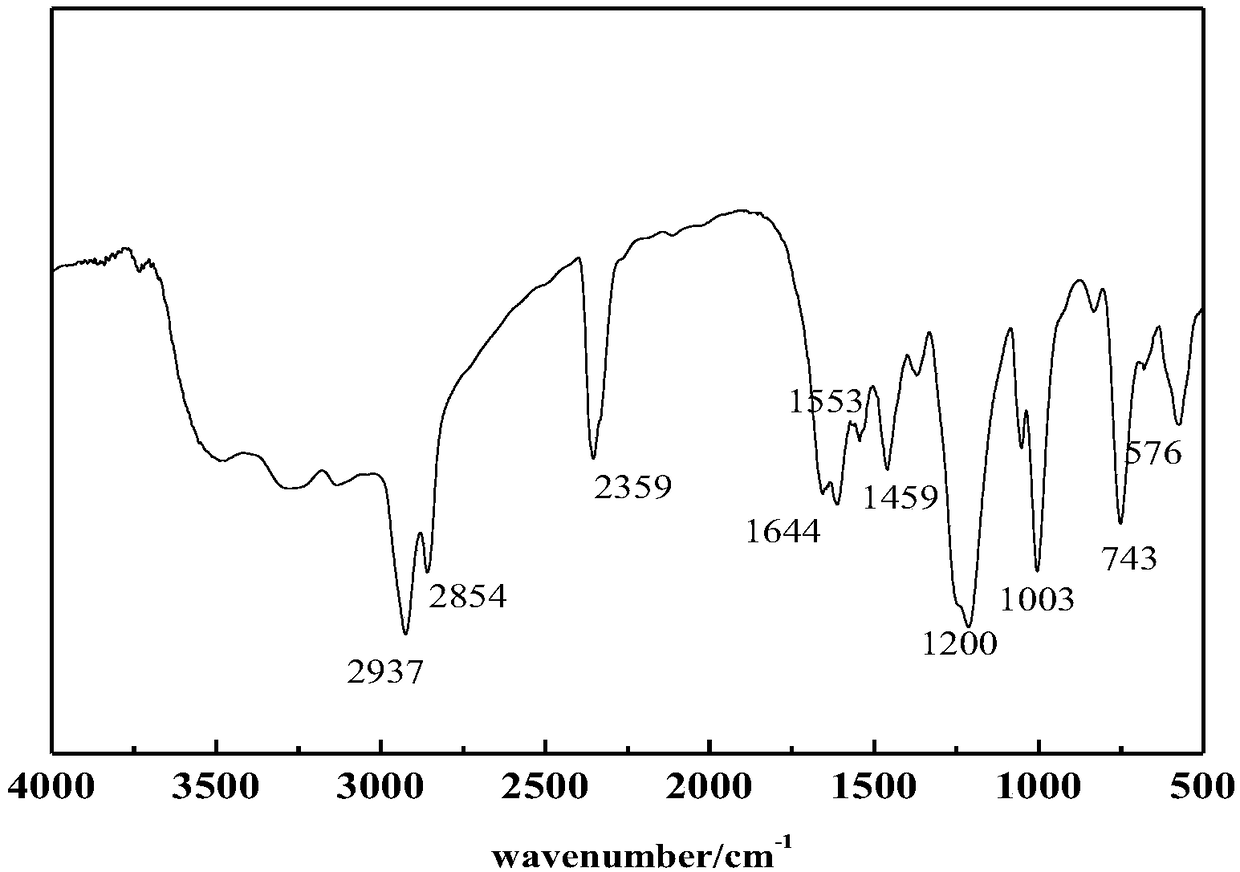

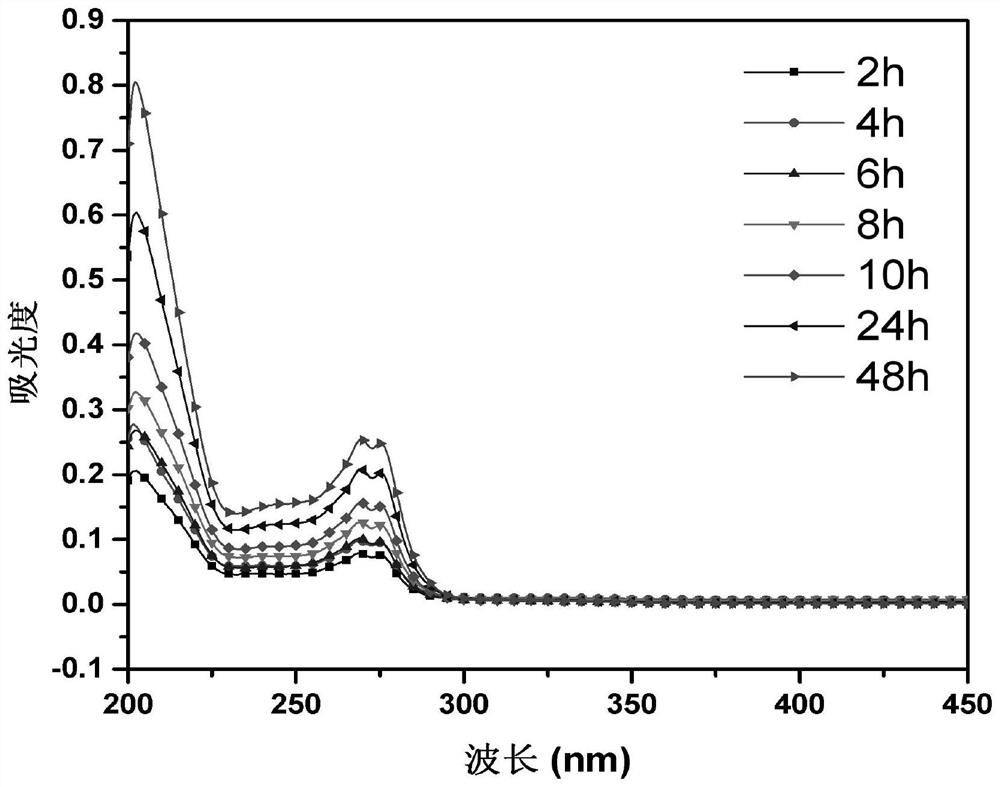

Imidazoline quaternary ammonium salt corrosion inhibitor and preparation method thereof

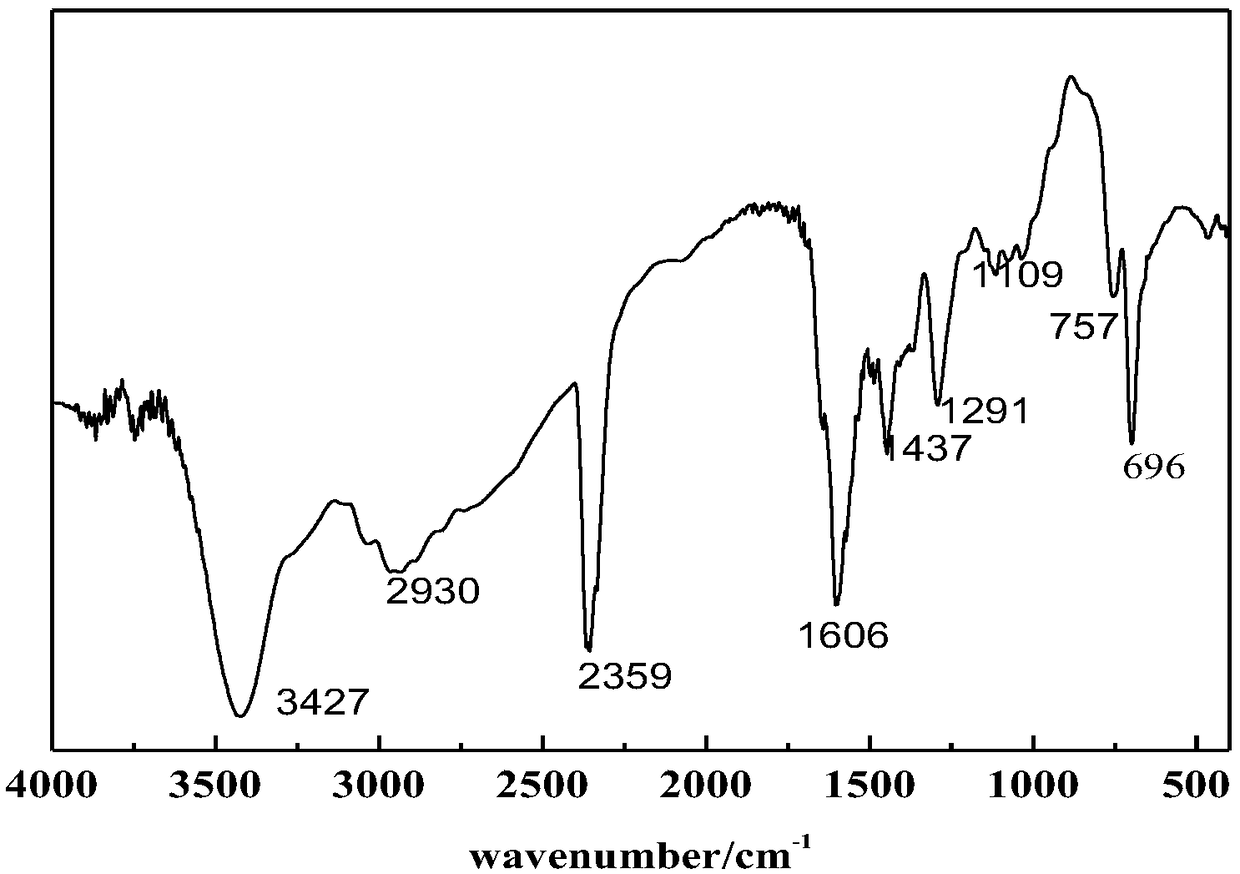

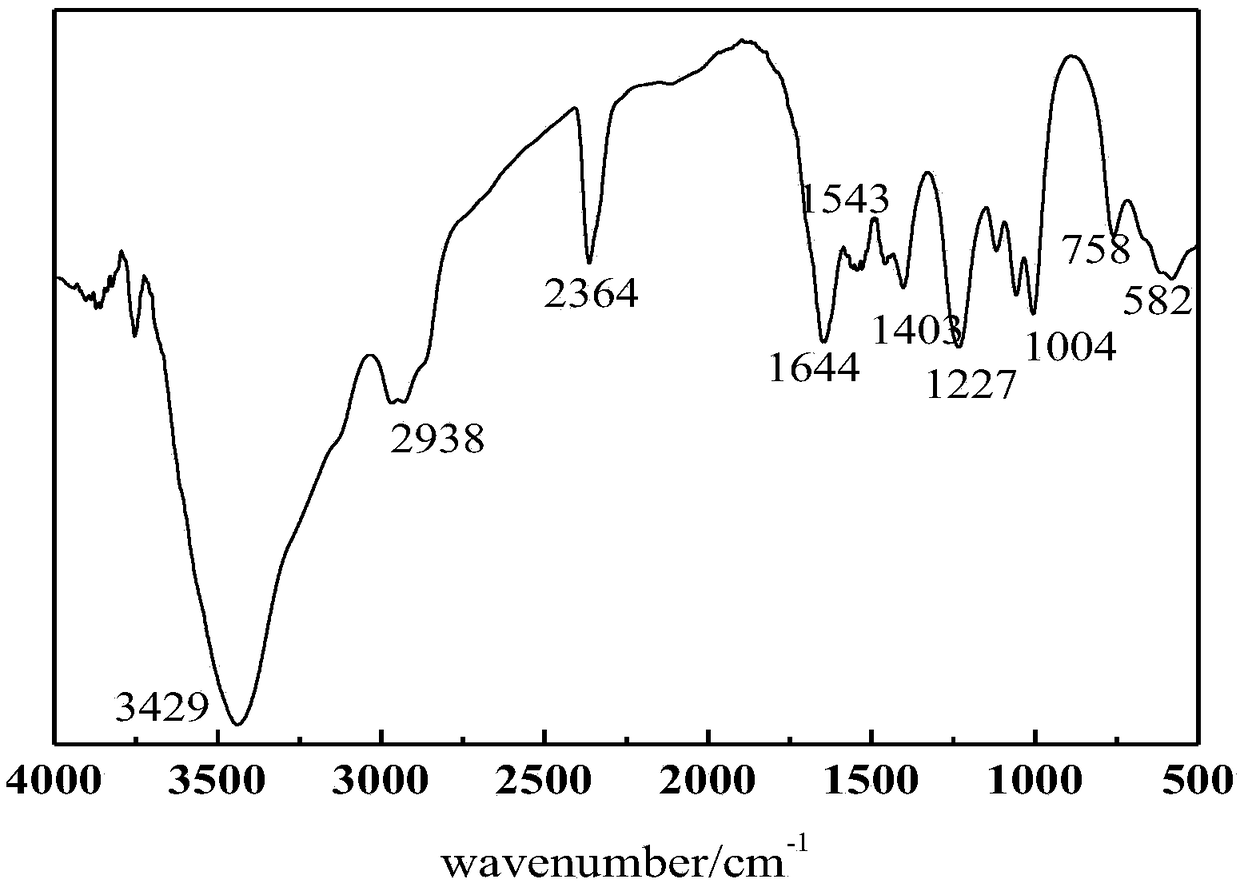

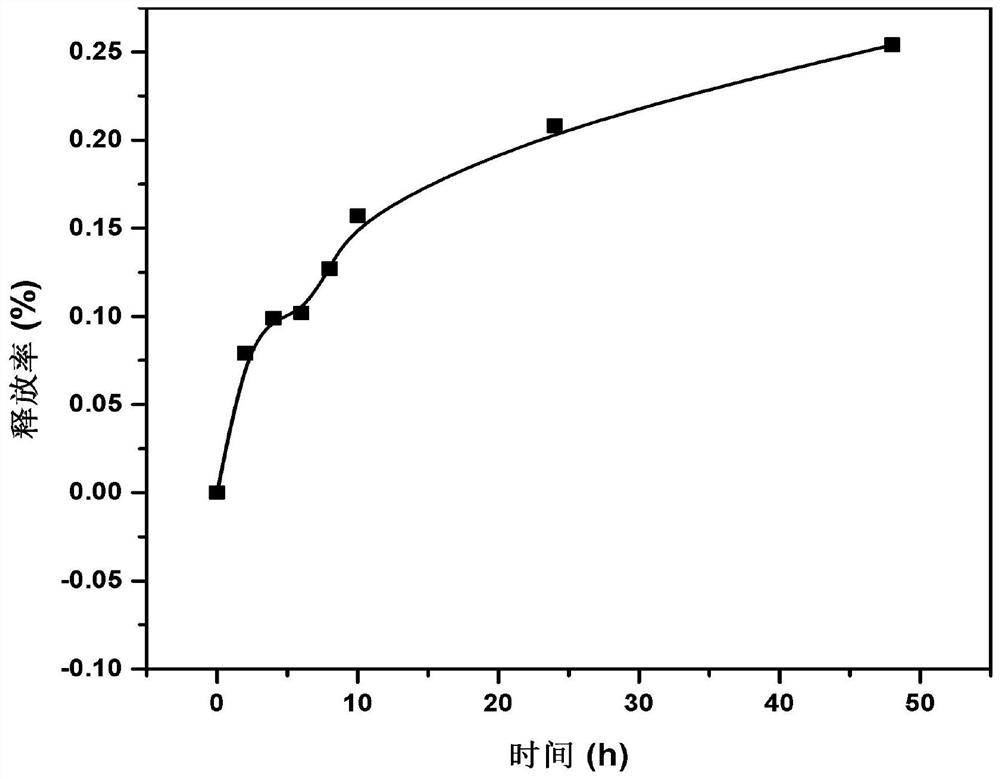

InactiveCN109053579ALow toxicityImprove release efficiencyOrganic chemistryBenzoic acidDiethylenetriamine

The invention discloses an imidazoline quaternary ammonium salt corrosion inhibitor which is prepared from the following preparation raw materials including a corrosion inhibitor main component raw material and an additive raw material; the corrosion inhibitor main component raw material is one of oleic acid, benzoic acid, fatty acid, lauric acid and natural eleostearic acid; and the additive rawmaterial includes diethylenetriamine, dimethyl sulfate or benzyl chloride, boric acid and xylene. The invention also discloses a preparation method of the imidazoline quaternary ammonium salt corrosion inhibitor and aims at solving the problem of poor corrosion inhibition performance of the existing corrosion inhibitor in an acid medium. The preparation method is simple, is liable to operate and can perform recovery utilization on a solvent. An imidazoline corrosion inhibitor has the advantages of low toxicity, high slow release efficiency and wide use range. Physical characterization and performance test results of the corrosion inhibitor show that oleic acid imidazoline quaternary ammonium salt has better slow release performance, and the slow release performance of the benzyl chloride is better than the slow release performance of the dimethyl sulfate after being quaternized. A polarization curve test shows that synthesized corrosion inhibitors are all cathodal depression type corrosion inhibitors.

Owner:YANAN UNIV

Phosphorus-free composite scale-inhibiting corrosion-retarding agent and application thereof in water treatment

InactiveCN102452721AImprove performanceExcellent resistance to CaCO

<sub>3</sub>

Dirt performanceScale removal and water softeningWater solublePolymer

The invention relates to a phosphorus-free composite scale-inhibiting corrosion-retarding agent and an application thereof. The phosphorus-free composite scale-inhibiting corrosion-retarding agent comprises a water-soluble borate and at least one scale-inhibiting dispersant, wherein the scale-inhibiting dispersant is a carboxylic-group-containing phosphorus-free polymer. The comprehensive property of the phosphorus-free composite scale-inhibiting corrosion-retarding agent is good. The agent has good CaCO3 scale inhibiting performance, good stabilizing performance upon Zn<2+> in water, and good corrosion retarding performance. The agent can be used in treating circulating cooling water. With the agent, harm of phosphorus discharging to the environment can be solved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of non-phosphorus corrosion and scale inhibitor

InactiveCN104355418AExcellent corrosion inhibition performancePrevent eutrophicationNature of treatment waterTreatment using complexing/solubilising chemicalsCorrosion inhibitorDegree of polymerization

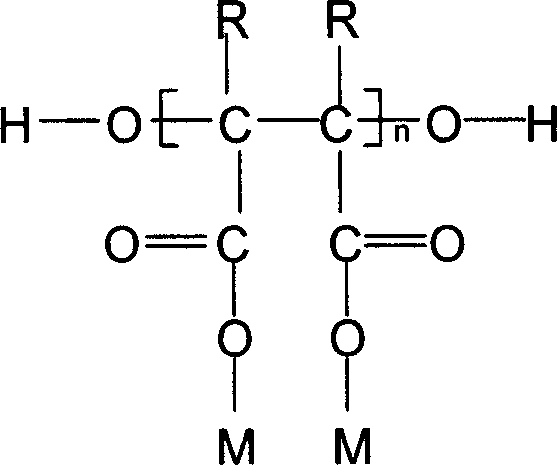

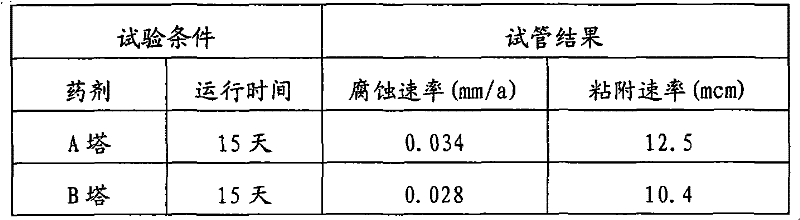

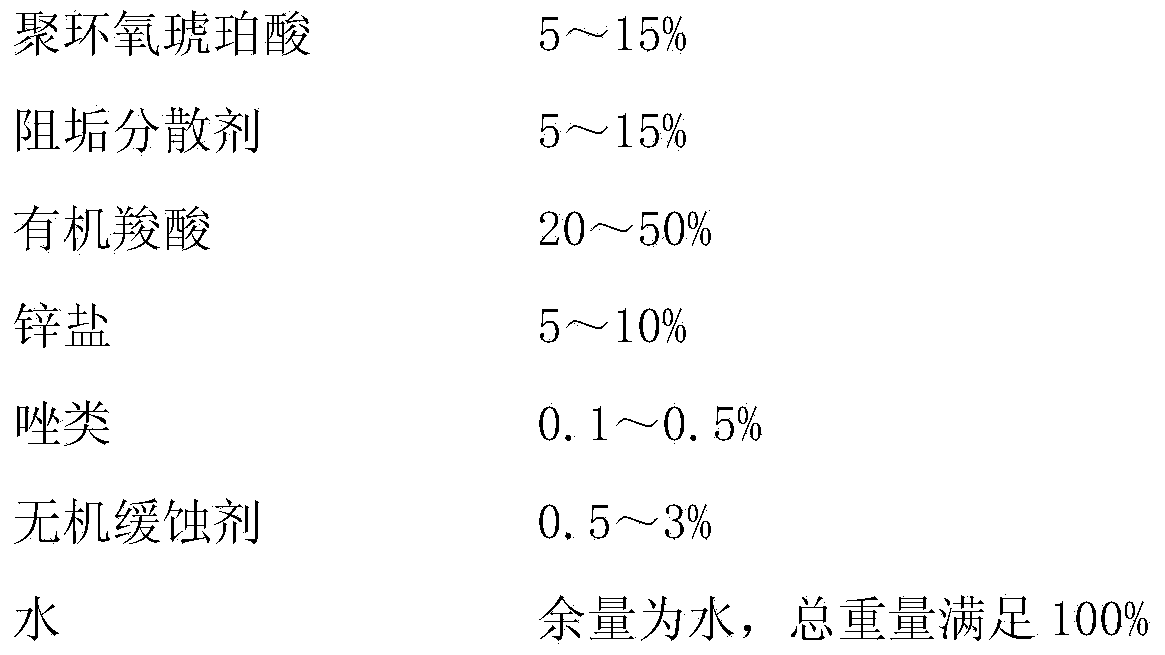

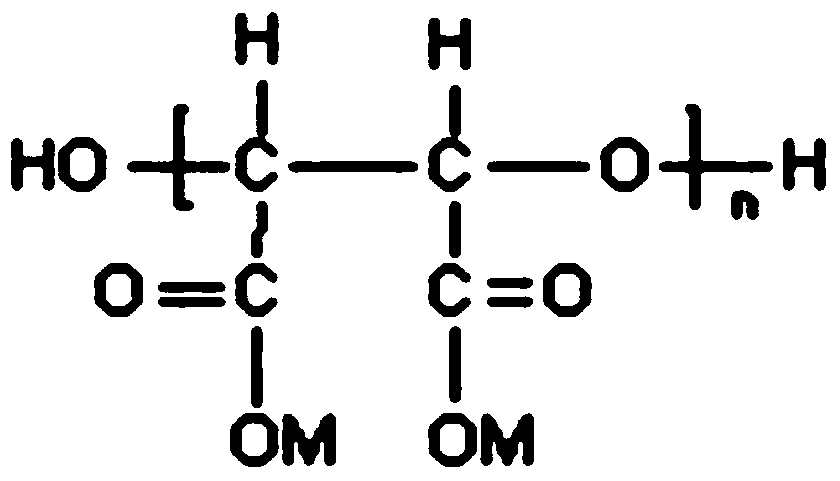

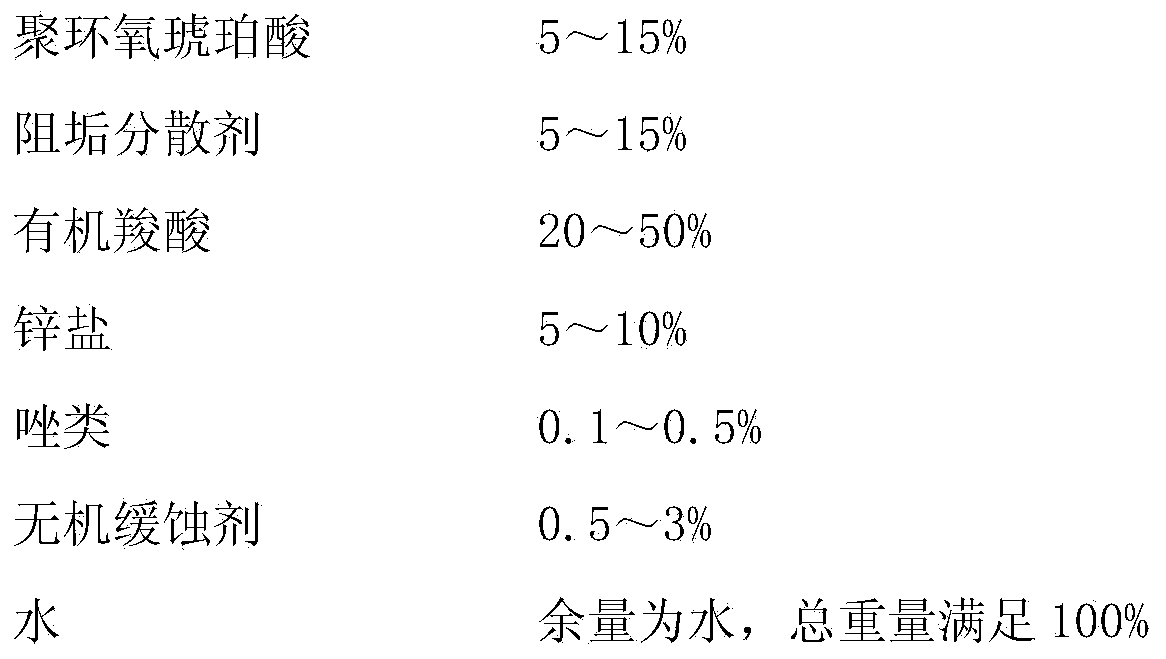

The invention relates to a preparation method of a non-phosphorus corrosion and scale inhibitor. The preparation method of the non-phosphorus corrosion and scale inhibitor is characterized by being blended from the following components in percentage by weight: 1) 5-15% of polyepoxysuccinic acid, 2) 5-15% of a dirt dispersion agent, 3) 20-50% of organic carboxylic acid, 4) 5-10% of zinc salt, 5) 0.1-0.5% of imidazole, 6) 0.5-3% of an inorganic corrosion inhibitor, and 7) the balance of water according to mass percent, wherein the polyepoxysuccinic acid is a market-sold liquid preparation, the solid content is 40%, and the degree of polymerization n is an integer of 10-50. The preparation steps are as follows: adding the zinc salt and the inorganic corrosion inhibitor in a fixed amount of water, fully stirring to completely dissolve the zinc salt and the inorganic corrosion inhibitor, then adding the polyepoxysuccinic acid, the dirt dispersion agent and the organic carboxylic acid, fully stirring, finally adding the imidazole until the imidazole is completely dissolved, and filtering.

Owner:CHINA NAT OFFSHORE OIL CORP +2

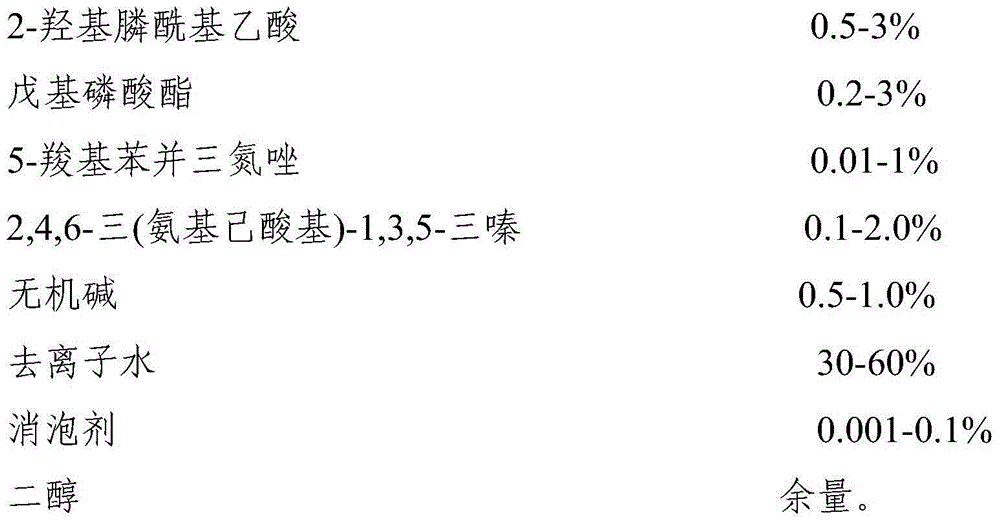

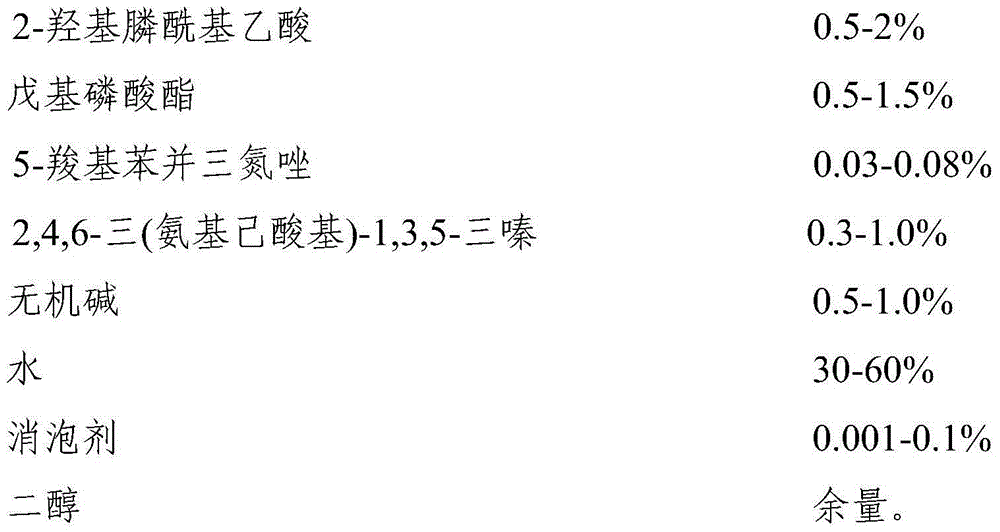

Inverter cooling liquid and preparation method thereof

ActiveCN104559945AExcellent corrosion inhibition performanceGood heat transfer performanceHeat-exchange elementsBenzotriazoleCorrosion

The invention provides an inverter cooling liquid. The inverter cooling liquid consists of the following raw materials in percentage by weight: 0.5-3 percent of 2-hydroxyphosphonoacetic acid, 0.2-3 percent of amyl phosphate, 0.01-1 percent of 5-carboxy benzotriazole, 0.1-2.0 percent of 2,4,6-tri-(aminocaproic acid)-1,3,5-triazine, 0.5-1.0 percent of inorganic base, 0.001-0.1 percent of antifoaming agent, 30-60 percent of water and the balance of glycol. The inverter cooling liquid has excellent corrosion inhibiting performance of an aluminum magnesium alloy, better heat exchange performance and compatibility among PVC, ethylene propylene diene monomer rubber and butadiene styrene rubber.

Owner:CHINA PETROLEUM & CHEM CORP

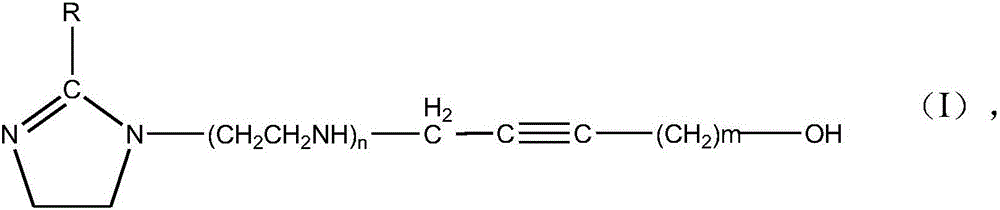

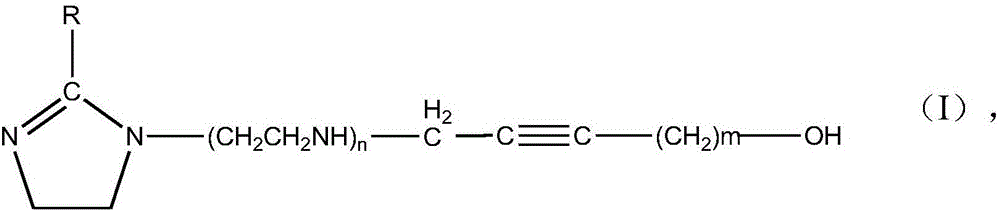

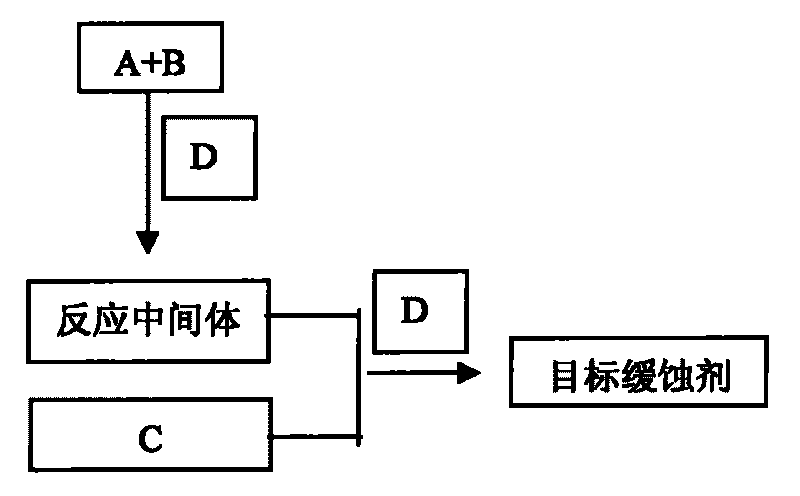

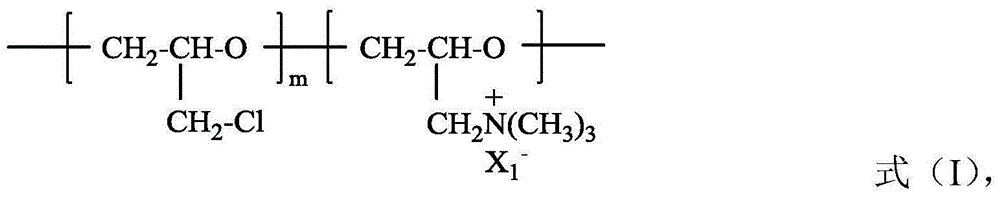

Alkynol-based imidazoline compound, corrosion inhibitor for carbon dioxide oil displacement, and preparations of alkynol-based imidazoline compound and corrosion inhibitor

ActiveCN106478510AGood corrosion inhibitionExcellent corrosion inhibition performanceOrganic chemistryCorrosion preventionCo2 floodingCorrosion inhibitor

The present invention discloses an alkynol-based imidazoline compound, a corrosion inhibitor for carbon dioxide oil displacement, and preparations of the alkynol-based imidazoline compound and the corrosion inhibitor, wherein the alkynol-based imidazoline compound has the following structure formula represented by a formula (I), and the corrosion inhibitor for carbon dioxide oil displacement comprises the alkynol-based imidazoline compound. According to the present invention, by improving the key alkynol-based imidazoline compound preparation method, the applications of the alkynol-based imidazoline compound, the application method and the like, the poor corrosion inhibition of the CO2 corrosion inhibitor can be effectively solved, and the corrosion inhibitor used for carbon dioxide oil displacement and prepared by using the alkynol-based imidazoline compound can effectively inhibit the corrosion on the pipeline during the carbon dioxide oil displacement process. The formula (I) is defined in the specification.

Owner:武汉楚博士科技股份有限公司 +1

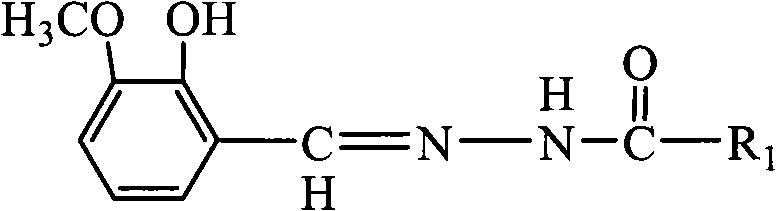

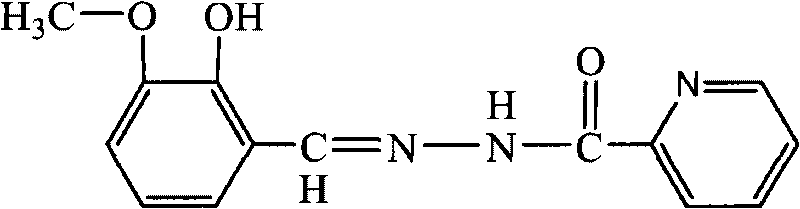

Preparation method of substituted pyridine carbonylhydrazone metal corrosion inhibitor

InactiveCN101709472AGood biodegradabilityExcellent corrosion inhibition performanceSolventFormylhydrazine

The invention discloses a preparation method of substituted pyridine carbonylhydrazone metal corrosion inhibitor. The method comprises the following steps: using methylisonicotinate and hydrazine hydrate in a molar ratio of 1:1-1.2:1 and absolute ethanol or methanol used as solvent of which volume is 3-6 times of hydrazine hydrate to react for 6-8h in a three-neck flask under the condition of refluxing at 70-80 DEG C and magnetic stirring, obtaining a product to perform reduced pressure distillation, recrystallizing with absolute ethanol, drying to obtain pyridine formylhydrazine, then using the obtained pyridine formylhydrazine and o-vanillin in a molar ratio of 1:1-1:1.2 and absolute ethanol or methanol used as solvent of which volume is 2-5 times of pyridine formylhydrazine to react for 7-9h under the condition of refluxing at 70-90 DEG C and magnetic stirring, cooling, performing suction filtration, washing with absolute ethanol, and recrystallizing. The preparation method of the invention designs the corrosion inhibitor molecule with good oil solubility which meets the environmental protection requirements; and the corrosion inhibitor molecule is characterized by good biodegradability, low toxicity and corrosion resistance within the pH value range of 4-9, and has good corrosion resistance to A3 carbon steel and copper.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

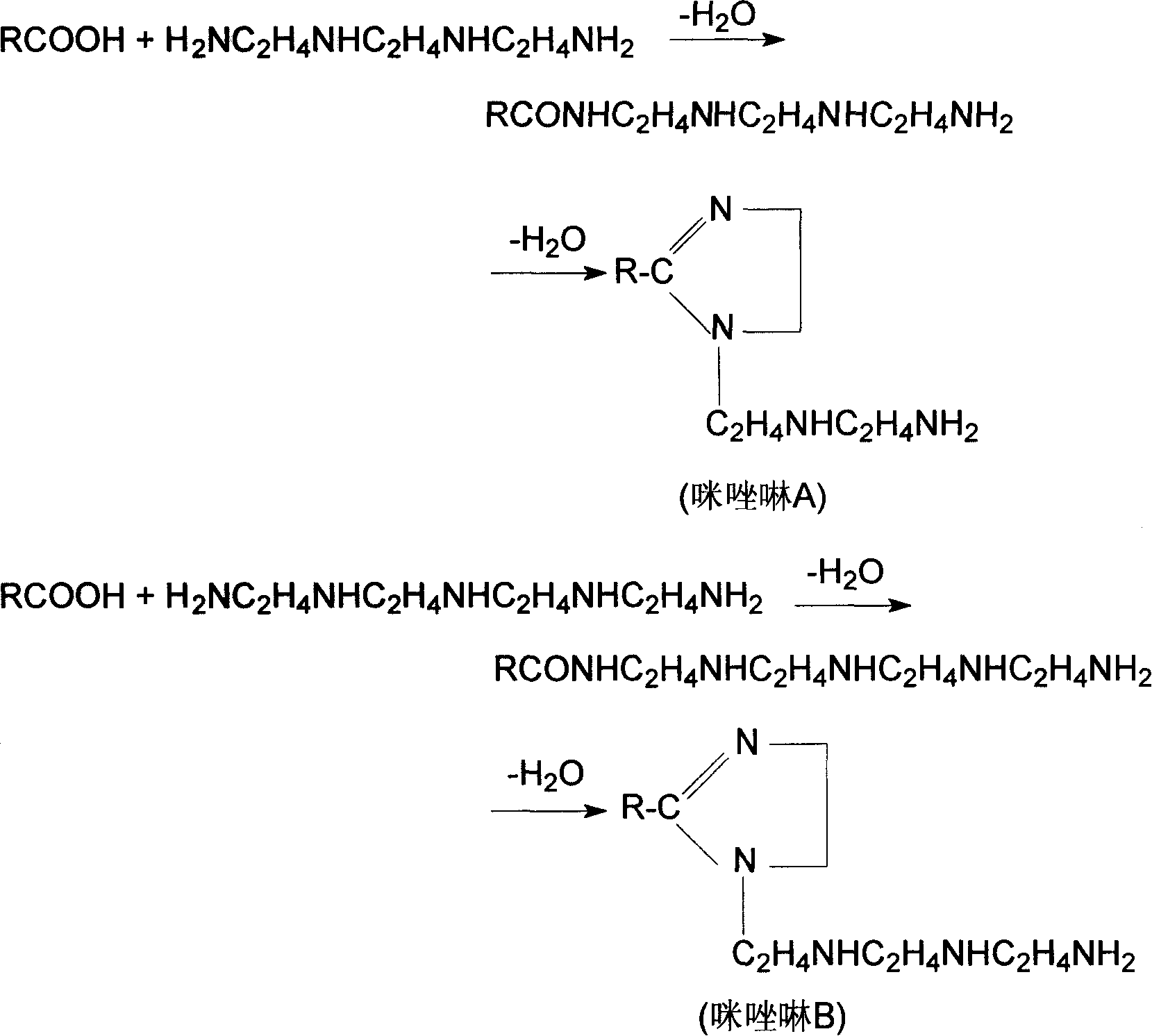

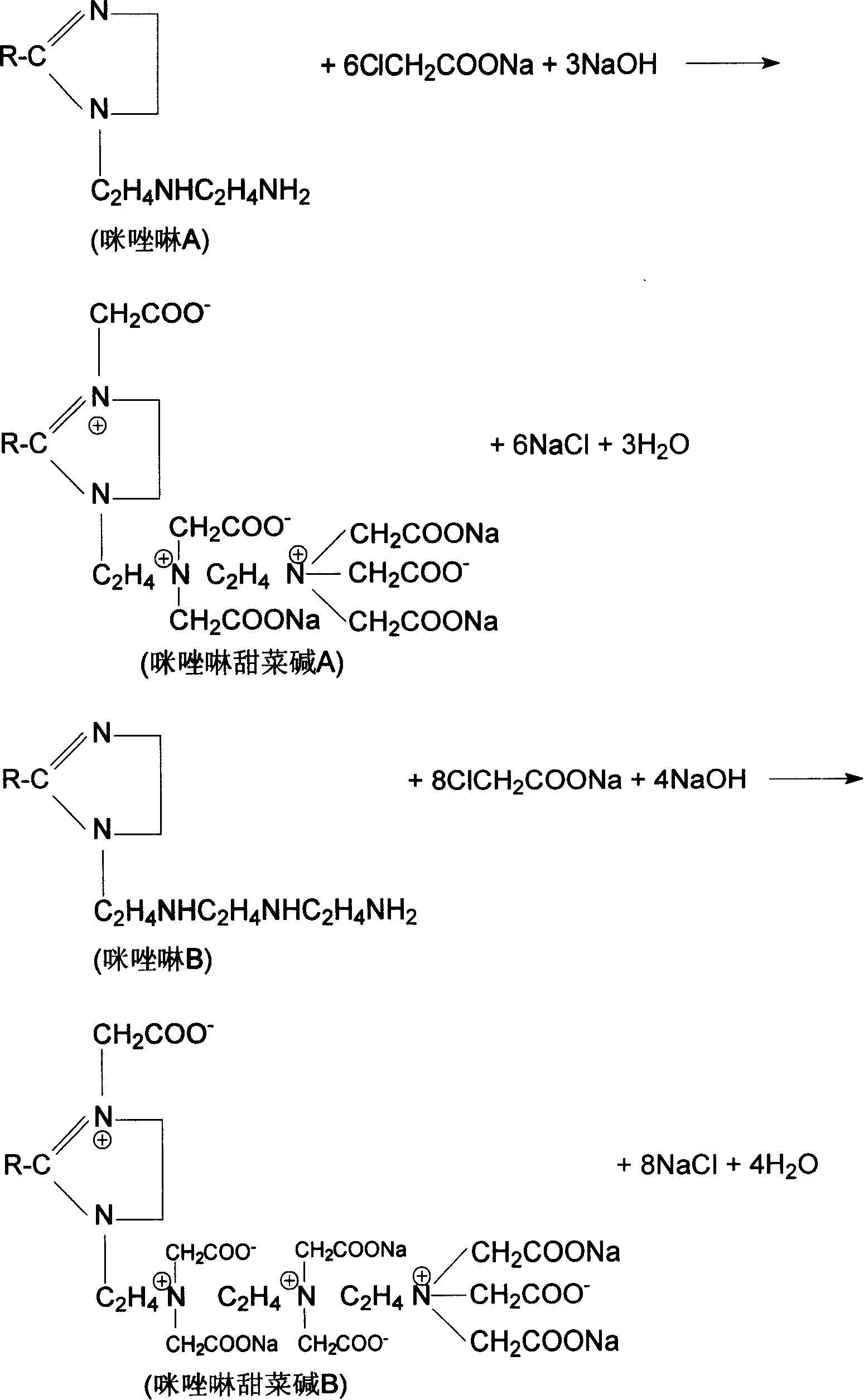

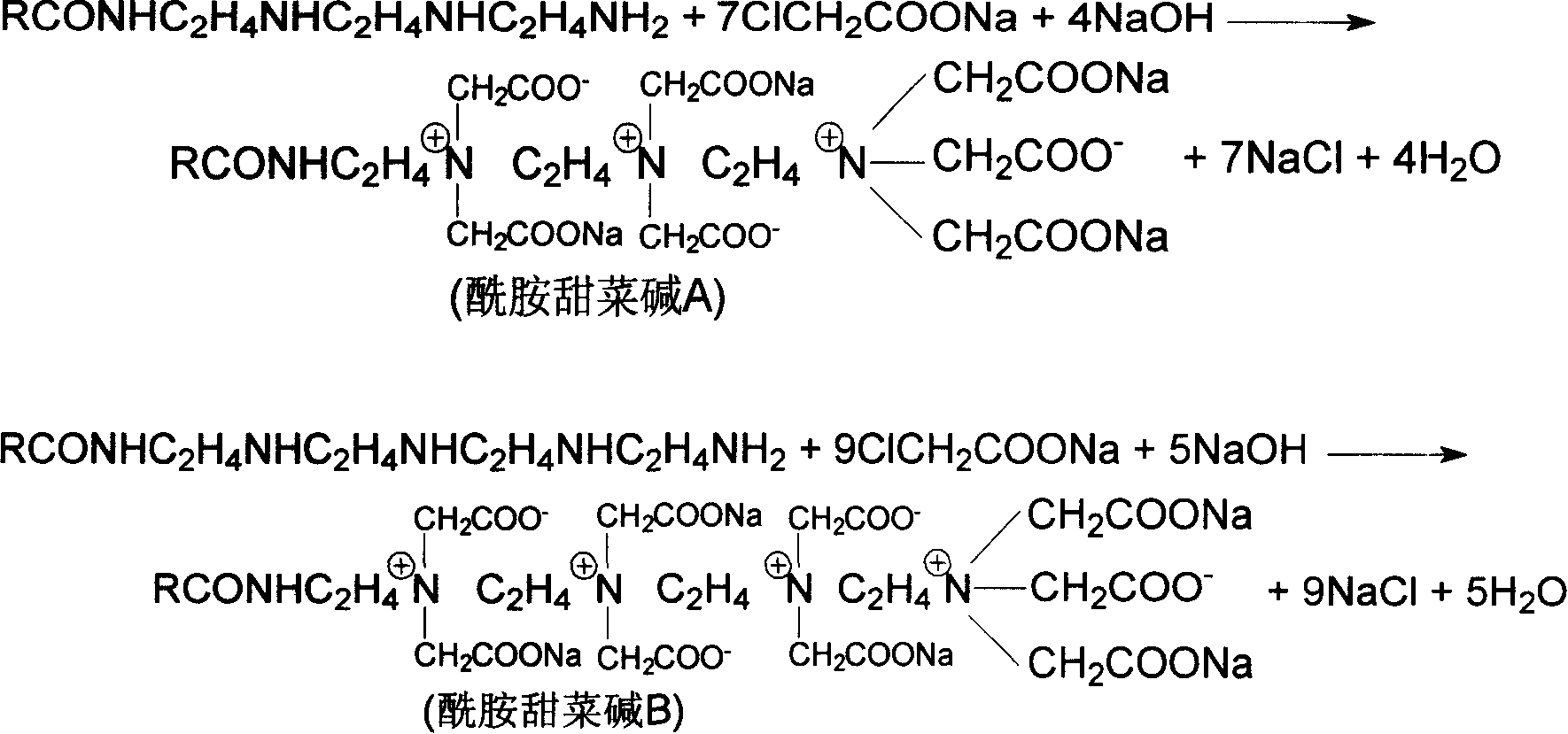

Method for preparing naphthenic acid imidazolines and betaine of amide thereof, and application of the same in HCl-H2S-H2O system

InactiveCN101190896AExcellent corrosion inhibition performanceReduce product costOrganic chemistryChemistryWater soluble

The invention relates to a preparation method of naphthenic acid imidazoline and the lycine of amide thereof and the application thereof in an HCl-H2S-H2O system. The naphthenic acid imidazoline reacts with chloroactic acid or sodium chloroacetate or the mixture of the chloroactic acid and the sodium chloroacetate at a controlled temperature of 50-95 DEG C and a pH value of 7-10 for three to ten hours to obtain the naphthenic acid imidazoline and the lycine of the amide thereof; the moll ratio of naphthenic base contained in the naphthenic acid imidazoline to the chloroactic acid or the sodium chloroacetate or the mixture of the chloroactic acid and the sodium chloroacetate is 1.0:4.1-13.0. The obtained product is applied in the HCl-H2S-H2O system as a water soluble corrosion inhibitor. The preparation method of the invention is characterized by comparatively low cost, simple and convenient preparation and short reaction time. The naphthenic acid imidazoline and the lycine of the amide thereof as the water soluble corrosion inhibitor have excellent corrosion inhibition performance and good intermiscibility with organic amine, thereby being beneficial for industrial application.

Owner:HUNAN UNIV OF SCI & TECH

Preparation method for corrosion inhibition component as well as product and application thereof

ActiveCN107012468AImprove solubilityExcellent corrosion inhibition performanceTransportation and packagingMixingSolventSolubility

The invention relates to a preparation method for a corrosion inhibition component as well as a product and application thereof. The method comprises the following steps: putting an organic ammonium salt and thiocyanate in a polar solvent for reaction to generate precipitates, and removing insoluble substances and the polar solvent in the reaction system to obtain the corrosion inhibition component. According to the corrosion inhibition component, the pH value is close to a neutral value, the solubility is good, and the corrosion inhibition performance is good.

Owner:CHINA PETROLEUM & CHEM CORP +1

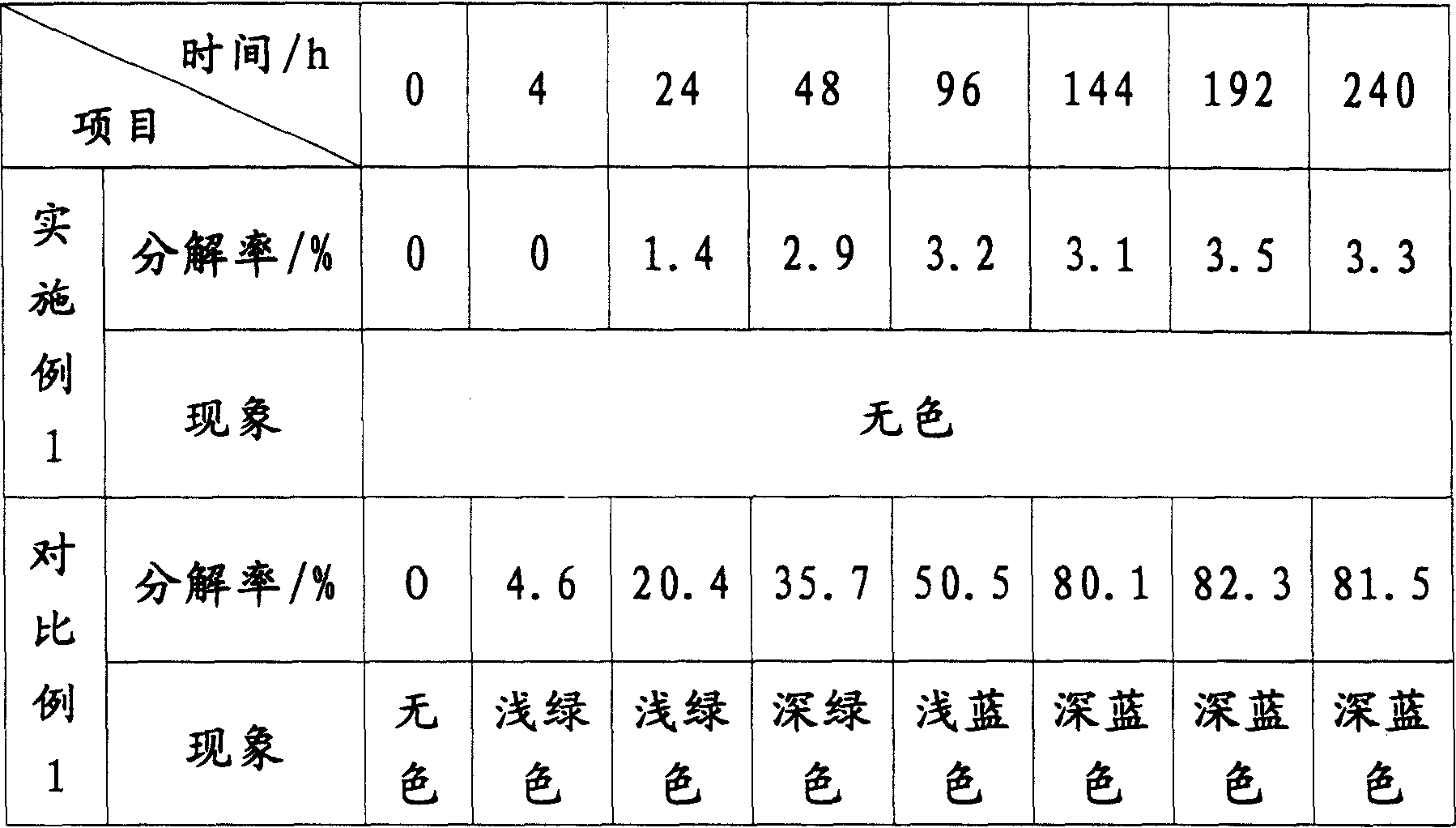

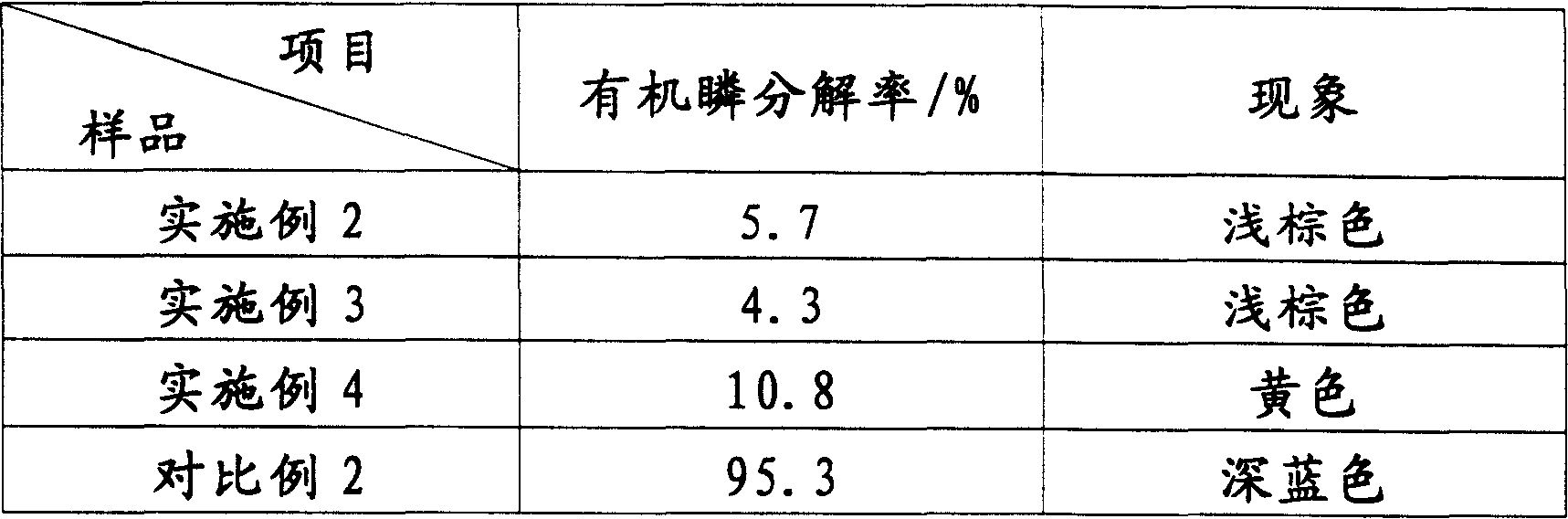

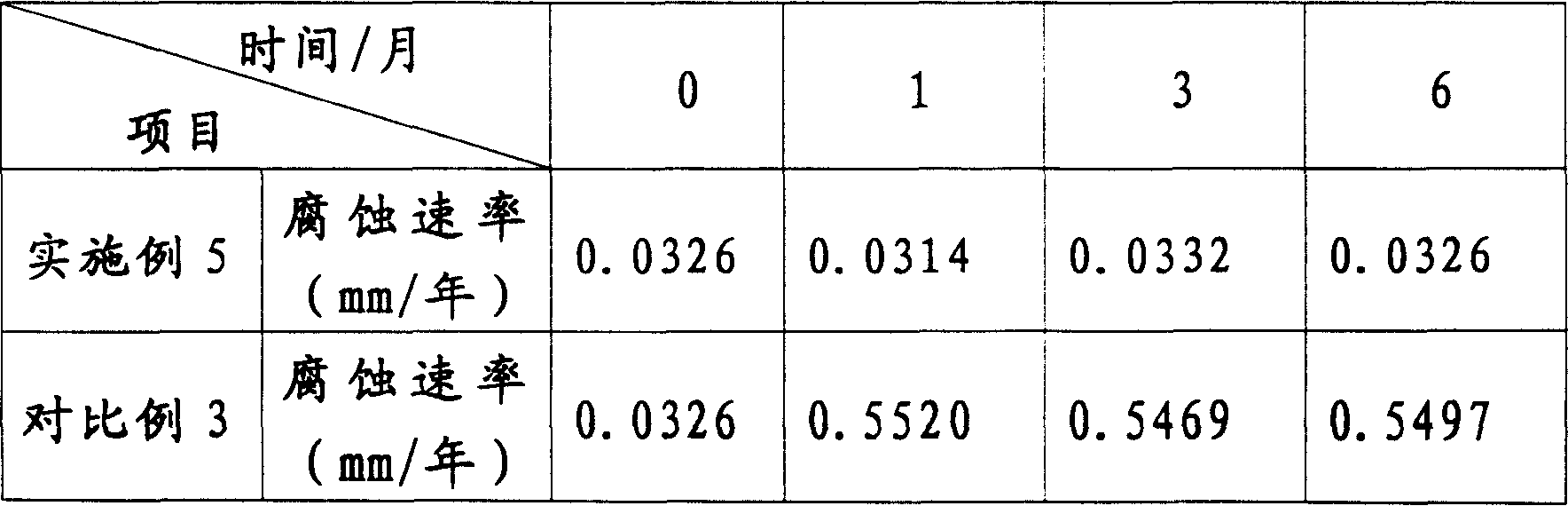

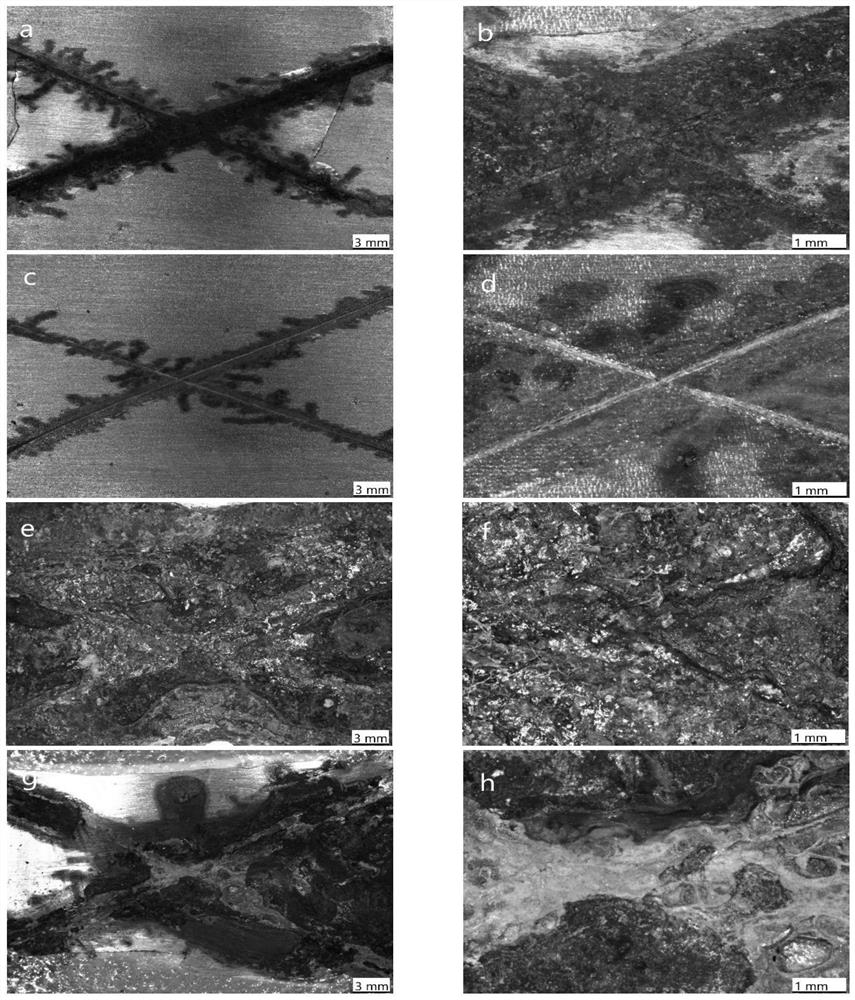

PH stimulation response intelligent repair coating and preparation method thereof

PendingCN113321985AExcellent corrosion inhibition performanceSmart Controlled ReleaseAnti-corrosive paintsEpoxy resin coatingsBenzimidazoleMetal substrate

The invention discloses a pH stimulation response intelligent repair coating and a preparation method thereof. The pH stimulation response intelligent repair coating comprises a corrosion inhibitor, a corrosion inhibitor carrier, a coating layer, a film forming substance, a curing agent and a solvent, wherein the corrosion inhibitor is 2-chloromethyl benzimidazole, the corrosion inhibitor carrier is mesoporous fumed silica, the coating layer is poly (sodium p-styrenesulfonate) and polyethyleneimine, the poly (sodium p-styrenesulfonate) and the polyethyleneimine sequentially coat the surface of the mesoporous fumed silica loaded with the 2-chloromethyl benzimidazole, epoxy resin is used as a film forming substance, and absolute ethyl alcohol is used as a solvent. When the pH value of a corrosive medium is not higher than 4, the prepared pH stimuli-responsive intelligent repair coating has a very prominent protection effect on a metal substrate. The lower the pH value is, the better the protection effect is.

Owner:JIANGSU UNIV OF SCI & TECH

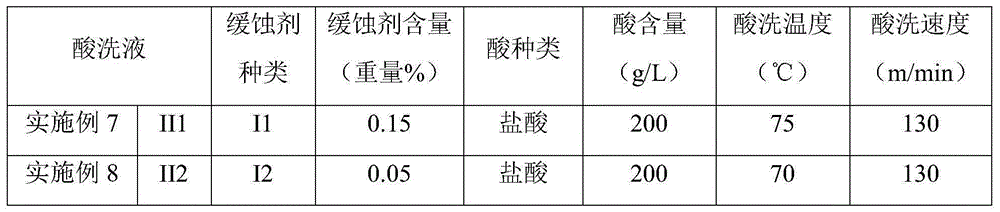

Acid adding inhibiter and method for acid pickling through acid adding inhibiter

ActiveCN105040007AExcellent corrosion inhibition performanceOvercome surface defectsAmmonium compoundsPhosphate

The invention relates to the field of inhibiters, and discloses an acid adding inhibiter and a method for acid pickling through the acid adding inhibiter. The acid adding inhibiter comprises quaternary ammonium compounds, thiourea, aluminum phosphate and / or aluminum dihydrogen phosphate and phytic acid and / or tannic acid. The acid adding inhibiter can be used in special steel such as automobile structural steel, is small in use amount and has excellent corrosion inhibition performance. Automobile structural steel hot-rolled acid pickling plates with good surface quality can be obtained. Besides, operation cost is low, and economic benefits are good.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

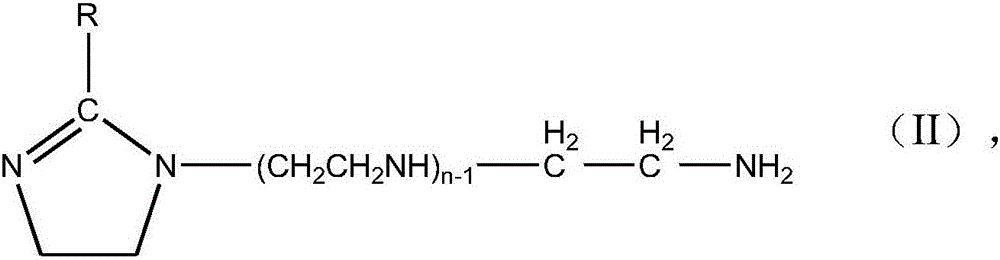

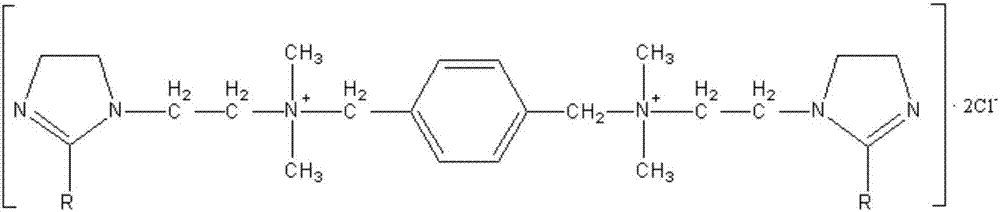

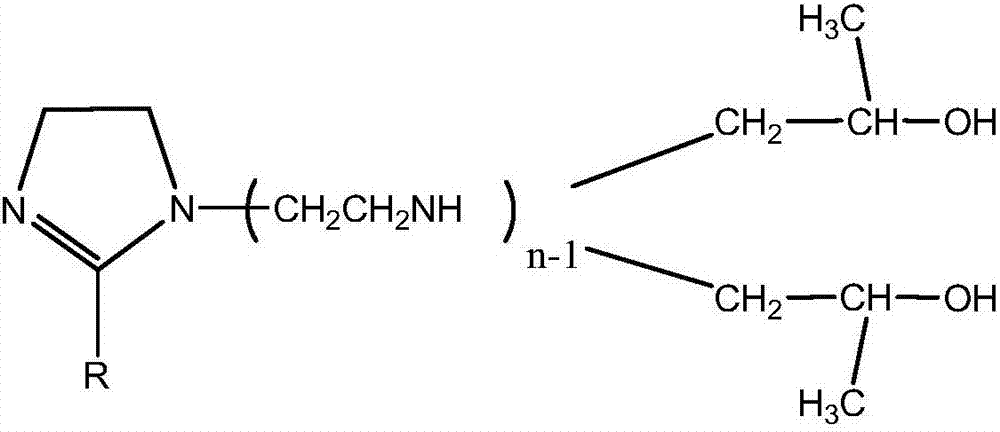

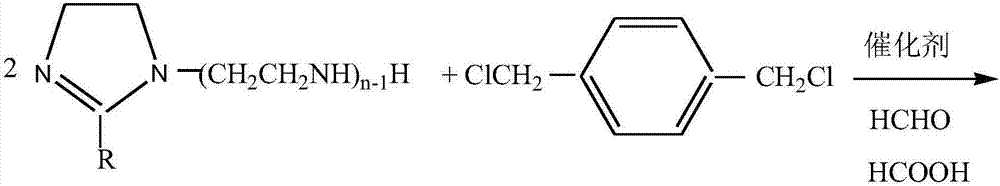

Compound imidazoline corrosion inhibitor, and preparation method thereof

InactiveCN107190265AGood water solubilityExcellent corrosion inhibition performanceOrganic chemistryLiquid systemCarbon dioxide

The invention discloses a compound imidazoline corrosion inhibitor. The compound imidazoline corrosion inhibitor is formed through mixing 20%-30% of imidazoline compound II, 20%-30% of imidazoline compound III, 5% of ethanediol and water. The compound imidazoline corrosion inhibitor disclosed by the invention is applicable to an oil-water mixed liquid system during an oilfield exploitation, production, and storage and transportation process, good in corrosion inhibition performance in an environment of pure carbon dioxide and in an environment of coexistence of hydrogen sulphide and carbon dioxide, and capable of efficiently inhibiting corrosion caused due to H2S, CO2, salts and the like.

Owner:TIANJIN ZHENGDA SCI &TECH CO LTD +2

Plant type composite efficient corrosion inhibitor as well as preparation method and application thereof

ActiveCN112680190AWide range of raw materialsRaw materials are environmentally friendlyOther chemical processesSodium molybdateSulfate zinc

The invention provides a plant type composite efficient corrosion inhibitor. The plant type composite efficient corrosion inhibitor is prepared from the following raw materials in percentage by mass: 12 to 66.0 percent of plants, 5.0 to 16.0 percent of sodium molybdate, 1.5 to 12 percent of sodium gluconate, 3.5 to 25 percent of sodium tartrate, 0 to 23 percent of zinc sulfate and 4.0 to 23.0 percent of monopotassium phosphate. The corrosion inhibitor disclosed by the invention is high in corrosion inhibition capability and can achieve a corrosion inhibition effect on a chlorine salt type snow-melting agent. After the corrosion inhibitor is added, the corrosion of the chlorine salt type snow-melting agent to metal and concrete and the harm to vegetation can be reduced. The corrosion inhibitor is mainly prepared from plants, is non-toxic, and is a very efficient and environment-friendly corrosion inhibitor. The invention further provides a preparation method and application of the plant type composite efficient corrosion inhibitor.

Owner:新疆交通科学研究院有限责任公司

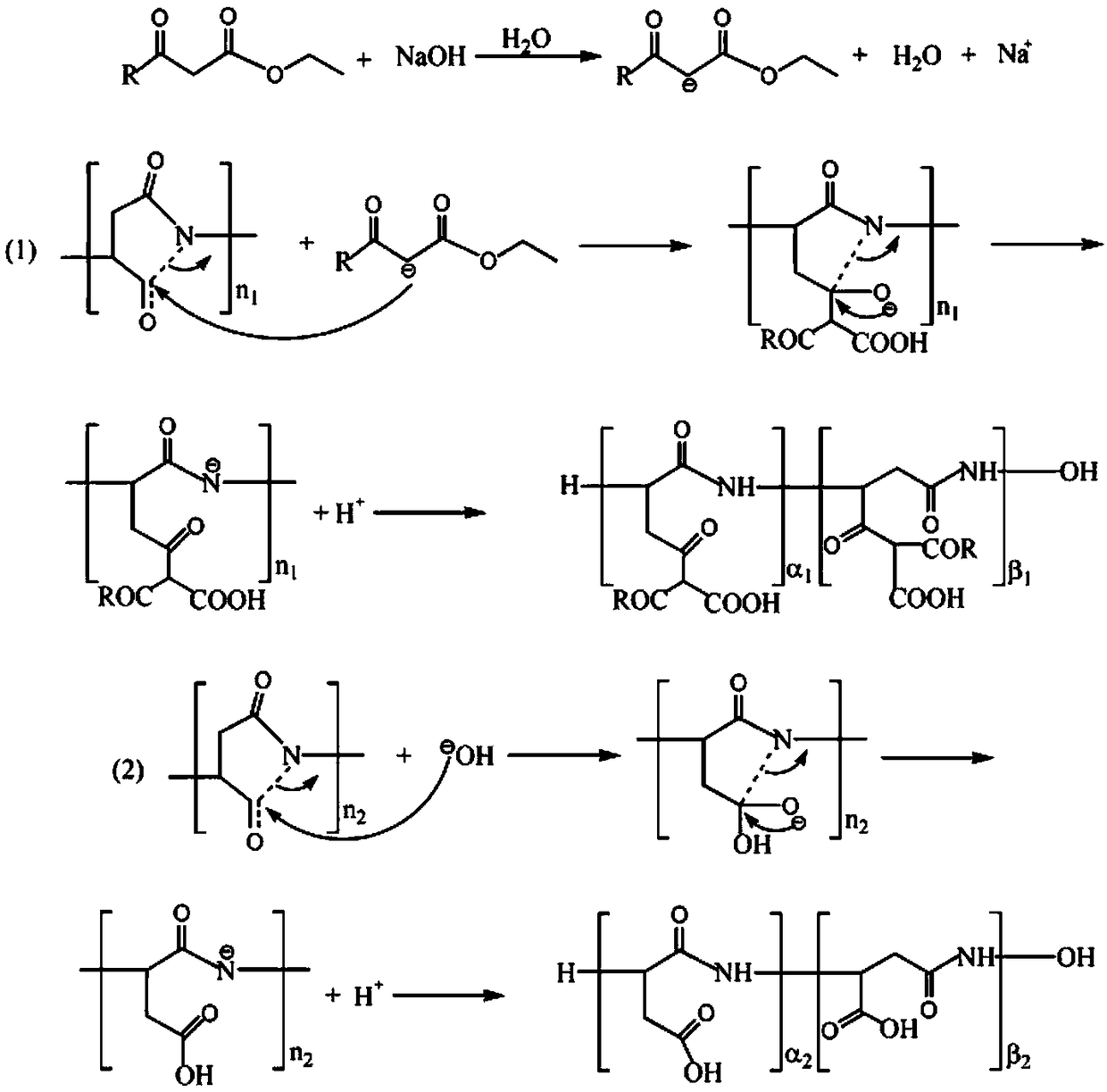

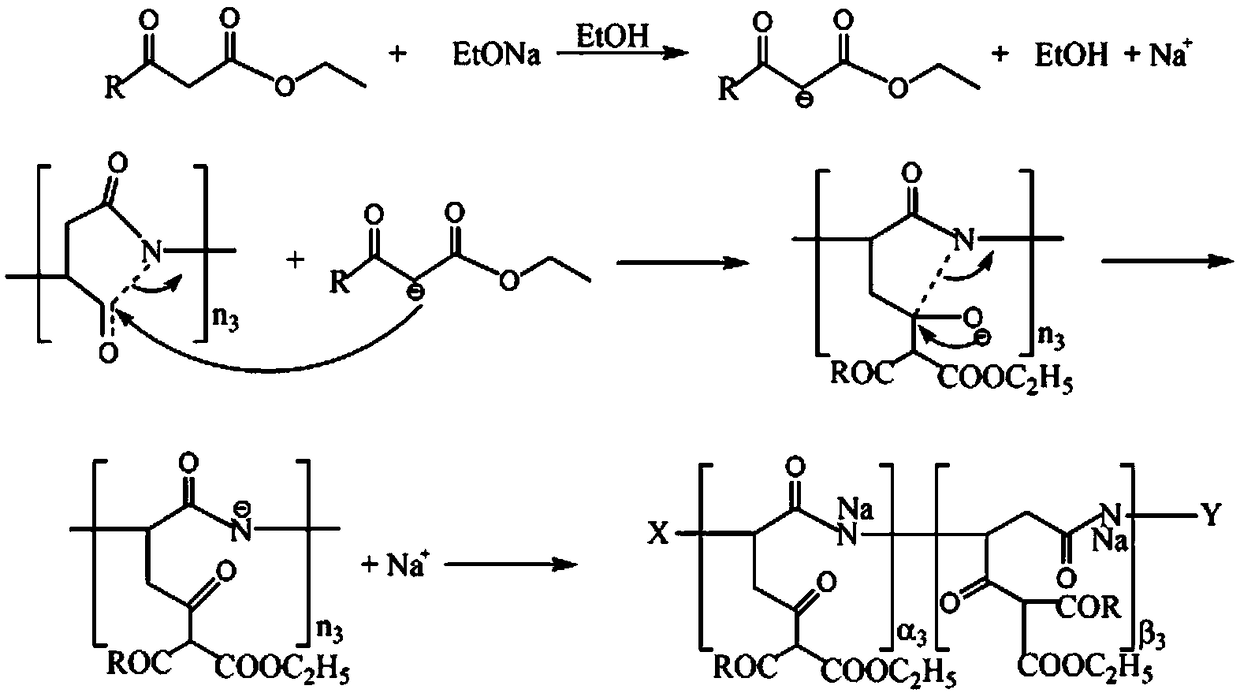

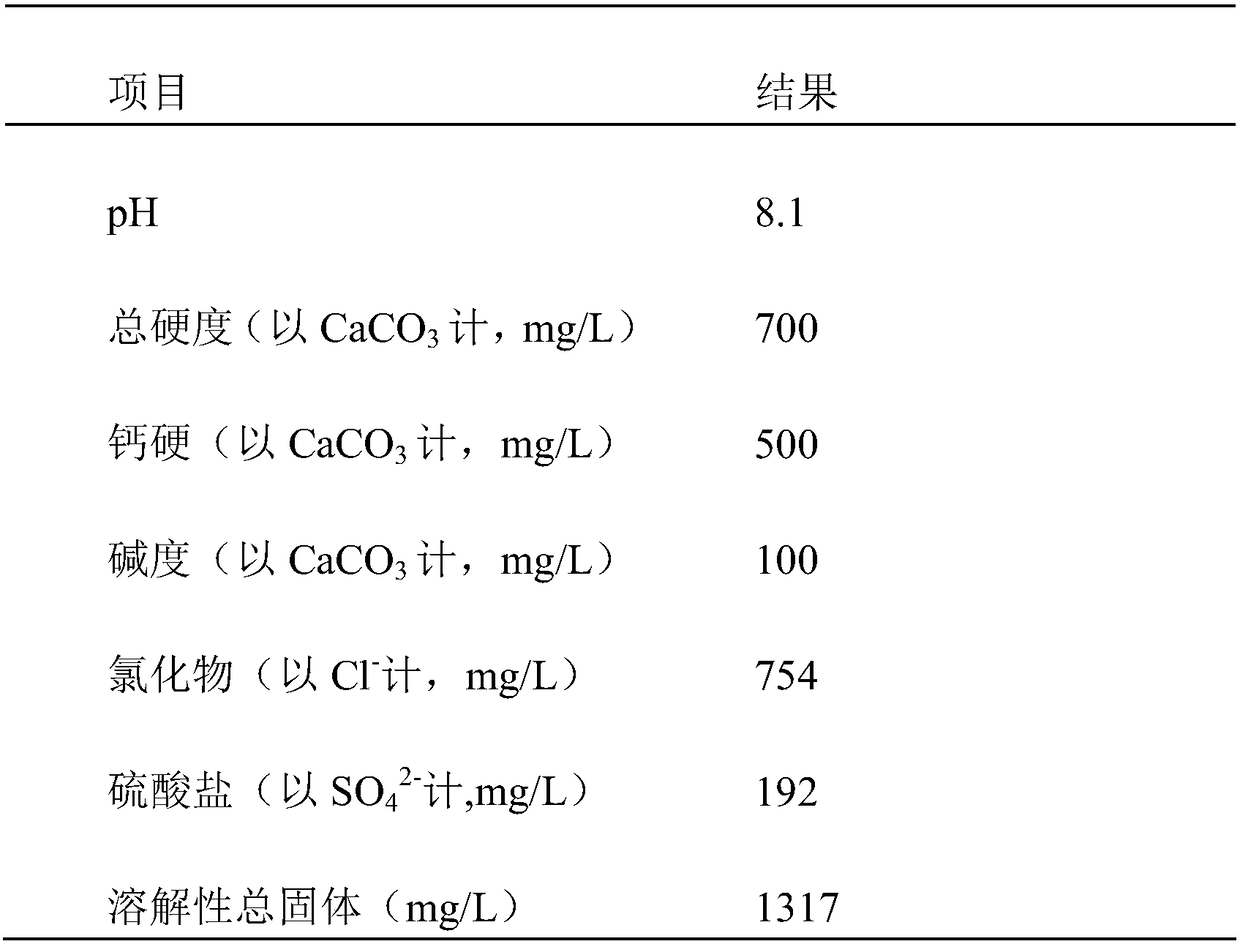

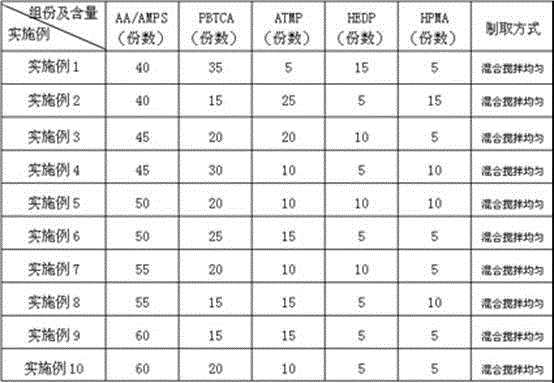

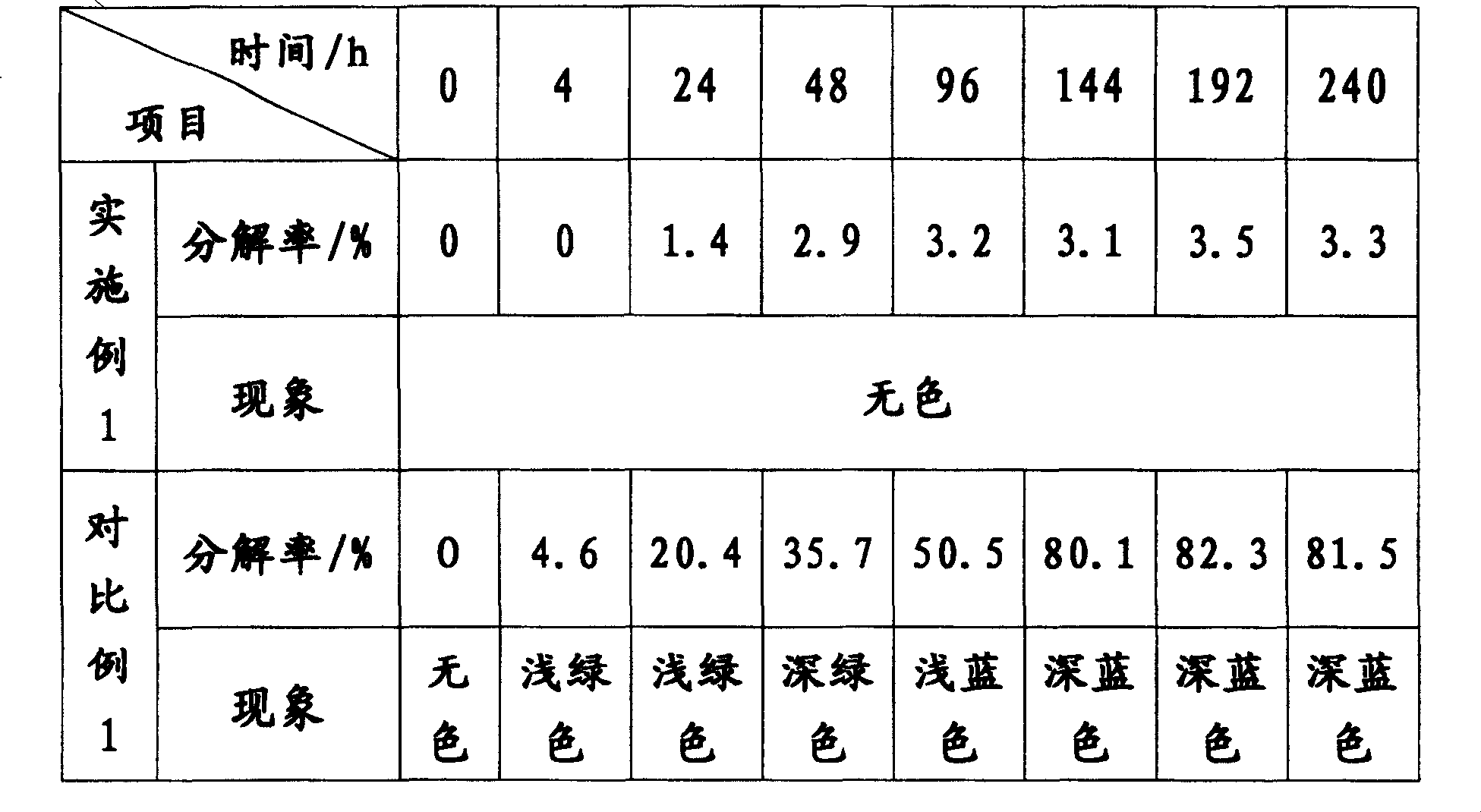

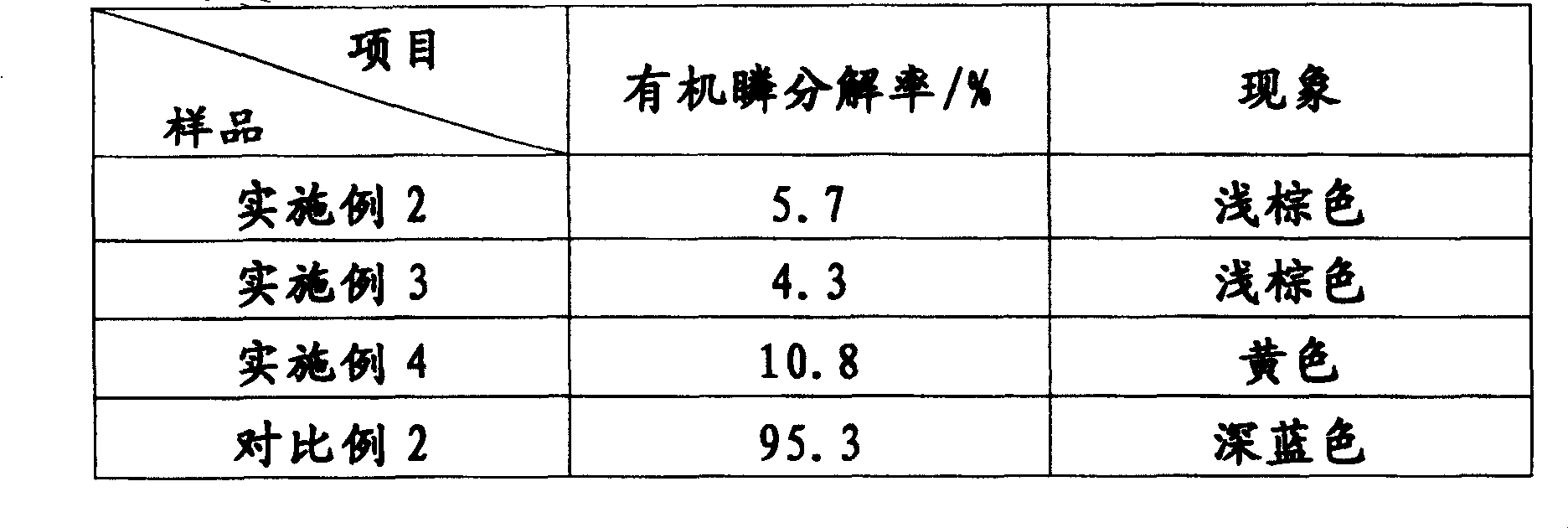

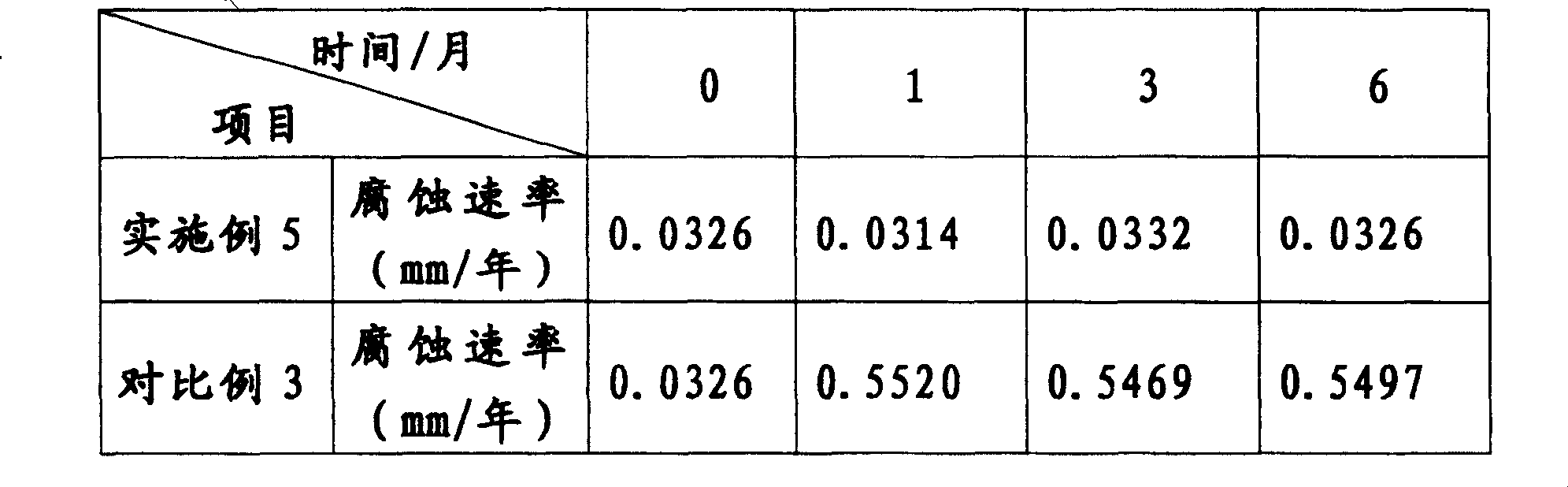

Ecological water treatment chemical with both corrosion inhibition and scale inhibition performances

ActiveCN109019887AExcellent corrosion and scale inhibitionGood synergySpecific water treatment objectivesScale removal and water softeningSodium molybdateWater treatment system

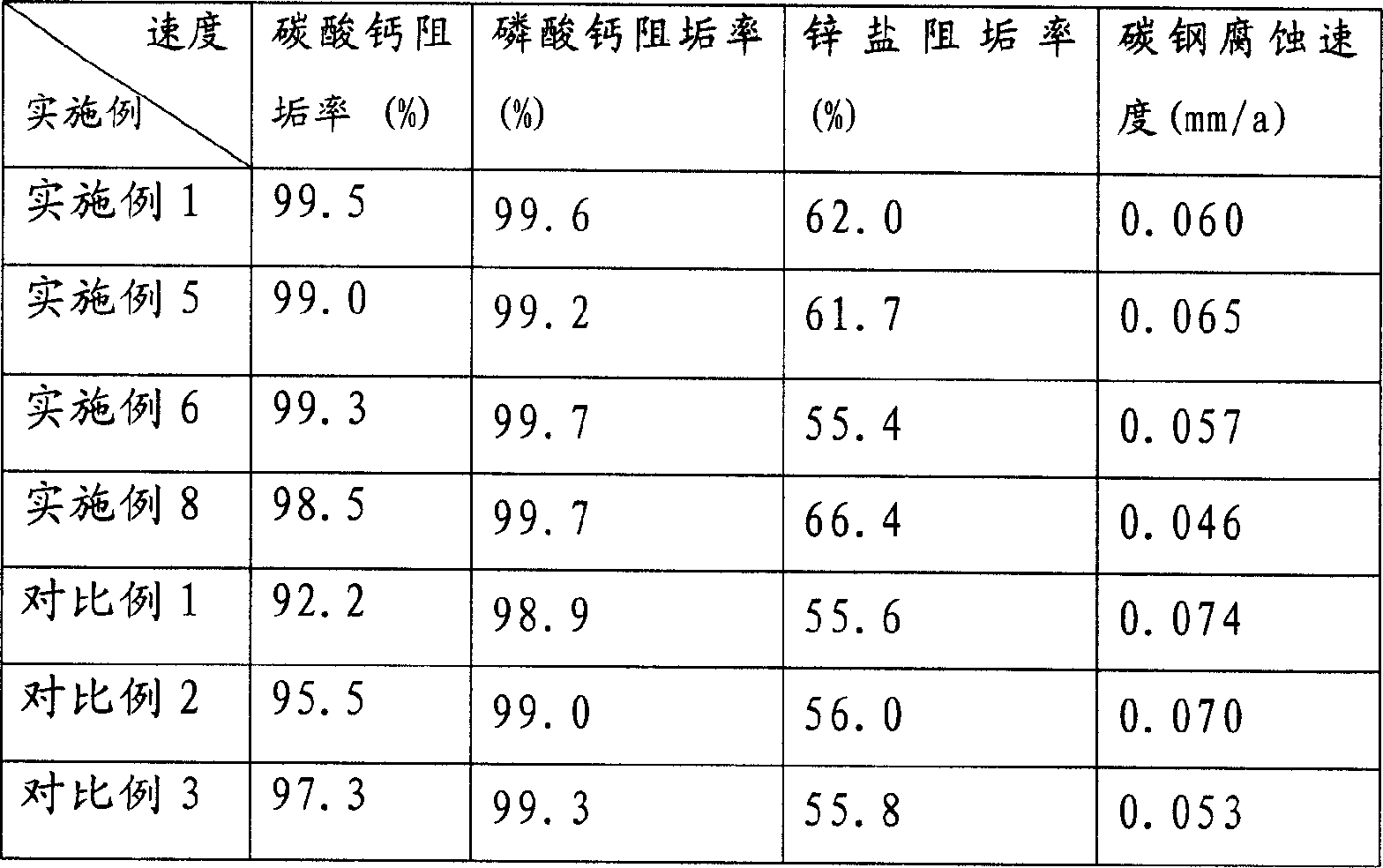

The invention discloses an ecological water treatment chemical with both corrosion inhibition and scale inhibition performances. The ecological water treatment chemical comprises beta-dicarbonyl compound modified polyaspartic acid used as a main agent, and sodium molybdate, hydroxyethylidene diphosphonic acid and zinc salts used as auxiliary agents. The ecological water treatment chemical of the invention can be applied to a circulating cooling water treatment system, and has excellent corrosion and scale inhibition performances; the chemical has a calcium carbonate inhibition rate of 100% andan annual A3 carbon steel corrosion rate of less than 0.075 mm; the concentration of Zn<2+> in discharged water is 0-1.5 mg / L, and the content of phosphorus in the discharged water is 0-0.05 mg / L; soharm to the environment due to high contents of phosphorus and zinc is avoided, and increasingly strict environmental protection requirements are met.

Owner:LANZHOU JIAOTONG UNIV

High-efficiency grey water dispersing agent

ActiveCN103086524BEnhanced inhibitory effectGood dispersionScale removal and water softeningHigh concentrationPhosphate

The invention relates to a high-efficiency grey water dispersing agent which is a composition consisting of 40-60 percent of acrylic acid-2-polyscrylide-2-methyl acrylsulfonate, 15-35 percent of 2-phosphate-1,2,4-tricarboxylic acid butane, 5-25 percent of amino trimethylene phosphonic acid, 5-15 percent of hydroxyethylidene-1,1-diphosphonic acid and 5-15 percent of hydrolytic polymaleic anhydride. The dispersing agent is stable in property under the conditions of 40MPa and 250 DEG C, has a high dispersing capacity at the high temperature of 300 DEG C, has a good dispersing function on high-basicity, high-hardness, high-PH value and high ash content and high concentration multiple under the required high-concentration times in a water-coal-slurry pressurization and gasification device, can effectively delay the scale forming tendency and is applicable to a circulating cooling water system in industries such as power, metallurgy and papermaking. The addition in a water system is determined according to the water quality and working conditions, and the amount is 50-80mg / l according to the flow sum of a low-pressure grey water pump and a high-pressure grey water pump.

Owner:JIANGSU TIANMAI CHEM CO LTD +1

Corrosion inhibitor suitable for dynamic strong alkaline cleaning of metal workpieces and preparation method of corrosion inhibitor

ActiveCN110760863AIncrease surface adsorption capacityCorrosion stabilityMetallic materialsMaterials processing

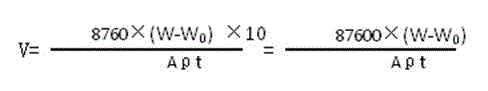

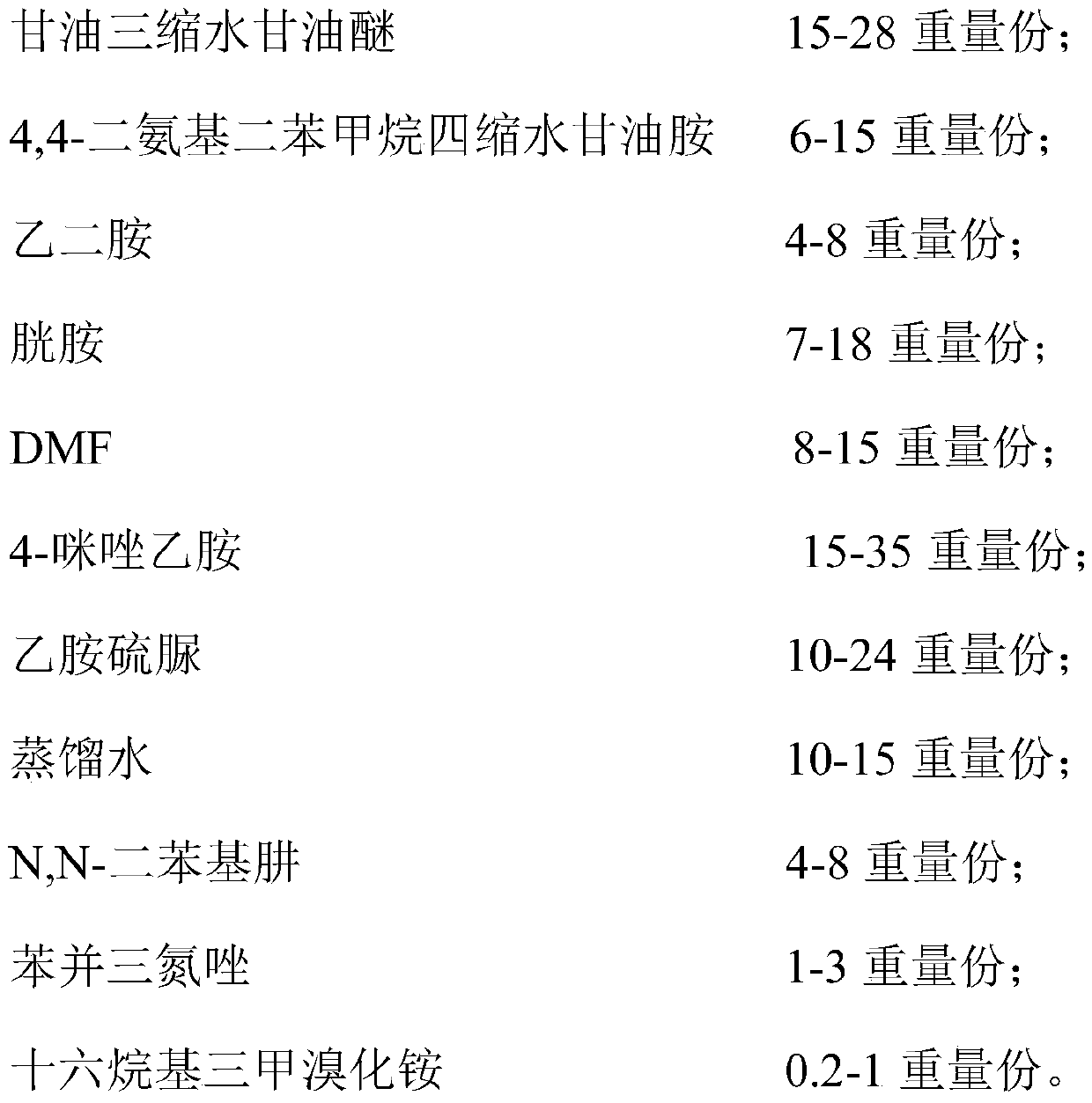

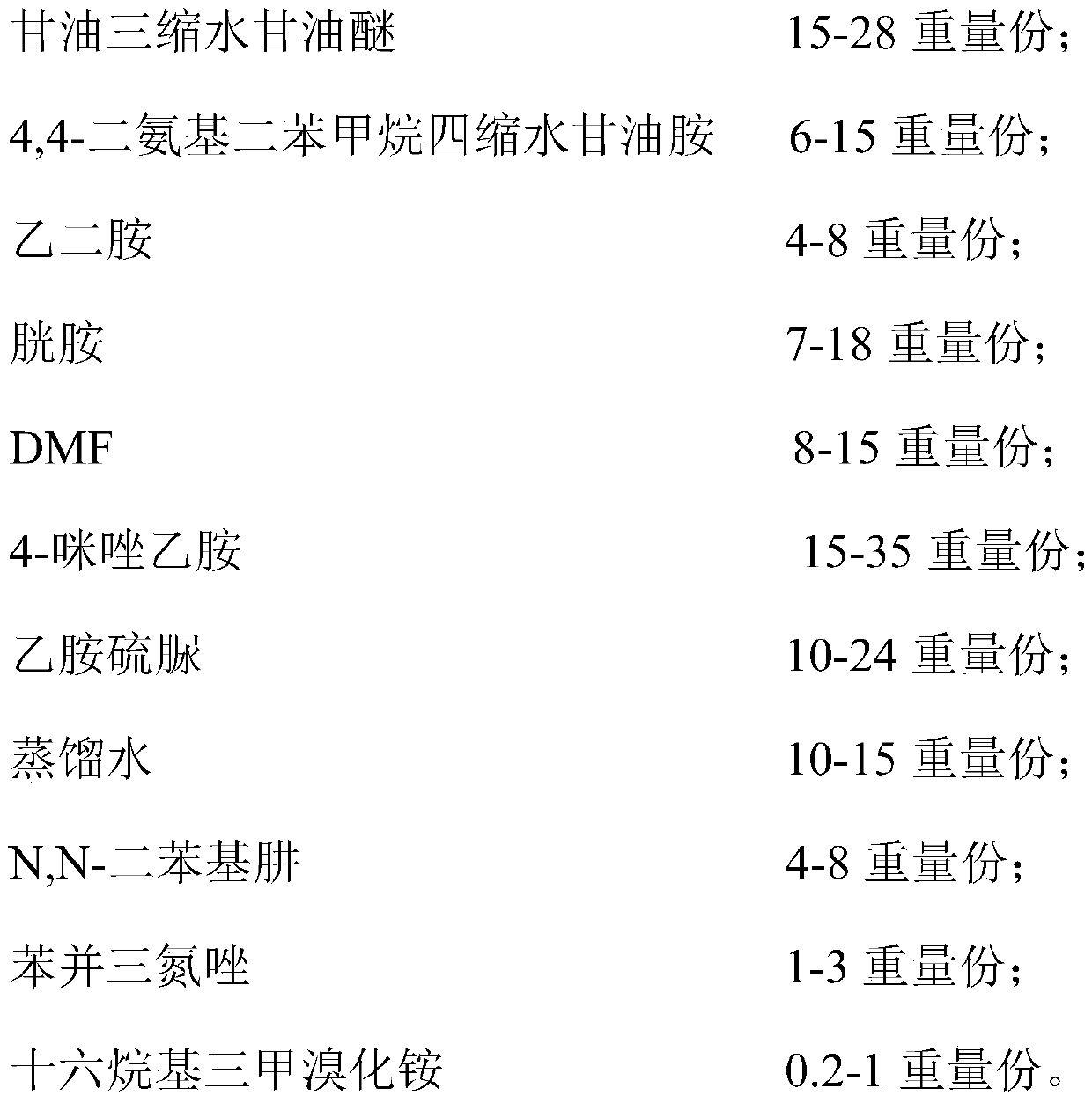

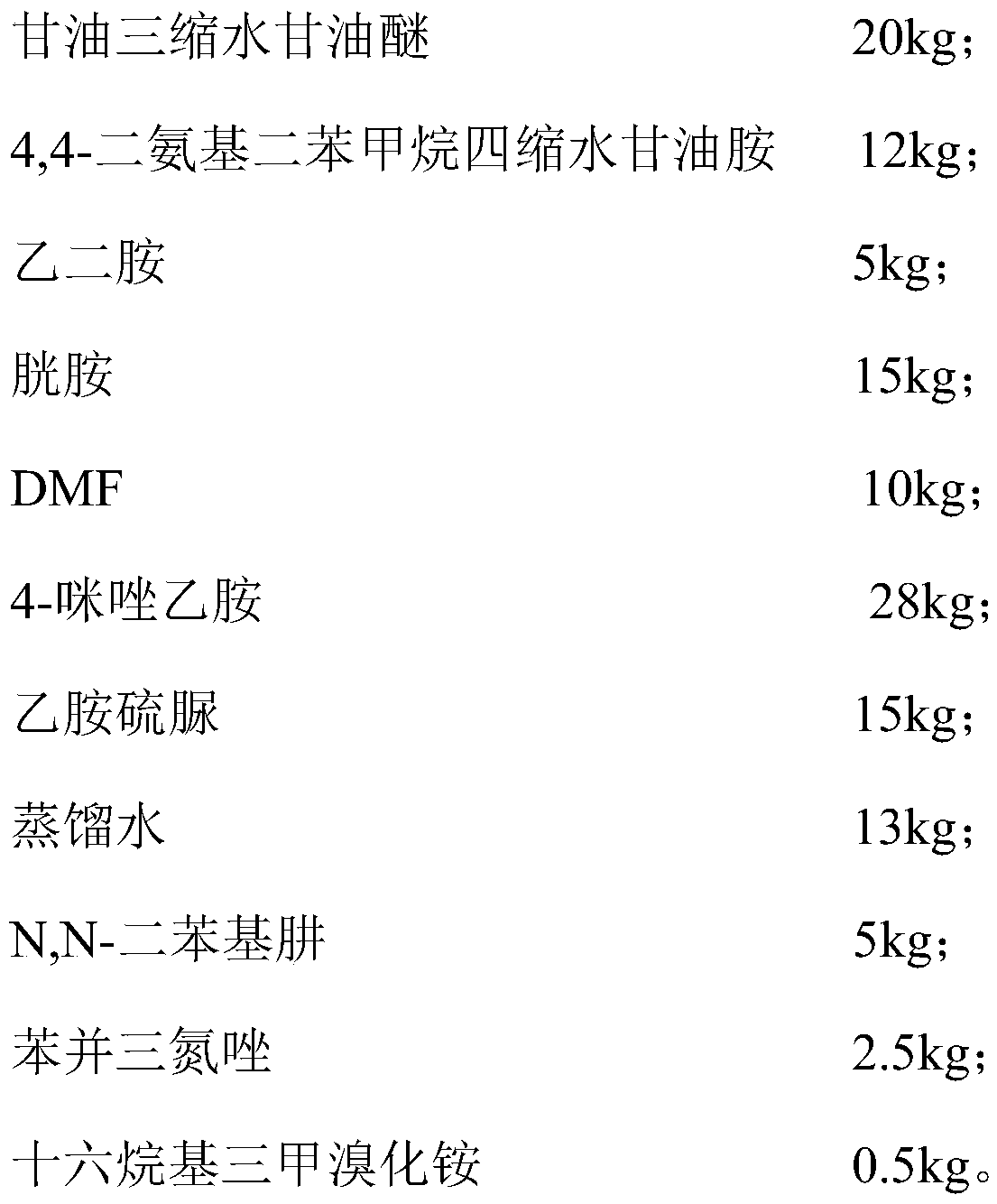

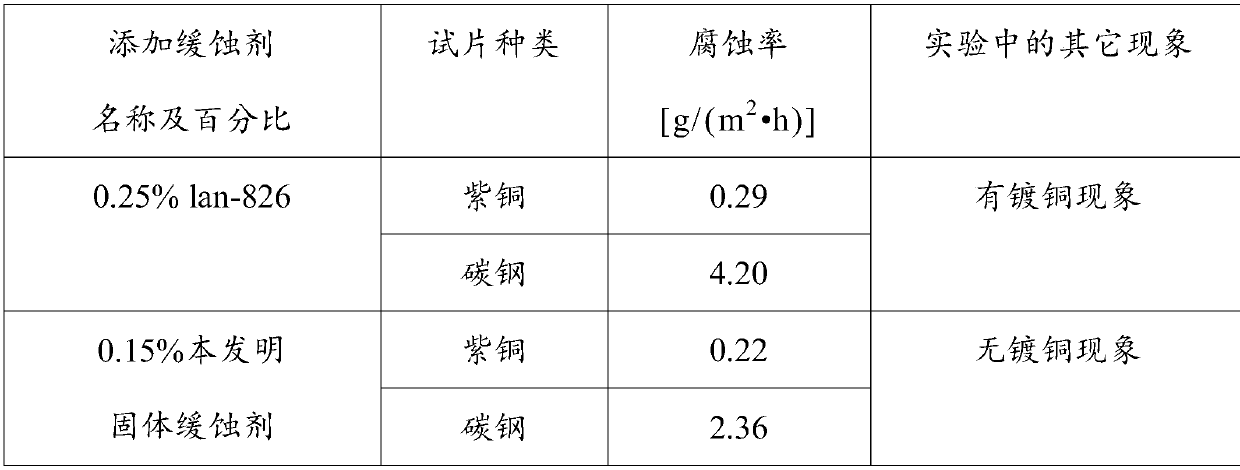

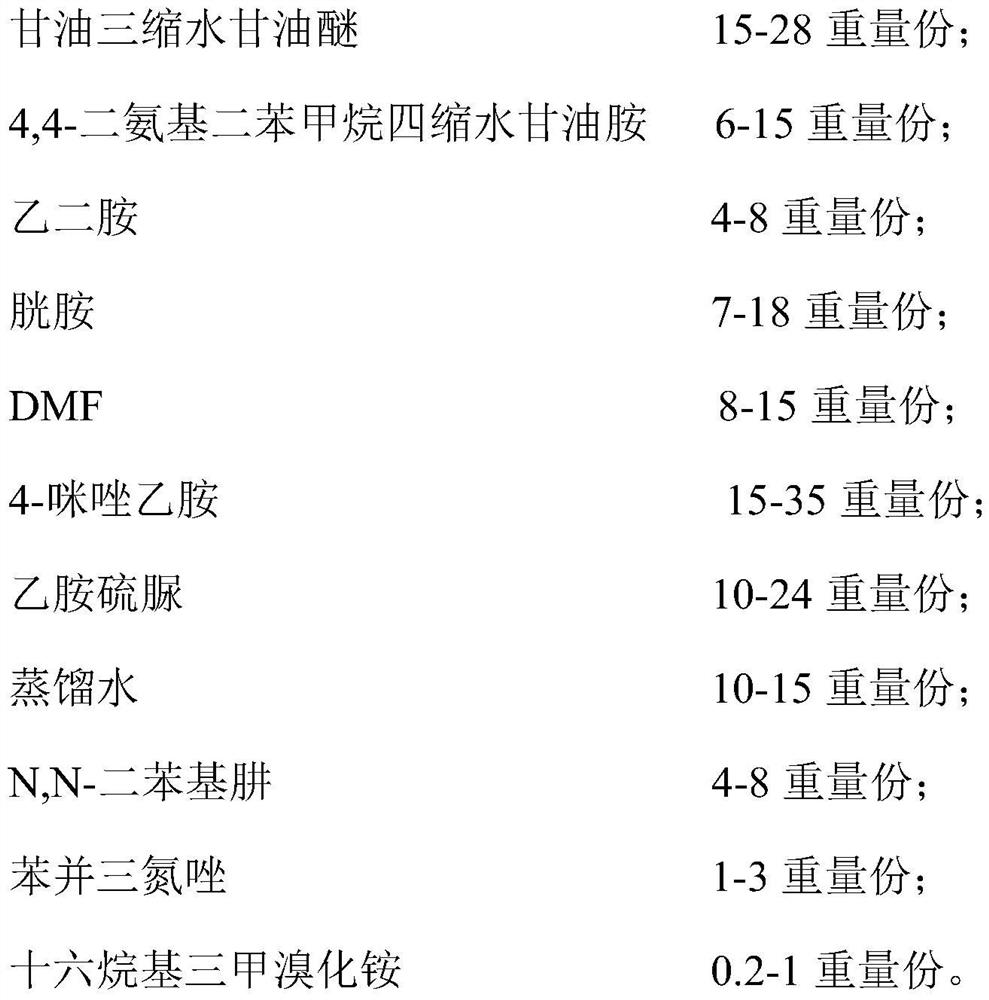

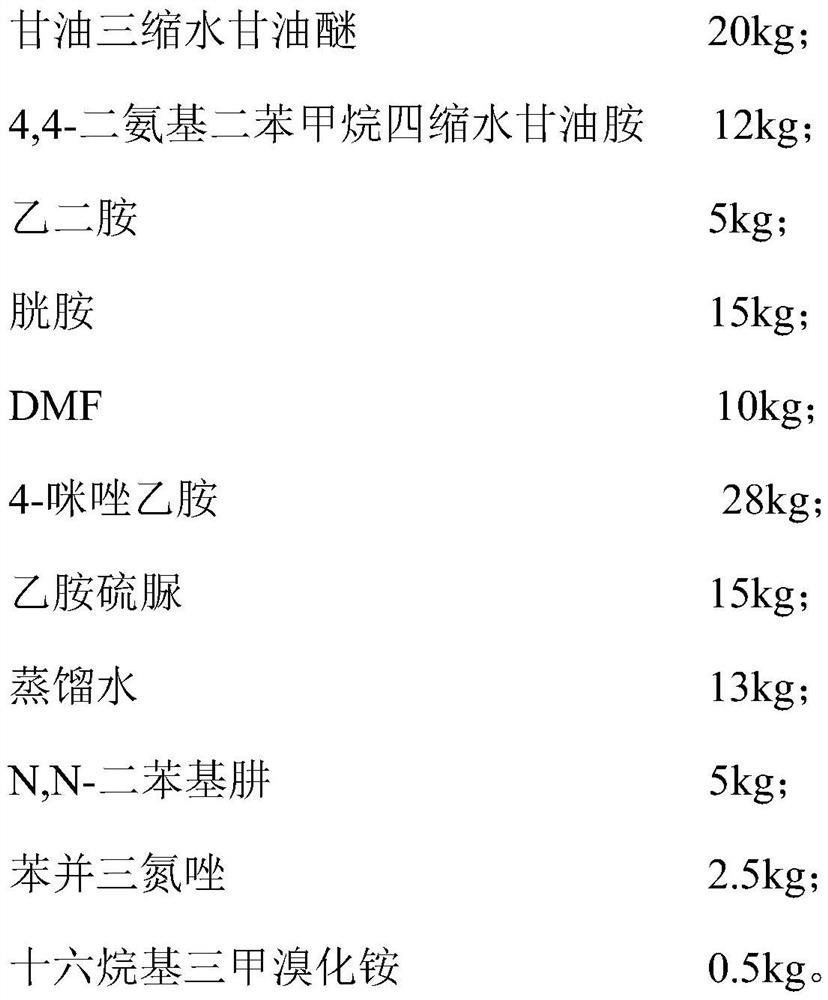

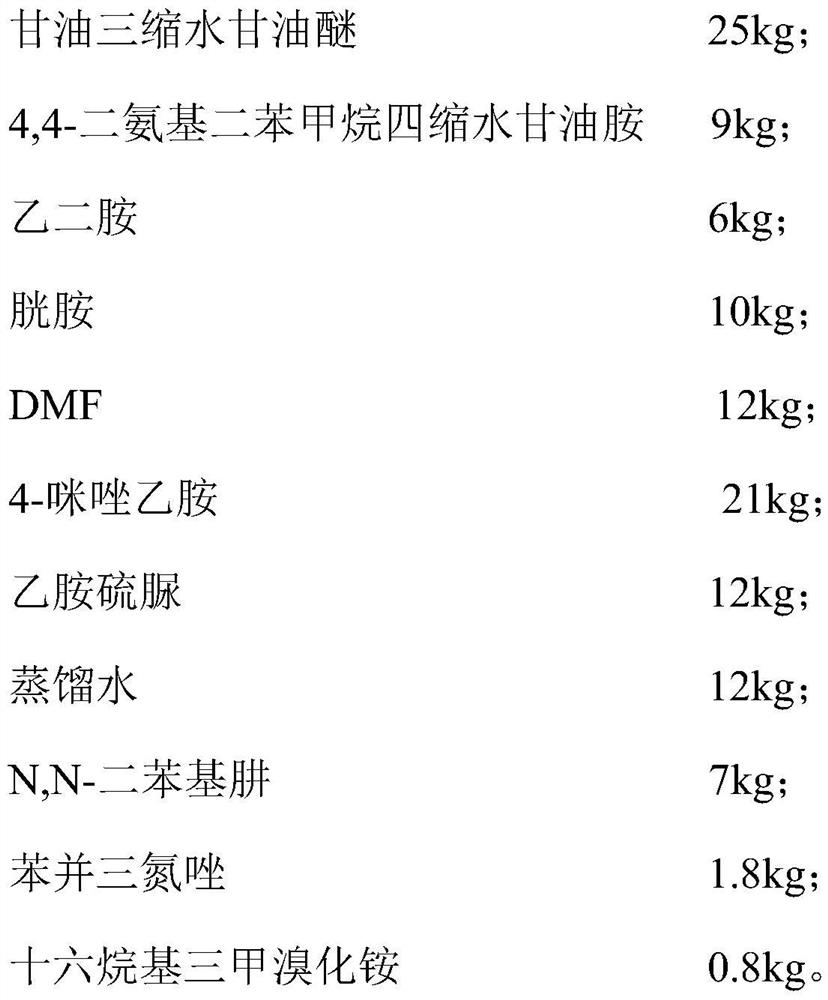

The invention belongs to the technical field of metal material processing, particularly relates to a corrosion inhibitor suitable for dynamic strong alkaline cleaning of metal workpieces, and furtherdiscloses a preparation method of the corrosion inhibitor. The corrosion inhibitor suitable for dynamic strong alkaline cleaning of the metal workpieces is synthesized from raw materials of glycerin triglycidyl ether, 4,4-diaminodiphenylmethane tetraglycidyl amine, ethylenediamine, cystine, DMF, 4-imidazolylethylamine, aminethronii hydrobromidum, N,N-diphenylhydrazine and benzotriazole as raw materials. Through the synergistic effect between properties of all components, a corrosion inhibitor product is high in alkali resistance, can be further stirred in an alkaline environment for a long time without decomposition, can be directly used for the dynamic strong alkaline cleaning operation step of the metal workpieces such as brass, and has the more stable corrosion inhibition property and the higher corrosion inhibition effect.

Owner:HUANGSHAN UNIV

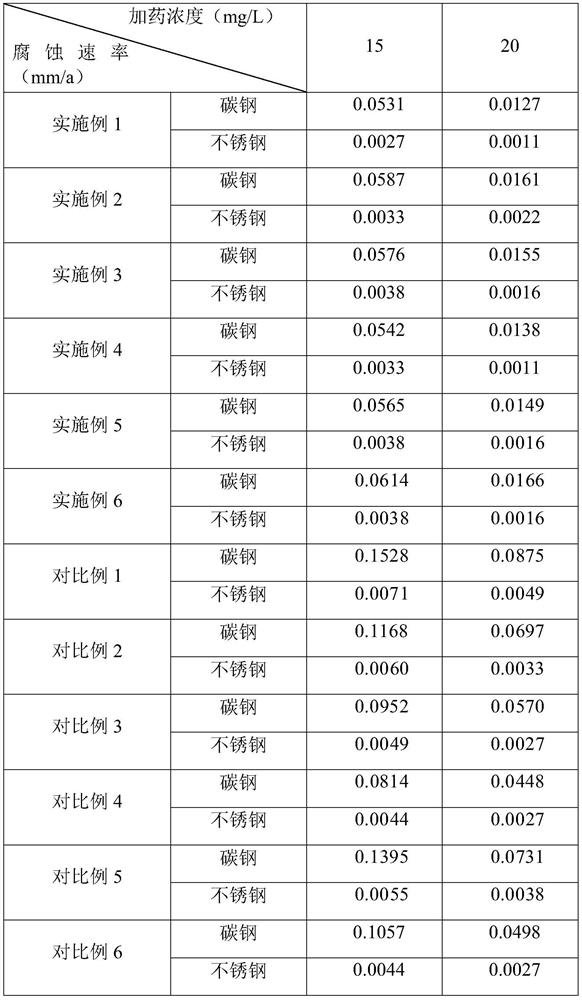

Efficient low-phosphorus scale and corrosion inhibitor and preparation method thereof

PendingCN112499777AHigh corrosion inhibition performanceExcellent corrosion inhibition performanceSpecific water treatment objectivesScale removal and water softeningEnvironmental geologyCorrosion inhibitor

The invention discloses an efficient low-phosphorus scale and corrosion inhibitor and a preparation method thereof. The efficient low-phosphorus scale and corrosion inhibitor comprises the following raw materials in parts by weight: 5-15 parts of organic phosphine, 10-20 parts of sulfonate copolymer, 10-15 parts of carboxylic acid polymer, 10-20 parts of borate, 5-15 parts of sodium nitrite, 5-15parts of zinc salt and 10-50 parts of deionized water. The efficient low-phosphorus scale and corrosion inhibitor has the characteristics of small amount and high efficiency. The efficient low-phosphorus scale and corrosion inhibitor is suitable for a circulating cooling water system with low hardness and low alkalinity, and has excellent corrosion inhibition performance on carbon steel and stainless steel equipment.

Owner:SHANDONG TIANQING TECH DEV

Molybdenum phosphine system composite anti-erosion anti-sludging agent and preparation method thereof

ActiveCN100460566CExcellent corrosion inhibition performanceInhibit oxidative decompositionScale removal and water softeningChemical inhibitorsMolybdatePhosphine

The invention provides a molybdate-phosphonate compound corrosion inhibitior and the method for preparing the same. Said corrosion inhibitior comprises of solidum molybdate 1-20 wt%, organic phosphine 1-40 wt%, oxidant 1-10 wt% and excipient 97wt%. The compound corrosion inhibitior is characterized by convenient operation and management and satable corrosion inhibition performance.

Owner:CHINA PETROLEUM & CHEM CORP +1

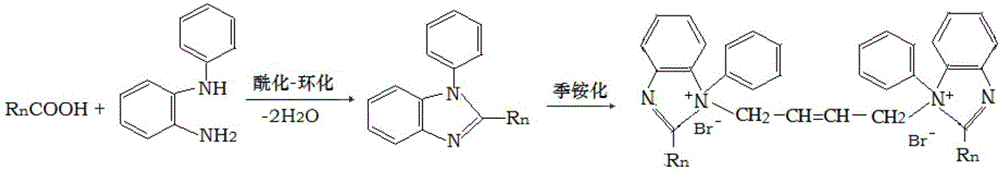

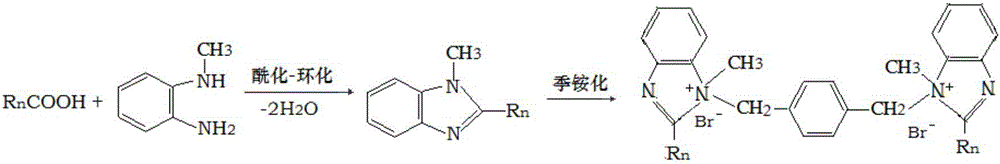

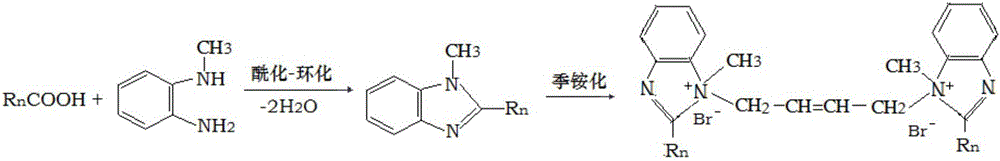

Mixed fatty group di(benzimidazoline-ammonium-salt) as well as preparation method and application thereof

ActiveCN106083727AImprove hydrophobicityGood water solubilityOrganic chemistrySolubilityTectorial membrane

The invention belongs to the field of fine organic chemical engineering, and in particular relates to a mixed fatty group di(benzimidazoline-ammonium-salt) as well as a preparation method and application thereof. The invention provides a structure of the mixed fatty group di(benzimidazoline-ammonium-salt), and further provides a preparation method and application of the mixed fatty group di(benzimidazoline-ammonium-salt). After a mixed fatty group and a quaternary ammonium group are introduced into benzimidazoline molecules, the hydrophobicity of a protection membrane can be improved, the metal corrosion velocity can be reduced, and the water solubility of a corrosion inhibitor can be improved. Results of experimental determination show that the corrosion inhibition effect of the corrosion inhibitor provided by the technical scheme of the invention is remarkably superior to that of a conventional corrosion inhibitor. The technical defects that in the prior art a corrosion inhibitor is poor in corrosion inhibition effect and poor in water solubility are solved. In addition, swill-cooked dirty oil is used as a raw material of the mixed fatty group di(benzimidazoline-ammonium-salt), so that the production cost is lowered, and furthermore the environment can be protected.

Owner:GUANGDONG UNIV OF TECH

Non-phosphorus corrosion and scale inhibitor for low-hardness water system industrial recycling cooling water

ActiveCN103523936AExcellent corrosion inhibition performanceLow in zinc saltsScale removal and water softeningChemistryPolyaspartic acid

The invention discloses a non-phosphorus corrosion and scale inhibitor suitable for the low-hardness water quality. The non-phosphorus corrosion and scale inhibitor is characterized by comprising, by weight, 15% to 20% of AMPS quadripolymer water solutions with the concentration of 30%, 10% to 15% of polyaspartic acid solutions the concentration of 50%, 5% to 10% of hydroxyl carboxylate, 5% to 15% of long-chain alkyl sulfonates, 5% to 10% of N-long-chain alkyl amino carboxylate, 1% to 5% of tungstate, 1% to 3% of zinc salt, 1% to 2% of pH stabilizers selected from sodium hydroxide or hydrochloric acid, and the balance deionized water.

Owner:CNOOC TIANJIN CHEM RES & DESIGN INST +2

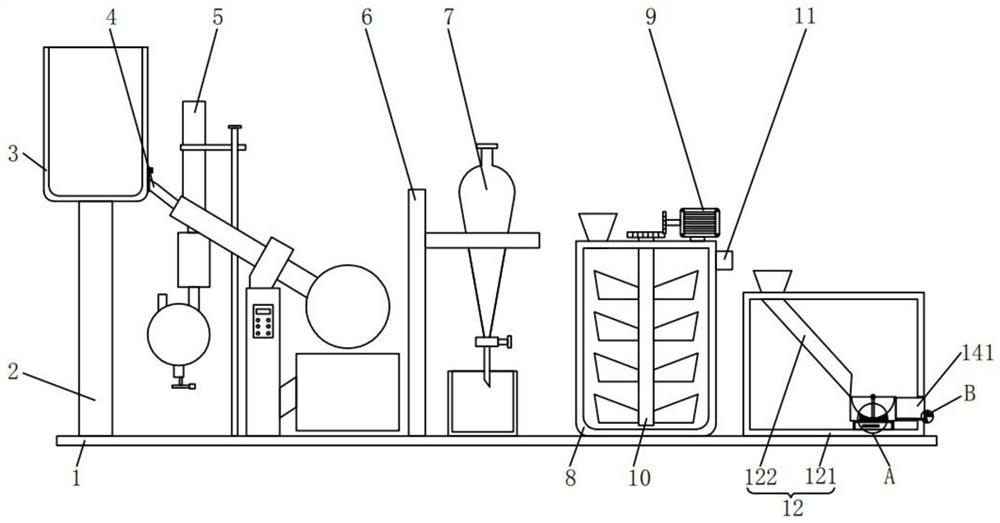

Preparation method and preparation system of special corrosion inhibitor for metal equipment

PendingCN112048722AExcellent corrosion inhibition performanceGood thermal stabilityElectric machineryEthyl acetate

The invention provides a preparation method and preparation system of a special corrosion inhibitor for metal equipment. The preparation method comprises the following steps that A, abietic acid and K2CO3 are dissolved in dimethylformamide, iodomethane (MeI) is added, stirring is carried out for 3 hours, and a TLC point plate reacts completely; and B, reduced pressure rotary evaporation is carriedout to remove MeI, extracting is carried out with ethyl acetate (EA), concentrating is carried out, and washing with water is carried out to remove dimethylformamide. According to the preparation method and preparation system of the special corrosion inhibitor for the metal equipment, the corrosion inhibitor has good anti-H2S / CO2-corrosion inhibition performance, the thermal stability is good, the toxicity is low, no special pungent smell is generated, the corrosion inhibition rate of the corrosion inhibitor is high and can reach 90%, a second motor drives a filter screen to rotate, so that solid in a mixing solution in a fixing groove is filtered through the filter screen, and the solid falls into a collection box and liquid flows into a sliding shell from a filtering opening. The deviceis simple in structure, solid and liquid can be separated from each other, and the problem of low filtering speed due to the fact that the solid blocks the filtering opening can be solved.

Owner:武汉思越化学技术有限公司

A pickling solid corrosion inhibitor for power plant boilers

ActiveCN107541736BImprove performanceExcellent corrosion inhibition performanceThioureaMaterials science

The invention discloses a solid corrosion inhibitor for pickling a power station boiler, and belongs to the field of corrosion inhibitors. The solid corrosion inhibitor for pickling the power stationboiler comprises 12 to 15 parts of methenamine, 6 to 8 parts of ammonium thiocyanate, 0.6 to 1 parts of bromogeramine, 0.1 to 0.2 part of benzotriazole, 2 to 5 parts of stannous chloride, 2 to 5 partsof sodium thiosulfate and 1 to 3 parts of thiourea. According to the solid corrosion inhibitor disclosed by the invention, most acids, expect nitric acid, have high corrosion inhibiting efficiency onmost metals, except zinc and aluminium; moreover, various types of corrosion and potential safety hazards, such as H<+> ion corrosion, H atomic corrosion, Fe<3+> corrosion and Cu<2+> corrosion, in apickling process are taken into full consideration, so that the solid corrosion inhibitor for pickling the power station boiler has the prominent advantages of more complete corrosion inhibiting spots, higher corrosion inhibiting efficiency, and wider application range and the like.

Owner:青岛沃尔特节能工程技术有限公司

A corrosion inhibitor suitable for dynamic strong alkali cleaning of metal workpieces and preparation method thereof

The invention belongs to the technical field of metal material processing, specifically relates to a corrosion inhibitor suitable for dynamic strong alkali cleaning of metal workpieces, and further discloses a preparation method thereof. The present invention is applicable to the corrosion inhibitor of metal workpiece dynamic strong alkali cleaning, with glycerol triglycidyl ether, 4,4-diaminodiphenylmethane tetraglycidylamine, ethylenediamine, cystamine, DMF, 4-imidazole Ethylamine, ethylthiocarbamate, N,N-diphenylhydrazine and benzotriazole are synthesized from raw materials; with the help of the synergistic effect between the properties of each component, the corrosion inhibitor product is not only alkali-resistant Strong, can be stirred in the lye environment for a long time without decomposition, can be directly used in the dynamic strong alkali cleaning operation of brass and other metal workpieces, and has more stable corrosion inhibition performance and stronger corrosion inhibition Effect.

Owner:HUANGSHAN UNIV

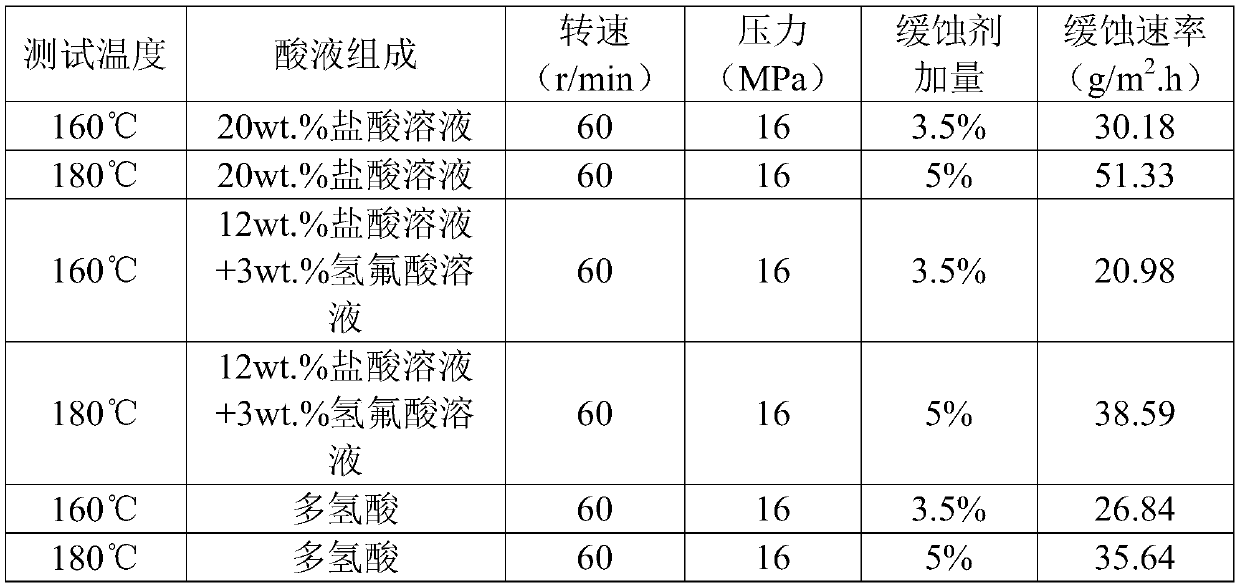

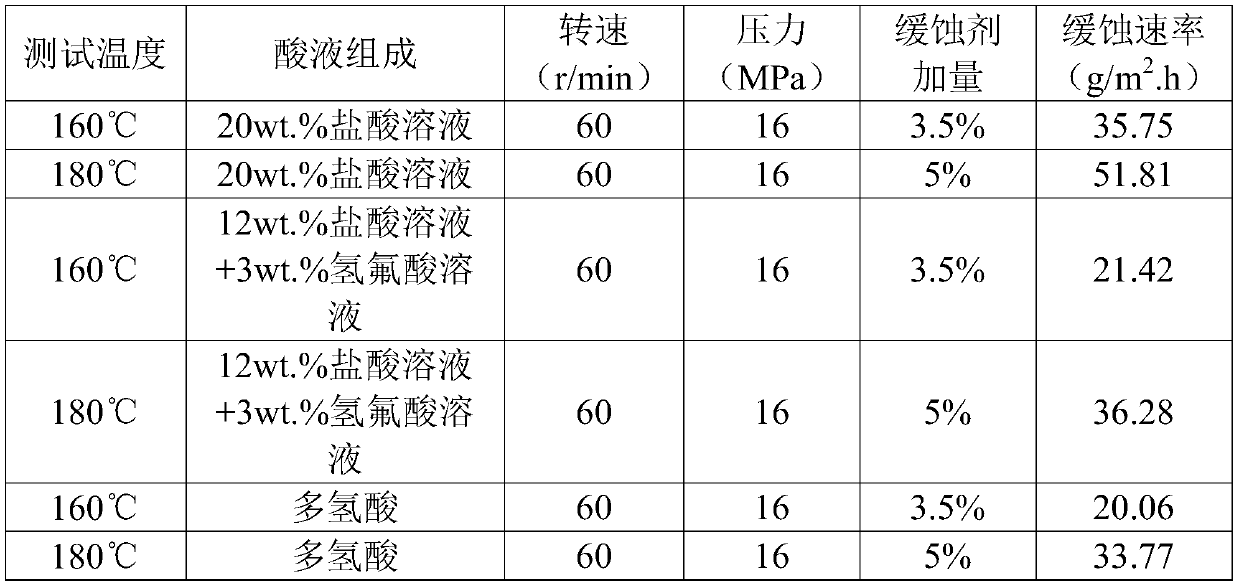

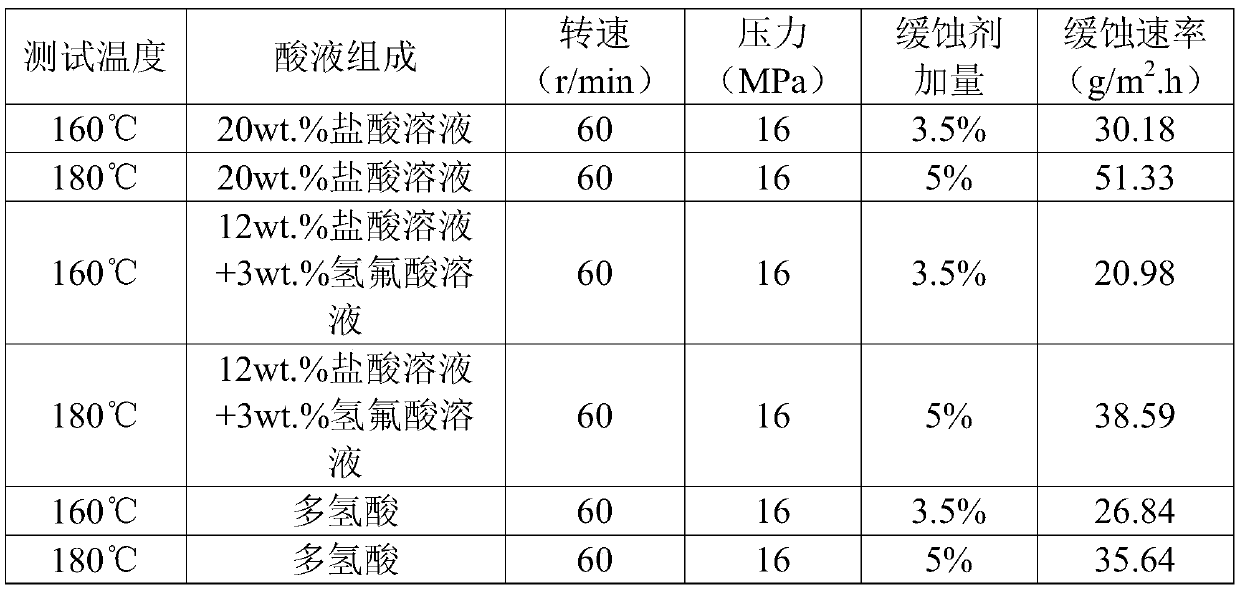

High-temperature corrosion inhibitor for acidification

ActiveCN111592872AExcellent corrosion inhibition performanceImprove solubilityDrilling compositionPolyethylene polyaminePolyaspartic acid

The invention discloses a high-temperature corrosion inhibitor for acidification. The high-temperature corrosion inhibitor comprises the following components in percentage by mass: 30-40% of a corrosion inhibition main agent, 10-17% of an emulsifier, 5.5-9% of a high-temperature synergist, 5-10% of C6-C10 straight-chain alkynediol and the balance of water, wherein the corrosion inhibition main agent is a mixture of a mixed solution containing aldehyde ketone amine polycondensate and polyaspartic acid; the mixed solution containing the aldehyde ketone amine condensation polymer is a mixed solution generated by condensation polymerization of formaldehyde, acetophenone and polyethylene polyamine, or a mixed solution generated by condensation polymerization of formaldehyde, cyclohexanone and polyethylene polyamine; the high-temperature synergist is a mixture of a metal oxide and an alkali metal organic salt; the temperature resistance of the high-temperature corrosion inhibitor for acidification reaches 160-180 DEG C, the corrosion inhibition performance is good, water is adopted as a solvent to replace methanol which is mostly adopted as a solvent in a traditional corrosion inhibitor,and thus the high-temperature corrosion inhibitor for acidification is more environmentally friendly, safe and reliable in product performance and more convenient to transport.

Owner:CNPC BOHAI DRILLING ENG +1

Composite corrosion and scale inhibitor and its application in water treatment

ActiveCN102452724BImprove performanceReduce dosageScale removal and water softeningWater solubleGluconates

The invention relates to a composite corrosion and scale inhibitor and application thereof. The composite corrosion and scale inhibitor comprises a) two different salts selected from the group consisting of water-soluble borate, water-soluble gluconate and water-soluble silicate, b) at least one organic phosphonic acid and c) at least one scale inhibition and dispersion agent, wherein the scale inhibition and dispersion agent is a polymer containing carboxylic groups. The composite corrosion and scale inhibitor provided in the invention has good comprehensive performance, an excellent effect on inhibiting CaCO3 scale, strong capability in stabilizing Zn<2+> in water and good corrosion inhibition, is applicable to treatment of circulating cooling water and uses a small amount of organic phosphonic acid, thereby reducing harm to environment caused by discharge of phosphorus.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com