Inverter cooling liquid and preparation method thereof

A technology of coolant and inverter, applied in the field of engine coolant, can solve the problems that the voltage cannot be too large, affect the power of the locomotive, and the loss is large, and achieve the effect of good heat exchange performance and excellent corrosion inhibition performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

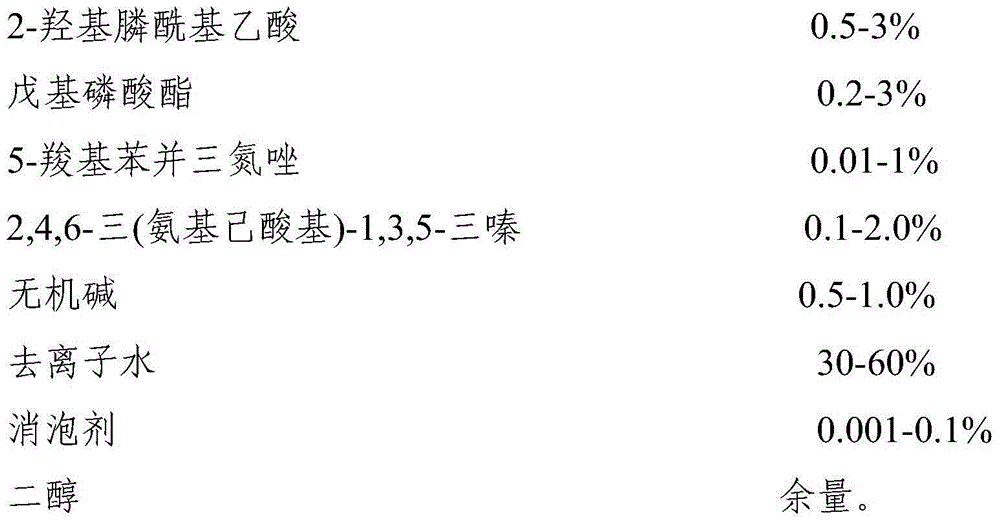

[0023] The composition of the inverter cooling liquid of the present embodiment is as follows:

[0024]

[0025]

[0026] Its preparation process is as follows:

[0027] 1) Dissolve 2,4,6-tris(aminocaproic acid)-1,3,5-triazine and sodium hydroxide in part of deionized water according to the ratio in A blending kettle, and set aside;

[0028] 2) Mix and stir 2-hydroxyphosphonoacetic acid, amyl phosphate and ethylene glycol according to the ratio for 30 minutes, and set aside;

[0029] 3) Finally, add the solution of step 1 and step 2 to 5-carboxybenzotriazole, the remaining part of deionized water and defoamer hexanoic acid, and stir at room temperature for 30 minutes.

Embodiment 2

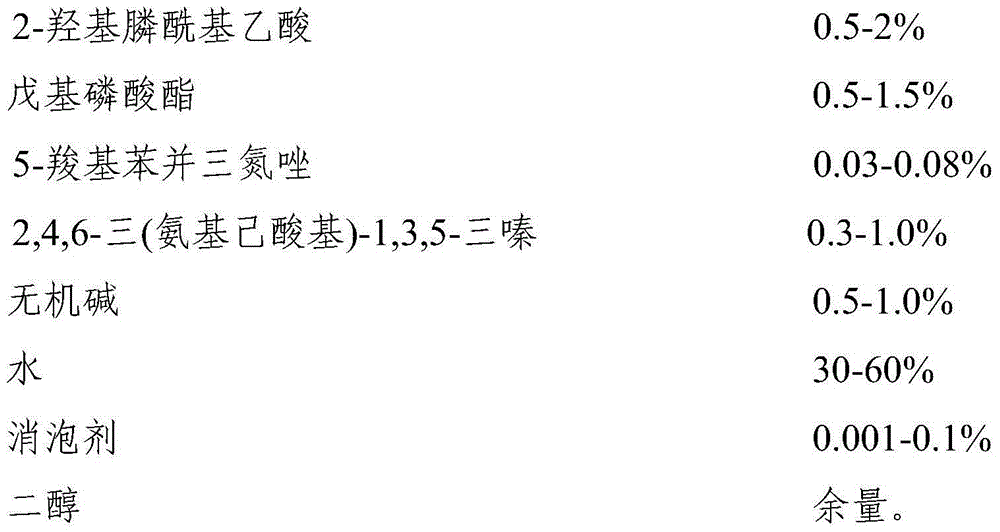

[0031] The composition of the inverter cooling liquid of the present embodiment is as follows:

[0032]

[0033] Its preparation process is as follows:

[0034] 1) Dissolve 2,4,6-tris(aminocaproic acid)-1,3,5-triazine and potassium hydroxide in part of deionized water according to the ratio in A blending kettle, and set aside;

[0035] 2) Mix 2-hydroxyphosphonoacetic acid, amyl phosphate and 1, 2-propanediol according to the proportion and stir for 30 minutes, then set aside;

[0036] 3) Finally, add the solution of step 1 and step 2 to 5-carboxybenzotriazole, the remaining part of deionized water, defoamer hexanoic acid, and stir at room temperature for 30 minutes.

Embodiment 3

[0038] The composition of the inverter cooling liquid of the present embodiment is as follows:

[0039]

[0040] Its preparation process is as follows:

[0041] 1) Dissolve 2,4,6-tris(aminocaproic acid)-1,3,5-triazine and sodium hydroxide in part of deionized water according to the ratio in A blending kettle, and set aside;

[0042] 2) Mix 2-hydroxyphosphonoacetic acid, pentyl phosphate and 1,3-propanediol according to the proportion and stir for 30 minutes, then set aside;

[0043] 3) Finally, add the solution of step 1 and step 2 to 5-carboxybenzotriazole, the remaining part of deionized water, defoamer hexanoic acid, and stir at room temperature for 30 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com