A corrosion inhibitor suitable for dynamic strong alkali cleaning of metal workpieces and preparation method thereof

A metal workpiece and corrosion inhibitor technology, applied in the field of metal material processing, can solve the problems of unstable corrosion inhibitor performance and unsatisfactory corrosion inhibition performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

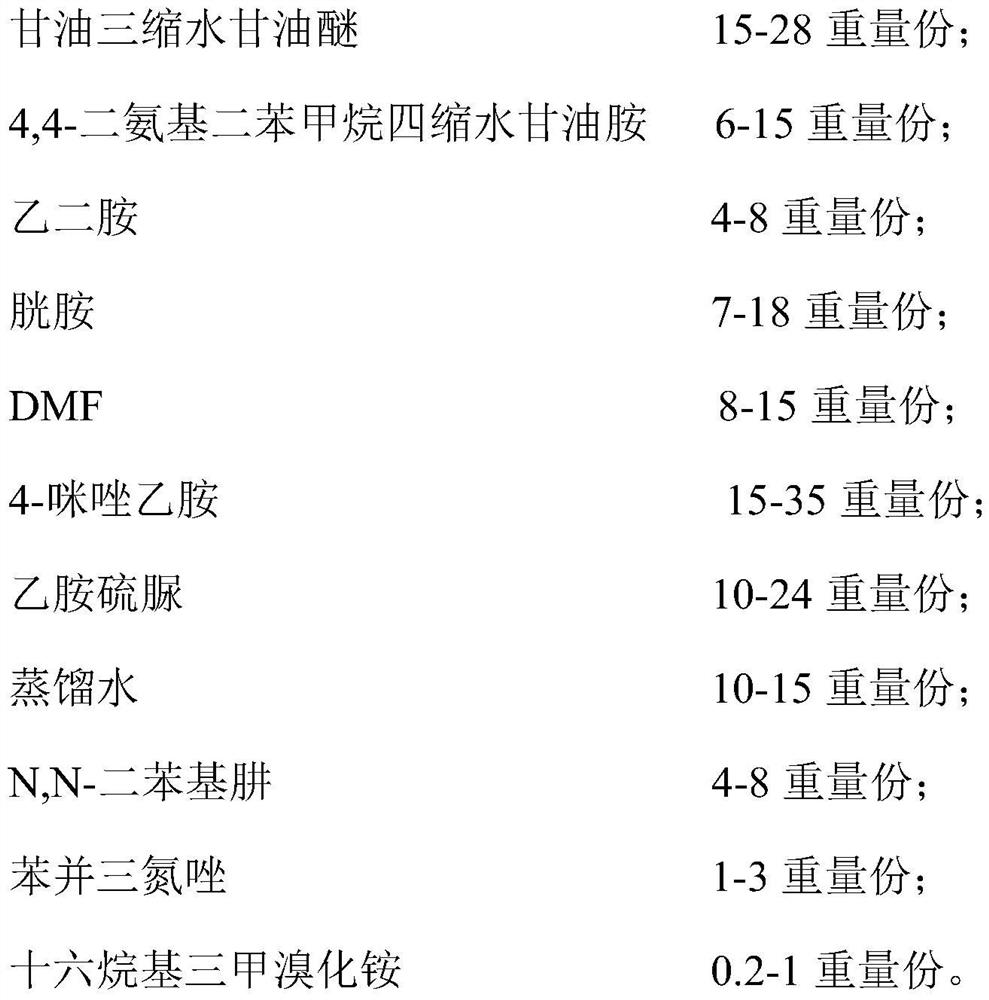

[0022] The corrosion inhibitor that is applicable to the dynamic strong alkali cleaning of metal workpiece described in this embodiment, its preparation raw material comprises the component of following weight:

[0023]

[0024] The preparation method of the corrosion inhibitor suitable for dynamic strong alkali cleaning of metal workpieces described in this embodiment comprises the following steps:

[0025] (1) First add glycerol triglycidyl ether and cetyltrimethylammonium bromide in the formula quantity into the reaction kettle, start stirring, keep the temperature at 75° C., and add cystamine in the formula quantity to carry out the chain extension reaction for 2 hours;

[0026] (2) Then add the formulated amount of 4,4-diaminodiphenylmethane tetraglycidylamine, ethylenediamine and DMF, and continue the heat preservation reaction at 75°C for 3h;

[0027] (3) When the epoxy equivalent of the above-mentioned reactants is greater than 1000g / mol, add 4-imidazole ethylamine ...

Embodiment 2

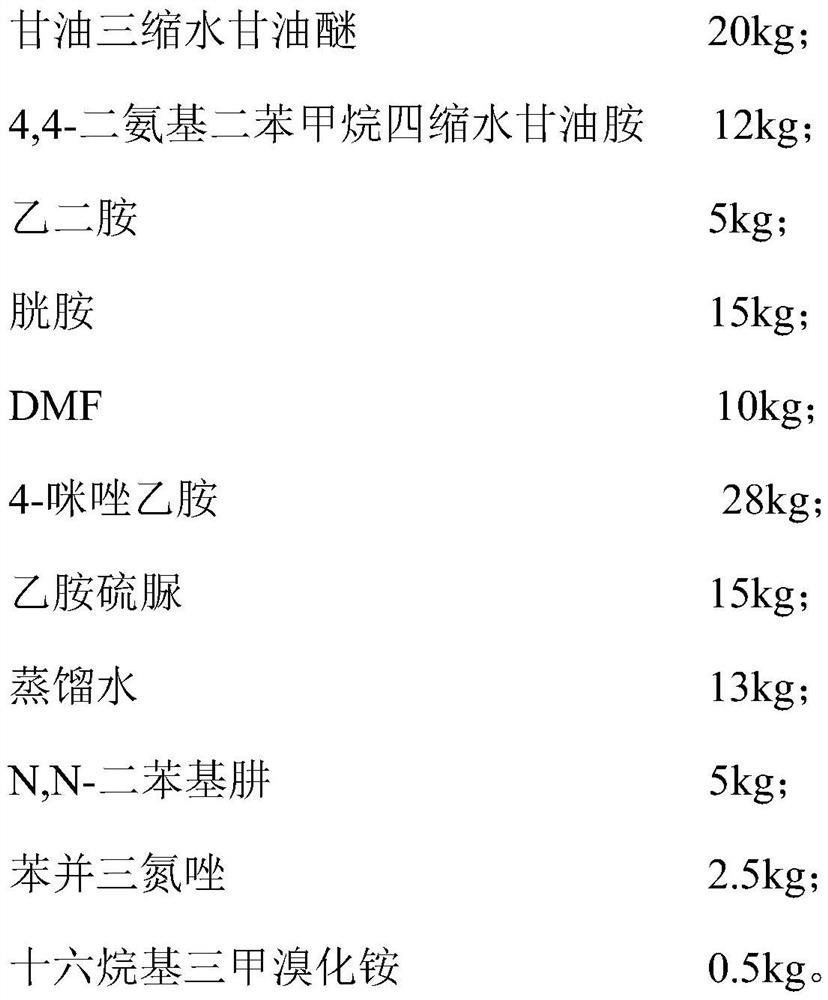

[0030] The corrosion inhibitor that is applicable to the dynamic strong alkali cleaning of metal workpiece described in this embodiment, its preparation raw material comprises the component of following weight:

[0031]

[0032] The preparation method of the corrosion inhibitor suitable for dynamic strong alkali cleaning of metal workpieces described in this embodiment comprises the following steps:

[0033] (1) First add glycerol triglycidyl ether and cetyltrimethylammonium bromide in the formula quantity into the reaction kettle, start stirring, keep the temperature at 75° C., and add cystamine in the formula quantity to carry out the chain extension reaction for 2 hours;

[0034] (2) Then add the formulated amount of 4,4-diaminodiphenylmethane tetraglycidylamine, ethylenediamine and DMF, and continue the heat preservation reaction at 75°C for 3h;

[0035] (3) When the epoxy equivalent of the above-mentioned reactant is greater than 1000g / mol, add 4-imidazole ethylamine a...

Embodiment 3

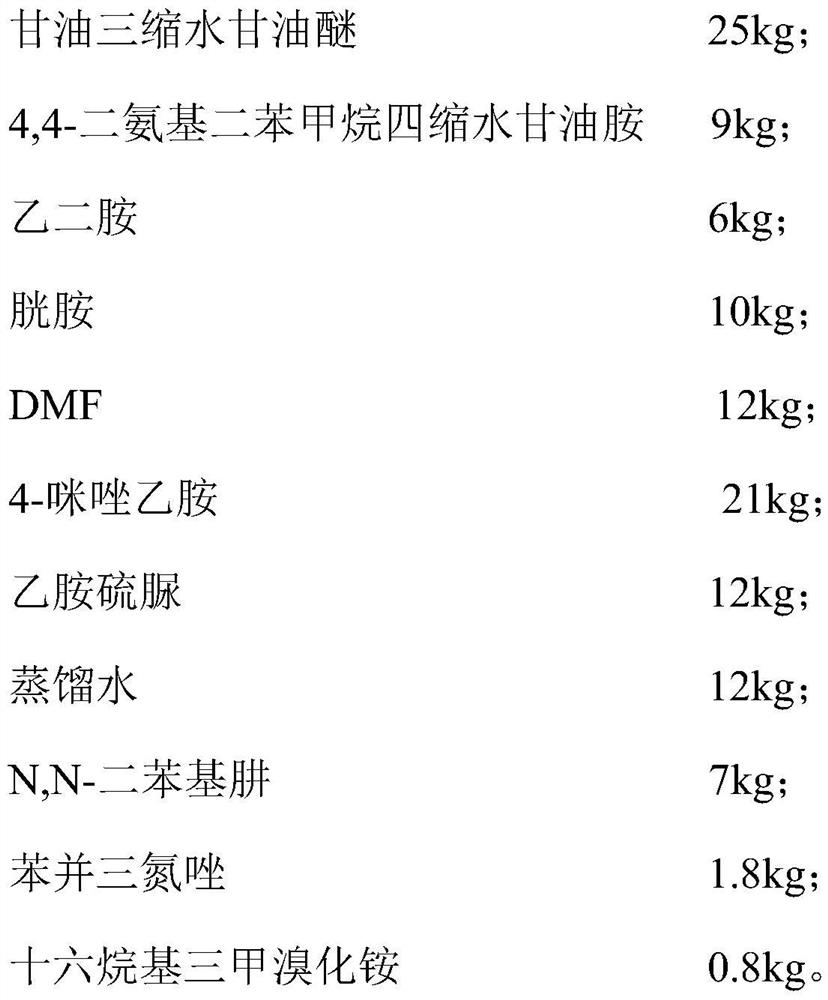

[0038] The corrosion inhibitor that is applicable to the dynamic strong alkali cleaning of metal workpiece described in this embodiment, its preparation raw material comprises the component of following weight:

[0039]

[0040] The preparation method of the corrosion inhibitor suitable for dynamic strong alkali cleaning of metal workpieces described in this embodiment comprises the following steps:

[0041] (1) First add glycerol triglycidyl ether and cetyltrimethylammonium bromide in the formula quantity into the reaction kettle, start stirring, keep the temperature at 70° C., and add cystamine in the formula quantity to carry out the chain extension reaction for 2 hours;

[0042] (2) Then add the formulated amount of 4,4-diaminodiphenylmethane tetraglycidylamine, ethylenediamine and DMF, and continue the heat preservation reaction at 70°C for 4h;

[0043] (3) When the epoxy equivalent of the above-mentioned reactants is greater than 1000g / mol, add 4-imidazole ethylamine ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com