Preparation method and preparation system of special corrosion inhibitor for metal equipment

A technology for preparing systems and corrosion inhibitors, applied in the field of corrosion inhibitors, can solve problems such as clogging, achieve high corrosion inhibition rate, avoid slow filtration speed, and good corrosion inhibition performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

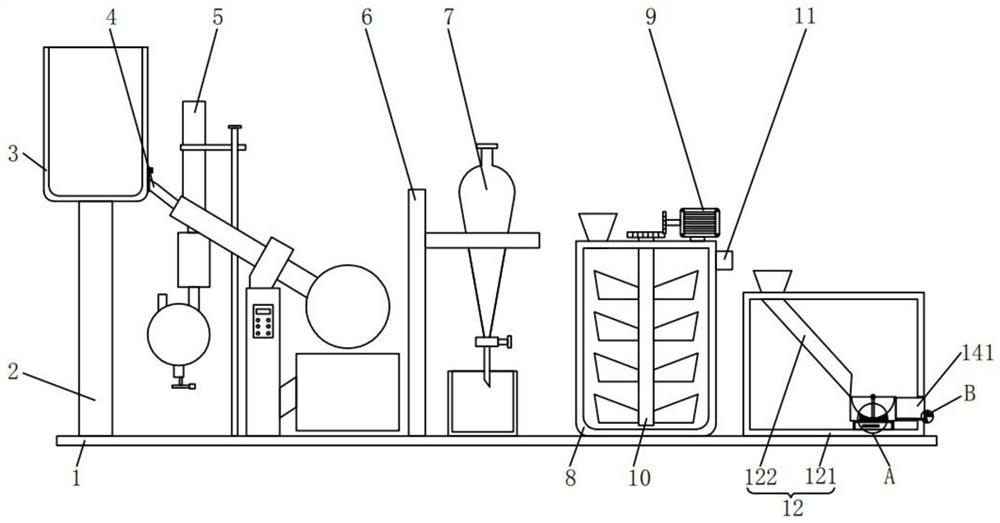

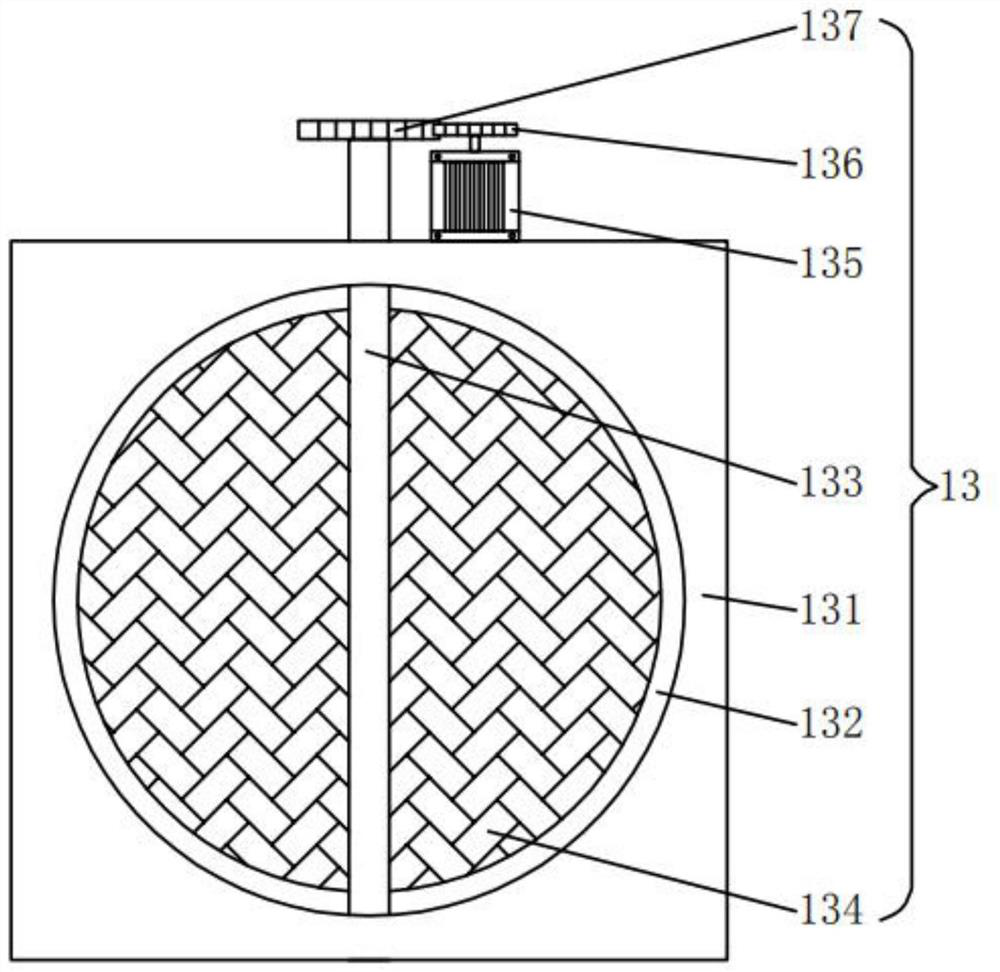

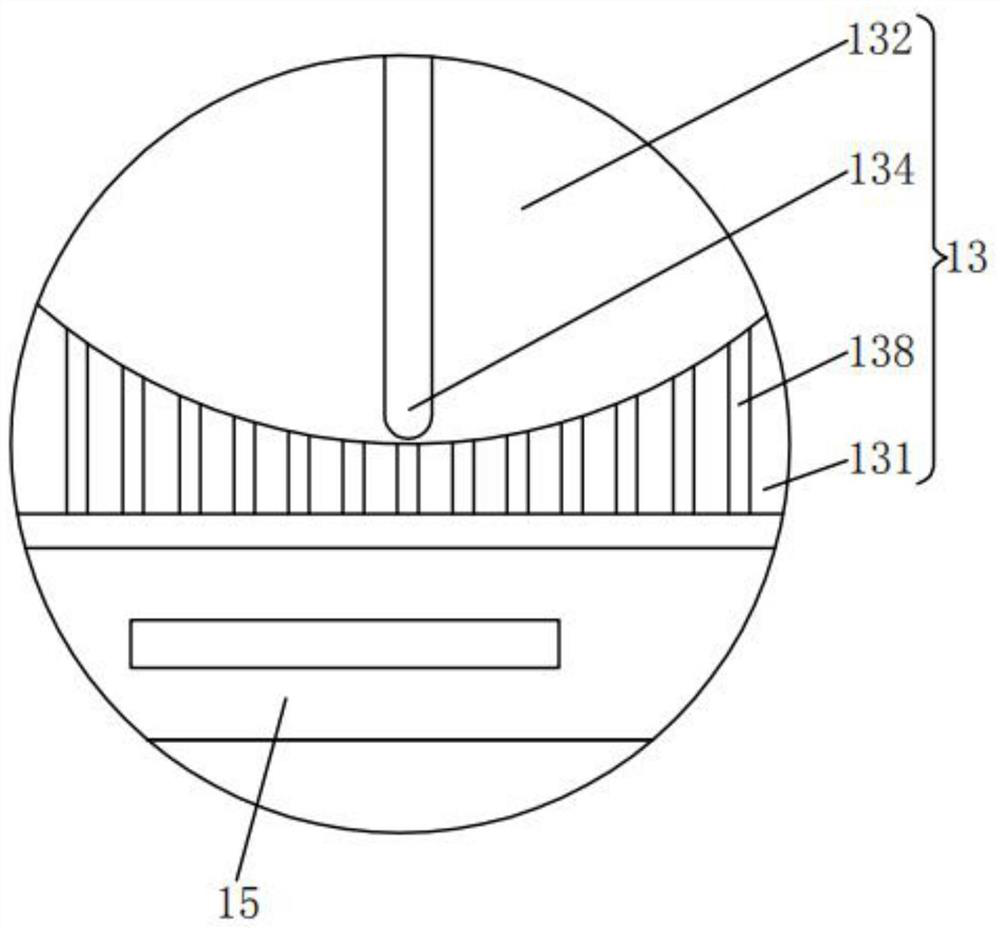

[0028] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0029] The method for preparing a special corrosion inhibitor for metal equipment comprises the following steps:

[0030] A: Dissolve abietic acid and K2CO3 in dimethylformamide, add methyl iodide (MeI), stir for 3 hours, and the TLC plate reaction is complete;

[0031] B: Remove MeI by rotary evaporation under reduced pressure, extract with ethyl acetate (EA), concentrate, wash with water to remove dimethylformamide, wash the organic layer with saturated sodium chloride, dry, and concentrate, and the remaining components are washed with 1:10 acetic acid Ethyl ester (EA) / petroleum ether (PE) is purified by a silica gel column to obtain the first compound of formula;

[0032] C: Add ethylenediamine and trimethylaluminum (AlMe3) to toluene at 0-10°C, mix well, then add the first compound obtained in step B, fully stir and reflux for 12 hours;

[0033] D...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com