High-temperature corrosion inhibitor for acidification

A high-temperature corrosion inhibitor and corrosion inhibition technology, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of poor compatibility between corrosion inhibitors and acid liquid systems, increased cost of corrosion inhibitors, etc., and achieve product performance Safe and reliable, reducing the risk of flammability, and convenient transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

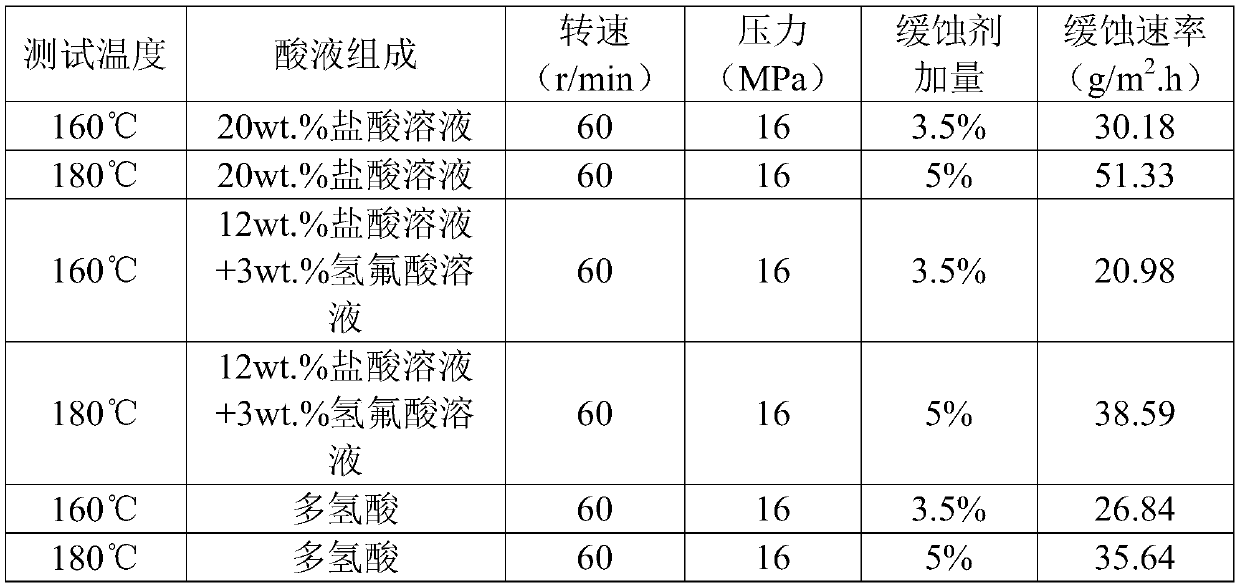

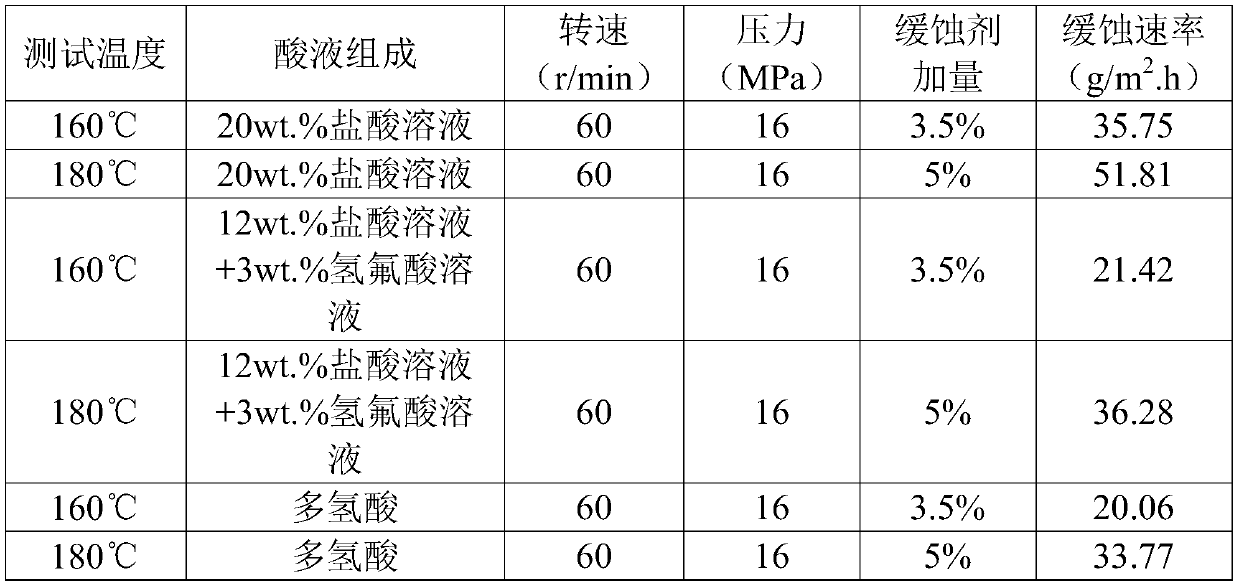

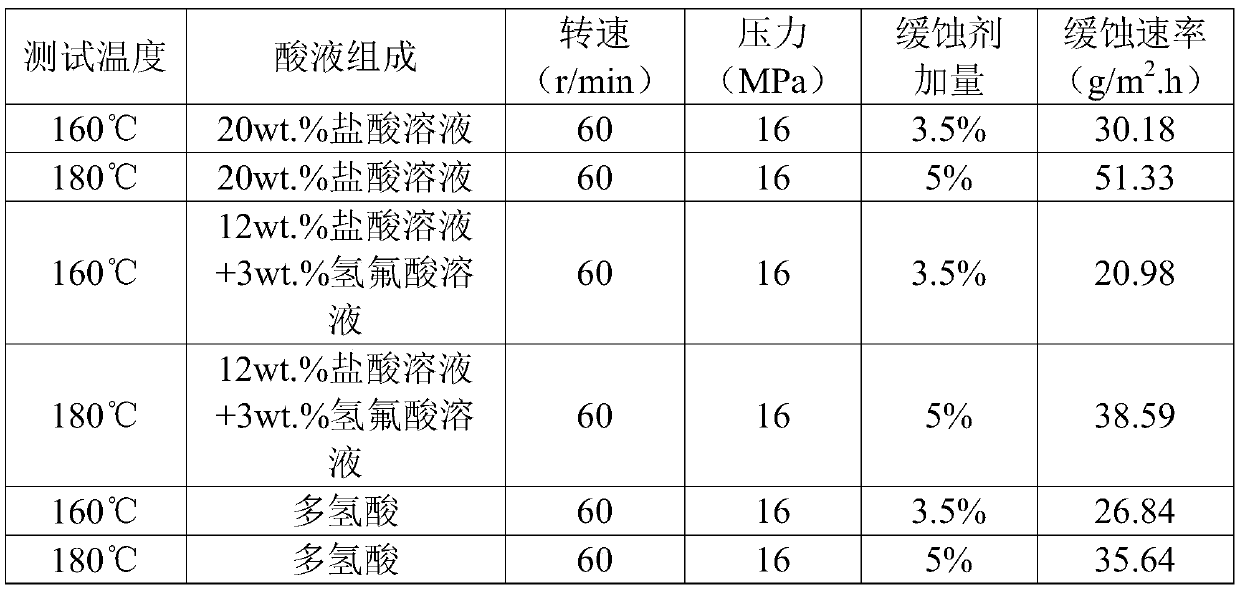

Embodiment 1

[0024] A preparation method of high-temperature corrosion inhibitor, the steps are as follows:

[0025] 1) Prepare a mixed solution containing aldehyde, ketone and amine condensation polymers: add 70g of formaldehyde and 300g of acetophenone into the reaction flask, then add 2mL of 37.5wt.% hydrochloric acid, and stir at a stirring speed of 0.5~1r / s at a rate of 0.5~ Raise the temperature to 90°C at a rate of 2min / °C, keep it warm for 4h, and then cool down to room temperature and let it stand for 4h to separate the water in the lower layer. Add 200g of polyvinylpolyamine (number average molecular weight: 3000) dropwise to the solution state aldehyde and ketone polycondensate under the stirring speed of 0.5-2min / °C. When it is lowered to room temperature, the obtained product is a mixed solution containing aldehyde, ketone and amine polycondensates; after testing, in the mixed solution containing aldehyde, ketone and amine polycondensates, the molecular weight of aldehyde, ket...

Embodiment 2

[0028] A preparation method of high-temperature corrosion inhibitor, the steps are as follows:

[0029] 1) Prepare a mixed solution containing aldehyde, ketone and amine condensation polymers: add 32g of formaldehyde and 120g of acetophenone into the reaction flask, then add 2mL of 37.5wt.% hydrochloric acid, and stir at a stirring speed of 0.5~1r / s at a rate of 0.5~ Raise the temperature to 80°C at a speed of 2min / °C, keep it warm for 5h, and then lower it to room temperature and let it stand for 4.5h to separate and separate the water in the lower layer, and the product in the upper layer is aldehyde and ketone condensation polymer; At a stirring speed of s, add 450g of polyethylene polyamine (number average molecular weight: 4200) dropwise to the solution aldehyde and ketone polycondensate. After the dropwise addition is completed, raise the temperature to 80°C at a speed of 0.5-2min / °C, and keep it warm for 4h. After cooling down to room temperature, the obtained product i...

Embodiment 3

[0032] A preparation method of high-temperature corrosion inhibitor, the steps are as follows:

[0033]1) Preparation of a mixture containing aldehyde, ketone and amine condensation polymers: Add 150g of formaldehyde and 120g of cyclohexanone into the reaction flask, then add 2mL of 37.5wt.% hydrochloric acid, and stir at a stirring speed of 0.5~1r / s at a rate of 0.5~ Raise the temperature to 90°C at a speed of 2min / °C, keep it warm for 4h, and then lower it to room temperature and let it stand for 5h to separate the water in the lower layer. Add 270g of polyvinylpolyamine (number average molecular weight: 3800) dropwise to the solution state aldehyde and ketone polycondensate under the stirring speed of 0.5-2min / °C, heat it up to 70°C at a speed of 0.5-2min / °C, keep it for 5h, and then When it is lowered to room temperature, the obtained product is a mixed solution containing aldehyde, ketone and amine polycondensates; after testing, in the mixed solution containing aldehyde,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com