PH stimulation response intelligent repair coating and preparation method thereof

A technology of intelligent repair and stimulus response, applied in anti-corrosion coatings, epoxy resin coatings, coatings, etc., can solve the problems of corrosion inhibitor carrier damage, difficult to achieve, unable to play a sustainable role, etc., to achieve excellent corrosion inhibition performance, intelligent Controlled release effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] In embodiment 1 and embodiment 6: curing agent all adopts the adduct of diethylenetriamine and butyl glycidyl ether and is 539 curing agent; Epoxy resin all adopts E-51 epoxy resin; The average particle diameter of silicon oxide is 436nm, and the average pore diameter is 20nm; the average molecular weight of poly(sodium p-styrene sulfonate) is 8×10 4 g / mol; the average molecular weight of polyethyleneimine is 1.8×10 3 g / mol.

[0026] Example 1

[0027] According to the present invention, a pH-stimulus-responsive intelligent repair coating is prepared according to the following feeding ratio (mass percentage):

[0028]

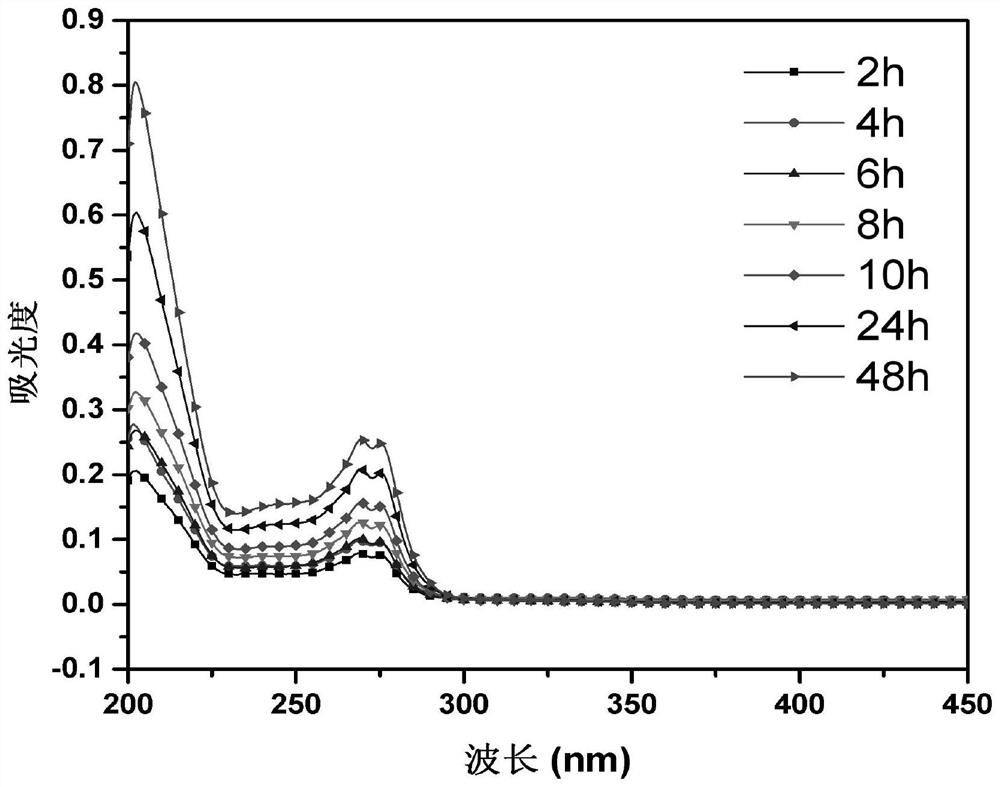

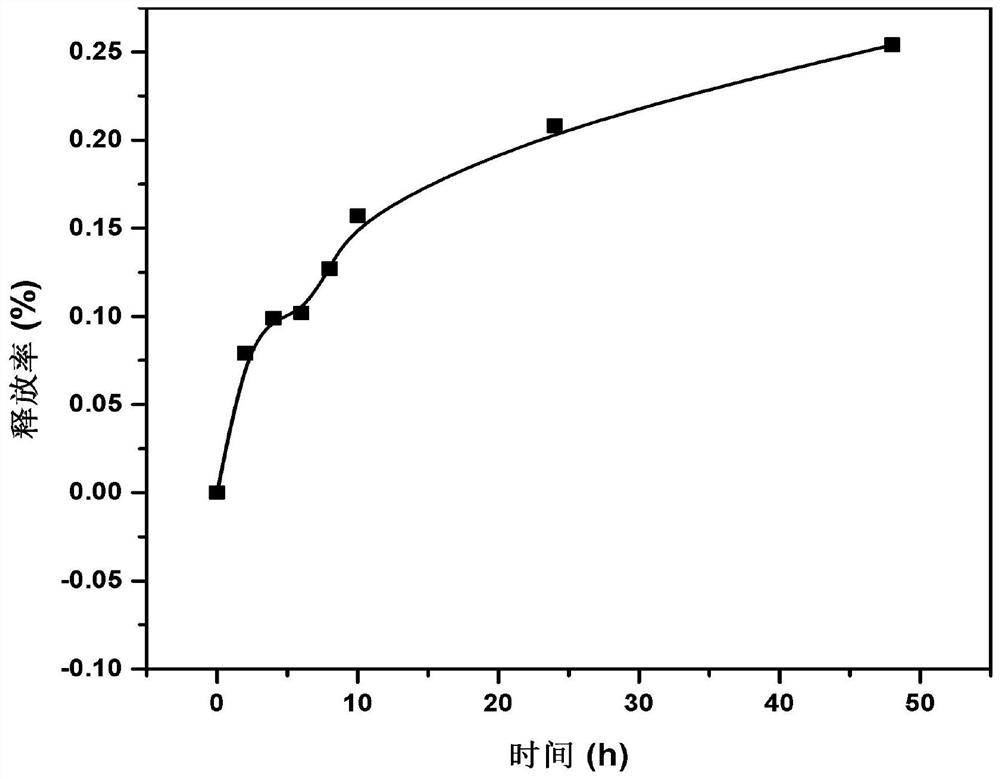

[0029] Dissolve 2-chloromethylbenzimidazole in absolute ethanol, then add mesoporous fumed silica, disperse by ultrasonic wave for 30min, and stir for 1h with a magnetic stirrer (rotating speed: 600r / min). Place the above mixed system in a vacuum drying oven at 25°C for 12 hours, then centrifuge for 30 minutes at a speed of 4000r / min, separate the ...

Embodiment 2

[0032] According to the present invention, a pH-stimulus-responsive intelligent repair coating is prepared according to the following feeding ratio (mass percentage):

[0033]

[0034]

[0035] The preparation method of embodiment 2 is the same as embodiment 1, and the difference is only that the above-mentioned feeding ratio is different;

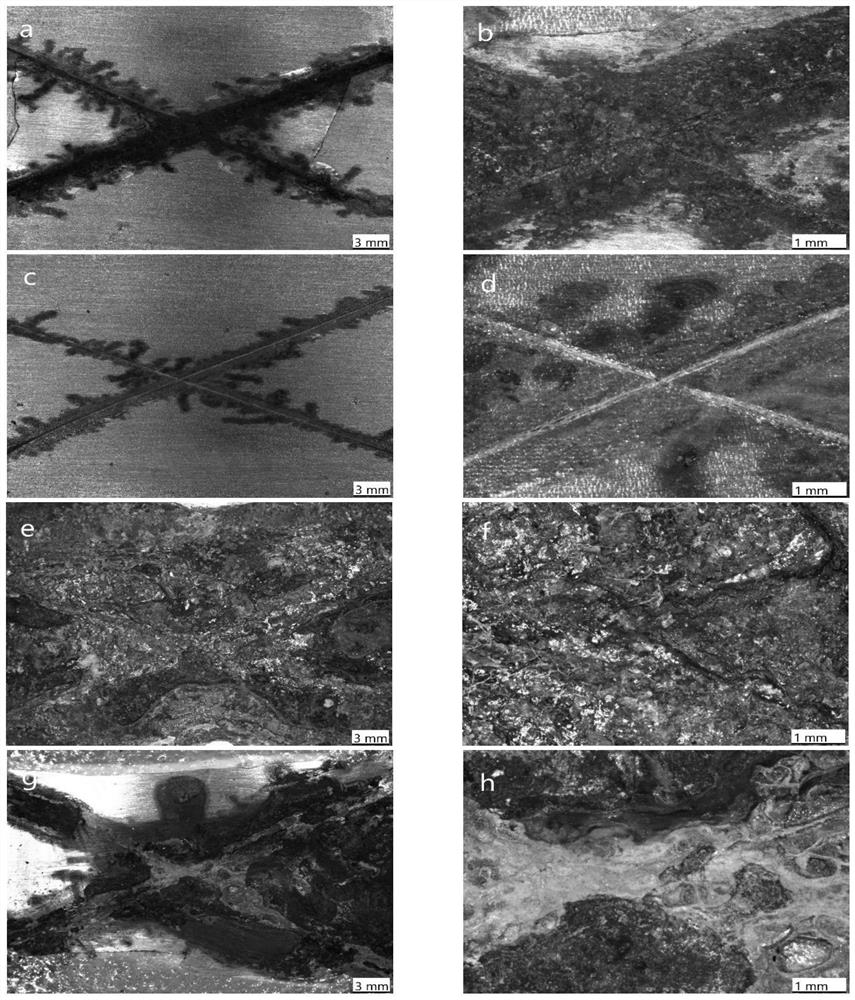

[0036] When the pH value of the corrosive medium is not higher than 4.6, it has a very prominent protective effect on the metal substrate. The lower the pH, the better the protection.

Embodiment 3

[0038] According to the present invention, a pH-stimulus-responsive intelligent repair coating is prepared according to the following feeding ratio (mass percentage):

[0039]

[0040] The preparation method of embodiment 3 is the same as that of embodiment 1, and the difference is only that the above-mentioned feeding ratio is different;

[0041] When the pH value of the corrosive medium is not higher than 4.3, it has a very prominent protective effect on the metal substrate. The lower the pH, the better the protection.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

| Average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com