Efficient low-phosphorus scale and corrosion inhibitor and preparation method thereof

A scale and corrosion inhibitor, high-efficiency technology, applied in chemical instruments and methods, scale removal and water softening, natural water treatment, etc., to achieve excellent corrosion inhibition performance, improve the effect of corrosion inhibition performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

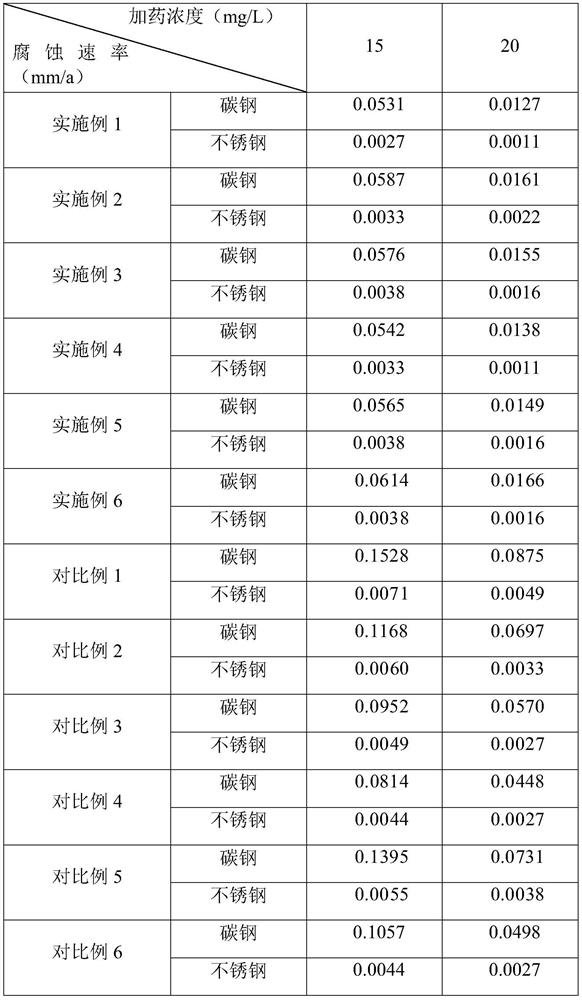

Examples

Embodiment 1

[0029] Add 10kg of sodium nitrite and 30kg of deionized water into the stirring tank, stir and dissolve; add 15kg of borax to the above solution, stir and dissolve, then add 10kg of zinc sulfate heptahydrate, stir and dissolve; finally add 12kg of 2-phosphine to the reaction kettle Acyl-1,2,4-butanetricarboxylic acid, 12kg polyepoxysuccinic acid, 15kg acrylic acid / 2-acrylamide-2-methylpropanesulfonic acid copolymer; stir evenly at room temperature for 20-30min to obtain high-efficiency Low phosphorus scale and corrosion inhibitor.

Embodiment 2

[0031] Add 5kg of sodium nitrite and 20kg of deionized water into the stirring tank, stir and dissolve; add 10kg of disodium octaborate tetrahydrate to the above solution, stir and dissolve, then add 15kg of zinc chloride, stir and dissolve; Add 5kg of hydroxyethylene diphosphonic acid, 10kg of polyepoxysuccinic acid, and 10kg of acrylic acid / propylene sulfonate sodium copolymer; stir evenly at room temperature for 20 to 30 minutes to obtain a high-efficiency low-phosphorus scale and corrosion inhibitor.

Embodiment 3

[0033] Add 15kg of sodium nitrite and 50kg of deionized water into the stirring tank, stir and dissolve; add 20kg of potassium tetraborate to the above solution, stir and dissolve, then add 5kg of zinc chloride, stir and dissolve; finally add 10kg2 -Hydroxyphosphinoacetic acid, 15kg polyaspartic acid, 20kg acrylic acid / 2-acrylamide-2-methylpropanesulfonic acid / hydroxypropyl acrylate terpolymer; stir evenly at room temperature for 20-30min to obtain high-efficiency and low-efficiency Phosphorus scale and corrosion inhibitor.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

| Alkalinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com