Phosphorus-free corrosion and scale inhibitor and preparation method thereof

A phosphorus-free corrosion and scale inhibitor technology, applied in chemical instruments and methods, descaling and water softening, complex/solubilizer treatment, etc., can solve the problem of reducing the service life of heat transfer equipment, forming fouling, and affecting normal Production and other issues, to achieve good promotion and application value, mild preparation conditions, and promote the effect of uniform spreading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

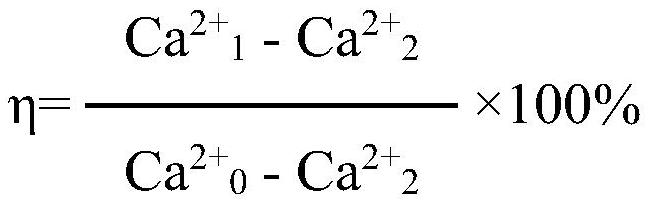

Method used

Image

Examples

Embodiment 1

[0034] Add 100 parts by mass of maleic anhydride, 190 parts of sorbitol solids, 100 parts of water, and 1 part of concentrated sulfuric acid into the reaction kettle, heat up to 65°C, stir for 2 hours, distill under reduced pressure, and maintain a vacuum of 70kPa to no Moisture steams out and obtains the sorbitol maleate mixture of about 350 parts of quality;

[0035] Take 60 parts by mass of the above mixture and add it to the reaction kettle, add 30 parts of water, 8 parts of zinc chloride, 1 part of polydimethyldiallyl ammonium chloride, 0.5 part of benzotriazole under stirring, Heating to 50°C for 1.5 hours and cooling to obtain a light yellow liquid non-phosphorus corrosion and scale inhibitor. According to the above test method, the scale inhibition rate is 97.8%, the corrosion inhibition rate is 91.6%, and the bactericidal rate is 18%.

Embodiment 2

[0037]Add 100 parts by mass of maleic anhydride, 365 parts of solid sorbitol, 100 parts of water, and 1 part of concentrated sulfuric acid into the reactor, heat up to 80°C, stir and react for 1.5 hours, distill under reduced pressure, and maintain a vacuum of 90kPa to no Moisture steams out and obtains the sorbitol maleate mixture of about 510 parts of quality;

[0038] Take 50 parts of the above-mentioned mixture in parts by mass and add it to the reactor, add 40 parts of water, 2 parts of zinc chloride, 2 parts of polydimethyldiallyl ammonium chloride, 0.5 part of benzotriazole under stirring, Heating to 45°C for 2 hours, cooling to obtain a light yellow liquid non-phosphorus corrosion and scale inhibitor. According to the above test method, the scale inhibition rate is 98.9%, the corrosion inhibition rate is 91.2%, and the bactericidal rate is 24%.

Embodiment 3

[0040] Add 100 parts by mass of maleic anhydride, 272 parts of sorbitol aqueous solution (190 parts of sorbitol), and 5 parts of potassium carbonate into the reaction kettle, heat up to 65°C, stir and react for 1 hour, distill under reduced pressure, and maintain vacuum 70kPa to moisture-free steaming obtains the sorbitol maleate mixture of about 350 parts of quality;

[0041] Take the above-mentioned mixture of 65 parts by mass and put it into the reaction kettle, add 25 parts of water, 6 parts of zinc chloride, 2 parts of polydimethyldiallyl ammonium chloride, 1 part of benzotriazole under stirring, Heating to 55°C to react for 1 hour, cooling to obtain a light yellow liquid non-phosphorus corrosion and scale inhibitor. According to the above test method, the scale inhibition rate is 97.9%, the corrosion inhibition rate is 92.1%, and the bactericidal rate is 28%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com