Corrosion inhibitor suitable for dynamic strong alkaline cleaning of metal workpieces and preparation method of corrosion inhibitor

A metal workpiece and corrosion inhibitor technology, applied in the field of metal material processing, can solve the problems of unstable corrosion inhibitor performance and unsatisfactory corrosion inhibition performance, improve hydrophobicity and stability, enhance corrosion inhibition ability, and facilitate direct effect used

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

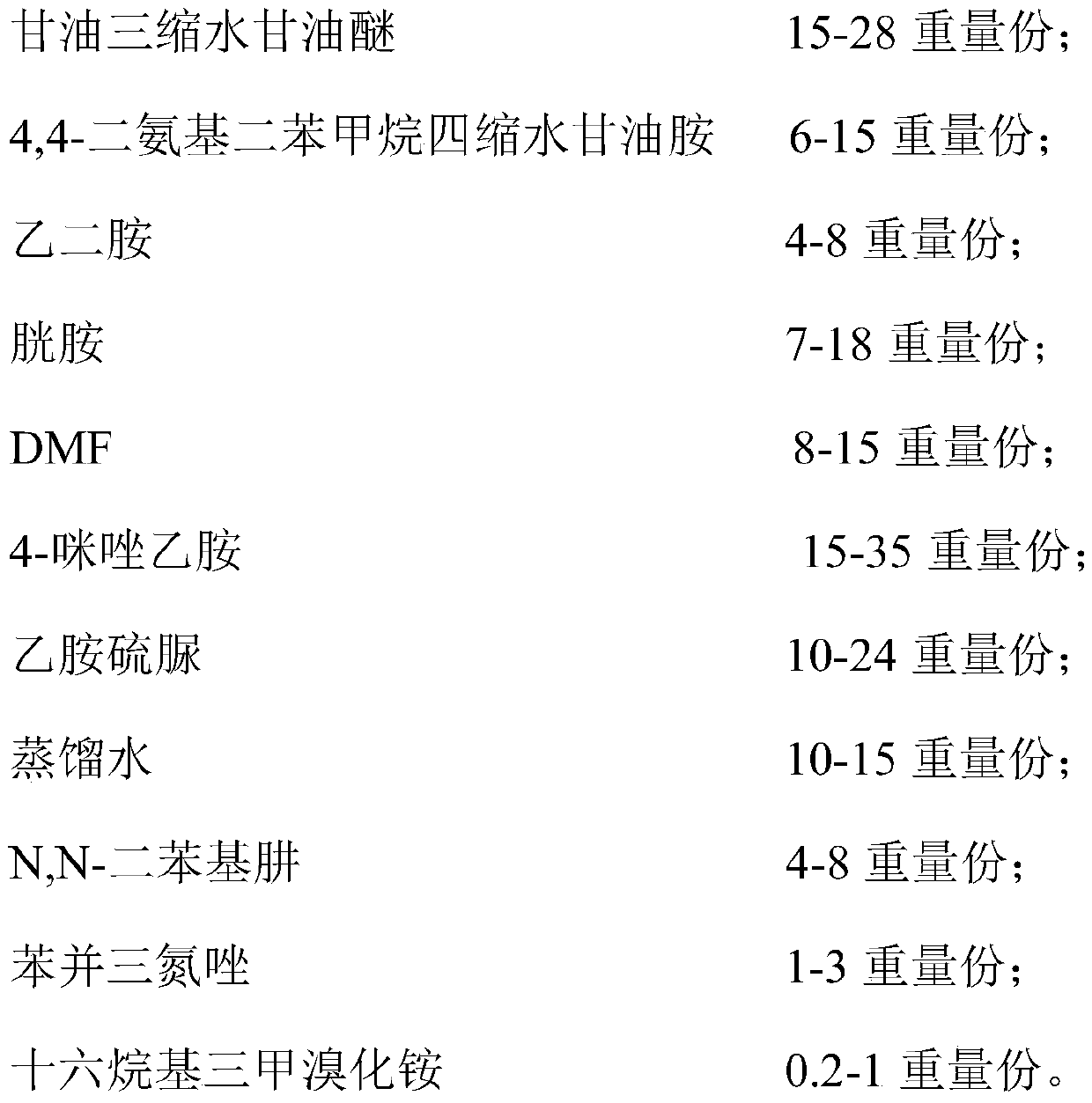

[0022] The corrosion inhibitor that is applicable to the dynamic strong alkali cleaning of metal workpiece described in this embodiment, its preparation raw material comprises the component of following weight:

[0023]

[0024] The preparation method of the corrosion inhibitor suitable for dynamic strong alkali cleaning of metal workpieces described in this embodiment comprises the following steps:

[0025] (1) First add glycerol triglycidyl ether and cetyltrimethylammonium bromide in the formula quantity into the reaction kettle, start stirring, keep the temperature at 75° C., and add cystamine in the formula quantity to carry out the chain extension reaction for 2 hours;

[0026] (2) Then add the formulated amount of 4,4-diaminodiphenylmethane tetraglycidylamine, ethylenediamine and DMF, and continue the heat preservation reaction at 75°C for 3h;

[0027] (3) When the epoxy equivalent of the above-mentioned reactants is greater than 1000g / mol, add 4-imidazole ethylamine ...

Embodiment 2

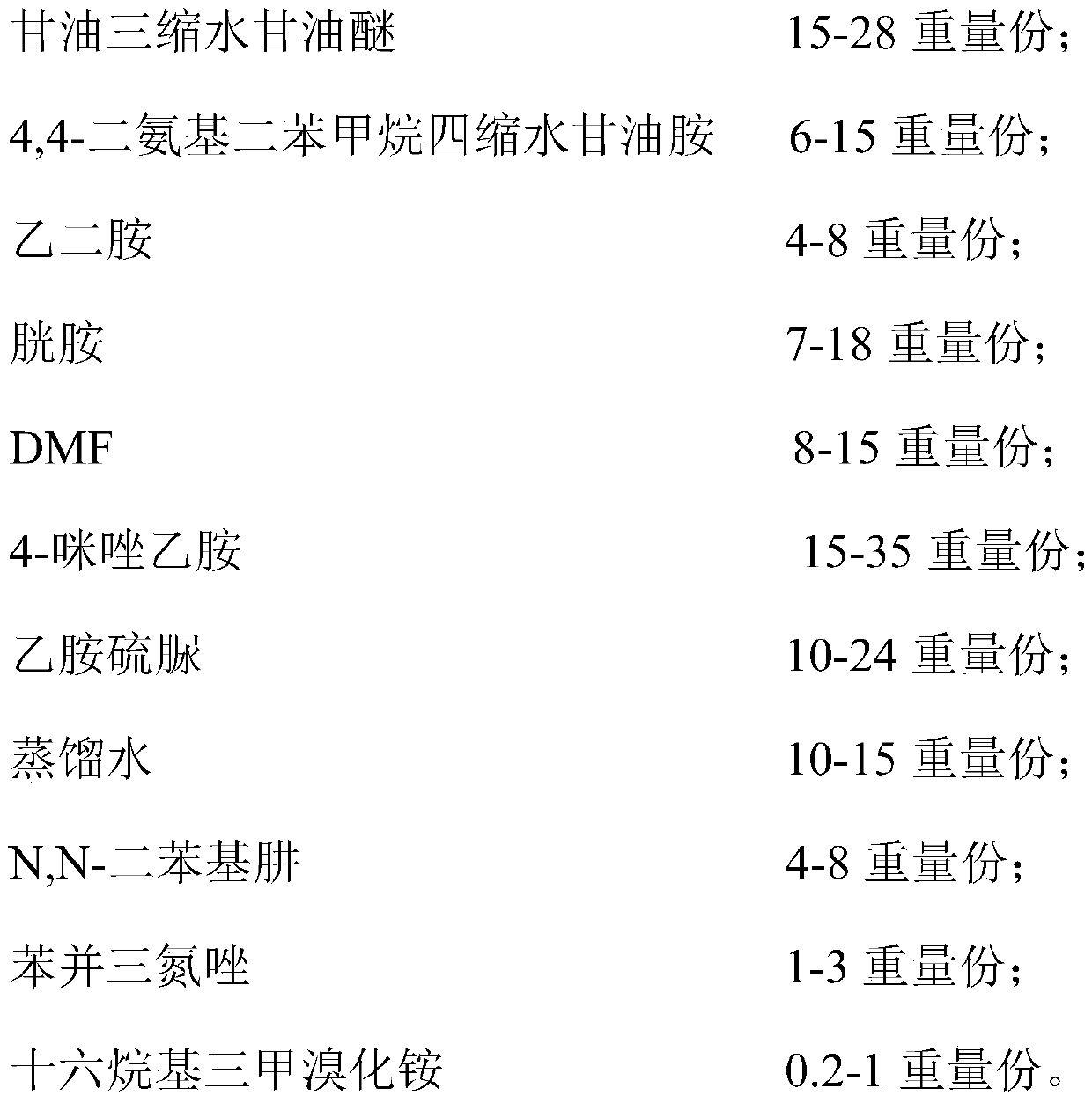

[0030] The corrosion inhibitor that is applicable to the dynamic strong alkali cleaning of metal workpiece described in this embodiment, its preparation raw material comprises the component of following weight:

[0031]

[0032] The preparation method of the corrosion inhibitor suitable for dynamic strong alkali cleaning of metal workpieces described in this embodiment comprises the following steps:

[0033] (1) First add glycerol triglycidyl ether and cetyltrimethylammonium bromide in the formula quantity into the reaction kettle, start stirring, keep the temperature at 75° C., and add cystamine in the formula quantity to carry out the chain extension reaction for 2 hours;

[0034] (2) Then add the formulated amount of 4,4-diaminodiphenylmethane tetraglycidylamine, ethylenediamine and DMF, and continue the heat preservation reaction at 75°C for 3h;

[0035] (3) When the epoxy equivalent of the above-mentioned reactant is greater than 1000g / mol, add 4-imidazole ethylamine a...

Embodiment 3

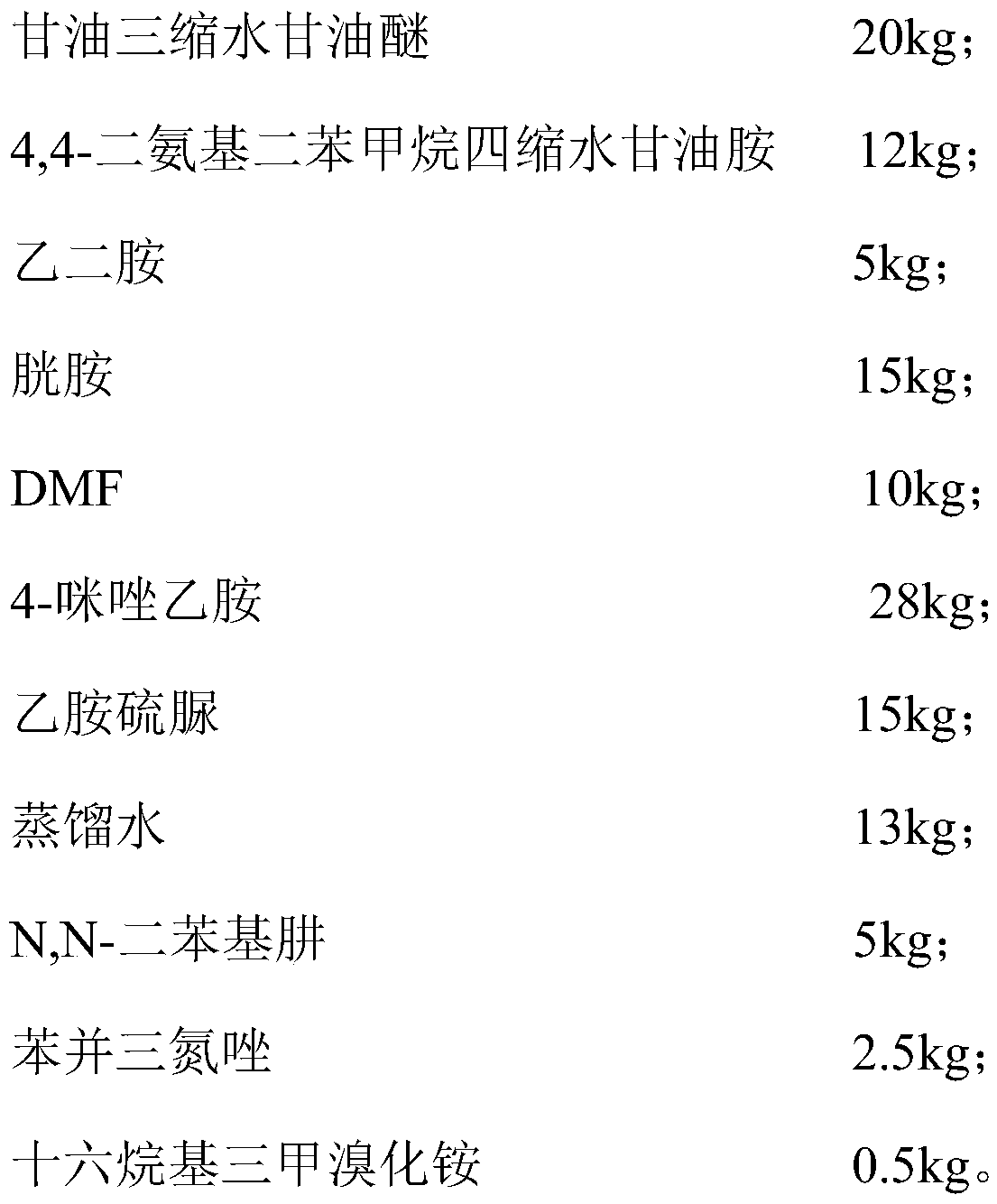

[0038] The corrosion inhibitor that is applicable to the dynamic strong alkali cleaning of metal workpiece described in this embodiment, its preparation raw material comprises the component of following weight:

[0039]

[0040] The preparation method of the corrosion inhibitor suitable for dynamic strong alkali cleaning of metal workpieces described in this embodiment comprises the following steps:

[0041] (1) First add glycerol triglycidyl ether and cetyltrimethylammonium bromide in the formula quantity into the reaction kettle, start stirring, keep the temperature at 70° C., and add cystamine in the formula quantity to carry out the chain extension reaction for 2 hours;

[0042] (2) Then add the formulated amount of 4,4-diaminodiphenylmethane tetraglycidylamine, ethylenediamine and DMF, and continue the heat preservation reaction at 70°C for 4h;

[0043] (3) When the epoxy equivalent of the above-mentioned reactants is greater than 1000g / mol, add 4-imidazole ethylamine ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Epoxy equivalent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com