Preparation method of substituted pyridine carbonylhydrazone metal corrosion inhibitor

A metal corrosion inhibitor and a picolinyl hydrazone technology, which is applied in the field of preparation of a substituted picolinyl hydrazone metal corrosion inhibitor, can solve the problems of high hazard, large amount of corrosion inhibitor, unreasonable molecular design, etc. Good corrosion inhibition performance and good biodegradability

Inactive Publication Date: 2010-05-19

GUILIN UNIVERSITY OF TECHNOLOGY

View PDF0 Cites 7 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

For example, the amount of corrosion inhibitor is large, the cost is high, the molecular design is unreasonable, the synthesis route and process are complex, the production of harmful industrial by-products, the yield is low, and the quality is poor, etc.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

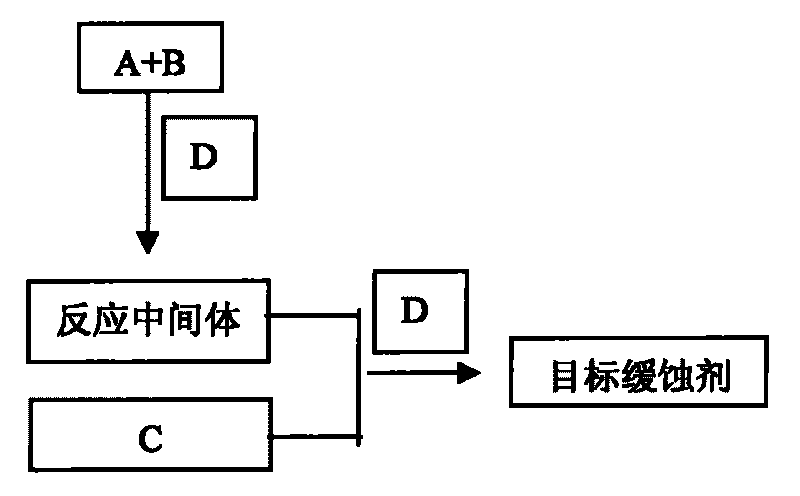

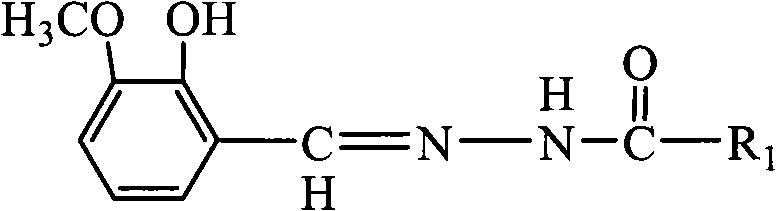

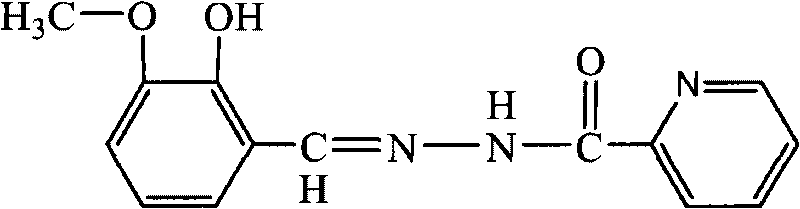

The invention discloses a preparation method of substituted pyridine carbonylhydrazone metal corrosion inhibitor. The method comprises the following steps: using methylisonicotinate and hydrazine hydrate in a molar ratio of 1:1-1.2:1 and absolute ethanol or methanol used as solvent of which volume is 3-6 times of hydrazine hydrate to react for 6-8h in a three-neck flask under the condition of refluxing at 70-80 DEG C and magnetic stirring, obtaining a product to perform reduced pressure distillation, recrystallizing with absolute ethanol, drying to obtain pyridine formylhydrazine, then using the obtained pyridine formylhydrazine and o-vanillin in a molar ratio of 1:1-1:1.2 and absolute ethanol or methanol used as solvent of which volume is 2-5 times of pyridine formylhydrazine to react for 7-9h under the condition of refluxing at 70-90 DEG C and magnetic stirring, cooling, performing suction filtration, washing with absolute ethanol, and recrystallizing. The preparation method of the invention designs the corrosion inhibitor molecule with good oil solubility which meets the environmental protection requirements; and the corrosion inhibitor molecule is characterized by good biodegradability, low toxicity and corrosion resistance within the pH value range of 4-9, and has good corrosion resistance to A3 carbon steel and copper.

Description

technical field The invention relates to a substituted pyridineformylhydrazone compound for metal material protection, belongs to the field of molecular design of green corrosion inhibitors, and particularly relates to a preparation method of a substituted pyridineformylhydrazone metal corrosion inhibitor. Background technique Compared with the most commonly used inorganic corrosion inhibitors (nitrite, phosphate, polyphosphate, carbonate, silicate, borate, chromate), there are more types of synthetic organic corrosion inhibitors . However, there are still many deficiencies in the molecular structure design, synthesis route and process, and application performance of organic corrosion inhibitors, and its theoretical progress still lags far behind practice. The selection and design of the molecular structure of green corrosion inhibitors must not only consider the corrosion inhibition effect, but also take into account the biological activity and versatility. In order to ad...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C23F11/14

Inventor 刘峥王国瑞刘宝玉陈世亮

Owner GUILIN UNIVERSITY OF TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com