Ecological water treatment chemical with both corrosion inhibition and scale inhibition performances

An ecological and water treatment technology, applied in the field of water treatment, can solve the problems of unsatisfactory corrosion inhibition effect, high consumption of ammonia water, and many phosphorus-containing chemicals, and achieve excellent corrosion and scale inhibition performance and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

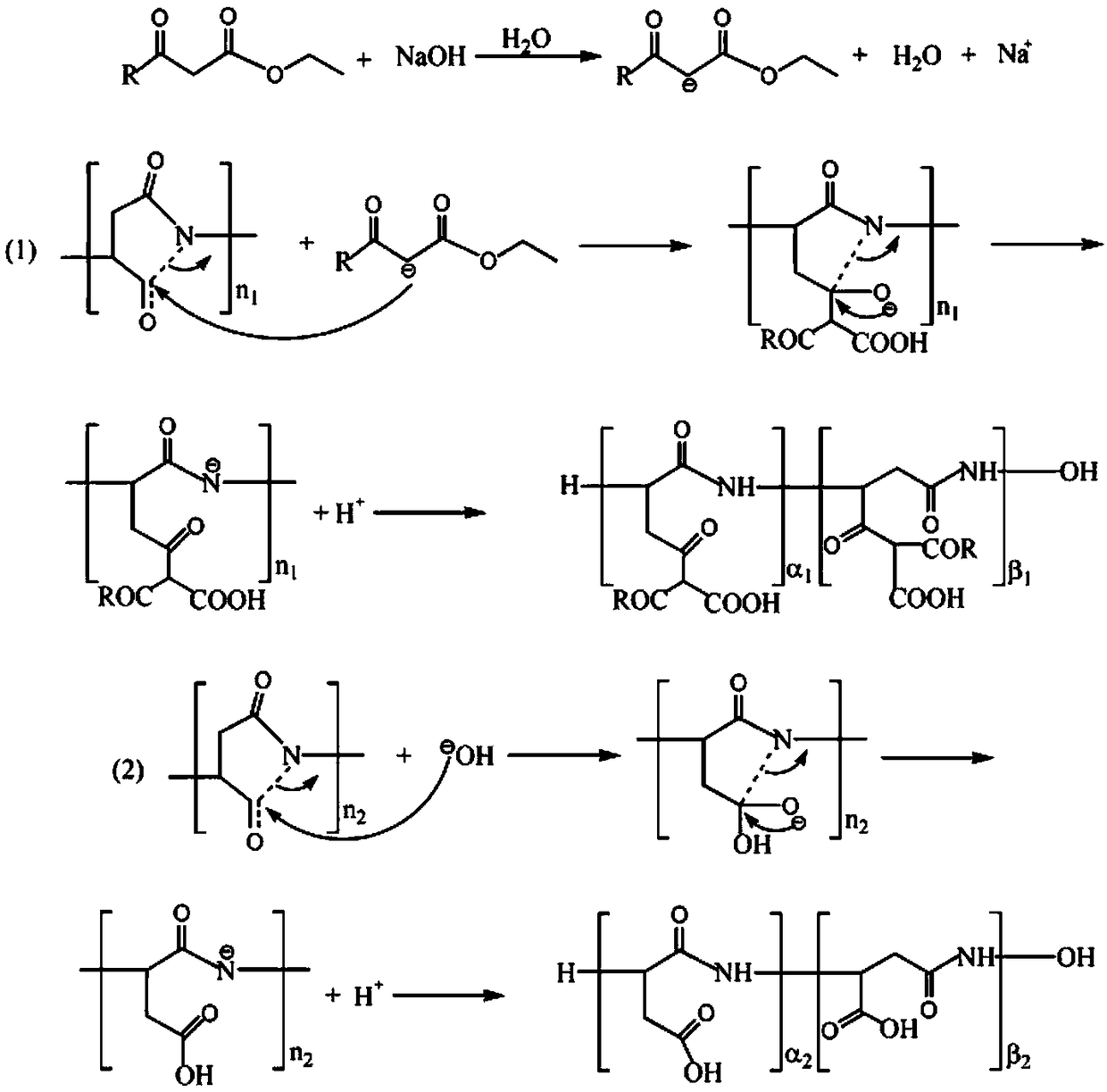

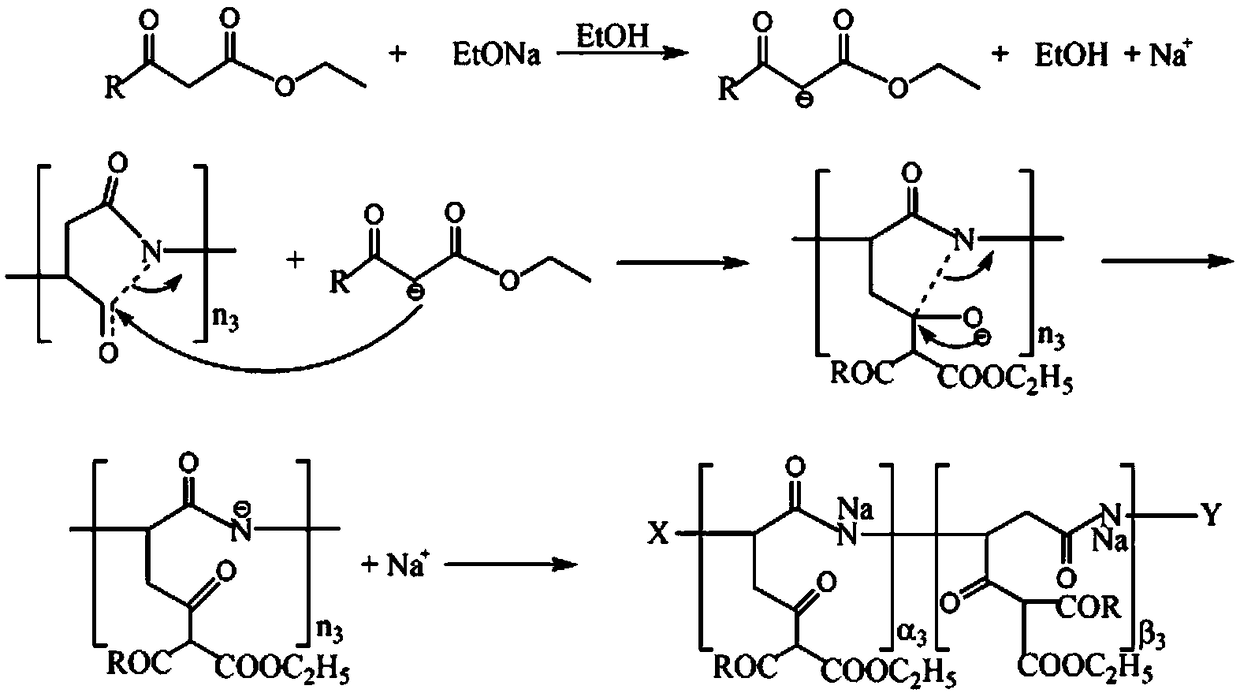

Method used

Image

Examples

Embodiment 1

[0059] Dissolve 9.8g of maleic anhydride in 20ml of distilled water at 60°C, add 6.72g of ammonium carbonate in portions in an ice-water bath, heat up to 90°C after dissolving, and perform amination and hydrolysis for 1.0h to obtain a white paste-like substance called maleic anhydride. amine. Then the temperature was raised to 180° C., and the high-temperature thermal polycondensation reaction was carried out for 1.0 h to obtain unpurified orange-yellow brittle solid PSI.

[0060] Weigh the above 15.0g PSI, dissolve it with 60ml N,N-dimethylformamide (DMF), stir it in a constant temperature water bath at 40°C for 4 hours, filter it with suction, discard the residue, add absolute ethanol, and precipitate Analyze for 30 minutes, then filter with Buchner funnel, the filter cake is purified PSI, and the filtrate is recovered.

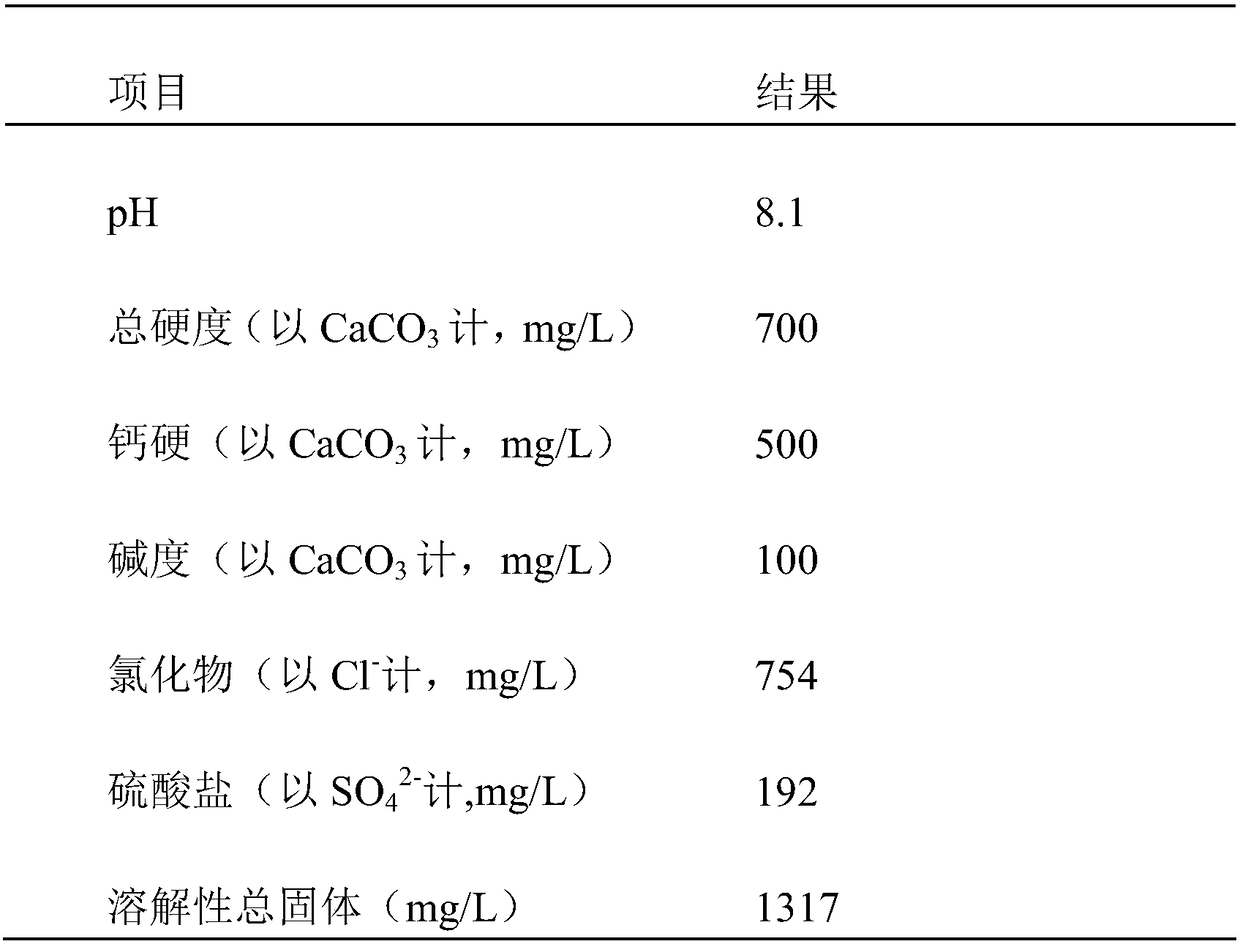

[0061] Weigh 15.2g of ethyl benzoylacetate (EBA) and 8g of NaOH into 186ml of water, add 9.7g of purified PSI after reacting for 50min, and react for anot...

Embodiment 2

[0065] Dissolve 9.8g of maleic anhydride in 20ml of distilled water at 60°C, add 5.76g of ammonium carbonate in portions in an ice-water bath, heat up to 80°C after dissolution, and perform amination and hydrolysis for 2.0 hours to obtain a white paste-like substance called maleic anhydride. amine. Then the temperature was raised to 165° C., and the high-temperature thermal polycondensation reaction was carried out for 1.5 h to obtain unpurified orange-yellow brittle solid PSI.

[0066] Weigh the above 15.0g PSI, dissolve it with 60ml N,N-dimethylformamide (DMF), stir it in a constant temperature water bath at 40°C for 4 hours, filter it with suction, discard the residue, add absolute ethanol, and precipitate Analyze for 30 minutes, then filter with Buchner funnel, the filter cake is purified PSI, and the filtrate is recovered.

[0067] Weigh 10.4g of EBA and 4.8g of NaOH into 141ml of water, react for 30 minutes, add 9.7g of purified PSI, and react for another 18 hours to ob...

Embodiment 3

[0071] Dissolve 9.8g of maleic anhydride in 20ml of distilled water at 60°C, add 6.72g of ammonium carbonate in portions in an ice-water bath, heat up to 85°C after dissolving, and perform amination and hydrolysis for 1.5h to obtain a white paste-like substance called maleic anhydride. amine. Then the temperature was raised to 170° C., and the high-temperature thermal polycondensation reaction was carried out for 1.2 hours to obtain unpurified orange-yellow brittle solid PSI.

[0072] Weigh the above 15.0g PSI, dissolve it with 60ml N,N-dimethylformamide (DMF), stir it in a constant temperature water bath at 40°C for 4 hours, filter it with suction, discard the residue, add absolute ethanol, and precipitate Analyze for 30 minutes, then filter with Buchner funnel, the filter cake is purified PSI, and the filtrate is recovered.

[0073] Weigh 12.8g of EBA and 6.4g of NaOH into 164ml of water, react for 40min, add 9.7g of purified PSI, react for another 20 hours, and obtain a re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com