Phosphorus-free composite anti-scaling corrosion inhibitor and application thereof and treatment method of circulating cooling water

A technology of scale and corrosion inhibitor, circulating cooling water, applied in water/sludge/sewage treatment, special treatment targets, descaling and water softening, etc. Achieve good scale and corrosion inhibition performance, avoid environmental problems, and meet the requirements of scale and corrosion inhibition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

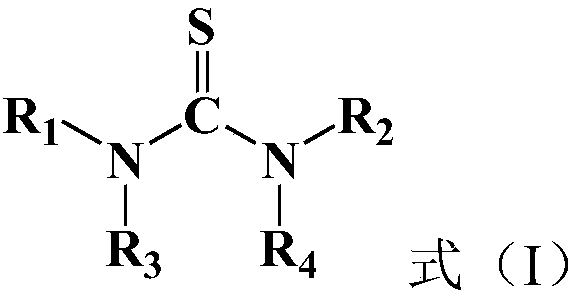

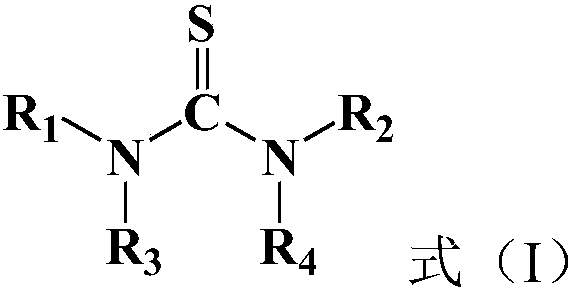

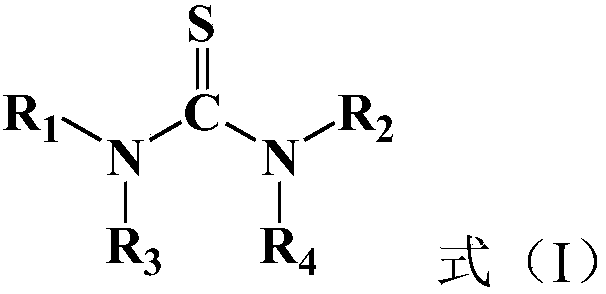

[0025] The preparation method of the copolymer used in the present invention may include: mixing monomers, initiators and molecular weight regulators at 50-95°C, and continuing to react at 75-95°C for 1-4h, wherein the single Solids include thiourea derivatives, unsaturated carboxylic acids and acrylates.

[0026] Wherein, the dosage and specific selection of thiourea derivatives, unsaturated carboxylic acid and acrylate as monomers are as mentioned above, and will not be repeated here.

[0027] According to a preferred embodiment, the mixing method when preparing the copolymer is:

[0028] (a) the solution of the monomer and the solution of the initiator are respectively added dropwise to the solution of the molecular weight regulator, or

[0029] (b) adding dropwise the solution of the monomer and the solution of the molecular weight regulator into the solution of the initiator respectively, or

[0030] (c) The solution of the initiator is added dropwise to the mixed solut...

Embodiment 1

[0073] Weigh 30g sodium carboxymethylinulin (substitution degree is 1), 10g carboxymethyl-α-cyclodextrin and 30g copolymer 1 (limiting viscosity at 30°C is 0.078dl / g, dissolve 7.2g sodium metabisulfite In 20ml of water, 1.2g of ammonium persulfate was dissolved in 40ml of water, 24.5g of monomer allylthiourea, 18g of methylene succinic acid, 18g of methyl acrylate and 100ml of water were polymerized, and the solid content was 29.4% by weight), Add 30g of water and shake well to obtain the stock solution S1 of composite scale and corrosion inhibitor agent.

[0074] Take 1g of the prepared composite scale and corrosion inhibitor stock solution S1 and add them to 10L of test water 1 and 2 respectively, so that the contents of carboxymethylinulin sodium, carboxymethyl-α-cyclodextrin and copolymer in the water are respectively 6mg / L, 10mg / L and 9mg / L, then carry out the calcium carbonate scale inhibition performance measurement and the corrosion inhibition performance measurement ...

Embodiment 2

[0076] Weigh 3.14g of zinc chloride, dissolve it in 15g of copolymer 2 (at 30°C, the limiting viscosity is 0.078dl / g, 2.4g of ammonium persulfate is dissolved in 40ml of water, 6g of sodium pyrosulfite is dissolved in 20ml of water, and monomer propylene sulfide Urea 27.6g, maleic anhydride 21g, ethyl acrylate 12g and 100ml water polymerization obtain, solid content is 30.1% by weight), then add 45g sodium carboxymethylinulin (substitution degree is 0.6) and 18g methyl-β- Cyclodextrin, and then add 8.86g of water, shake well to obtain composite scale and corrosion inhibitor stock solution S2.

[0077] Take 0.9g of the prepared composite scale and corrosion inhibitor stock solution S2 and add them to 10L of test water 1 and 2 respectively, so that the content of sodium carboxymethylinulin, methyl-β-cyclodextrin, copolymer and zinc ions in the water 9mg / L, 18mg / L, 4.5mg / L and 1.5mg / L respectively, and then the calcium carbonate scale inhibition performance and corrosion inhibiti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Ultimate viscosity | aaaaa | aaaaa |

| Ultimate viscosity | aaaaa | aaaaa |

| Ultimate viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com