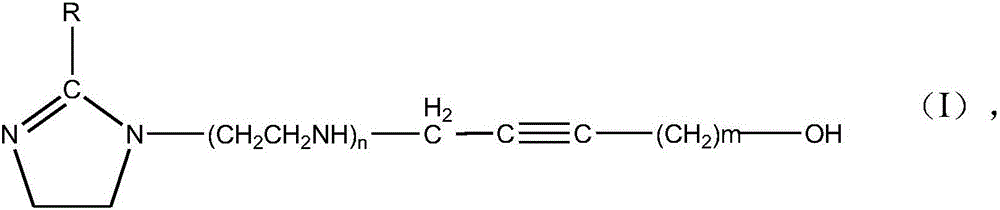

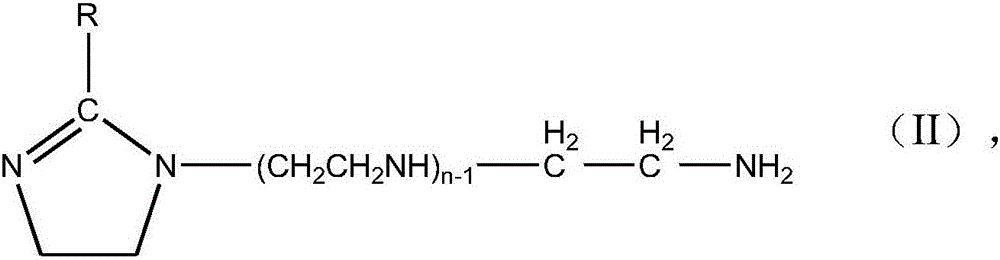

Alkynol-based imidazoline compound, corrosion inhibitor for carbon dioxide oil displacement, and preparations of alkynol-based imidazoline compound and corrosion inhibitor

A technology based on imidazoline and carbon dioxide, which is applied in drilling compositions, organic chemistry, mechanical equipment, etc., can solve the problems of small amount of corrosion inhibitor and poor corrosion inhibition performance, and achieve good corrosion inhibition effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] 282 grams of oleic acid and 103 grams of diethylenetriamine were dropped into the three-necked flask, and the heating and stirring reaction was started. When the reaction temperature reaches 150°C, maintain the temperature for 3 hours; continue to raise the temperature to 200°C, maintain the temperature for 3 hours; further raise the temperature to 230°C, maintain the temperature for 3 hours to obtain the oleic acid-based imidazoline intermediate.

[0043]

[0044] Put 174.5 grams of oleic acid-based imidazoline prepared above, 35 grams of formaldehyde solution (40% in mass concentration) and 35 grams of 3-butyn-1-ol into a three-necked flask, raise the temperature to 90° C., and maintain the temperature for 6 hours, the acetylenol-based imidazoline intermediate was obtained.

[0045]

[0046] In the there-necked flask, add 40 grams of acetylenyl imidazoline prepared above, 25 grams of isopropanol, 15 grams of OP-10, 3 grams of potassium iodide and 17 grams of wat...

Embodiment 2

[0054] 338 grams of erucic acid and 195 grams of tetraethylenepentamine were dropped into the three-necked flask, and the heating and stirring reaction was started. When the reaction temperature reaches 150°C, maintain the temperature for 3 hours; continue to raise the temperature to 200°C, maintain the temperature for 3 hours; further raise the temperature to 230°C, maintain the temperature for 3 hours to obtain the erucic acid imidazoline intermediate.

[0055]

[0056] Put 245.5 grams of erucyl imidazoline prepared above, 37 grams of formaldehyde solution (38% in mass concentration) and 28 grams of 2-propyn-1-ol into a three-necked flask, heat up to 90° C., and maintain the temperature for 6 hours, the acetylenol-based imidazoline intermediate was obtained.

[0057]

[0058] In the there-necked flask, add 48 grams of acetylenyl imidazoline prepared above, 20 grams of ethylene glycol, 20 grams of OP-10, 2 grams of potassium iodide and 10 grams of water and stir to obta...

Embodiment 3

[0066] 200 grams of lauric acid and 148 grams of triethylenetetramine were dropped into a three-necked flask, and the heating and stirring reaction was started. When the reaction temperature reaches 150°C, maintain the temperature for 3 hours; continue to raise the temperature to 200°C, maintain the temperature for 3 hours; further raise the temperature to 230°C, maintain the temperature for 3 hours to obtain the lauryl imidazoline intermediate.

[0067]

[0068] Put 155 grams of the above-prepared lauryl imidazoline, 35 grams of formaldehyde aqueous solution (mass concentration of 40%) and 45 grams of 4-pentyn-1-ol into a three-necked flask, raise the temperature to 90 ° C, and maintain the temperature for 6 hours , to obtain the alkynol-based imidazoline intermediate.

[0069]

[0070] In the there-necked flask, add 35 grams of the above-prepared acetylenol-based imidazoline, 30 grams of ethanol, 10 grams of OP-10, 5 grams of sodium iodide and 20 grams of water and sti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com