Mixed fatty group di(benzimidazoline-ammonium-salt) as well as preparation method and application thereof

A technology of imidazoline quaternary ammonium salt and benzimidazoline, which is applied in the field of mixed aliphatic bismuth and its preparation, can solve problems such as poor corrosion inhibition effect, achieve the effects of protecting the environment, increasing hydrophobicity, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

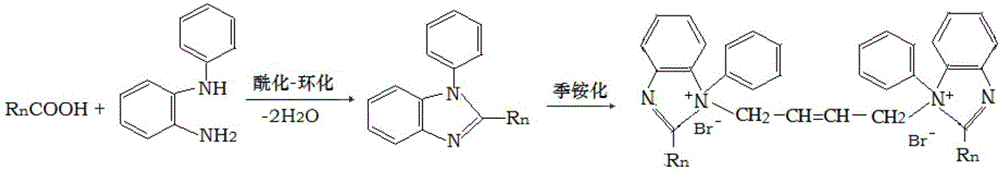

[0022] This example is a specific example of preparing 1,4-bis(2-mixed aliphatic-1-benzoimidazoline phenyl quaternary ammonium)-2-butene corrosion inhibitor.

[0023] The chemical reaction formula of the reaction principle of the present embodiment is:

[0024]

[0025] Hydrolyze waste oil to obtain mixed fatty acids, set aside.

[0026] In a three-necked flask equipped with a water separator, a thermometer, a condenser, and a stirring device, add 27.2g of mixed fatty acids, 16.6g of N-phenyl-o-phenylenediamine, and 60ml of xylene, and pass into nitrogen protection. The by-product water is separated from the system by a device, slowly heated to 140°C, and reacted for 3.5-4.0 hours. When the amount of collected water is close to the theoretical water yield, then raise the temperature to 170-180°C to distill the solvent, and heat to reflux for 4-5 hours. After continuing the cyclization reaction at 210-220°C for 3 hours, distill under reduced pressure of 20-25 mmHg until no...

Embodiment 2

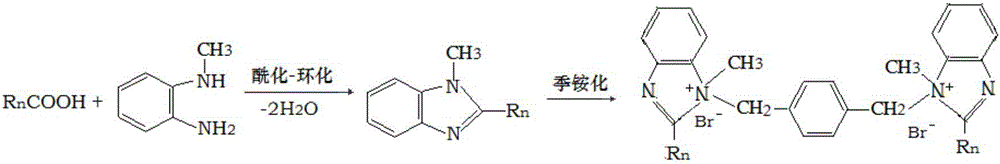

[0029] This example is a specific example of preparing 1,4-bis(2-mixed aliphatic-1-benzimidazolinylmethylmethylenequaternary ammonium)benzene corrosion inhibitor.

[0030] The chemical reaction formula of the reaction principle of the present embodiment is:

[0031]

[0032] Hydrolyze waste oil to obtain mixed fatty acids, set aside.

[0033] In a three-necked flask equipped with a water separator, a thermometer, a condenser and a stirring device, add 27.2g of mixed fatty acids, 17.5g of N-methyl-o-phenylenediamine and 80ml of xylene, pass into nitrogen protection, and continuously use water during the reaction The by-product water is separated from the system by a device, slowly heated to 140°C, and reacted for 3.5-4.0 hours. When the amount of collected water is close to the theoretical water yield, then raise the temperature to 170-180°C to distill the solvent, and heat to reflux for 4-5 hours. After continuing the cyclization reaction at 210-220°C for 3 hours, distill...

Embodiment 3

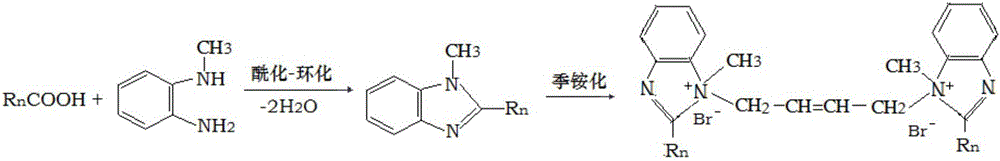

[0036] This example is a specific example of preparing 1,4-bis(2-mixed aliphatic-1-benzoimidazolinylmethyl quaternary ammonium)-2-butene corrosion inhibitor.

[0037] The chemical reaction formula of the reaction principle of the present embodiment is:

[0038]

[0039] Hydrolyze waste oil to obtain mixed fatty acids, set aside.

[0040] In a three-necked flask equipped with a water separator, a thermometer, a condenser, and a stirring device, add 27.2g of mixed fatty acids, 18.5g of N-methyl-o-phenylenediamine, and 40ml of xylene, and pass into nitrogen protection. The by-product water is separated from the system by a device, slowly heated to 140°C, and reacted for 3.5-4.0 hours. When the amount of collected water is close to the theoretical water yield, then raise the temperature to 170-180°C to distill the solvent, and heat to reflux for 4-5 hours. After continuing the cyclization reaction at 210-220°C for 3 hours, distill under reduced pressure of 20-25 mmHg until no...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com