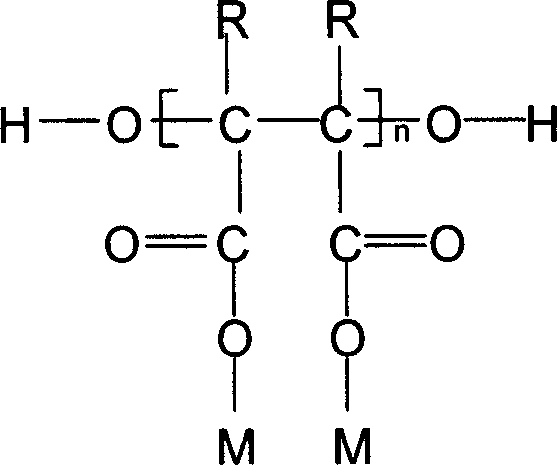

Composite scale-proof corrosion inbibitor containing poly epoxy succinic acid and its use

A technology of polyepoxysuccinic acid, scale and corrosion inhibitor, applied in descaling and water softening, water/sludge/sewage treatment, chemical instruments and methods, etc., to achieve good comprehensive performance, good corrosion inhibition performance, economical effect of dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

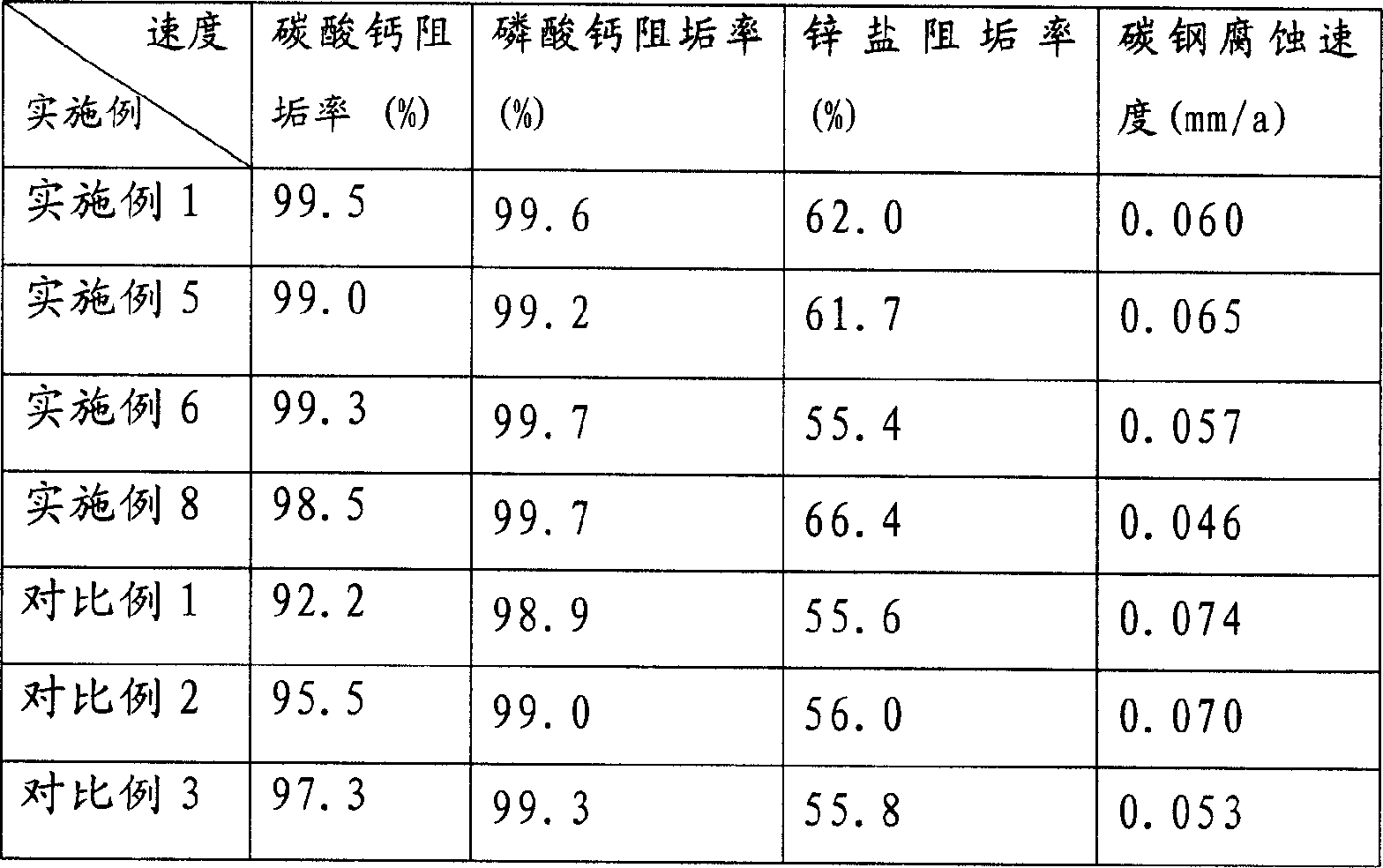

Examples

Embodiment 1

[0036] Preparation process: prepare 80.0g of composite scale and corrosion inhibitor containing polyepoxysuccinic acid

[0037] Weigh 13.3g of polyepoxysuccinic acid with 30% active component (product of Beijing Lianzhong Dadi Technology Co., Ltd., the same below) and acrylic acid / hydroxypropyl acrylate copolymer T-225 (limit viscosity at 30°C is 0.075dl / g, AA / HPA=70 / 30) 26.7g, PBTCA 8.0g with 50% active component and p-diphosphine sulfonic acid 10.0g with 40% active component, 1.7g zinc chloride, 20.3g water was added , shake well to obtain 80.0g of the desired preparation.

[0038] When the prepared agent is added to the test water at a concentration of 80.0mg / L, the effective concentrations of polyepoxysuccinic acid, T-225, PBTCA, p-diphosphine sulfonic acid and zinc ions in the water are 4.0mg respectively. / L, 8.0 mg / L, 4.0 mg / L, 4.0 mg / L and 0.8 mg / L.

Embodiment 2

[0040] Preparation process: prepare 80.0g pharmaceutical solution

[0041] Weigh 20.0 g of polyepoxysuccinic acid with 30% active component and acrylic acid / hydroxypropyl acrylate / methyl acrylate copolymer (limit viscosity at 30°C is 0.073dl / g, AA / HPA / MA=70 / 15 / 15) 25.0g, 8.0g of PBTCA with 50% active component and 10.0g of glycine dimethylidene phosphonic acid with 40% active component, add 17.0g of water, shake well to get 80.0g of the desired preparation Pharmacy.

[0042] When the prepared agent is added to the test water at a concentration of 80 mg / L, the effective concentrations of polyepoxysuccinic acid, AA / HPA / MA copolymer, PBTCA and glycine dimethylidene phosphonic acid in the water are 6.0 mg / L, 7.5 mg / L, 4.0 mg / L, 4.0 mg / L.

Embodiment 3

[0044] Preparation process: prepare 80.0g pharmaceutical solution

[0045] Weigh 13.3 g of polyepoxysuccinic acid with 30% active component and acrylic acid / 2-methyl-2'-acrylamidopropane sulfonic acid copolymer (limit viscosity at 30°C is 0.078 dl / g, AA / AMPS=70 / 30) 20.0g, 5.0g p-diphosphonic acid with 40% active component and 10.0g sulfamic acid dimethylidene phosphonic acid with 40% active component, add 31.7g water, shake well, That is, 80.0 g of the medicament to be prepared is obtained.

[0046] When the prepared agent is added to the test water at a concentration of 80.0mg / L, the water containing polyepoxysuccinic acid, AA / AMPS copolymer, p-diphosphine sulfonic acid, and sulfamic acid dimethylidene phosphonic acid. The effective concentrations were 4.0mg / L, 6.0mg / L, 2.0mg / L and 4.0mg / L, respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Ultimate viscosity | aaaaa | aaaaa |

| Ultimate viscosity | aaaaa | aaaaa |

| Ultimate viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com