Imidazoline quaternary ammonium salt corrosion inhibitor and preparation method thereof

A technology of imidazoline quaternary ammonium salt and corrosion inhibitor, which is applied in the field of metal corrosion and protection, can solve the problems of high requirements on device sealing, inability to perform solvent recovery, poor corrosion inhibition performance, etc., and achieves wide application range and low toxicity. , Easy to operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

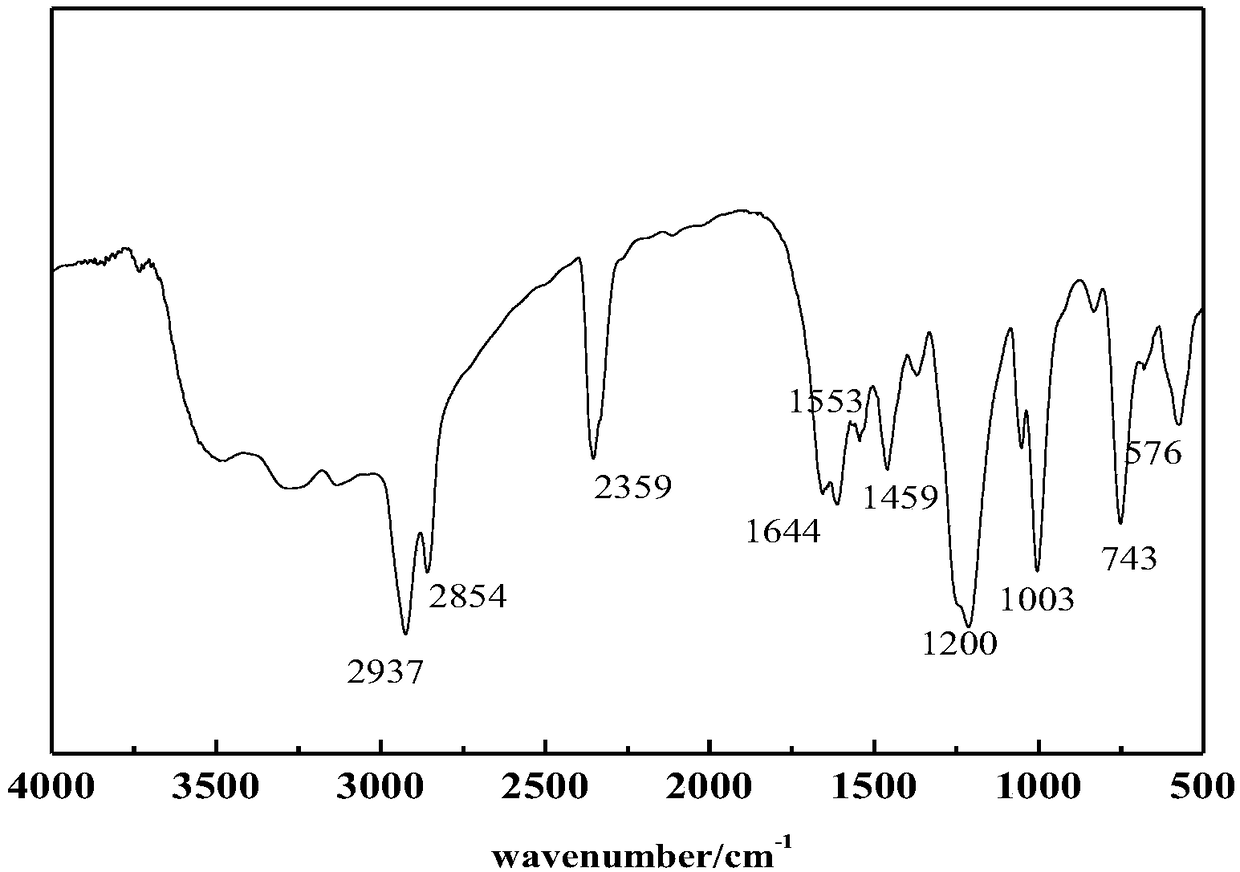

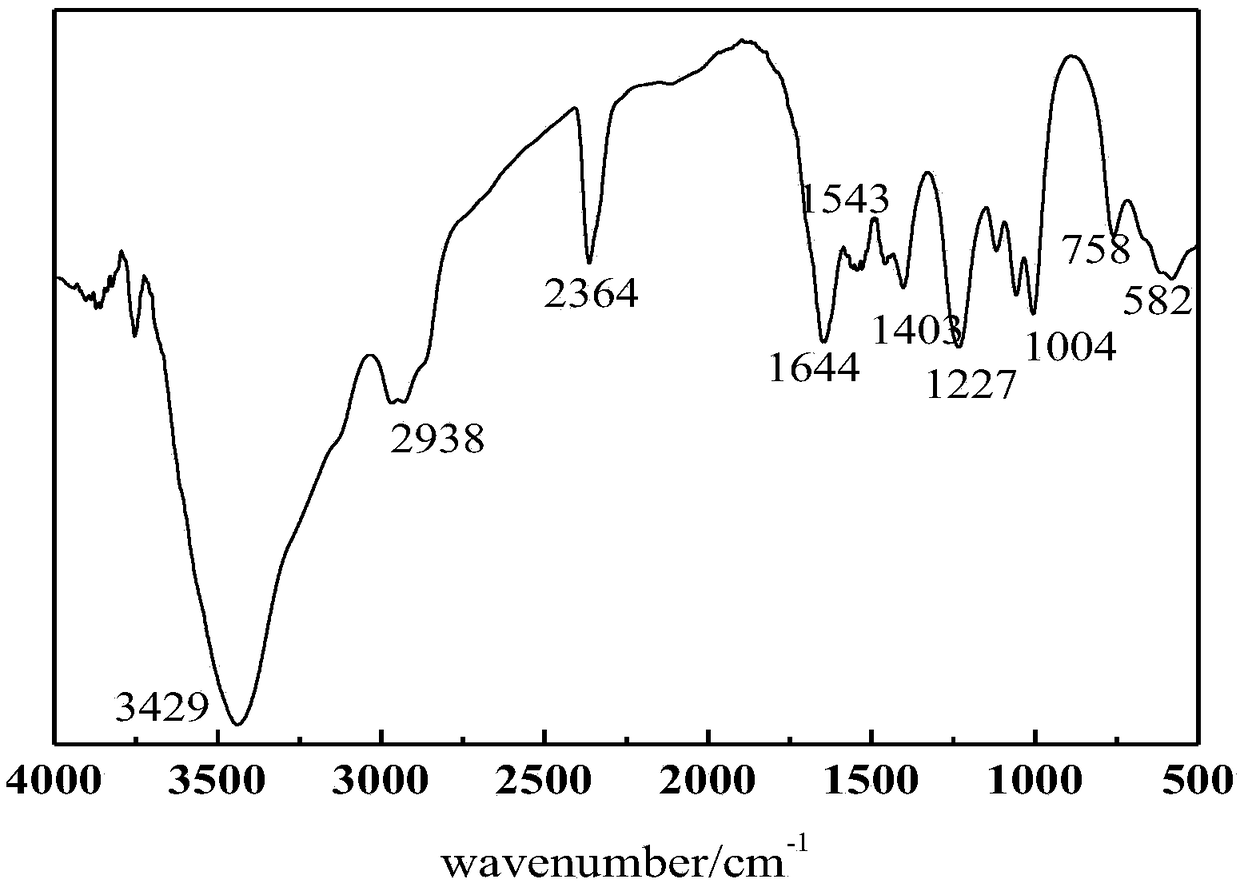

Image

Examples

preparation example Construction

[0029] A kind of preparation method of imidazoline quaternary ammonium salt corrosion inhibitor of the present invention, concrete operation process comprises the following steps:

[0030] Step 1. Add the main component raw materials of the corrosion inhibitor and boric acid into the three-necked flask in proportion, heat and stir with the electric heating mantle, and raise the temperature to 40°C-50°C, then add xylene in proportion to obtain the mixture I;

[0031] Step 2. When the temperature of the electric heating mantle rises to 100-120°C, use a constant pressure dropping funnel to add diethylenetriamine drop by drop to the mixture I for reaction, and continue to heat up to 160-180°C for amidation dehydration reaction , and then cyclization reaction at 240-260°C for 3-3.5 hours to obtain imidazoline oil-soluble corrosion inhibitor;

[0032] In step 2, diethylenetriamine is added, and the reaction time is 0.5-1 h.

[0033] The amidation dehydration reaction time in step 2...

Embodiment 1

[0038] An oleic acid imidazoline quaternary ammonium salt corrosion inhibitor, raw materials include oleic acid, diethylenetriamine, boric acid, xylene, and benzyl chloride. Among them, the molar ratio between oleic acid, diethylenetriamine, and benzyl chloride is 1:1:4 respectively, the molar ratio of boric acid and the main component raw material of corrosion inhibitor is 1:0.015, and the main component raw material of xylene and corrosion inhibitor The molar ratio is 1:0.8.

[0039] The preparation process is as follows:

[0040] Step 1. Add oleic acid and boric acid into a three-necked flask in proportion, heat and stir with an electric heating mantle, gradually raise the temperature to 40°C, and then add xylene to obtain mixture I;

[0041] Step 2. When the temperature of the electric heating mantle rises to 120°C, use a constant pressure dropping funnel to add diethylenetriamine dropwise to the mixture I. After reacting for 0.5h, continue to heat up to 170°C, and the am...

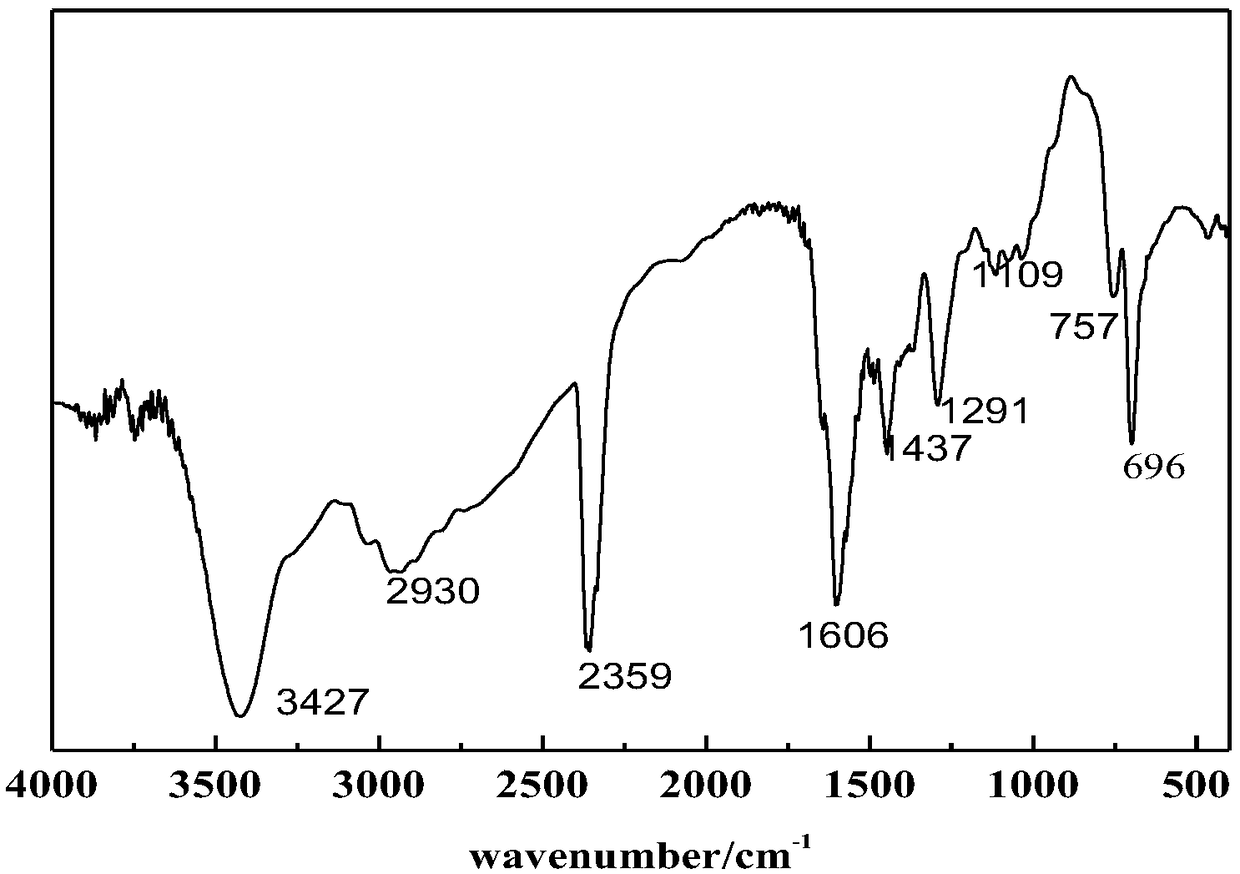

Embodiment 2

[0044] A benzoic acid imidazoline quaternary ammonium salt corrosion inhibitor, raw materials include benzoic acid, diethylenetriamine, boric acid, xylene, benzyl chloride. Among them, the ratio of the amount of benzoic acid, diethylenetriamine, and benzyl chloride is 1:1.05:4.5, the molar ratio of boric acid to the main component of the corrosion inhibitor is 1:0.02, and the ratio of xylene to the main component of the corrosion inhibitor is 1:0.02. The molar ratio is 1:1.

[0045] Step 1. Add benzoic acid and boric acid into a three-necked flask in proportion, heat and stir with an electric heating mantle, gradually raise the temperature to 45°C, and then add xylene to obtain mixture I;

[0046] Step 2. When the temperature of the electric heating mantle rises to 110°C, use a constant pressure dropping funnel to add diethylenetriamine dropwise to the mixture I. After reacting for 0.8h, continue to heat up to 160°C, and the amidation reaction occurs. After 3 hours, the cycli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com