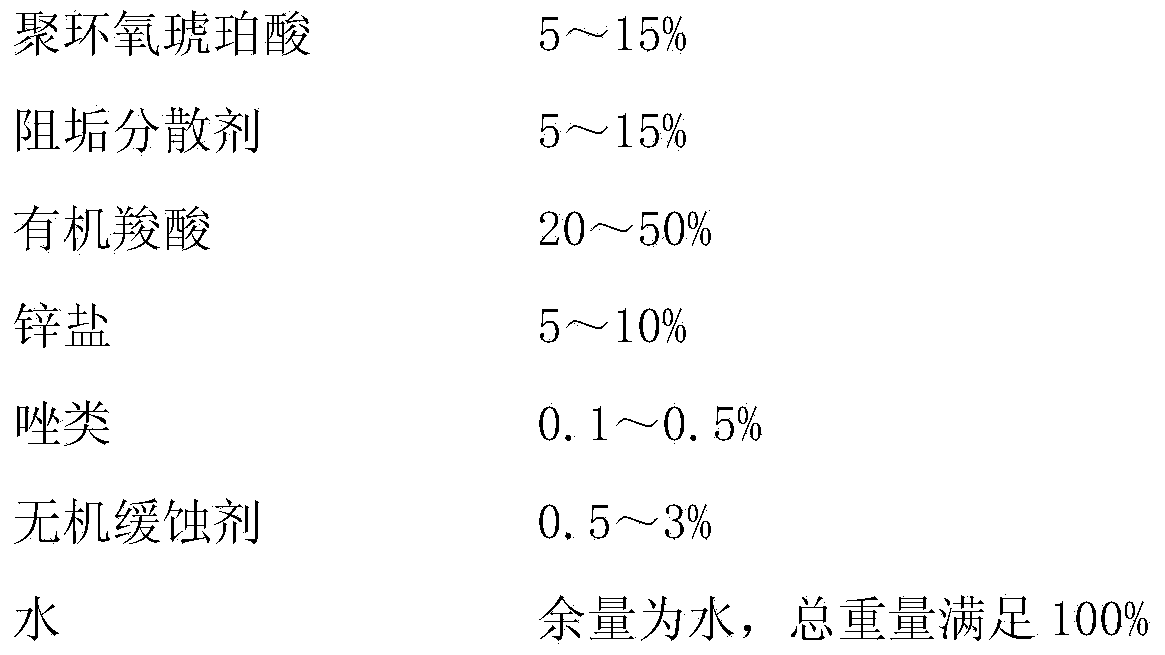

Preparation method of non-phosphorus corrosion and scale inhibitor

A phosphorus-free corrosion and scale inhibitor technology, applied in chemical instruments and methods, descaling and water softening, complex/solubilizing agent treatment, etc., can solve problems such as complex and cumbersome configuration process, adverse consequences, and large differences , to achieve the effects of avoiding eutrophication, good stability and excellent corrosion inhibition performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

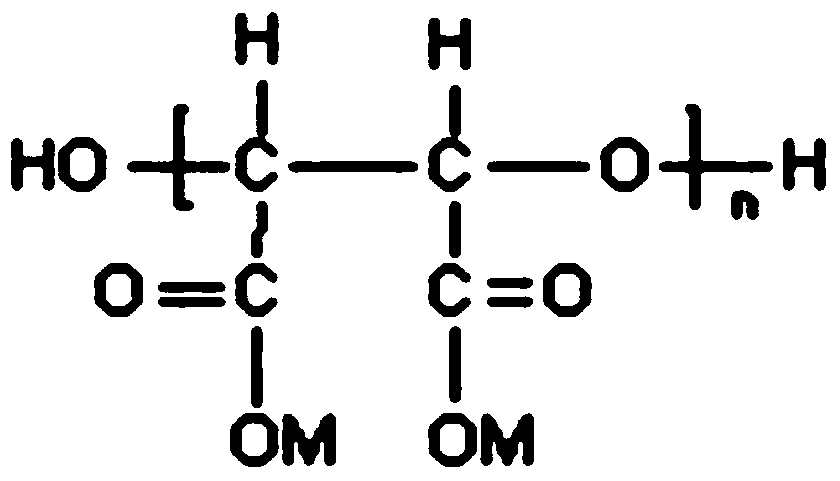

Image

Examples

Embodiment 1

[0028] Prepare 100g of phosphorus-free corrosion and scale inhibitor solution: add 7.5g of sodium gluconate, 11.05g of zinc sulfate, and 2.05g of rare earth metal salts to 58.45g of water, stir well, then add 10g of polyepoxysuccinic acid, scale inhibitor dispersion Add 10.7g of the agent, stir evenly, finally add 0.25g of benzotriazole and stir until fully dissolved, then filter to obtain.

[0029] 100 g of the prepared phosphorus-free corrosion and scale inhibitor solution was added to the industrial water to be treated at a concentration of 300 mg / L.

Embodiment 2

[0031] Prepare 100g of phosphorus-free corrosion and scale inhibitor solution: add 5.0g of sodium gluconate, 11.05g of zinc sulfate, and 2.05g of rare earth metal salts to 44.35g of water, stir well, then add 10g of polyepoxysuccinic acid, N-long 16.6g of alkanylamino carboxylic acid, 10.7g of scale inhibitor and dispersant, stir evenly, finally add 0.25g of benzotriazole, stir until fully dissolved, and filter.

[0032] 100 g of the prepared phosphorus-free corrosion and scale inhibitor solution was added to the industrial water to be treated at a concentration of 150 mg / L.

Embodiment 3

[0034] Prepare 100g of phosphorus-free corrosion and scale inhibitor solution: add 5.0g of sodium gluconate and 5.53g of zinc sulfate to 63.92g of water, stir well, then add 7.5g of polyepoxysuccinic acid, 12.5g of N-long chain alkyl aminocarboxylic acid g, 5.35g of scale inhibitor dispersant, stir evenly, finally add 0.2g of benzotriazole and stir until fully dissolved, then filter to obtain.

[0035] 100 g of the prepared phosphorus-free corrosion and scale inhibitor solution was added to the industrial water to be treated at a concentration of 400 mg / L.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com