Molybdenum phosphine system composite anti-erosion anti-sludging agent and preparation method thereof

Corrosion and scale inhibitor technology, scale inhibitor technology, applied in chemical instruments and methods, scale removal and water softening, compositions for inhibiting chemical changes, etc., can solve problems such as corrosion inhibition performance decline

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

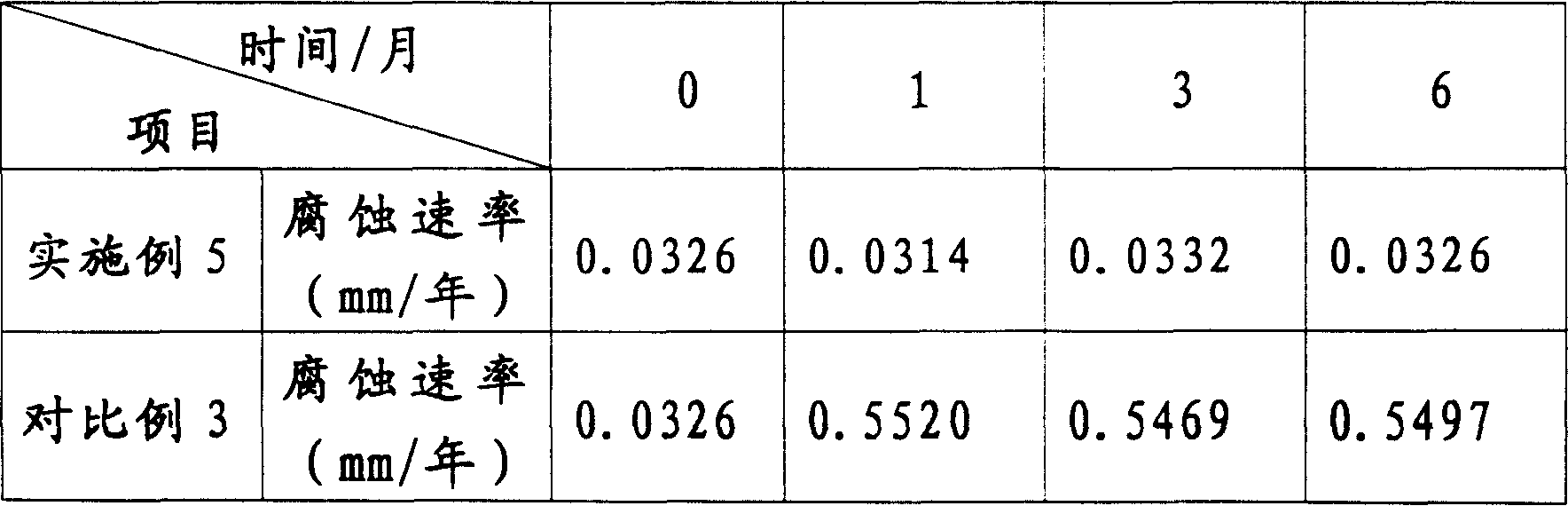

Examples

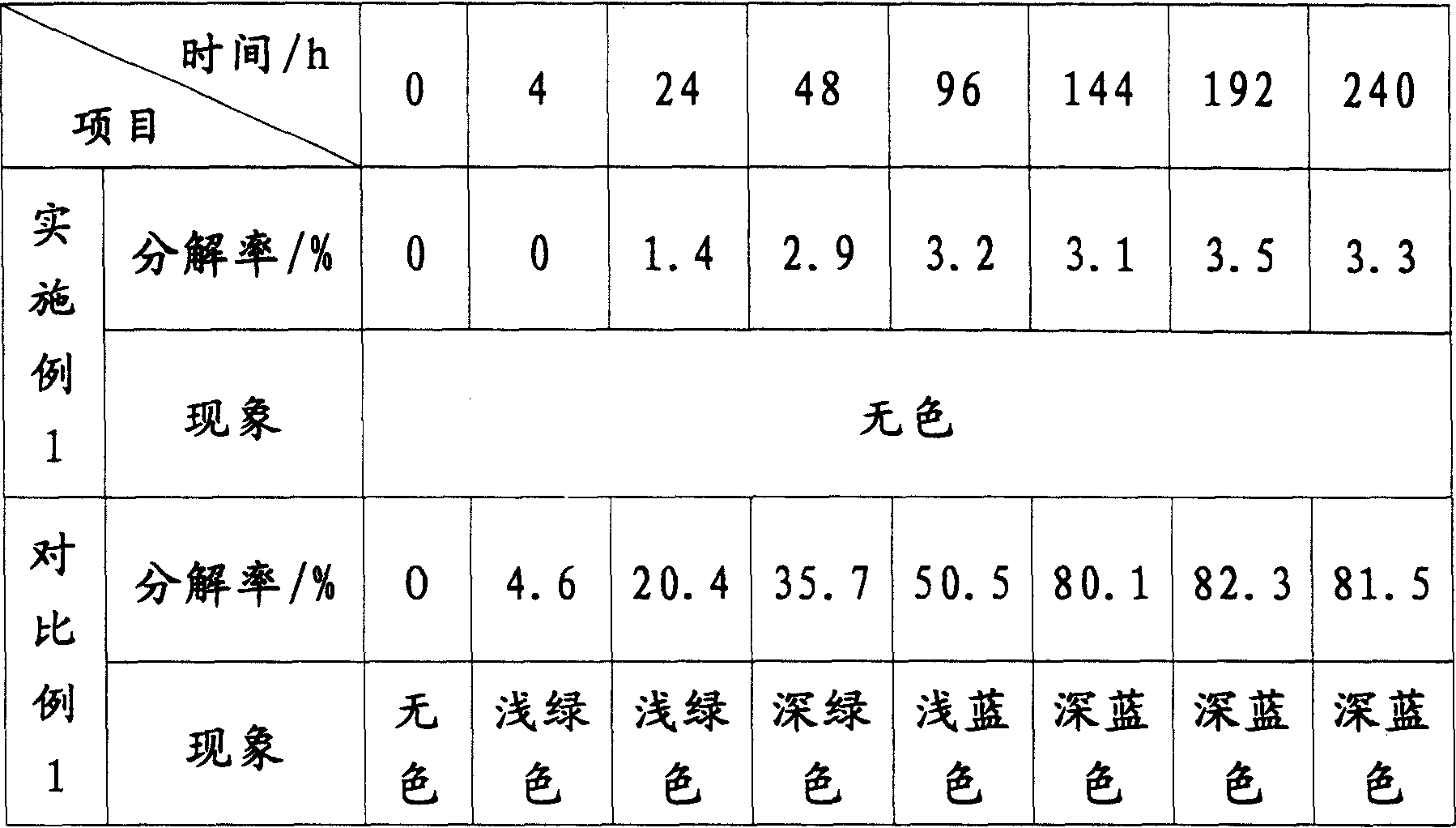

Embodiment 1

[0031] In a 200ml beaker filled with 45g deionized water, add 40g HEDP, 5g H 2 o 2 (Oxidizing agent), after stirring well, add 10g Na 2 MoO 4 2H 2 O, mix well to obtain the molybdenum-phosphine composite corrosion and scale inhibitor of the present invention. The prepared molybdenum-phosphine composite corrosion and scale inhibitor was transferred to a 150ml ground-mouth Erlenmeyer flask and stored at room temperature until use.

[0032] Take 10g Na 2 MoO 4 2H 2 O in a 200ml beaker, add 45g deionized water, stir to dissolve, then add 5g H 2 o 2 (Oxidizing agent), 40g HEDP, after mixing, obtain the molybdenum-phosphine composite corrosion and scale inhibitor of the present invention. The prepared molybdenum-phosphine composite corrosion and scale inhibitor was transferred to a 150ml ground-mouth Erlenmeyer flask and stored at room temperature until use.

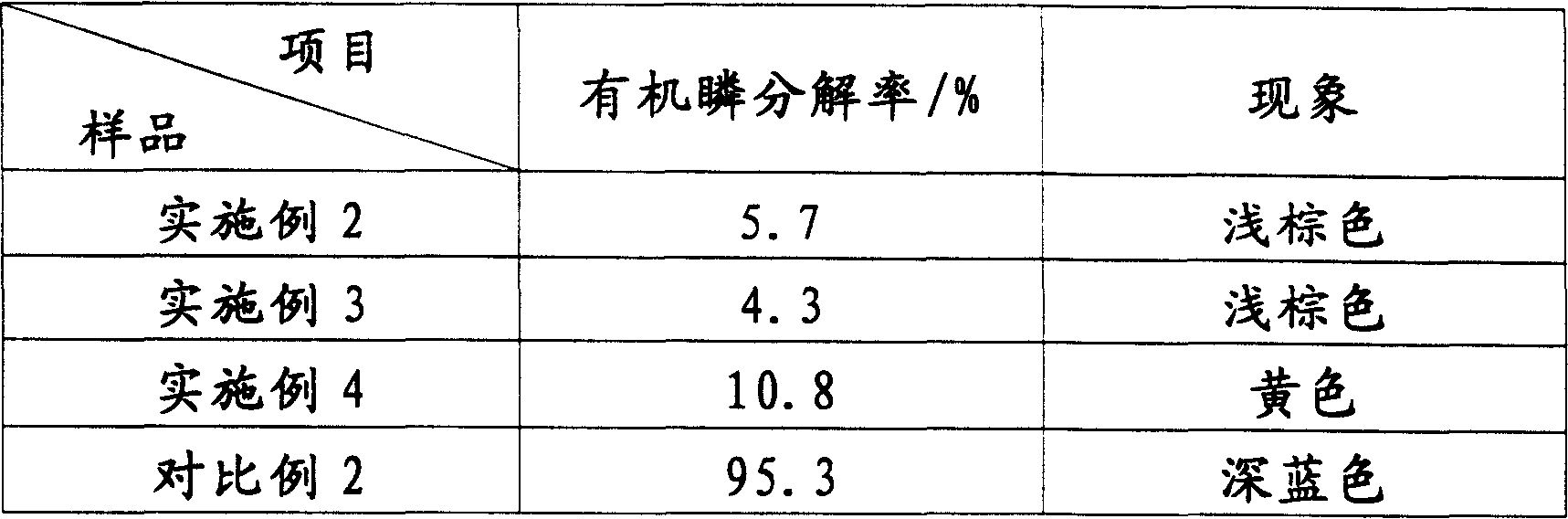

Embodiment 2

[0034] Take 5g of ammonium molybdate in a 200ml beaker, add 40g of deionized water, 10g of binary copolymer of acrylic acid and 2-acrylamido-2-methyl-propanesulfonic acid, 6g of anhydrous zinc chloride, and stir to dissolve , add 3g perchloric acid (oxidizing agent), then add 2g phosphoric acid, 5gHPAA, 4g PBTC in the beaker, make up to 100g with deionized water. After mixing, the molybdenum-phosphine composite corrosion and scale inhibitor of the present invention is obtained. The prepared molybdenum-phosphine composite corrosion and scale inhibitor was transferred to a 150ml ground-mouth Erlenmeyer flask and stored at room temperature until use.

Embodiment 3

[0036] The operation of Example 2 was repeated except that 8 g of perchloric acid (oxidizing agent) was added. The prepared molybdenum-phosphine composite corrosion and scale inhibitor was transferred to a 150ml ground-mouth Erlenmeyer flask and stored at room temperature until use.

PUM

| Property | Measurement | Unit |

|---|---|---|

| scale inhibition rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com