Room-temperature-cured-type clean solid propellant

A solid propellant, room temperature curing technology, applied in explosives, etc., can solve the problems of greenhouse effect, environmental pollution, easy formation of acid fog, etc., to achieve the effect of avoiding acid rain pollution and excellent process performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

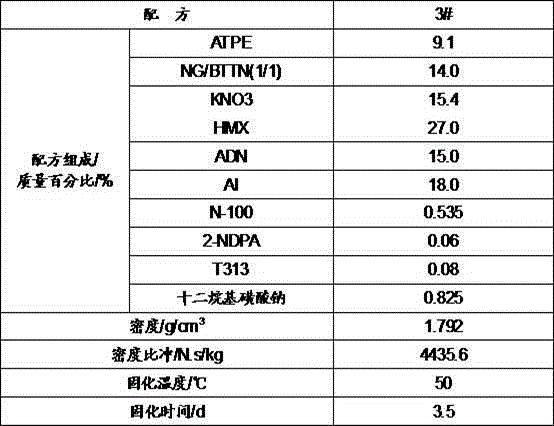

[0028] The following table 1 shows the composition and performance of the 1#ATPE / AN / IPDI clean propellant of the present invention.

[0029] Table 1 ATPE / AN / IPDI propellant formula and performance

[0030]

[0031] It can be seen from Table 1 that when the solid content is 75%, the ATPE / AN / IPDI propellant is completely cured in 4 days at 30°C, and the density of the propellant is 1.655g / cm 3 , The density specific impulse is 4061.2N.s / kg.

Embodiment 2

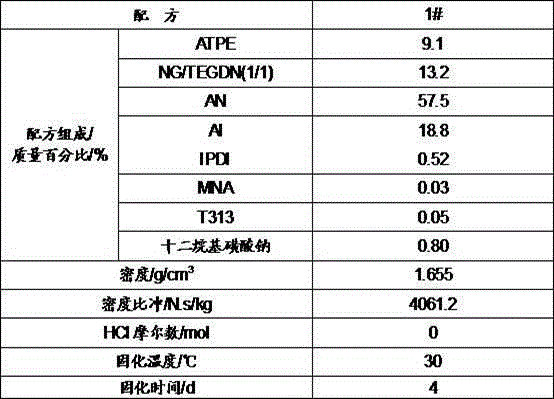

[0038] The following table 3 shows the composition and performance of the 3#ATPE / ADN / N-100 clean propellant of the present invention.

[0039] Table 33 #ATPE / ADN / N-100 propellant formula composition and performance

[0040]

[0041] It can be seen from Table 3 that when the curing temperature is 50°C, the curing time of 3#ATPE / ADN / N-100 clean propellant with a solid content of 75% is 3.5 days, and the density and density specific impulse of the propellant are respectively 1.792g / cm 3 and 4435.6N.s / kg.

Embodiment 3

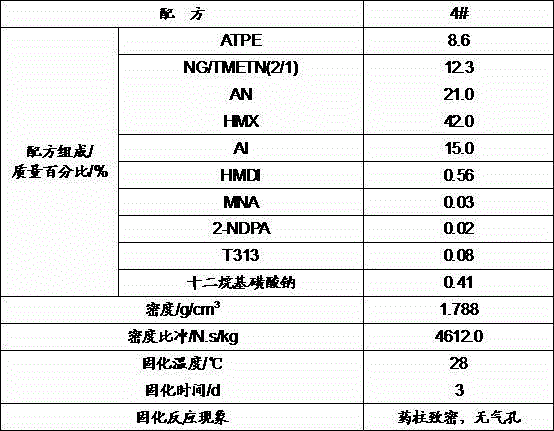

[0043] Table 4 below shows the formula composition and performance of the ATPE / AN / HMX / HMDI clean propellant of Example 4#.

[0044] Table 44#ATPE / AN / HMX / HMDI propellant formula composition and performance

[0045]

[0046] It can be seen from Table 4 that the density of 4#ATPE / AN / HMX / HMDI clean propellant is 1.788g / cm 3 , the density specific impulse is 4612.0N.s / kg, when the curing temperature is 28°C, the propellant 3d can be cured completely, and the grain is dense and free of pores.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com