Ring frame column type cable net reflective system driven by three telescopic rods

A reflective system and telescopic rod technology, applied in antennas, instruments, installations, etc., can solve problems such as the influence of reflective surface accuracy, high processing costs, and difficult to eliminate accumulated errors, so as to solve torsional instability and reduce development costs , Improve the effect of structural fundamental frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

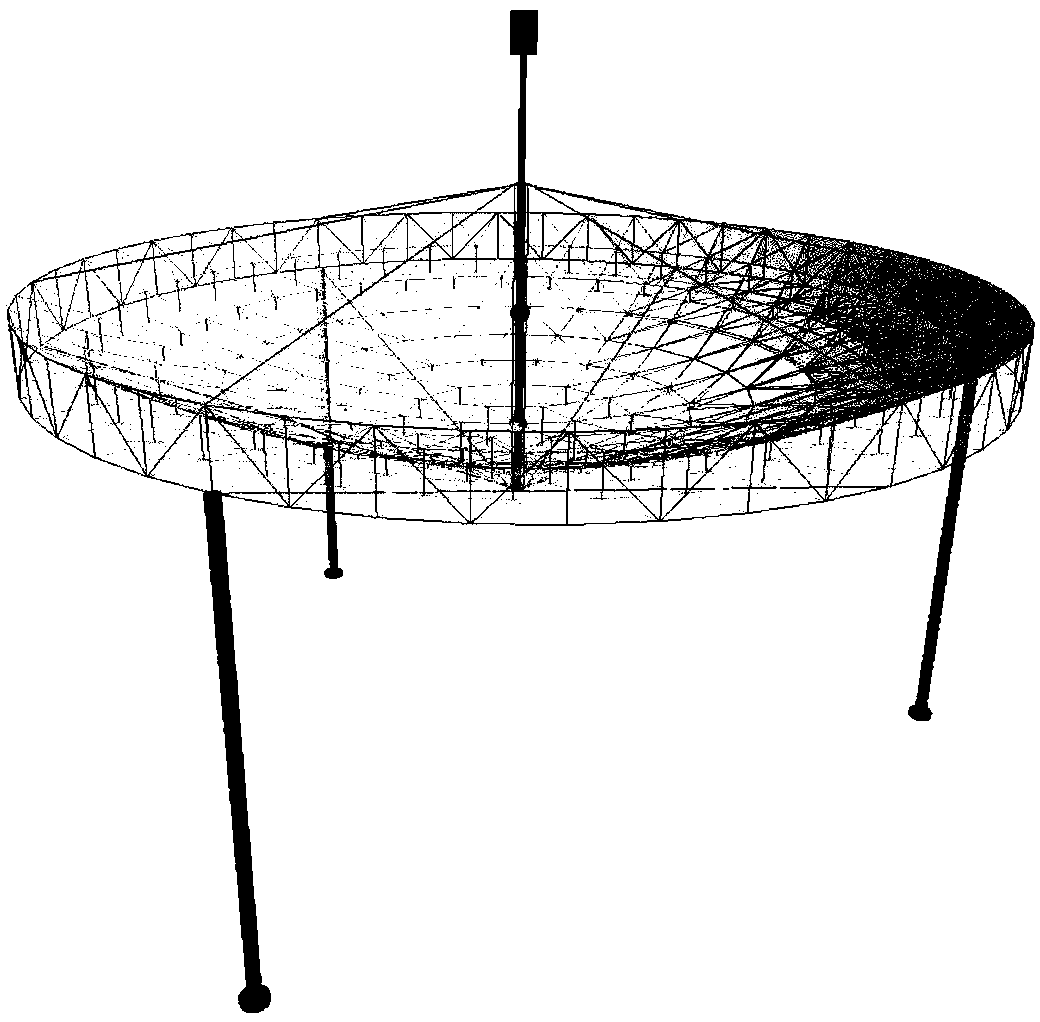

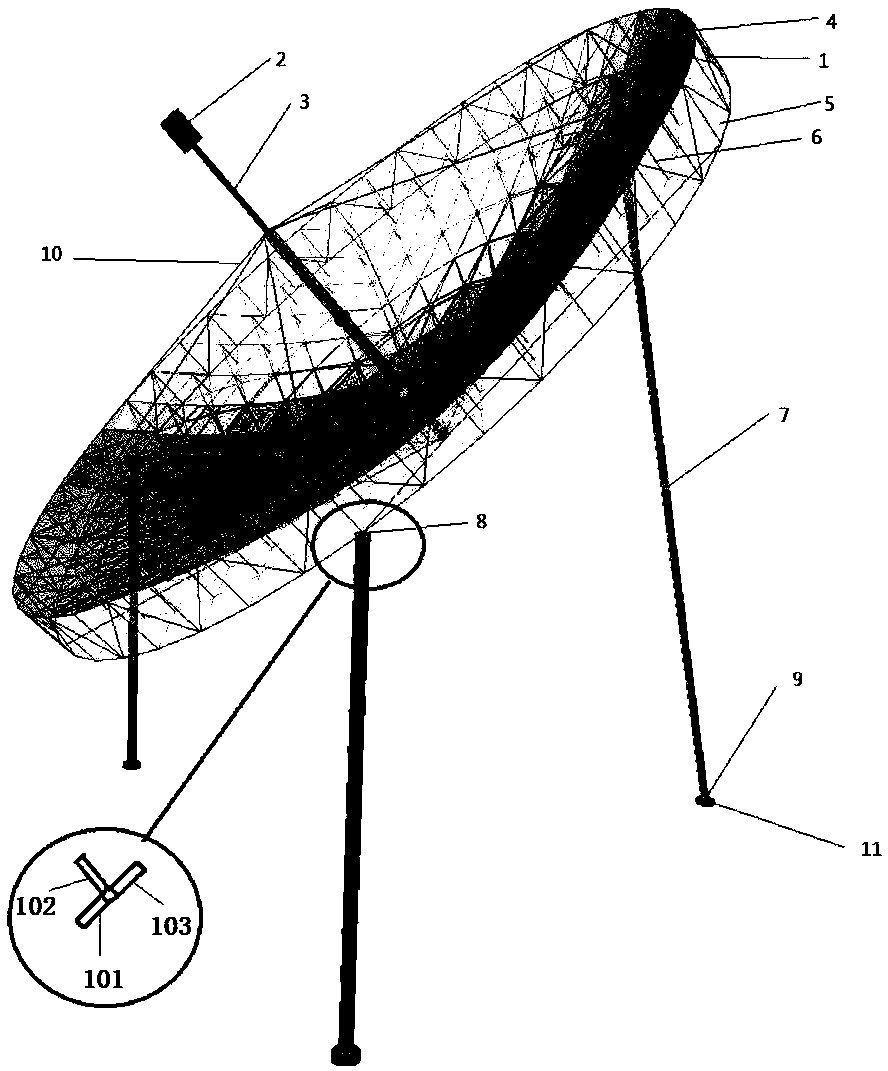

[0049] Embodiment 1, in the case where the working space is not limited, the ring frame column type cable net reflection system driven by three telescopic rods.

[0050] refer to figure 1 and figure 2 , this example includes: circular truss 1, feed source 2, central pillar 3, mesh cable 4, traction cable 5, fastening cable 6, three telescopic rods 7, spherical pair connection structure 8, rotating pair connection structure 9, support The cable 10 and the fixed platform 11; the circular truss 1, the feed source 2, the central pillar 3, the mesh cable 4, the traction cable 5, the fastening cable 6 and the support cable 10 together form a reflector; three telescopic rods 7, spherical pair connection The structure 8, the revolving joint connection structure 9 and the fixed platform 11 together constitute the tracker. in:

[0051] The circular truss 1 includes an upper ring and a lower ring, and a first layer of criss-cross flexible cable net is installed between the upper ring...

Embodiment 2

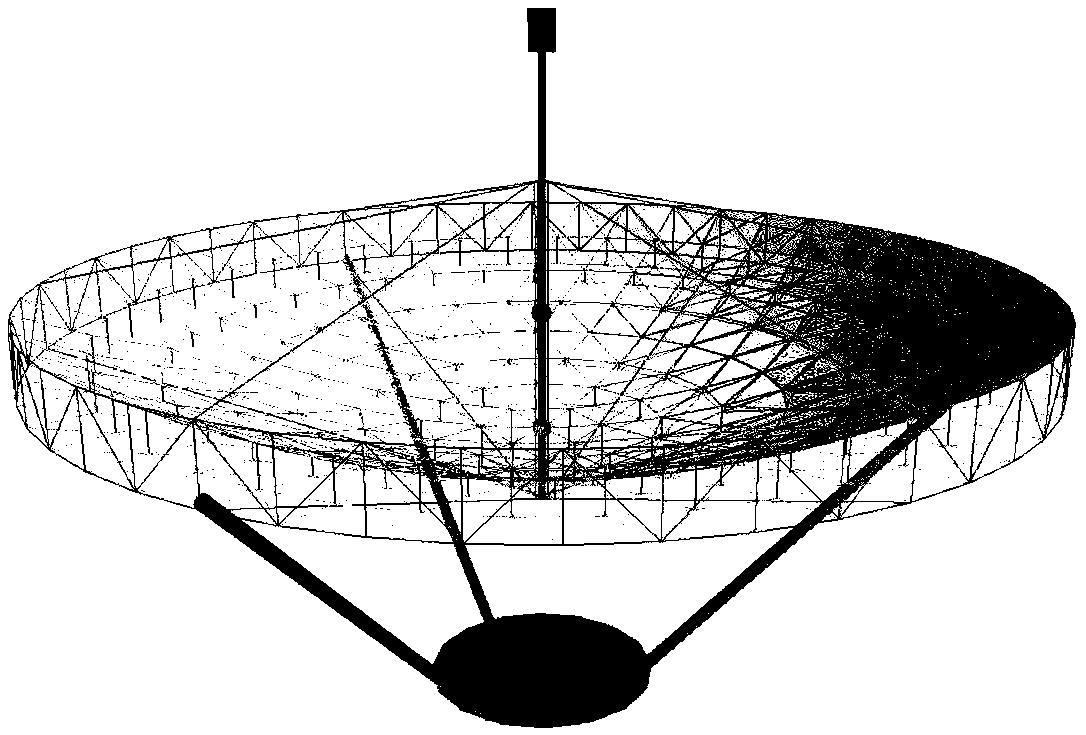

[0066] Embodiment 2, where the space is strictly limited, a ring-frame-column cable-net reflection system driven by three telescopic poles.

[0067] refer to image 3 and Figure 4, the structure of the reflection system of this example is the same as that of Example 1, the difference is that the working space of this example is strictly limited, and the diameter of the circumscribed circle at the lower end of the three telescopic rods (7) distributed in an equilateral triangle is much smaller than that of the reflection surface caliber.

[0068] Effect of the present invention can be verified by following simulation experiments:

[0069] Simulation 1, the surface accuracy of the reflector with a diameter of 15 m in embodiment 1 is simulated when the initial position has no gravity.

[0070] 1.1) Simulation system and structure

[0071] Assume that the diameter of the reflector is 15m, the focal diameter ratio is 0.4, the ring is divided into 48 equal parts, and the radial...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com