High-precision ultralow frequency six-dimensional force micro-vibration measuring system

A measurement system and micro-vibration technology, applied to measurement devices, ultrasonic/sonic/infrasonic waves, instruments, etc., can solve the problems of inflexible installation interface, low measurement accuracy of micro-vibration measurement system, etc., to improve anti-interference ability and test Accuracy, real-time measurement accuracy improvement, good signal-to-noise ratio effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Further illustrate the present invention below in conjunction with accompanying drawing.

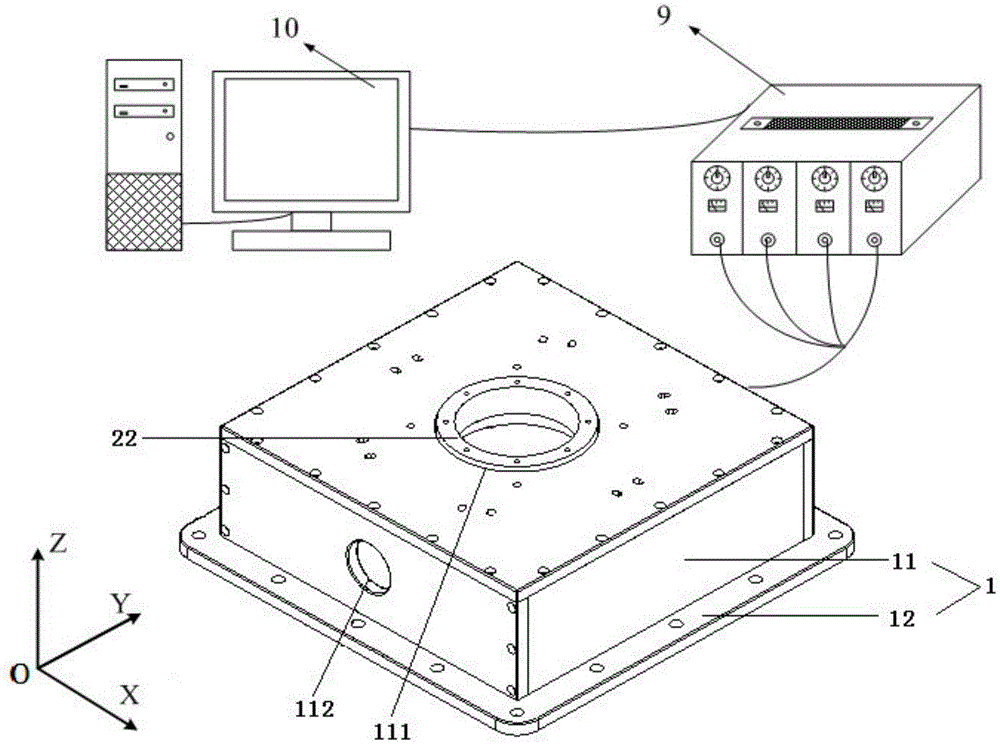

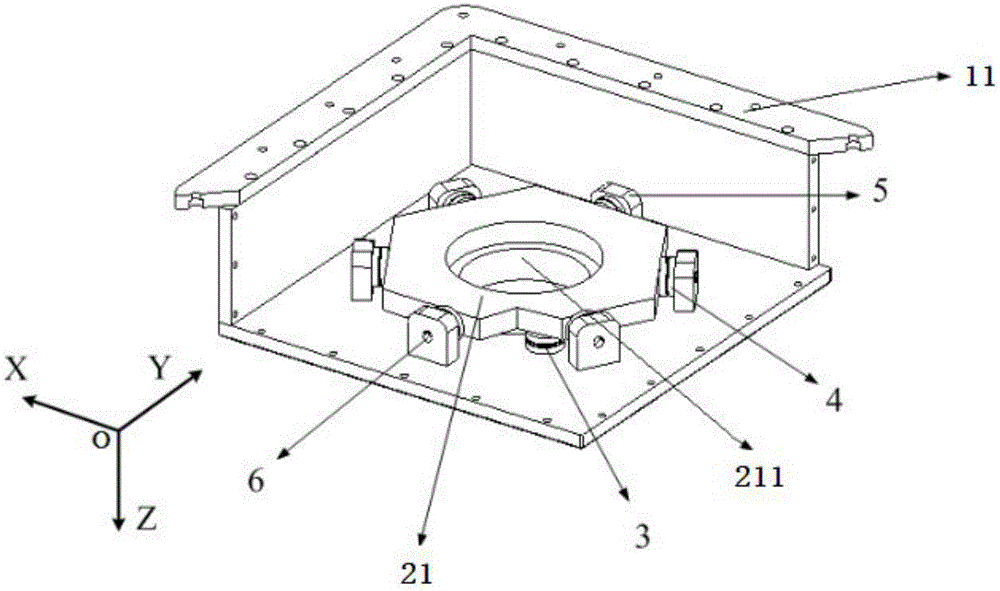

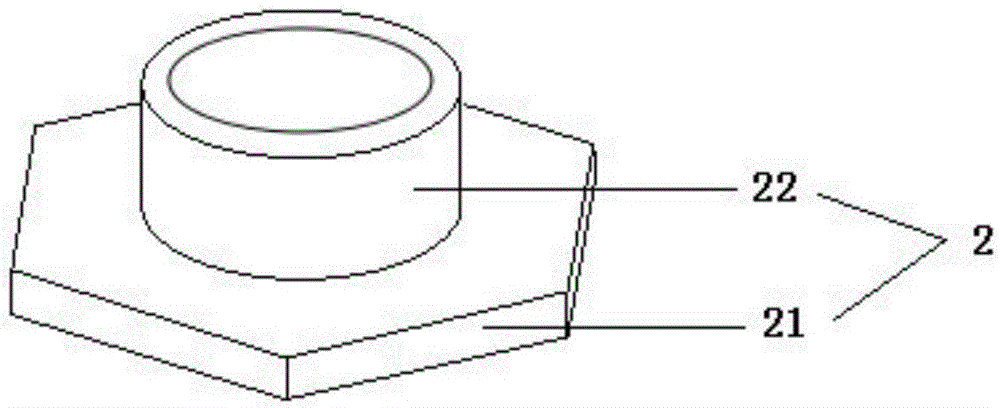

[0036] Such as Figure 1-5 As shown, the high-precision ultra-low frequency six-dimensional force micro-vibration measurement system of the present invention includes a box body 1, a load plate 2, four vertical piezoelectric sensors 3, six horizontal piezoelectric sensors 4, and six lateral positioning plates 5. Signal adjustment device 9 and data acquisition and processing system 10 .

[0037] Wherein, box body 1 is made up of casing 11 and base 12, and casing 11 is the hollow structure of bottom end opening, and the top surface of casing 11 is provided with first central through hole 111, and side is provided with window 112, facilitates casing 1 The internal piezoelectric sensor is routed and when the disturbance source is arranged inside the box body 1, it is convenient to operate the disturbance source; the base 12 is fixed on the bottom opening of the housing 11, and forms ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com