Cylindrical Cable Net Reflection System Driven by Single Telescopic Rod Turntable

A technology of reflection system and telescopic rod, which is applied in the direction of control/regulation system, non-electric variable control, control without feedback, etc., can solve the problem of low construction cost and material cost, low precision of reflective surface profile, and unsatisfactory use Requirements and other issues to achieve the effect of shortening the development cycle, eliminating the need for support structures, and reducing development costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Embodiment 1: A ring-column cable-net reflection system with a reflector diameter of 5 m.

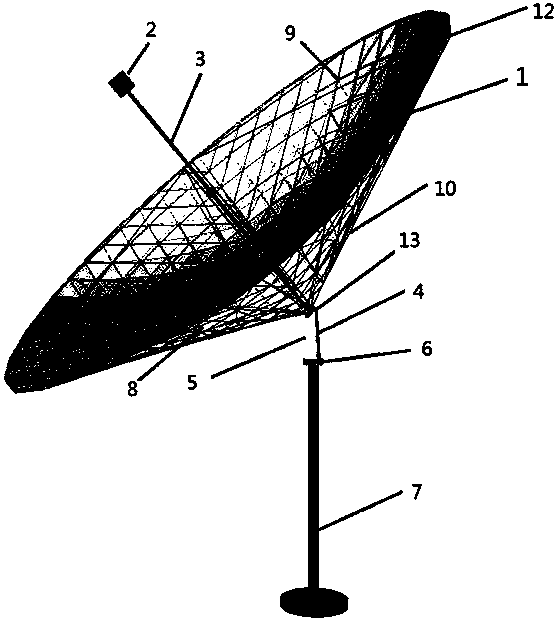

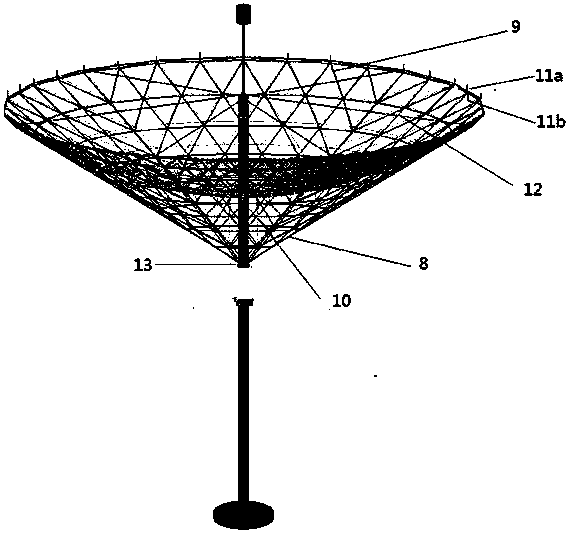

[0050] refer to figure 1 and figure 2 , this example includes two parts: reflector and tracker, among them:

[0051] The reflector includes an outer ring 1 , a central pillar 3 , fastening cables 8 , mesh cables 9 , traction cables 10 and a plurality of support cables 12 . in:

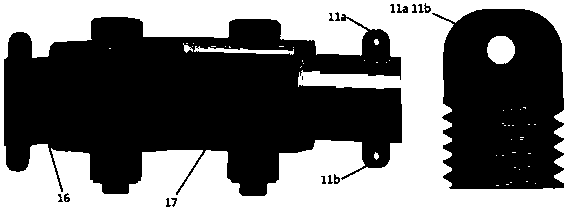

[0052] The outer ring 1 is composed of a plurality of radially drilled hollow tubes 16 and a plurality of connecting joints 17. By changing the number and length of the hollow tubes 16, the diameter of the outer ring 1 can be changed, that is, the design of the reflector Caliber, upper pin 11a and lower pin 11b are installed in the radial hole of hollow circular tube 16, the quantity of hollow circular tube 16 of this example is forty-eight, reflector aperture is 5m, is provided with evenly distributed connecting pins on this aperture, In this example, there are twelve connecting pins on the upper an...

Embodiment 2

[0060] Embodiment 2: A ring-column type cable net reflection system with a reflector diameter of 15 m.

[0061] This embodiment includes reflector and tracker two parts, and reflector aperture is 15m, and tracker structure is identical with embodiment 1, and the structural form of reflector is identical with embodiment 1, but structural parameter is different, namely:

[0062] The support cable 12 of this example is made up of each twelve flexible ropes at the front and rear; the central pillar 3 is provided with upper and lower rows of connecting holes, and the number of connecting holes in each row is six.

[0063] The central pillar 3 and the support cable 12 are connected symmetrically in a staggered manner, using the second connection form; that is, the upper and lower rows of connecting holes of the central pillar 3 and the connecting pins on the outer ring 1 respectively pass through twelve front and rear flexible ropes Symmetrical connection.

[0064] refer to Figur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com