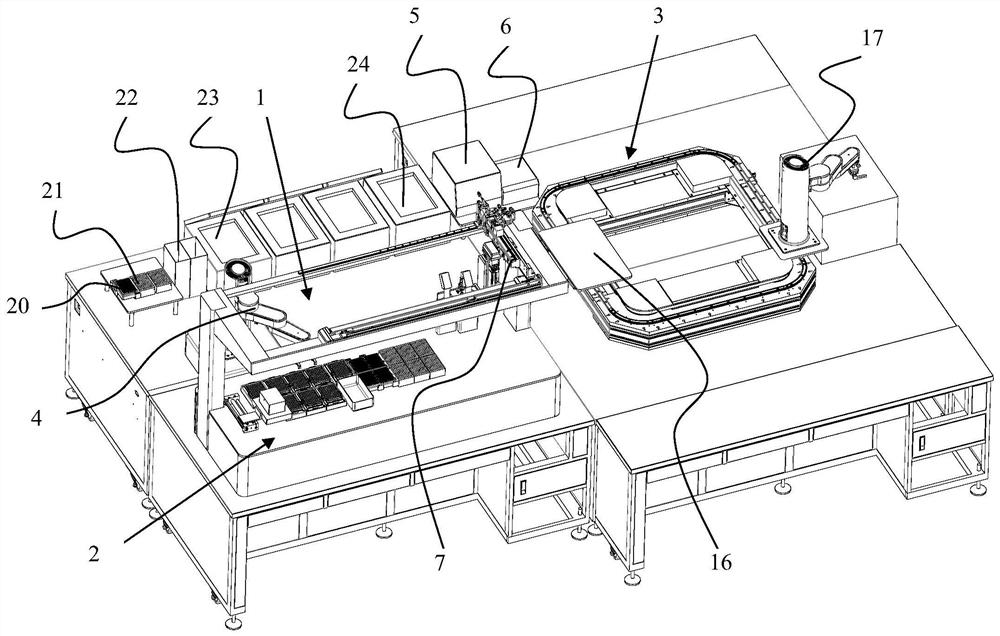

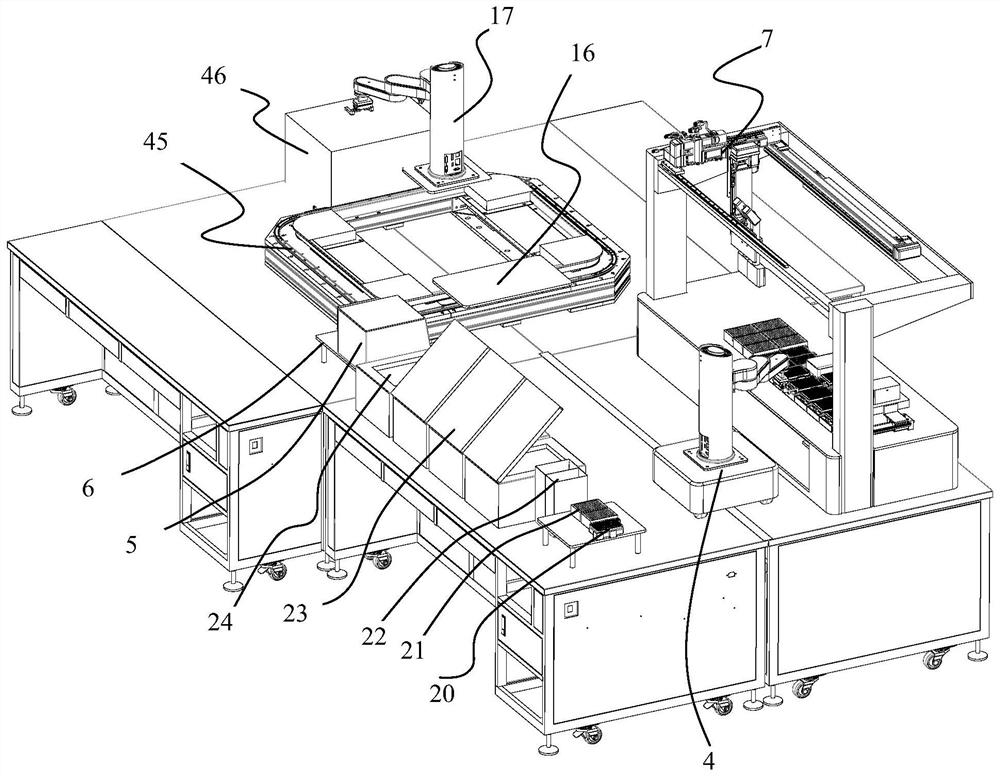

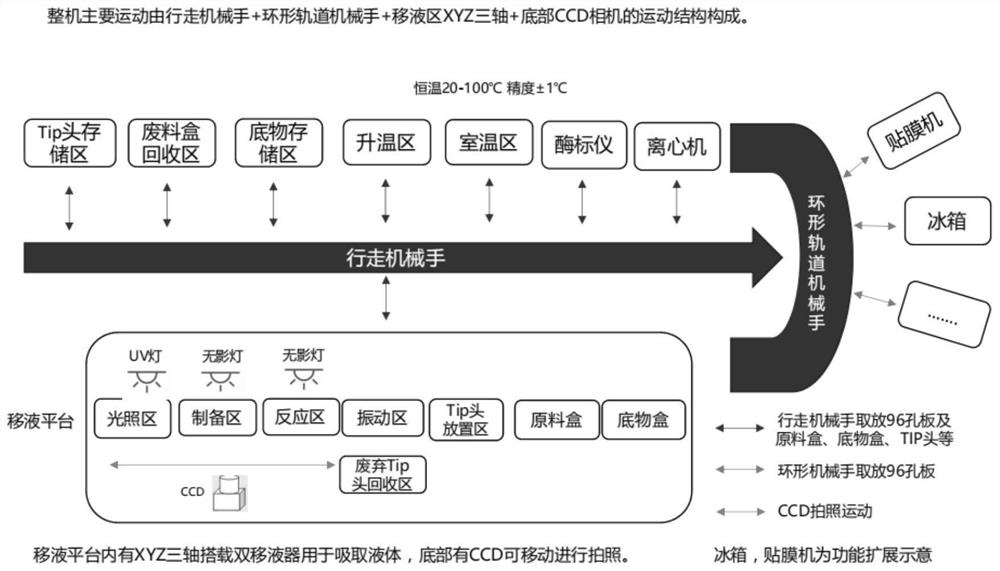

Functional material digital design, preparation and evaluation automation platform

A functional material and platform technology, applied in the field of "island" and its overall platform, can solve problems such as method and step error, ambiguity, lack of digital normative, etc., to save time, improve accuracy, save cost and time-consuming Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] Use the present invention for the preparation of MOFs protein

[0068] The first step: use the first manipulator 4 to place 1000 μl of ligand A, B and C solutions, five kinds of metal ions (Cu 2+ , Zn 2+ ,Co 2+ , Ni 2+ and Cd 2+ ) and 500 μl of the enzyme solution were transferred to a 96-well deep-well plate in storage area 14 of the raw material box as the mother solution in the raw material area.

[0069] Second step: utilize the second manipulator 7 to absorb and transfer five kinds of metal ions (Cu 2+ , Zn 2+ ,Co 2+ , Ni 2+ and Cd 2+ ) were placed in a 96-well plate in preparation zone 9, and repeated 3 times.

[0070] Step 3: Use the second manipulator 7 to suck up and transfer 50 μl of the enzyme solution to the same hole position as that in the preparation area of the second step.

[0071] Step 4: Use the second manipulator 7 to absorb and transfer 50 μl of the solutions of ligands A, B, and C into the 96-well plate in the preparation area 9, and mi...

Embodiment 2

[0080] 1. The second manipulator 7 operates the pipette gun 36 to absorb 1-10ml of PbX in the substrate box 15 respectively 2 A saturated DMF solution of CsX and CsX (X=F, Cl or Br) is added to the precursor solution sample tank in the raw material box 14 .

[0081] 2. The second manipulator 7 operates the pipette gun 36 to absorb the long carbon chain organic acid (10-20 carbon content) and the long carbon chain small molecule amine (10-20 carbon content) in the substrate box 15, and the suction volume is 0.1 Between -2ml, add in the precursor solution sample groove in the raw material box 14.

[0082] 3. The second manipulator 7 operates the pipette gun 36 to repeatedly suck-release the precursor solution sample in the raw material box 15 to make it evenly mixed.

[0083] 4. The second manipulator 7 operates the pipette gun 36 to absorb solvents (including but not limited to toluene, chloroform, n-hexane, ethyl acetate, etc.) and add them to the 96-orifice plate in the vibr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com