Displacement control method for arch bridge lattice girder hoisting to eliminate temperature influence

A technology of displacement control and lattice beams, which is applied to bridges, arch bridges, bridge forms, etc., can solve the problems of uneven line shape, influence on construction accuracy, suspender force, and vehicle speed that cannot meet the design requirements, so as to eliminate the cumulative error value of displacement, Large practical engineering application value, the effect of avoiding the undulation of the bridge deck

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

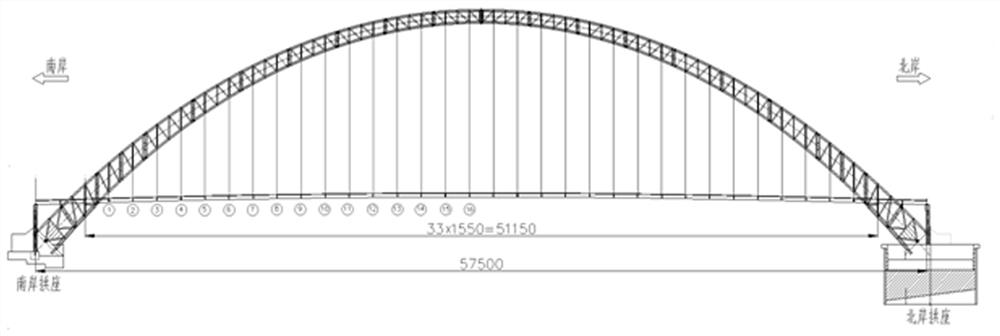

[0043] Long-span medium-supported concrete-filled steel tube arch bridge A, see attached figure 1 , will be hoisted from June to August, the design closing temperature is 25°C, and the average daytime temperature from June to August is 36°C, a total of 38 lattice beam sections, each section is based on a 2-day engineering quantity It is calculated that it will take 72 days to complete the project, but considering that the daytime temperature is too high, the installation and welding work can only be carried out at night. The construction chooses a period from 23:00 in the evening to before 6:00 the next morning when the temperature is stable and low. If you work at night The efficiency is calculated according to 80% of the daytime, and it is estimated that the project volume of 2 days can only be completed by 2d×80%×50%=0.8d, so that the construction period of 72 days is forced to be delayed to 180 days. , The loss due to the impact of the construction period alone is greater ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com